Hanging type inertia rotary sieve machine

A suspension type and suspension mechanism technology, applied in the direction of filter screen, solid separation, grille, etc., can solve the problems of limited screening, high maintenance cost, large centrifugal force, etc. The effect of different needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings.

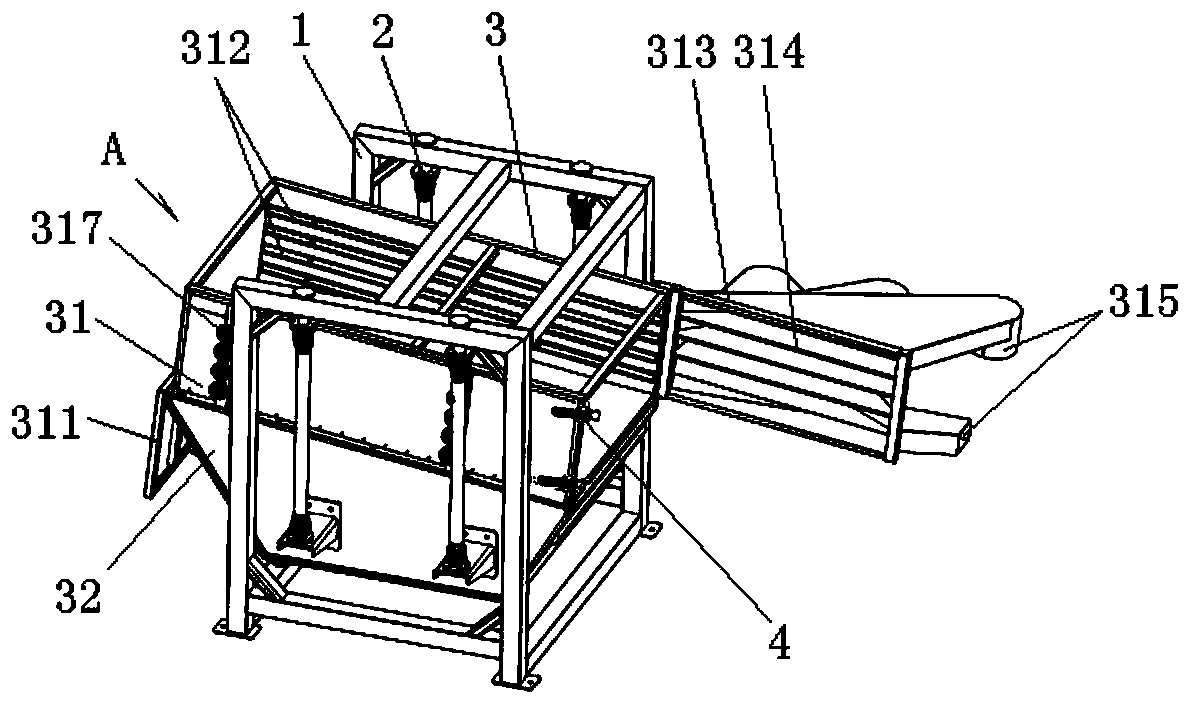

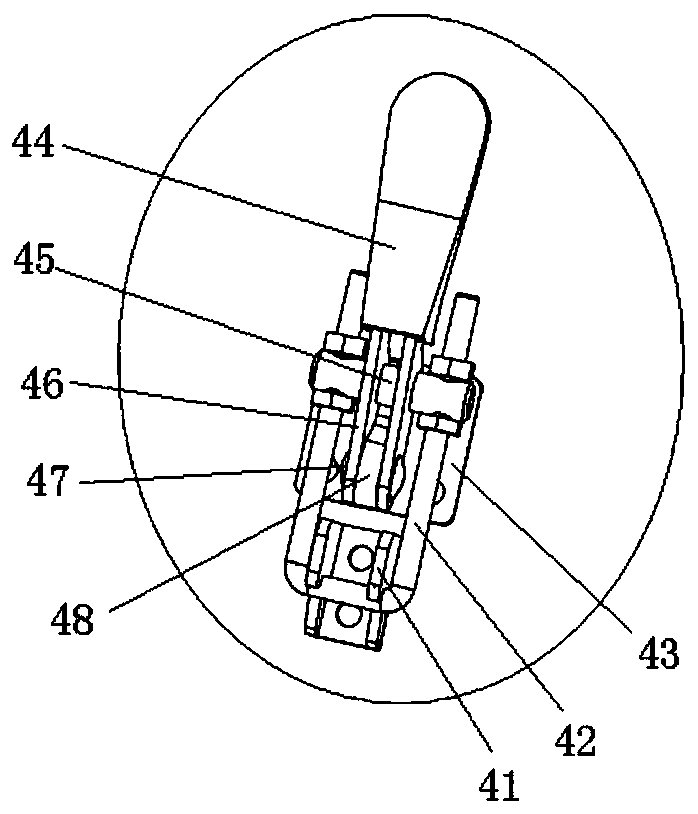

[0028] The suspended type inertial circular sieve machine provided by the present invention comprises a frame 1, and the frame 1 includes a plurality of uprights 11, an upper cross-column 12 and a lower cross-column 13 connected to the upper and lower ends of two uprights 11, suspended by a suspension mechanism 2 The screen body 3 on the frame 1, wherein: the screen body 3 is set as the upper screen frame 31 and the lower screen frame 32, wherein:

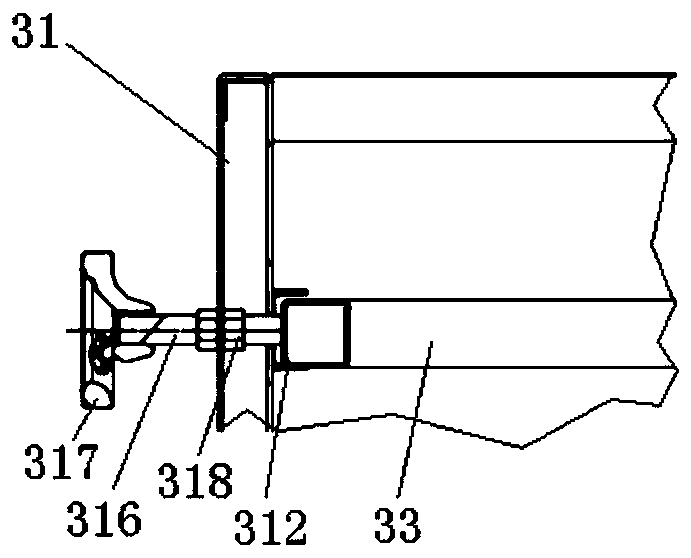

[0029] The rear end of the screen frame 31 is hinged with a rear door 311, and the front end is hinged with a discharge part 313. There are a number of slots 312 symmetrically arranged in the screen frame 31, and a screen plate 33 is placed on each symmetrical slot 312, so as to increase or decrease according to needs. The number of layers of the sieve plate 33, the sieve plate 33 is replaced, to meet the screening requirem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com