Sweet potato grading screening device capable of reducing damage

A technology of grading and sieving sweet potatoes, which is applied in the directions of sieving, solid separation, and separation of solids from solids by air flow. The effect of removing mud and dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

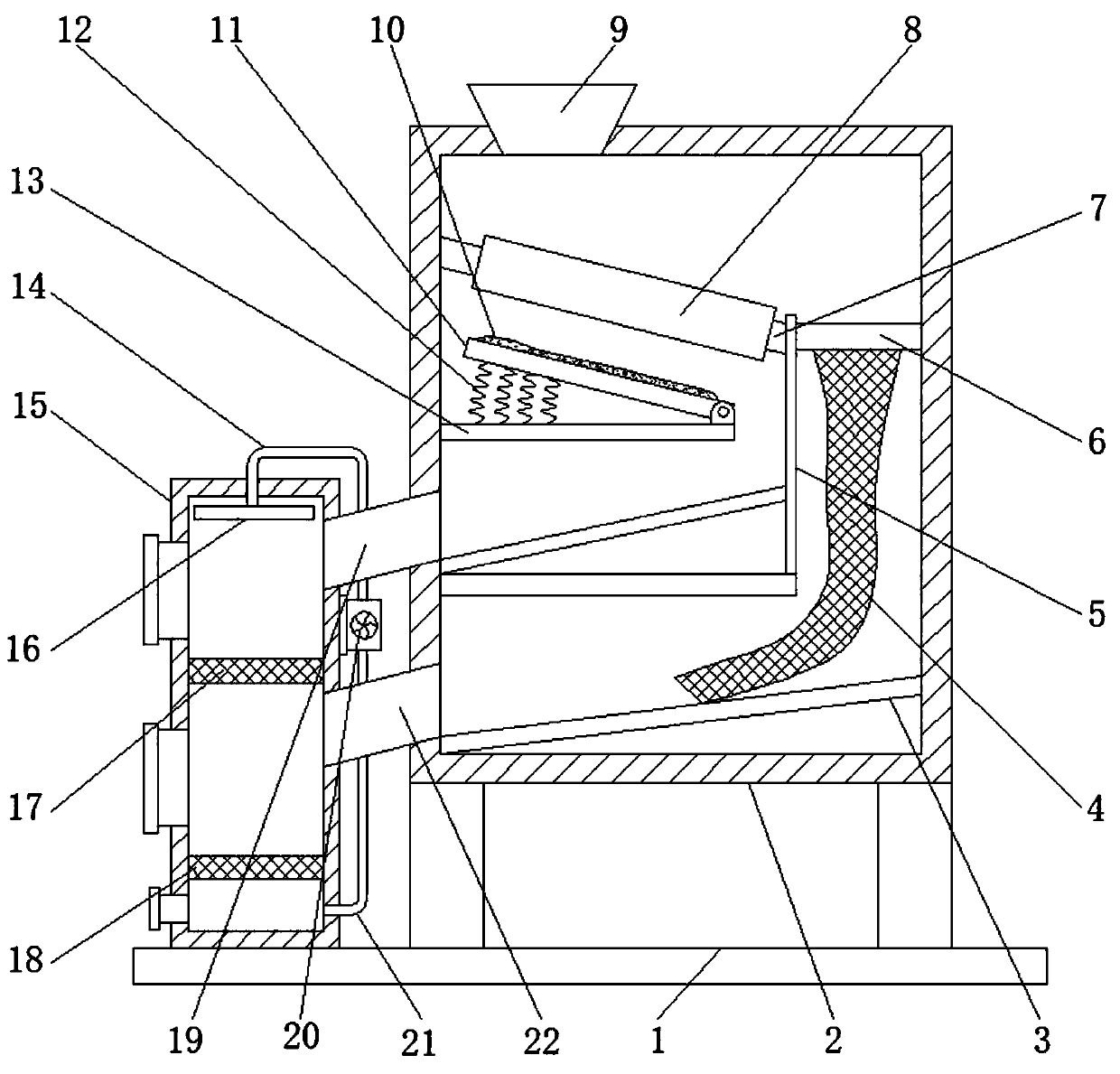

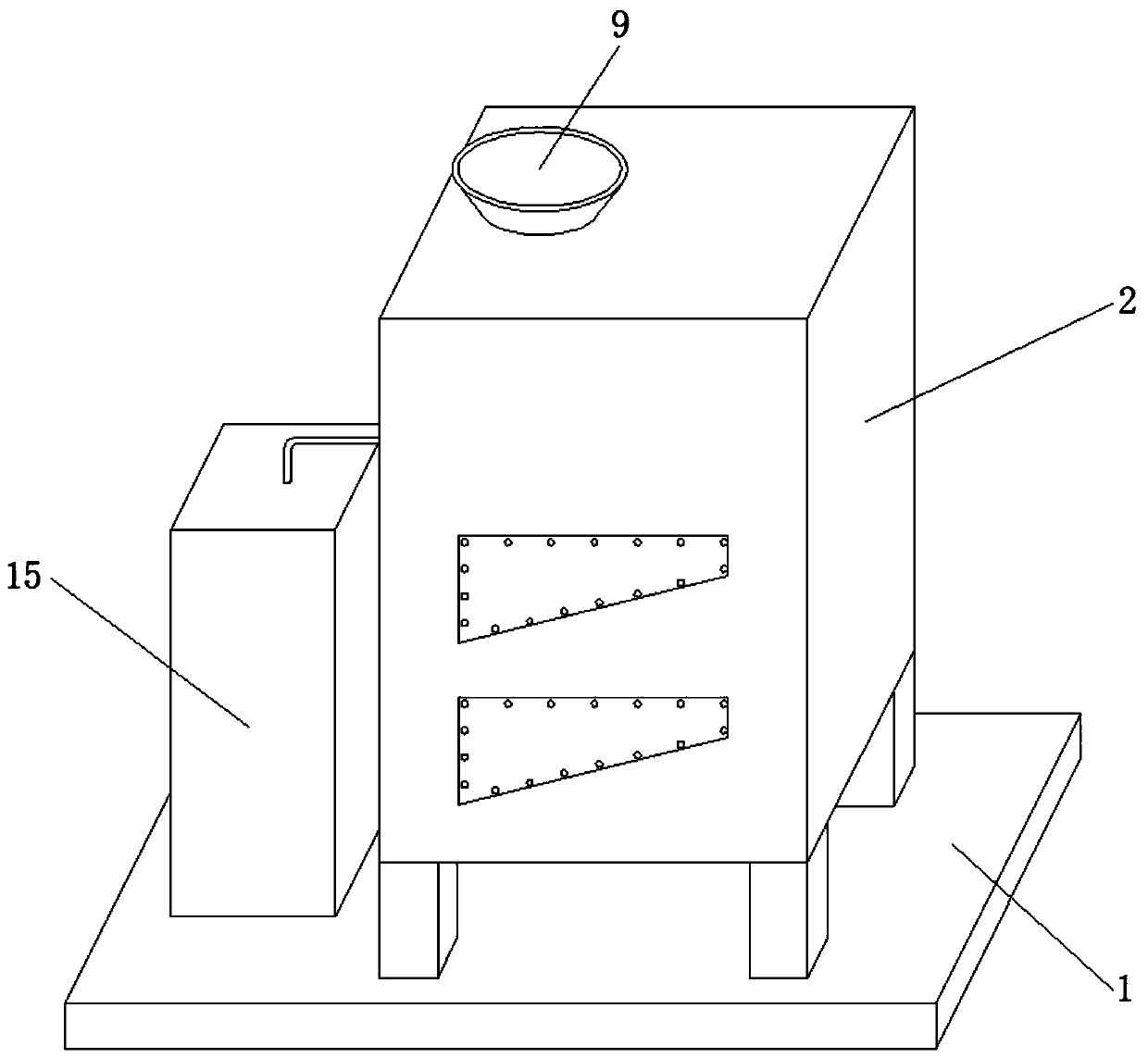

[0026] refer to Figure 1-2 , a sweet potato grading and screening device capable of reducing damage, comprising a bottom plate 1, the top outer wall of the bottom plate 1 is welded with supporting legs, and the top outer wall of the supporting legs is welded with a screening box 2, and the top outer wall of the screening box 2 has a concave hole, And the inner wall of the concave hole is welded with a feed hopper 9, one side outer wall of the screening box 2 is welded with a baffle plate, and the top outer wall of the baffle plate is welded with a riser 5, and one side outer wall of the riser 5 is welded with equidistantly distributed inclined Rod 7, and the outer wall of the inclined rod 7 is rotatably connected with a screening roller 8, the outer wall of one side of the vertical plate 5 and the inner wall of one side of the screening box 2 are welded with a slanting plate 3, and the inner wall of one side of the screening box 2 is welded with a fixed plate 13 , and the top...

Embodiment 2

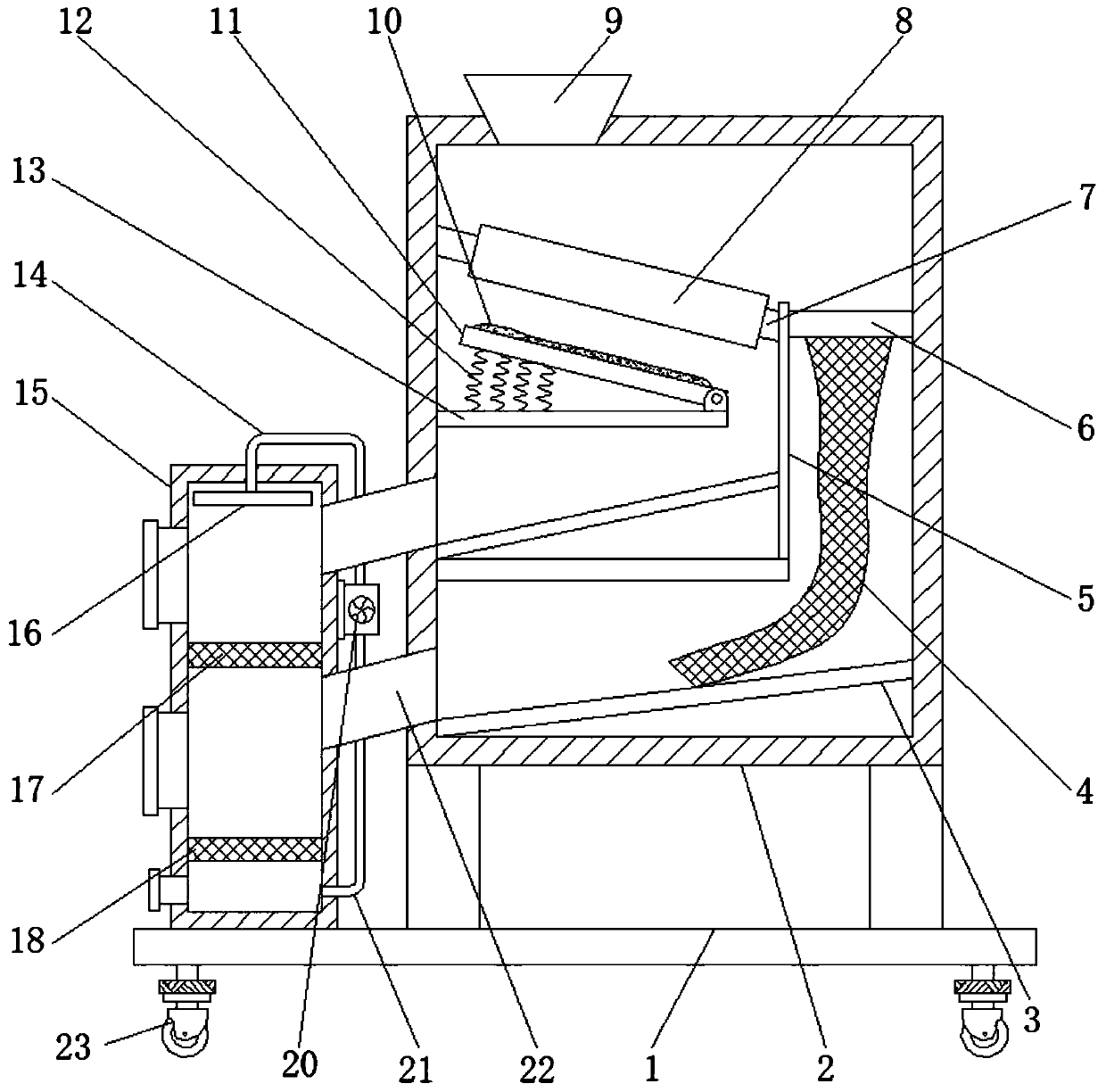

[0030] refer to image 3 , a sweet potato grading and screening device that can reduce damage. Compared with Embodiment 1, this embodiment also includes supporting legs welded at the four corners of the bottom outer wall of the bottom plate 1, and the bottom outer wall of the supporting legs is fastened by fastening bolts. Universal wheel 23 is connected.

[0031] Working principle: when in use, the universal wheel 23 located at the bottom of the device facilitates the movement of the device and makes the use more flexible.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com