Environment-friendly efficient mineral aggregate screening machine for mining production

A high-efficiency screening machine technology, applied in the direction of using liquid separation agent, filter screen, solid separation, etc., can solve the problems that affect the screening efficiency, the health of the workers, and the pollution of the environment, so as to improve the working environment and improve the screening Good efficiency and screening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

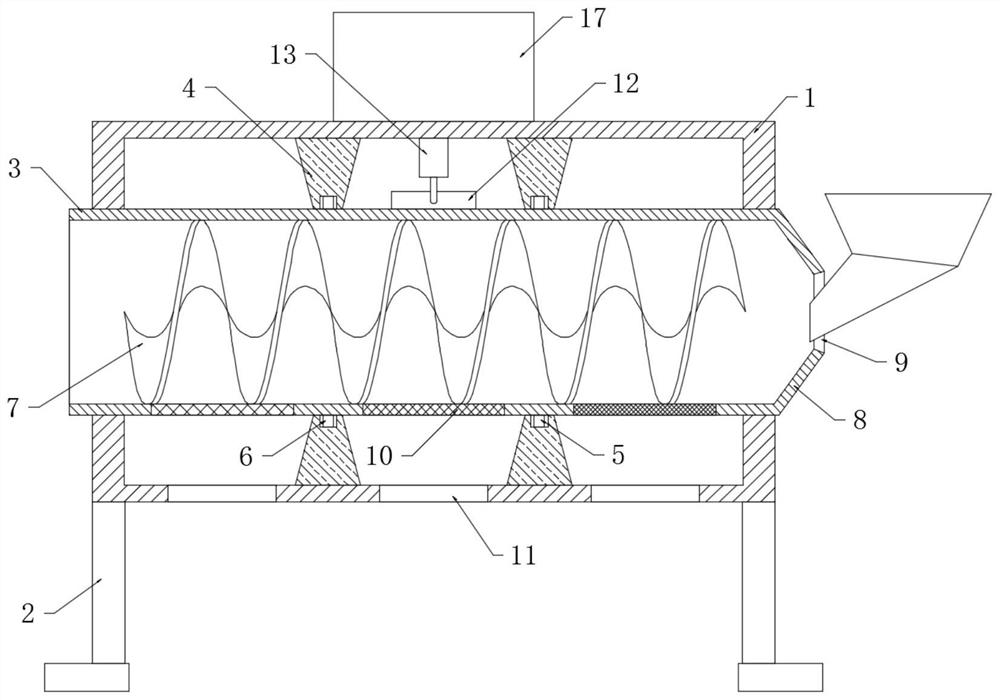

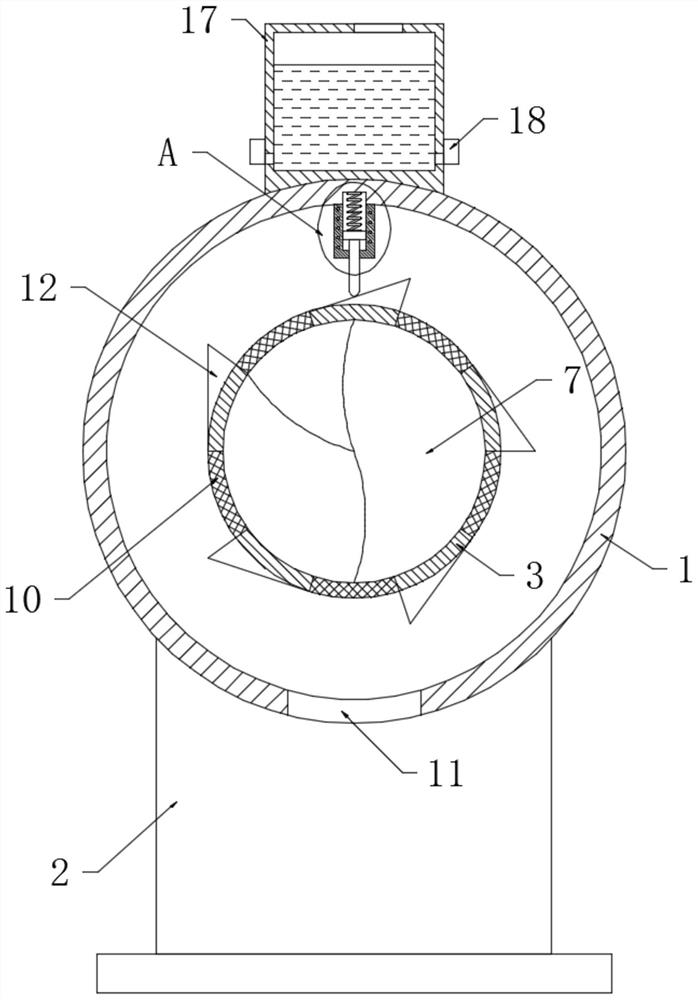

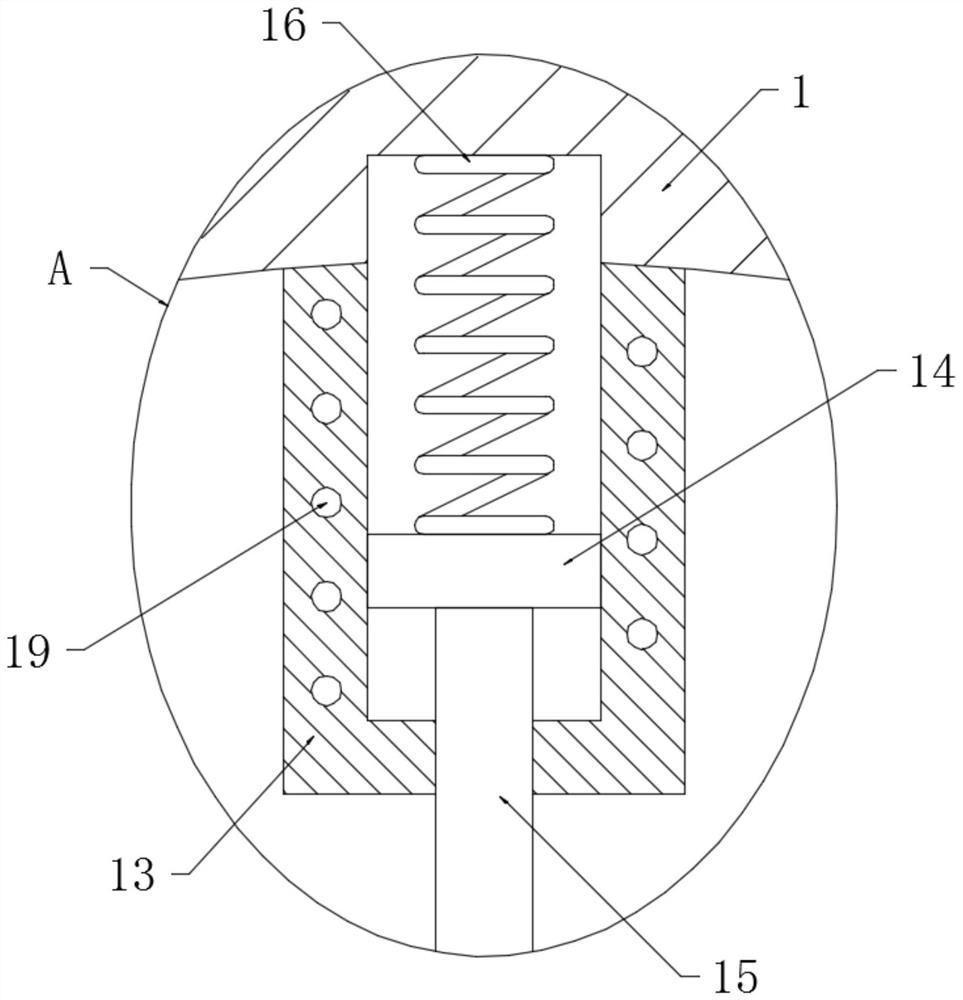

[0022] refer to Figure 1-3 , an environmentally friendly and high-efficiency mineral material screening machine for mining production, including a cylindrical chassis 1, the chassis 1 is arranged horizontally and the outer wall is fixedly connected with a fixed frame 2, and the two sides of the box wall of the chassis 1 run through and rotate and are connected with a cylindrical horizontal setting The sieve drum 3 is fixedly connected with two annular partitions 4 on the inner wall of the cabinet 1 to divide the inner space of the cabinet 1 into three, and an annular chute 5 is set on the inner ring surface of each annular partition 4, and the screening material Two annular guide rails 6 are fixedly connected to the outer wall of the barrel 3 , and the two annular guide rails 6 are respectively slidably connected with the two annular slide grooves 5 .

[0023] One end of the sieve cylinder 3 is fixedly connected with a feed cone 8, and the feed cone 8 is provided with a feed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com