Tea sifting and grading machine

A sieving machine and tea technology, which are applied in the directions of solid separation, tea treatment before extraction, and separation of solids from solids by air flow, can solve the problems of poor practicability, increased operation steps, and inconvenient use. The effect of dividing is good, and the effect of avoiding accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below through specific implementation examples and in conjunction with the accompanying drawings.

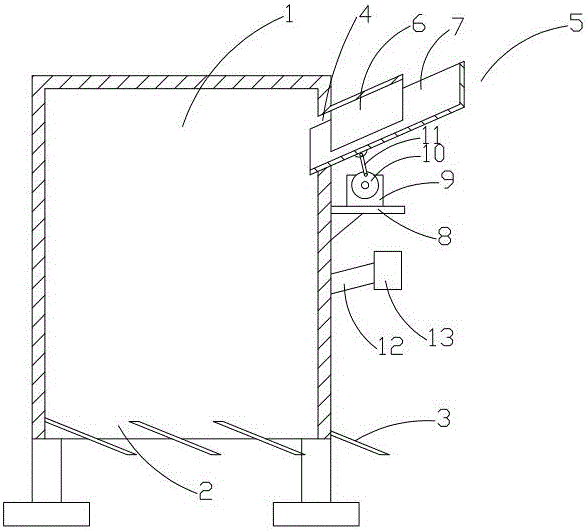

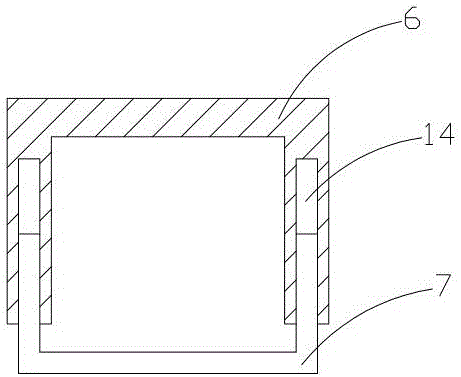

[0016] figure 1 , figure 2 Shown is a kind of tea screening machine provided by the present invention, which includes a box body 1, and the lower end of the box body 1 is provided with an opening 2, and the size of the opening 2 is equal to the size of the top surface of the box body 1; There are multiple inclined deflectors 3, and the distance between two adjacent deflectors 3 is equal, the inclination angle of the deflectors 3 is 30°-60°, and the deflectors 3 are fixed on the inner wall of the box body 1 On; the upper end of the box body 1 is provided with a feed port 4, the feed port 4 is opened on the side of the case body 1, and the feed port 4 is provided with a feed hopper 5, and the feed hopper 5 is arranged obliquely; The feed hopper 5 includes a fixed part 6 and a movable part 7, the movable part 7 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com