Irregular mixed material screening device

A technology of mixing materials and screening devices, which is applied in the direction of filter screen, solid separation, grille, etc., which can solve the problems of easy loosening and deformation, no screen, labor-intensive, etc., to achieve good screening effect, neat materials, and efficient operation reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

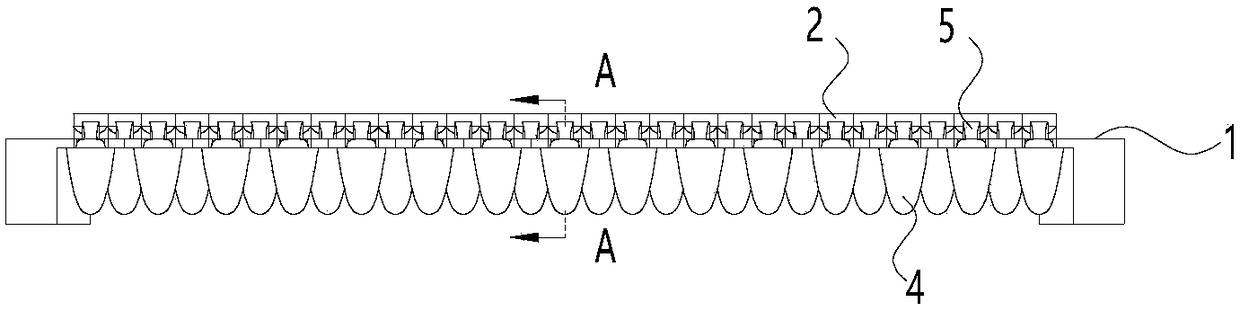

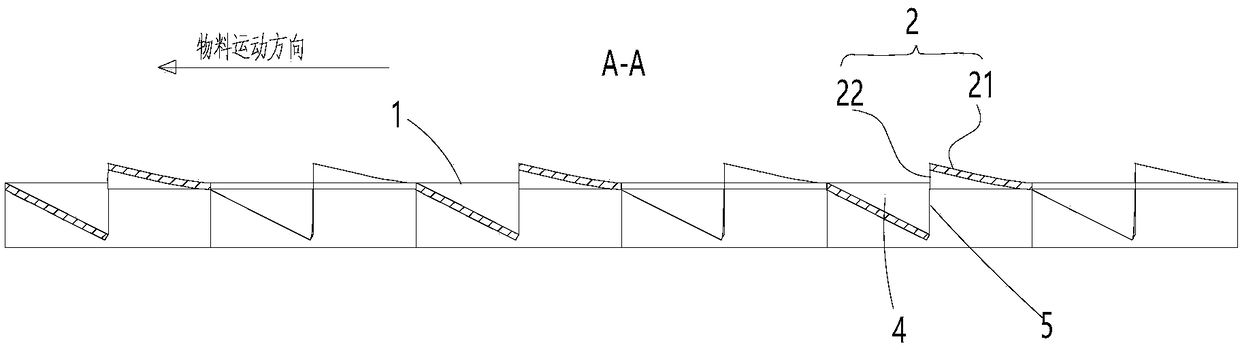

[0024] In order to describe the technical content, structural features, achieved goals and advantages of the invention in detail, the following will be described in detail in conjunction with the embodiments. Among them, the "front" side mentioned in the manual refers to the conveying direction of the material, which is different from the attached image 3 The directions of the arrows are the same, and the positional relationship of "up" and "down" in the manual is the same as that in the attached image 3 Corresponds to the upper and lower positional relationships in .

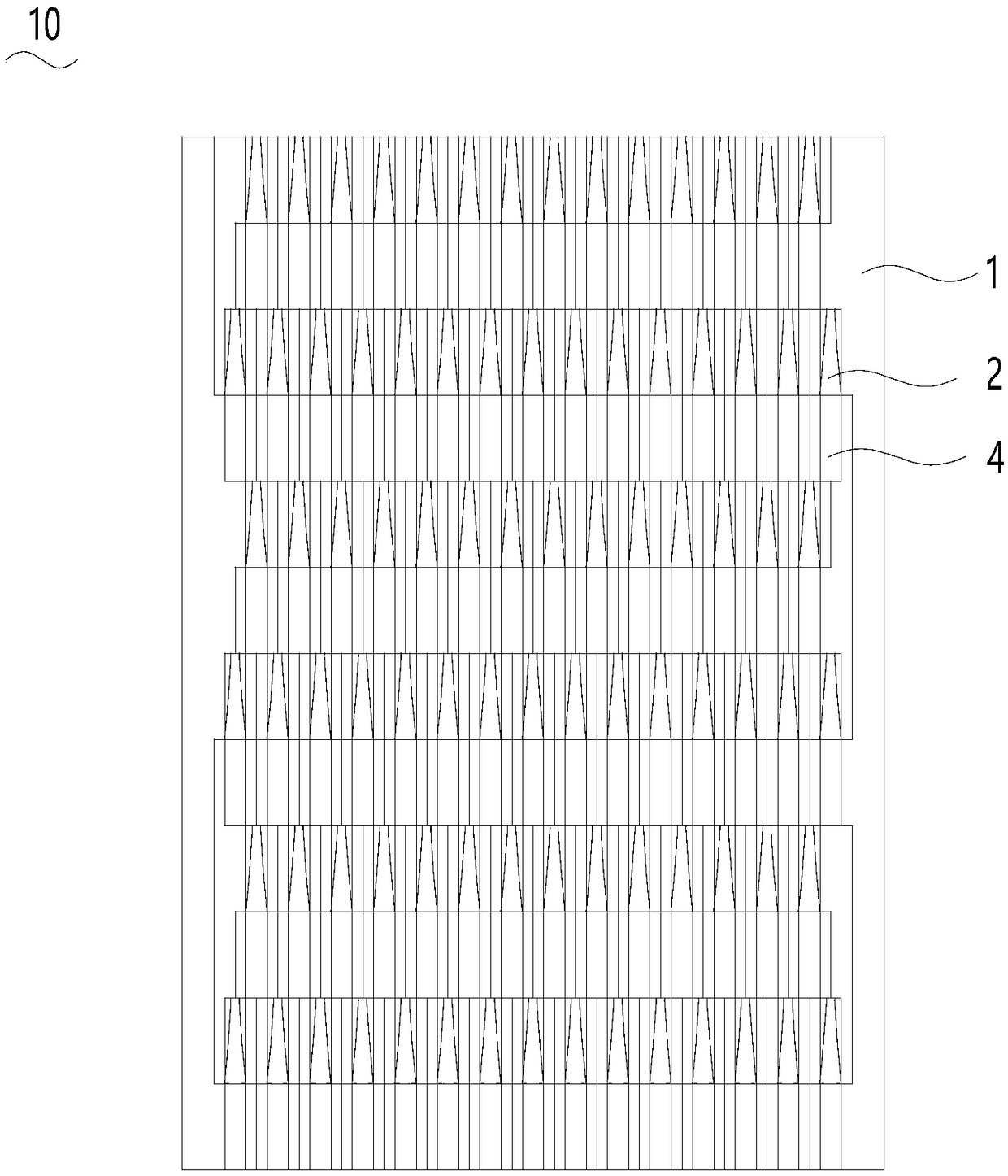

[0025] What the present invention is intended to protect is a screening device for irregularly mixed materials, including a frame, an exciting vibration motor, and a vibrating screen arranged on the frame, and the vibrating screen includes one or more screening net plates 10. According to the specific processing materials or different requirements, the installation method of the screening screen 10 can be p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Caliber | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com