Patents

Literature

72 results about "Point trajectory" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The continuous curve described by a point in motion. If the trajectory is a straight line, the motion of the point is said to be rectilinear; otherwise, it is said to be curvilinear.

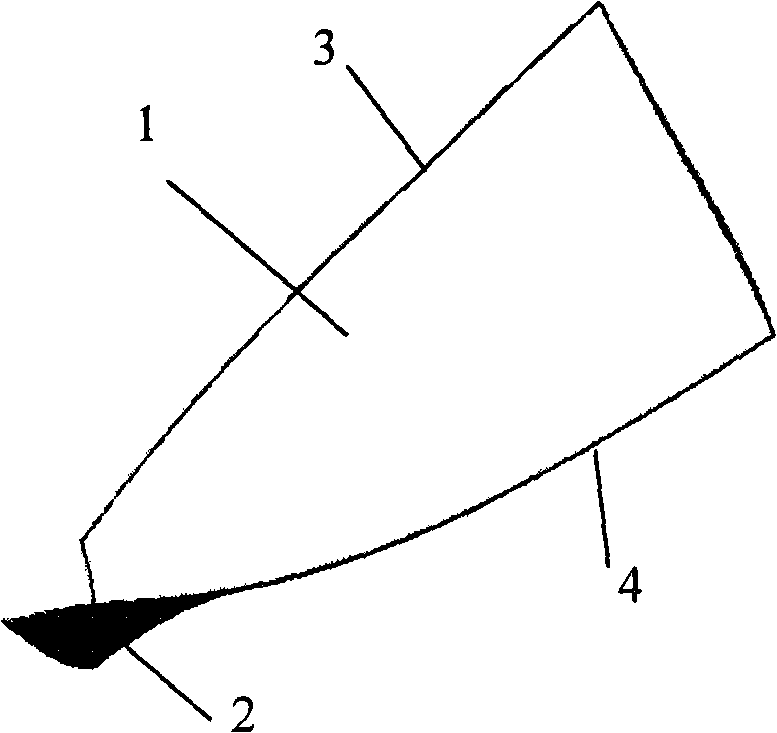

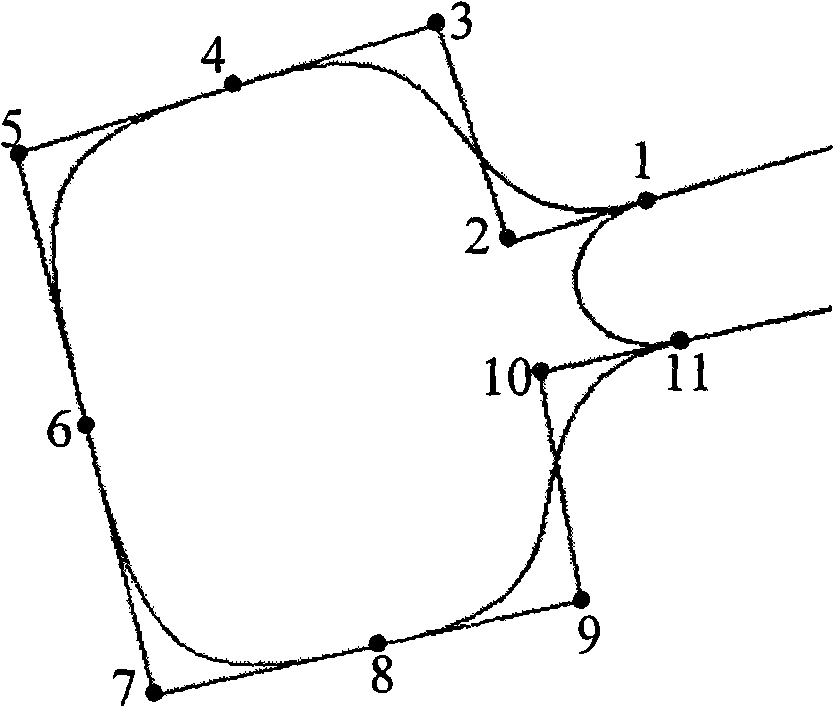

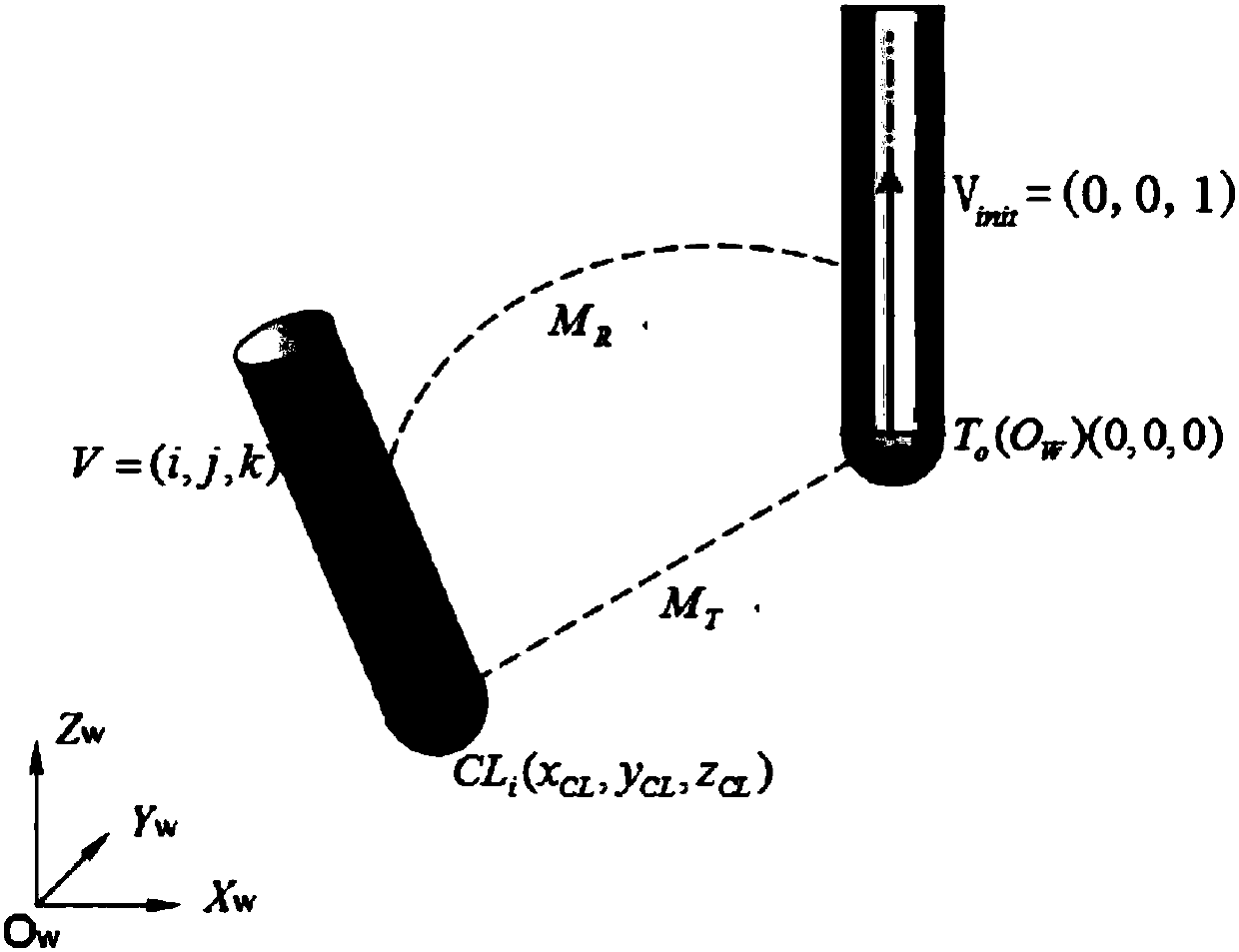

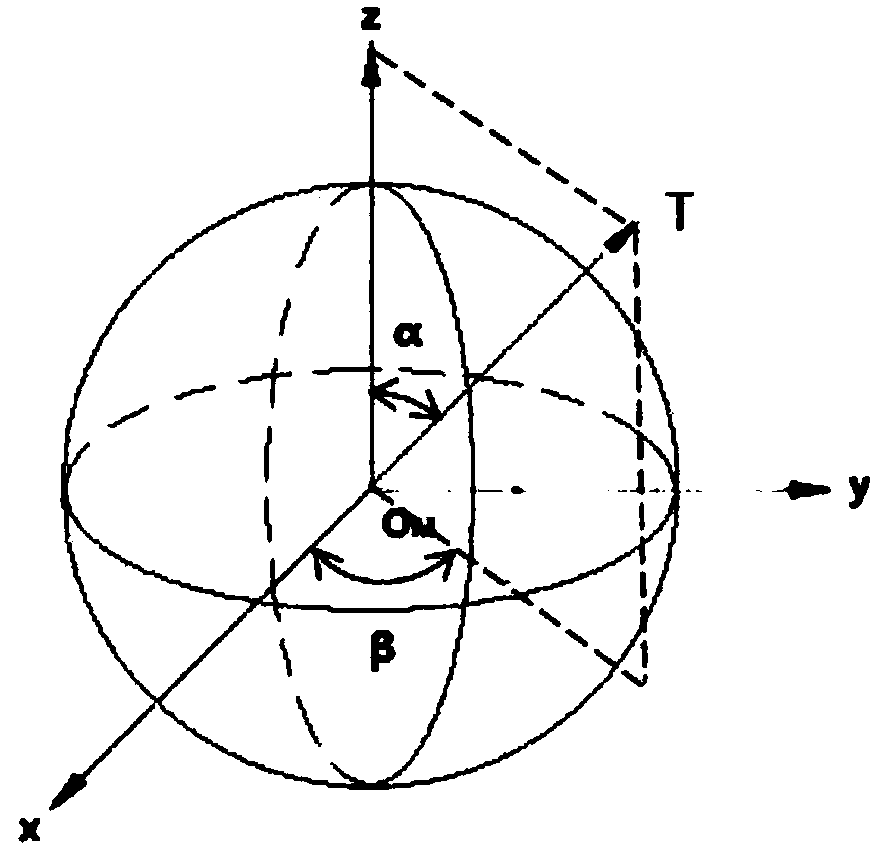

Radial direction milling method of thin wall blade edge head curved face

InactiveCN101323030APrevent overcutImprove machining accuracyMilling equipment detailsCutter locationDimensional modeling

The invention discloses a radial milling method for an edge head curved surface of a thin walled vane. At first, three-dimensional modeling is carried out on the thin walled vane to be processed, the processing coordinate system of the three-dimensional model of the thin walled vane is adjusted, a vane basin curved surface, a vane back curved surface, a front edge curved surface and a back edge curved surface are respectively extracted, effective processing regions are divided on the vane curved surface and contact point track is designed on the vane basin curved surface and the vane back curved surface, thus obtaining a contact point trajectory covering the whole processing region. Then a non-uniform B sampling curve that connects the trajectory of the vane basin cutter location and the trajectory of the vane back cutter location is constructed on the front edge and the back edge of the vane, and the corresponding cutter-axis vector and the cutter location are calculated. As only the vane basin curved surface and the vane back curved surface are involved in the cutting in the processing process, the front edge curved surface and the back edge curved surface are processed separately, thus avoiding over-cutting caused by intensive cutter locations on the front edge and the back edge and violent change of the cutter-axis vector. The processing precision can be improved to 0.05 to 0.10mm from 0.24 to 0.60mm of the prior art, and the processing efficiency can be improved at the same time.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

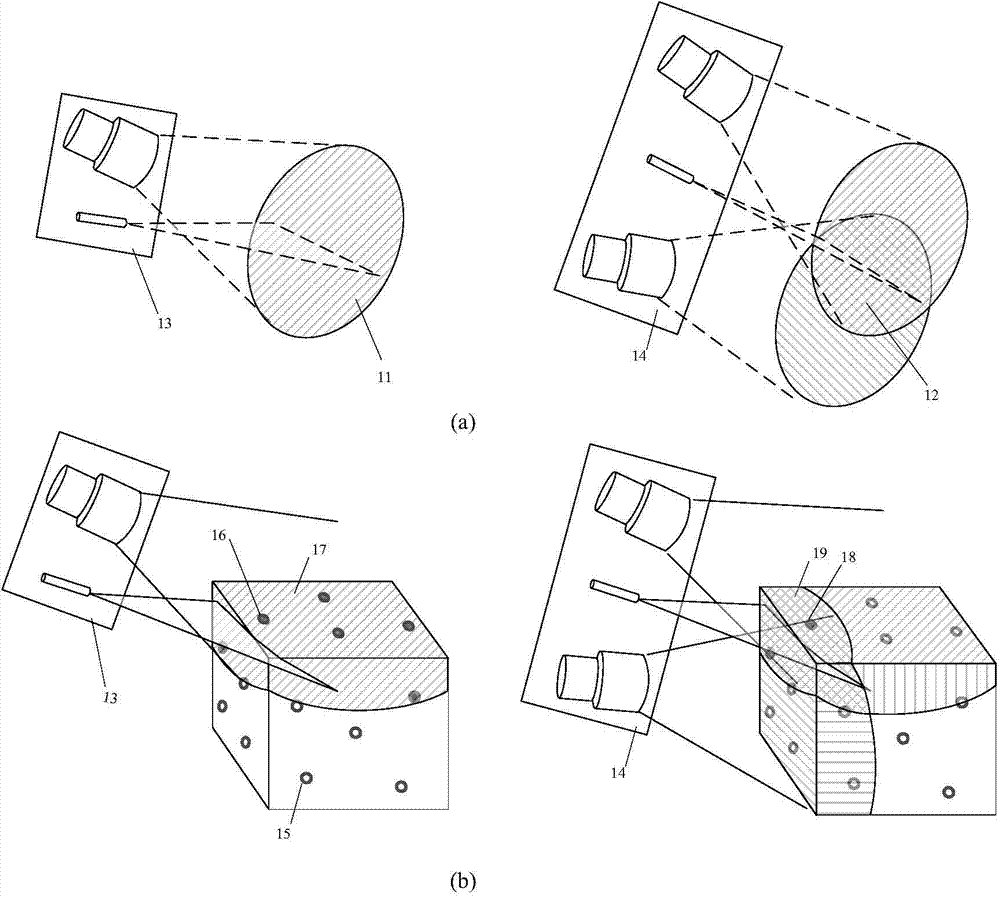

Handheld laser three-dimension scanning method and handheld laser three-dimension scanning equipment based on mark point trajectory tracking

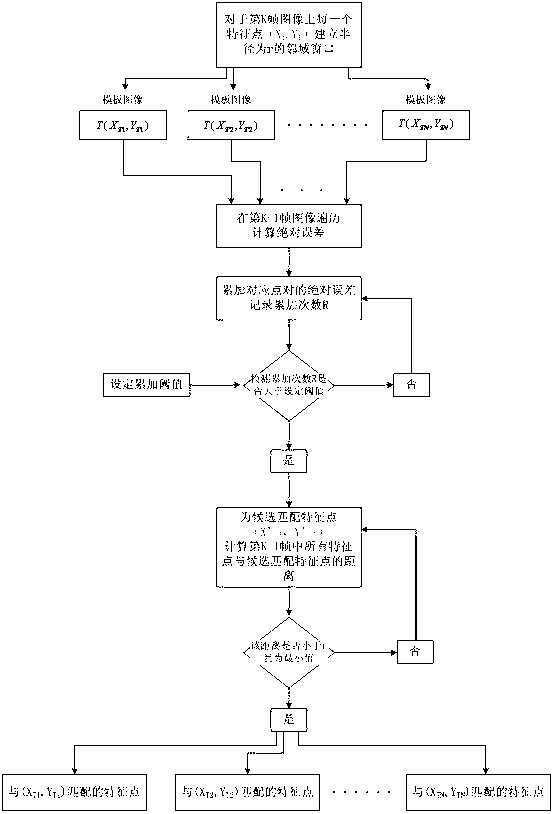

The invention relates to a handheld laser three-dimension scanning method based on single-camera mark point trajectory tracking. The handheld laser three-dimension scanning method comprises the following steps: (1) identifying and extracting the two-dimension position information of mark points in an image shot by a single camera, pre-judging according to the motion trajectories of the mark points in frames with a preset amount to obtain target positions in a current frame, then searching around the target positions to obtain mark points corresponding to the target positions, and establishing an initial matching relationship between the mark points in the current frame and an original mark point library; (2) utilizing the initial matching relationship to calculate the RT transfer matrix of an instrument from a current relative coordinate system Oc to a world coordinate system Ow, and utilizing a reprojection method for checking the previous initial matching relationship; (3) extracting a laser projection contour in a current frame image, and converting to three-dimensional coordinates under the world coordinate system Ow through the RT transfer matrix. The invention also discloses handheld laser three-dimension scanning equipment. According to the method and the equipment, the requirement for system hardware configuration is reduced, the smoothness during moving and splicing is good, the precision is relatively high, and the cost is relatively low.

Owner:杭州思锐迪科技有限公司

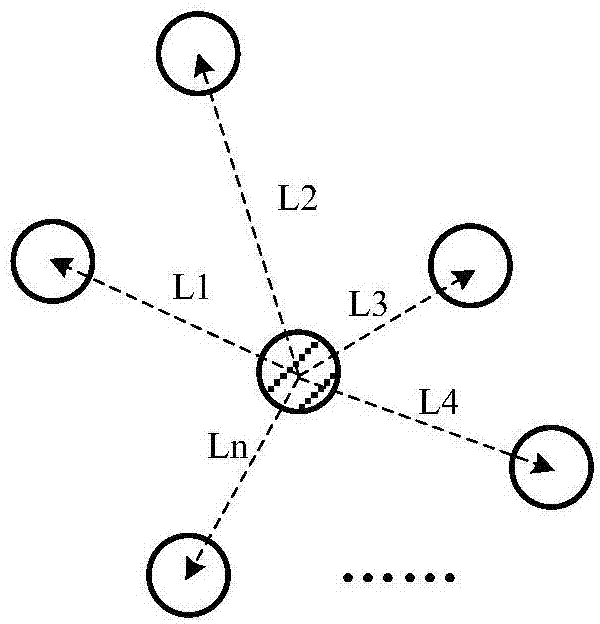

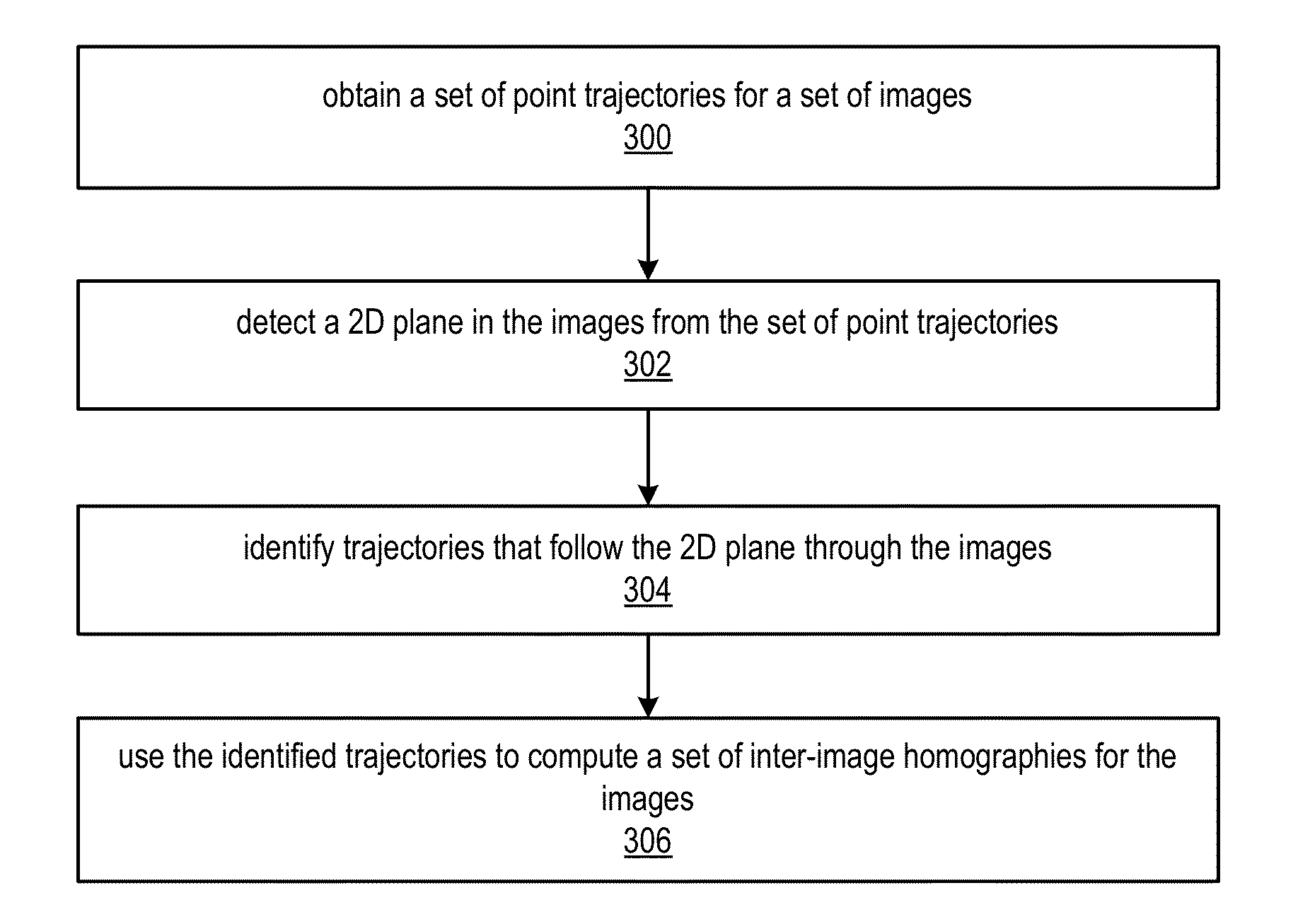

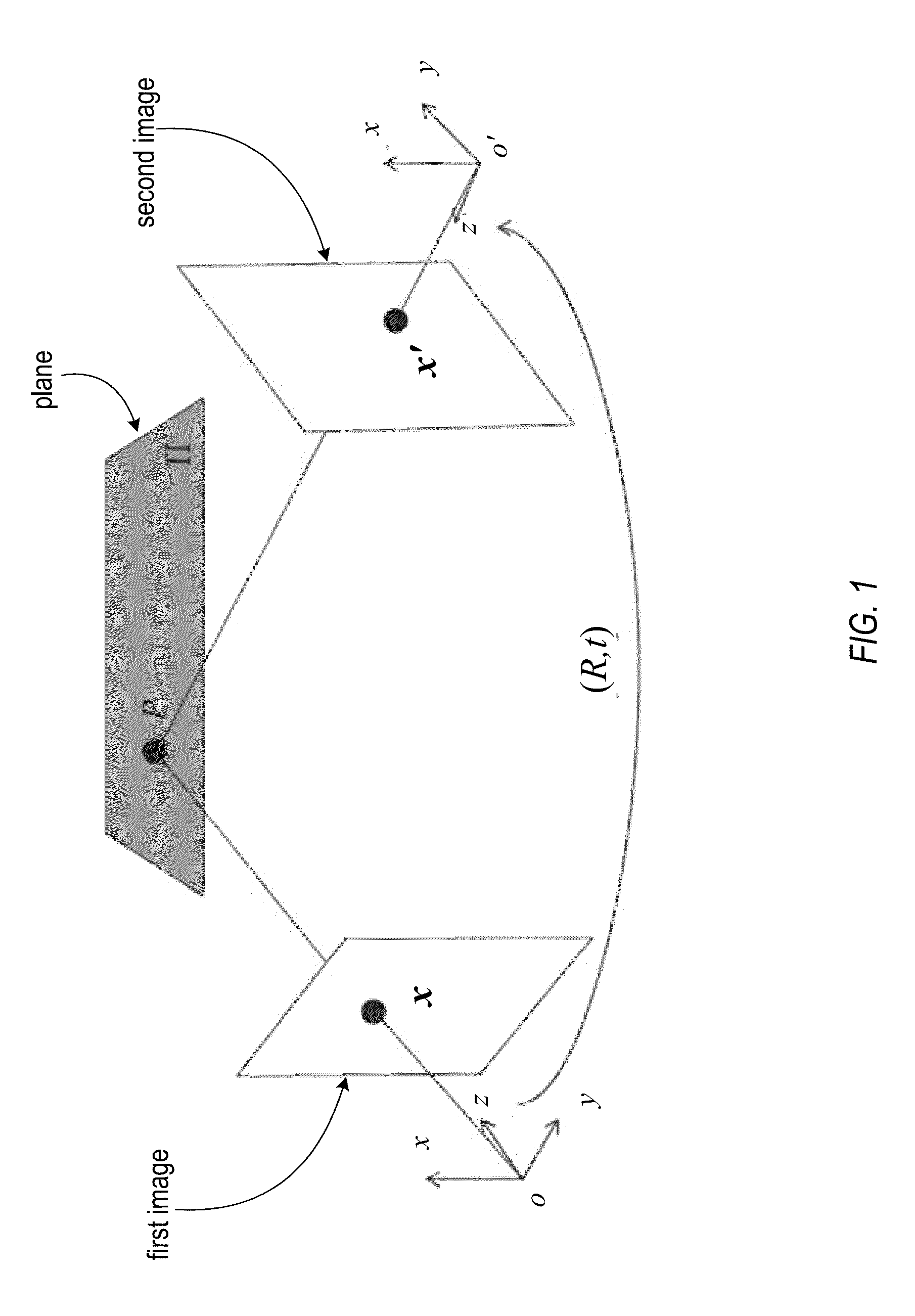

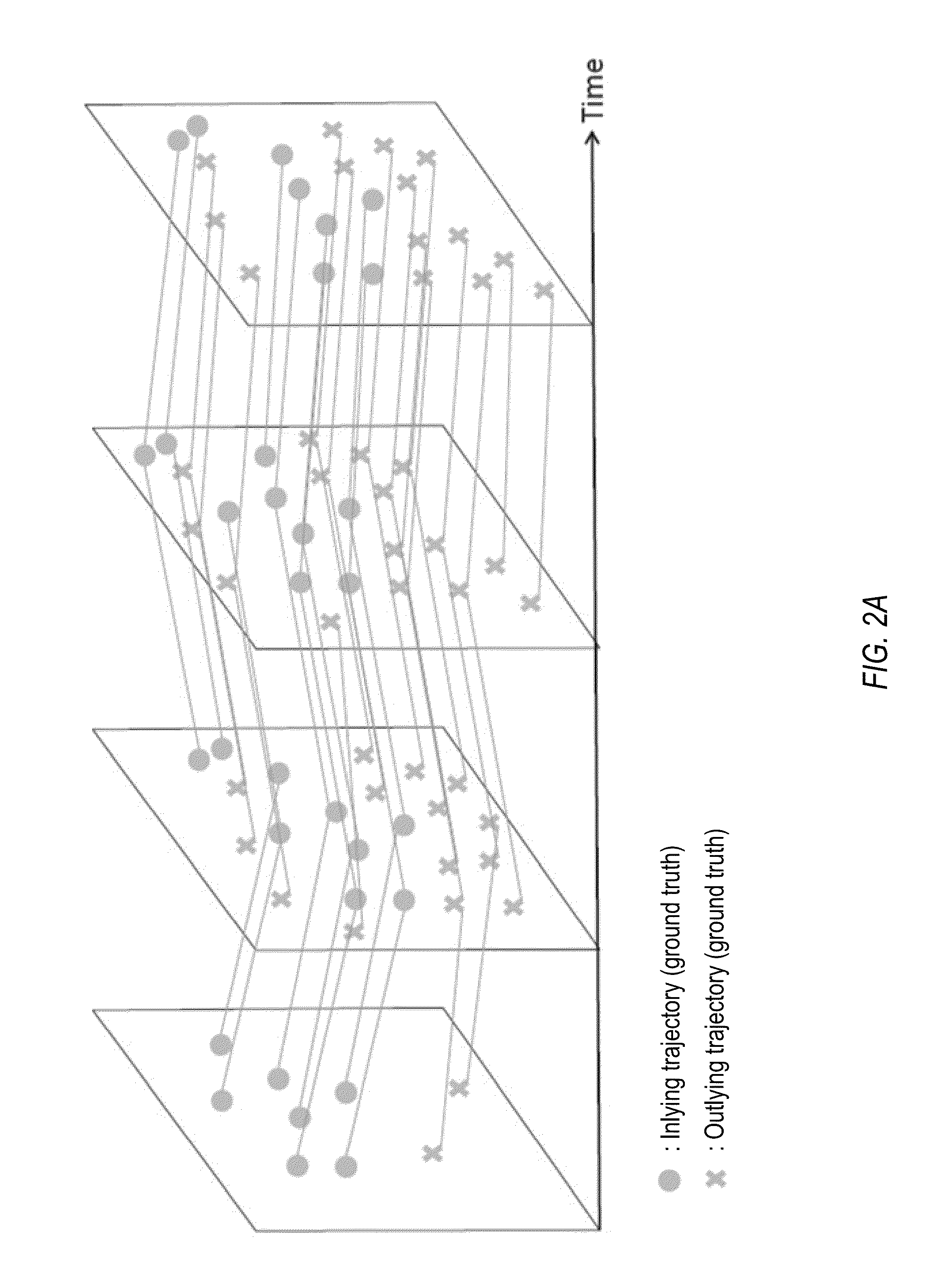

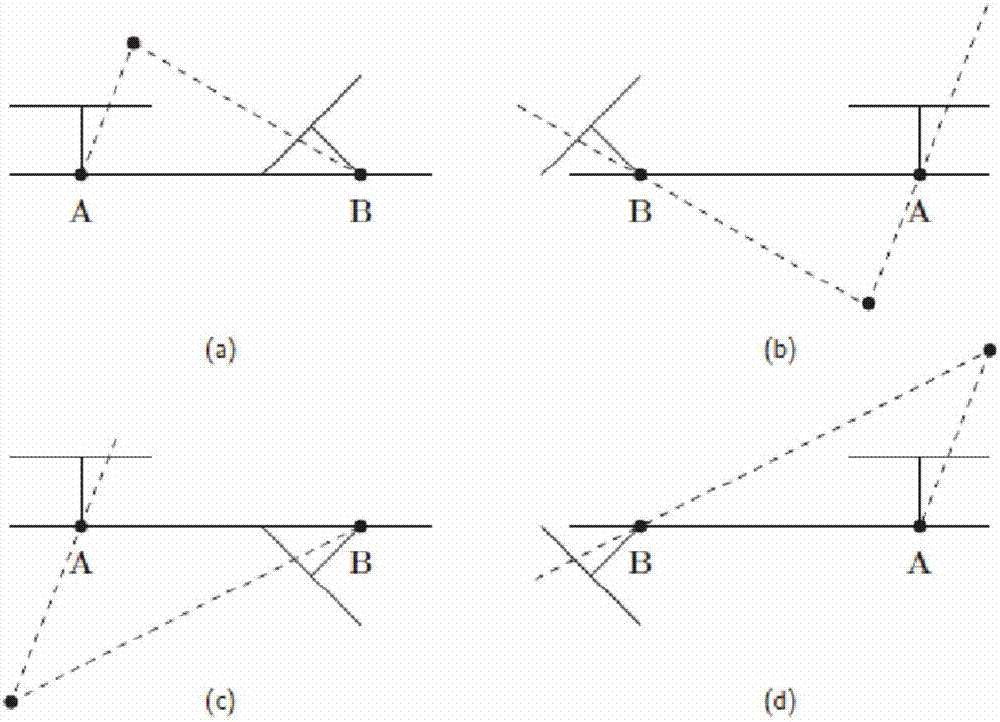

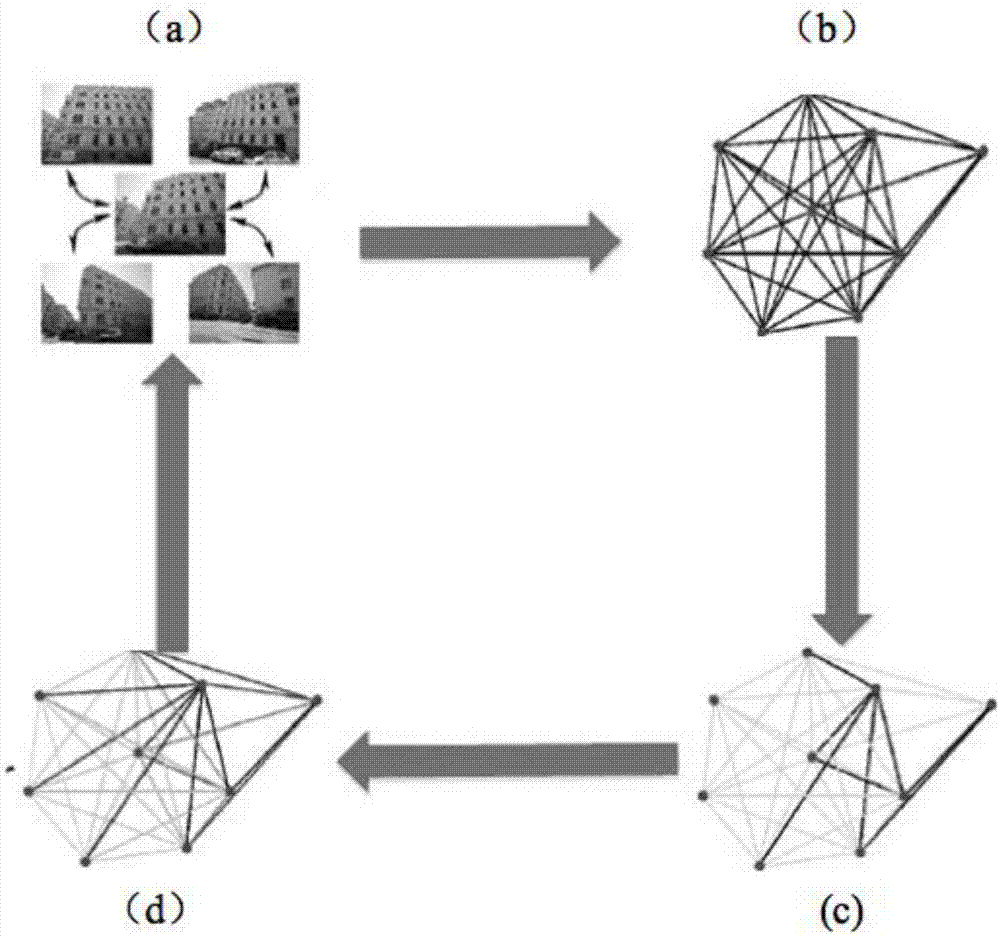

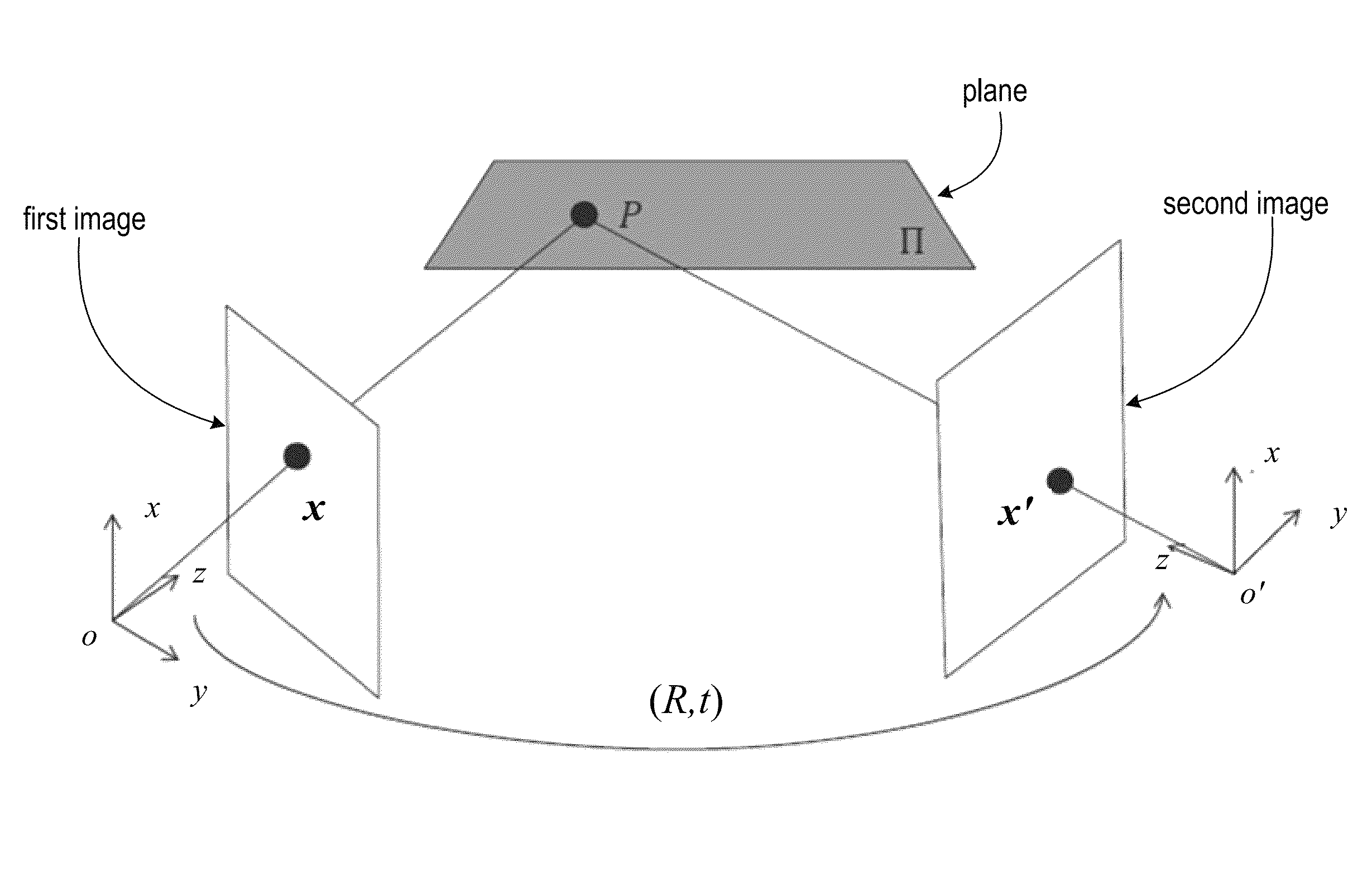

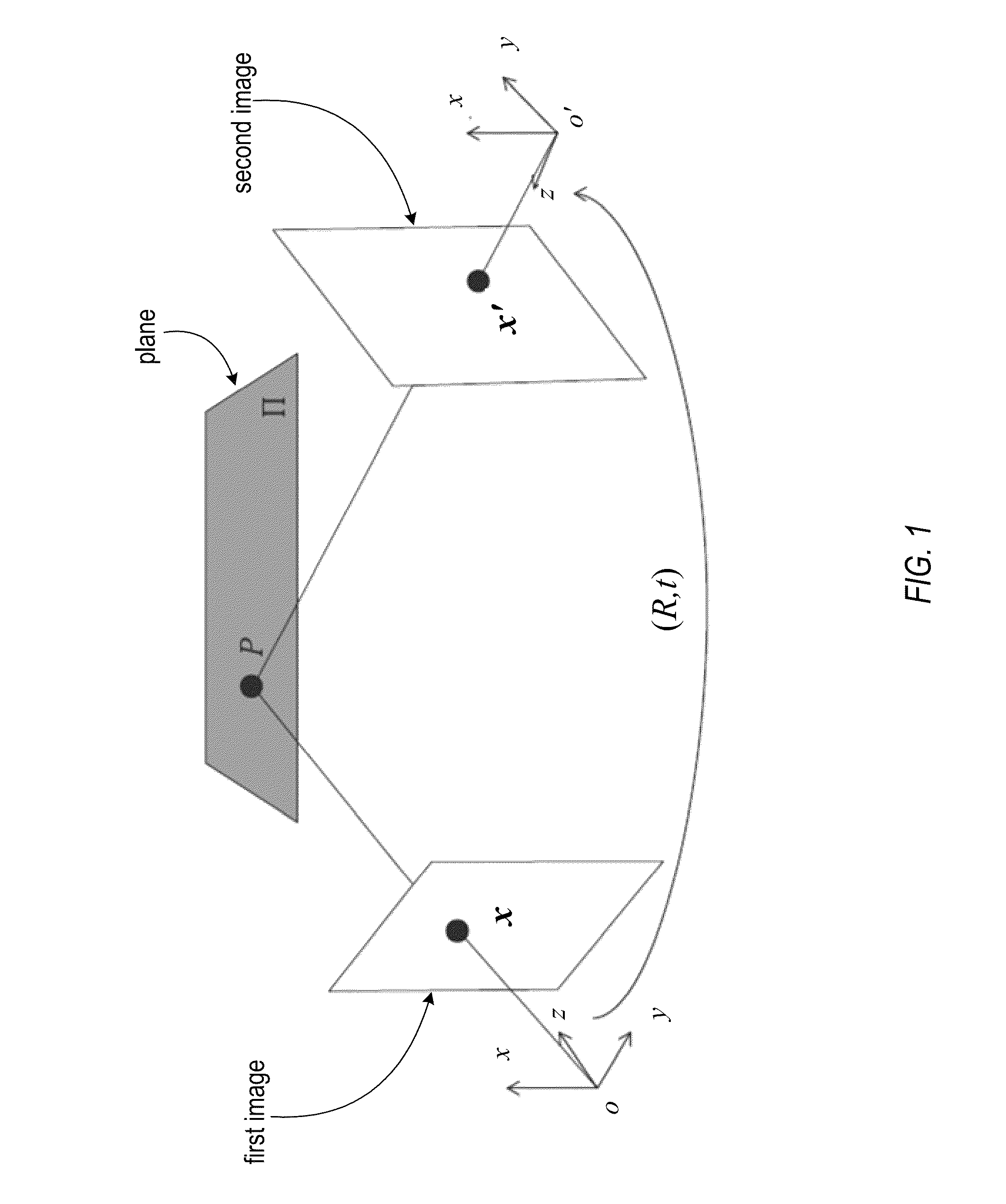

Plane Detection and Tracking for Structure from Motion

Plane detection and tracking algorithms are described that may take point trajectories as input and provide as output a set of inter-image homographies. The inter-image homographies may, for example, be used to generate estimates for 3D camera motion, camera intrinsic parameters, and plane normals using a plane-based self-calibration algorithm. A plane detection and tracking algorithm may obtain a set of point trajectories for a set of images (e.g., a video sequence, or a set of still photographs). A 2D plane may be detected from the trajectories, and trajectories that follow the 2D plane through the images may be identified. The identified trajectories may be used to compute a set of inter-image homographies for the images as output.

Owner:ADOBE INC

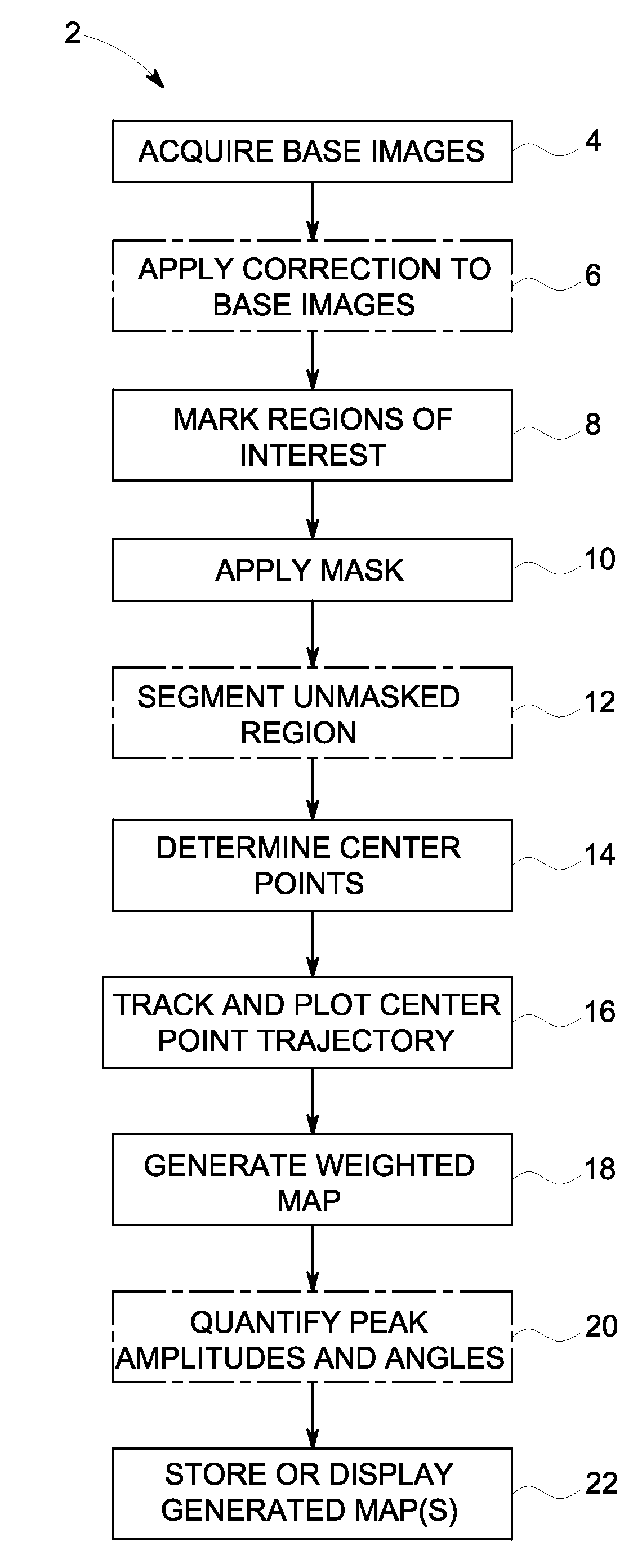

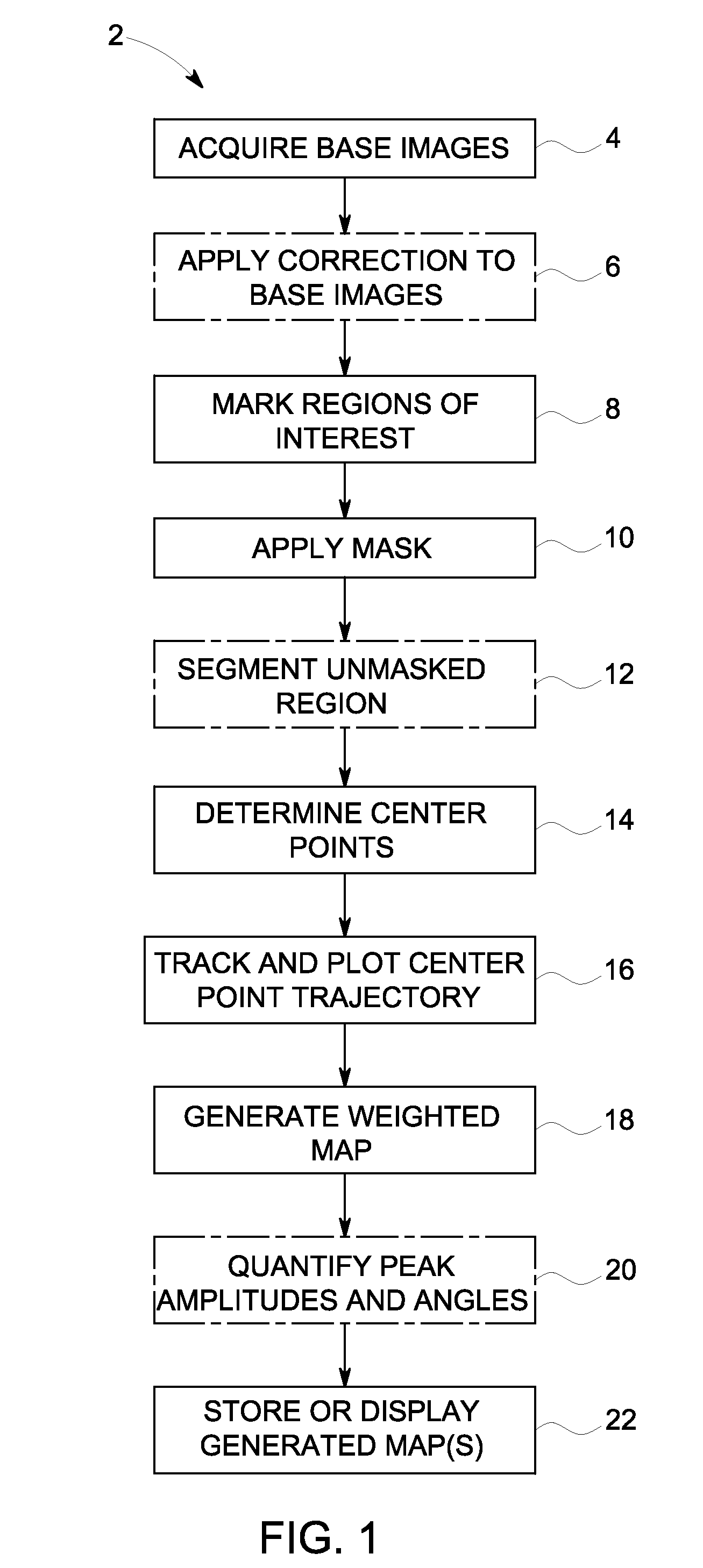

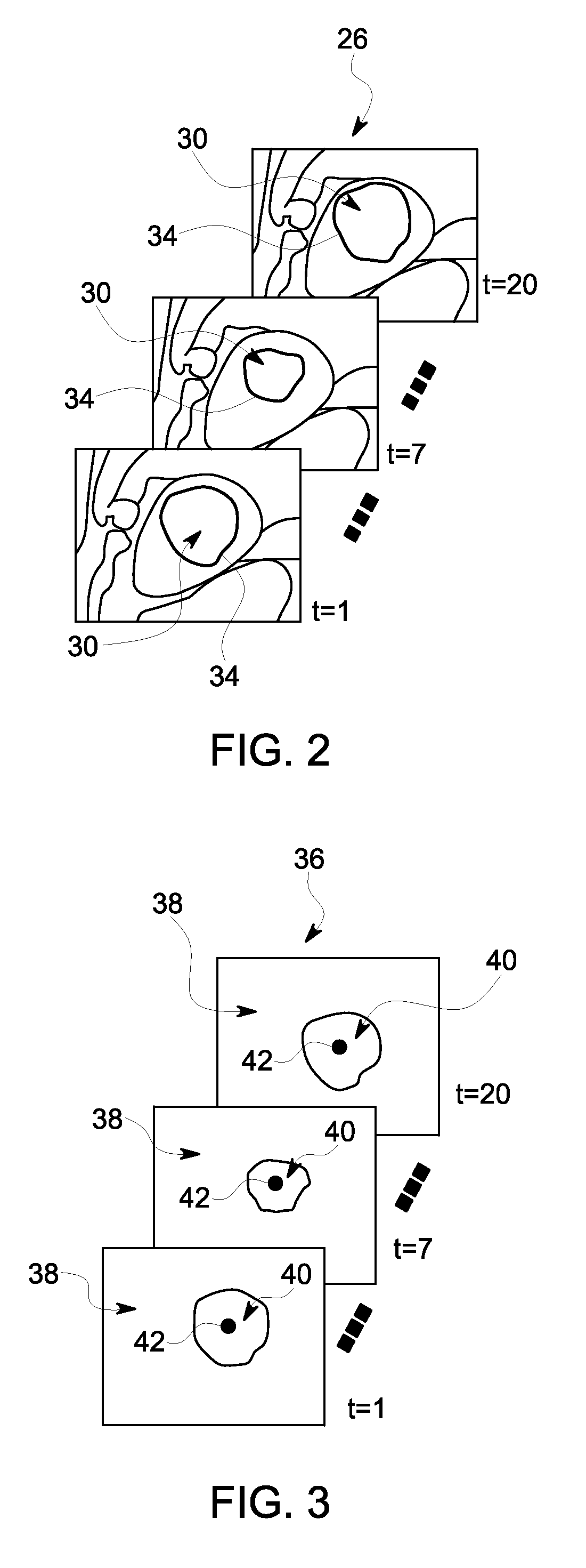

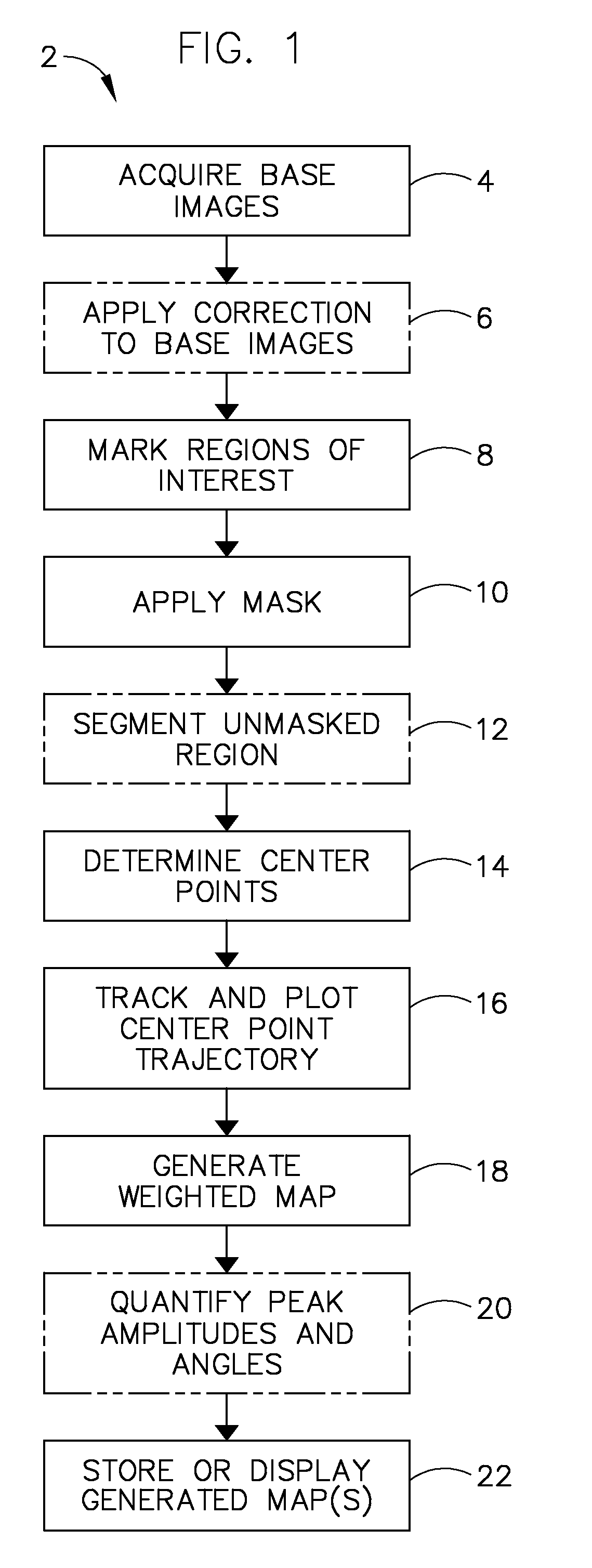

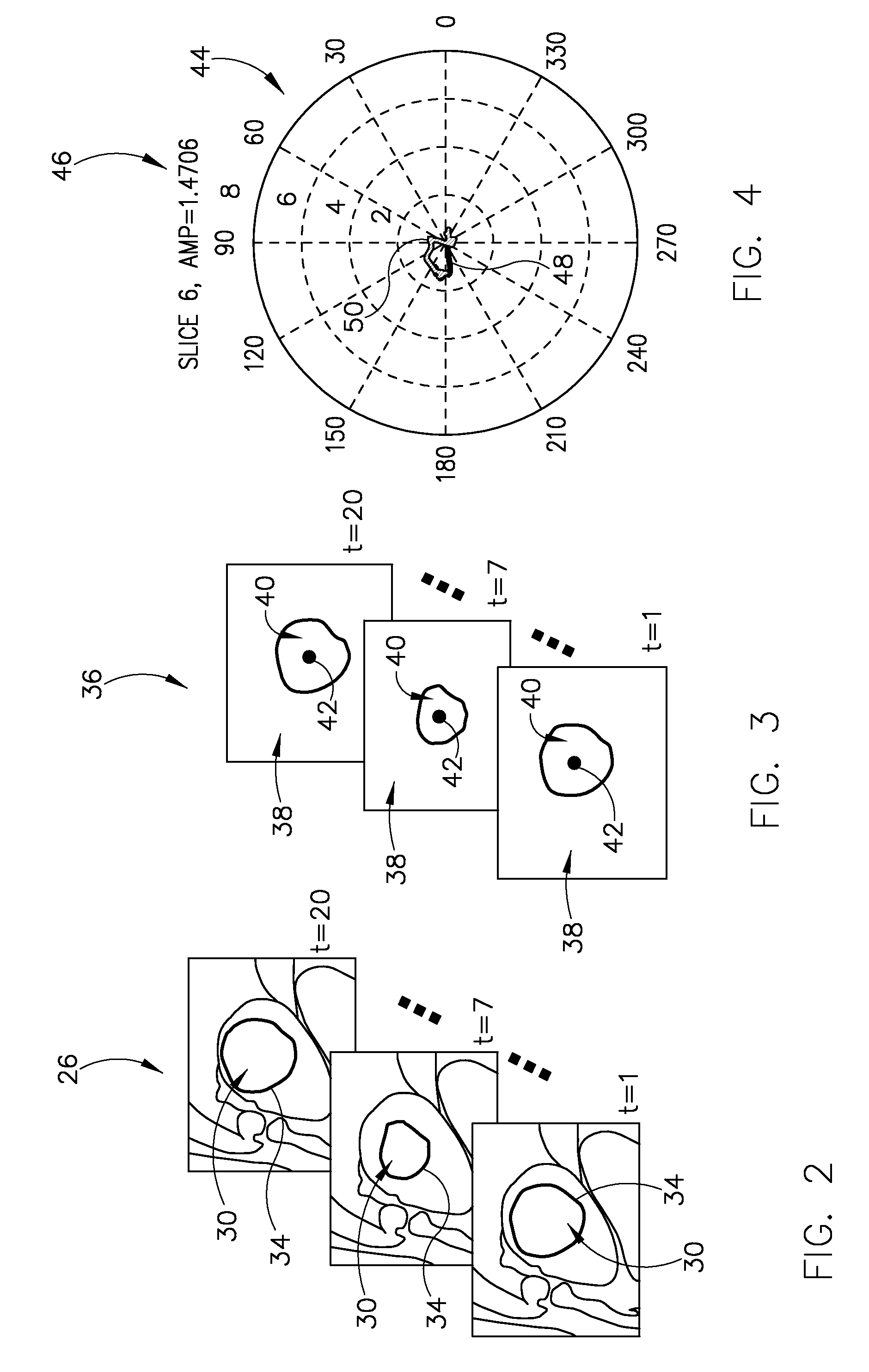

System and method for multi-segment center point trajectory mapping

A computer implemented method of mapping of multiple regional center point trajectory movements of cavity walls is provided in which images are acquired and a region-of-interest is identified in each of the images. The region-of-interest is divided into a plurality of distinct regions and a regional center point for each of the regions is located in the images. For each regional center point, a center point trajectory is determined based on variances in position of the center points from each other in the images. The center point trajectory of each regional center point is decomposed into radial and circumferential components so as to isolate radial component of the center point trajectory for each regional center point in each of the images and radial motion versus time curves are displayed for each regional center point based on the determined radial component for each regional center point in each of the images.

Owner:THE HENRY M JACKSON FOUND FOR THE ADVANCEMENT OF MILITARY MEDICINE INC +1

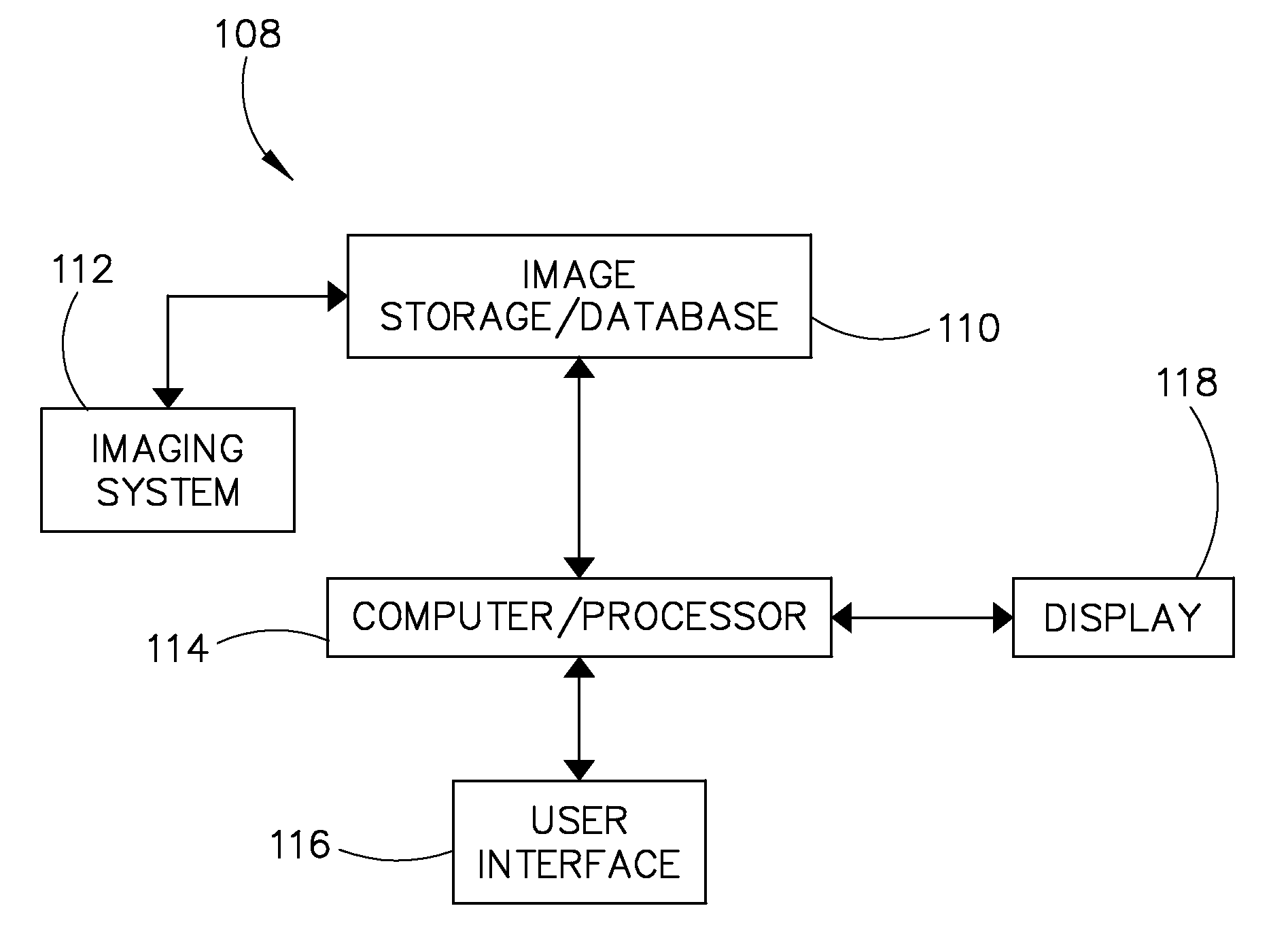

System and method for center point trajectory mapping

A system and method for center point trajectory mapping includes a computer readable storage medium having stored thereon a computer program comprises instructions, which when executed by a computer, cause the computer to acquire a first plurality of images, each image comprising a masked portion. The instructions also cause the computer to locate a center point of the masked portion in each of the plurality of images and to plot a map based on variances in position of the center points from each other. The instructions further cause the computer to display the map on a display.

Owner:GENERAL ELECTRIC CO +1

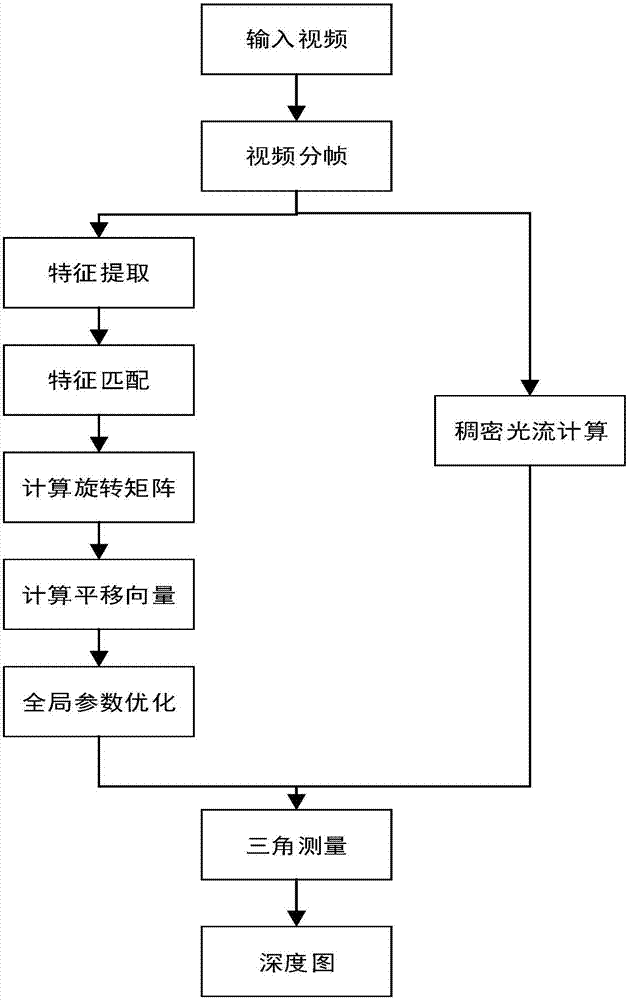

Method for calculating monocular video depth map

ActiveCN107481279AGuaranteed accuracyImprove efficiencyImage enhancementImage analysisEstimation methodsOptical flow

The invention provides a method for calculating a monocular video depth map. The method is characterized by comprising a step of decomposing a video to be recovered into frames according to a frame, a step of extracting picture feature points of each frame, a step of matching the feature points and forming a feature point trajectory, a step of calculating a global rotation matrix and a translation vector, a step of optimizing camera parameters, a step of calculating dense optical flow of a selected frame, and a step of calculating a depth value of the selected frame to obtain a depth map. According to the method of the technical scheme, a depth estimation method of surface from motion (SFM) based on a physical mechanism is used, and a dense optical flow is used for matching. According to the method, no training sample is needed, optimization modes of segmentation, plane fitting and the like are not used, and the calculation quantity is small. At the same time, according to the method, a problem that the depth values of all pixels can not be obtained especially in a texture-free area in a process from sparse reconstruction to dense reconstruction in the prior art is solved, while the calculation efficiency is improved, the accuracy of the depth map is ensured.

Owner:HUAZHONG UNIV OF SCI & TECH

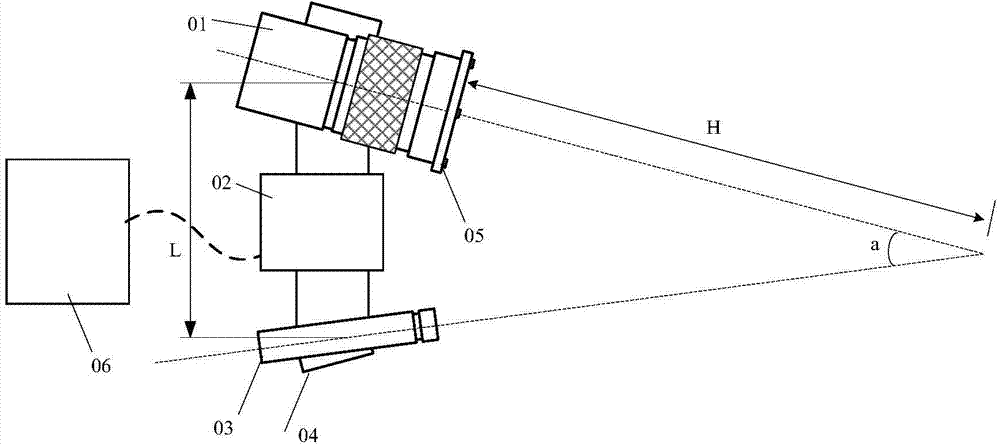

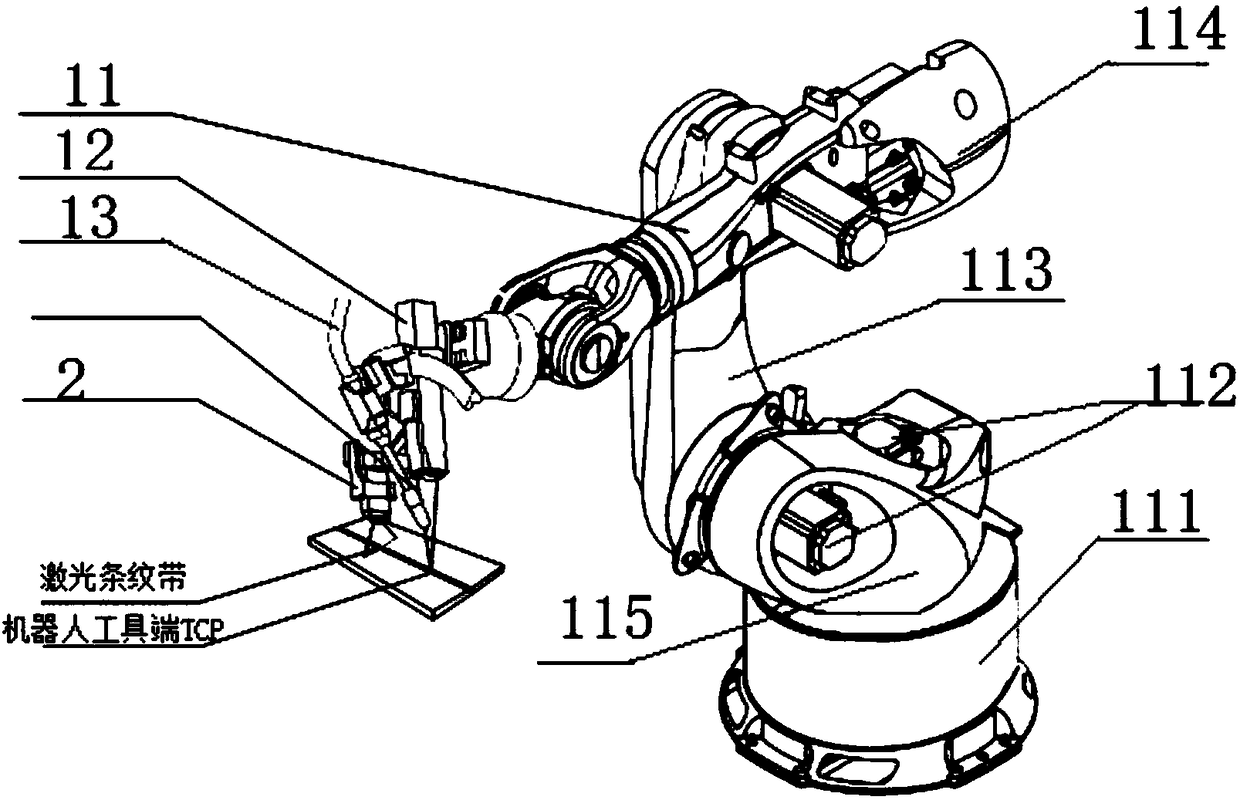

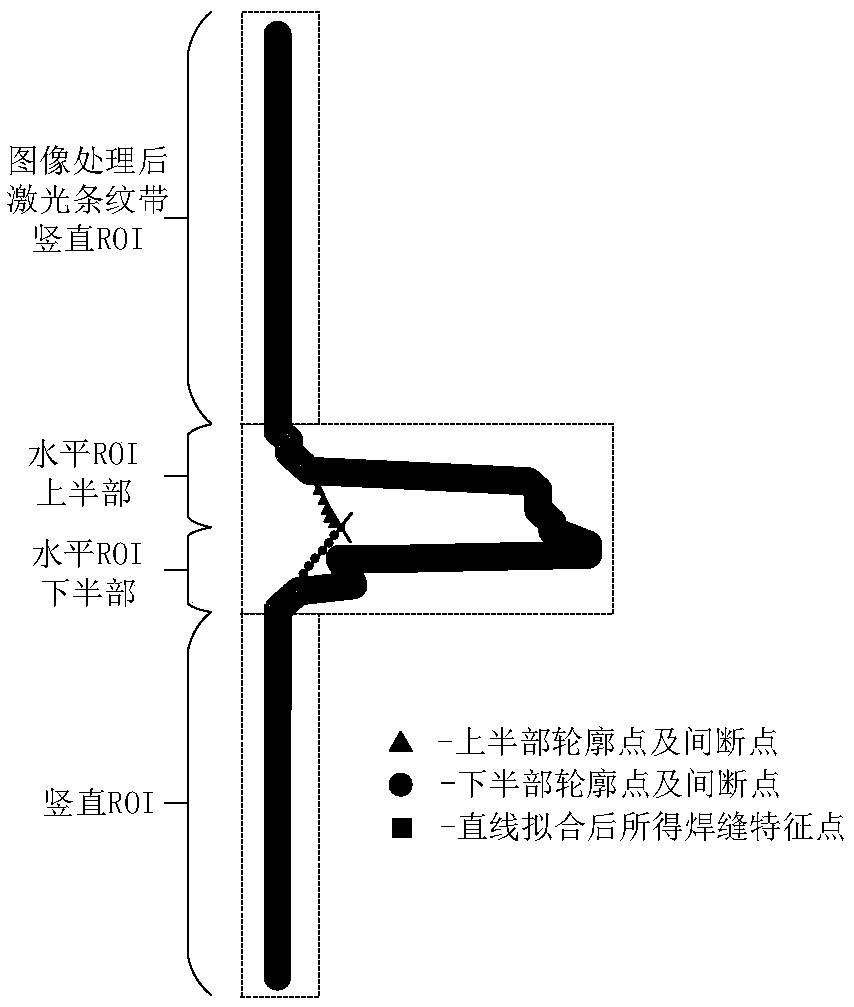

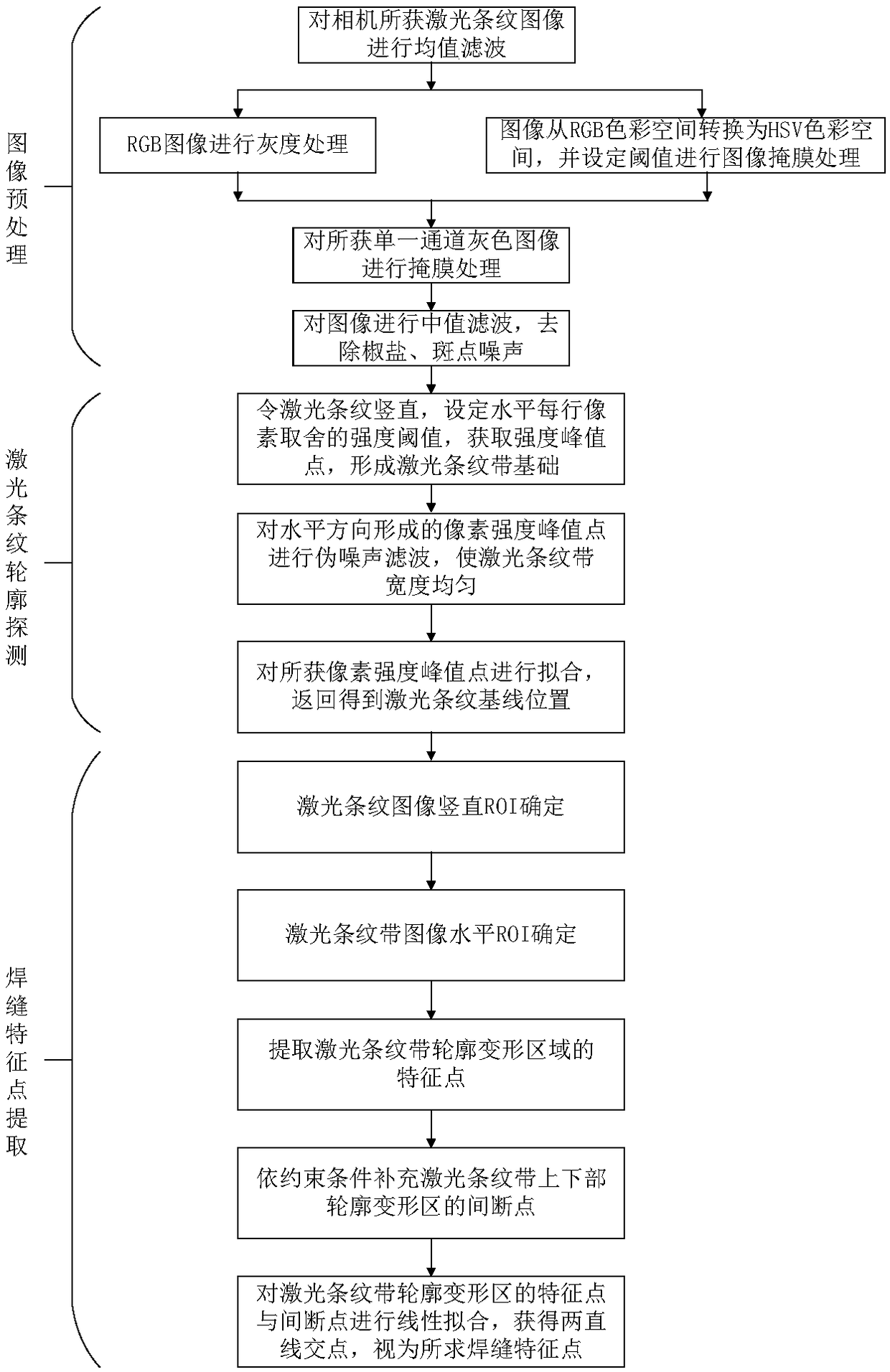

Active laser vision steady weld joint tracking system for laser-arc hybrid welding

ActiveCN109226967ATroubleshoot tracking errorsRealize automatic extractionImage enhancementProgramme-controlled manipulatorLaser-hybrid weldingEngineering

The invention discloses an active laser vision steady weld joint tracking system for laser-arc hybrid welding. The system comprises a laser-hybrid welding robot, an active laser vision system, a lasersource, an image processing system and a control system, wherein the active laser vision system and the laser source are both disposed on the laser-hybrid welding robot; the image processing system is disposed in the control system; and the laser-hybrid welding robot, the active laser vision system, the laser source, and the image processing system are all connected with the control system. The active laser vision steady weld joint tracking system solves the problem that during the traditional laser-arc hybrid welding, the arc light and the spattering interference causes the weld joint tracking system to generate excessive image noise, which ultimately affects the welding quality, the welding precision and efficiency, and solves the robot tracking errors caused by the weld joint feature point trajectory deviation during the teaching process, combines the weld joint image recognition with robot motion control to realize automatic extraction and accurate intelligent tracking of weld joint features.

Owner:TONGGAO ADVANCED MFG TECH TAICANG

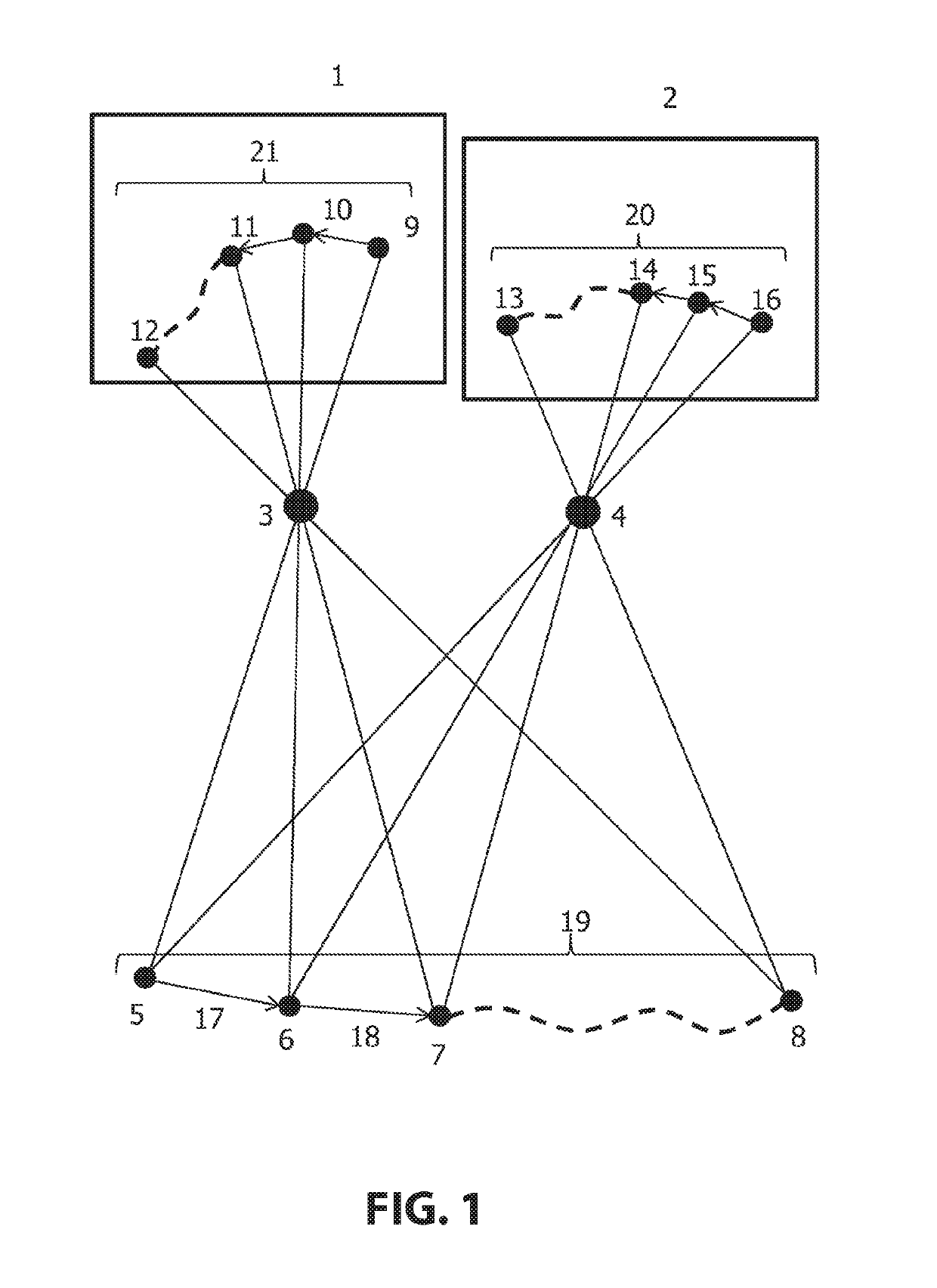

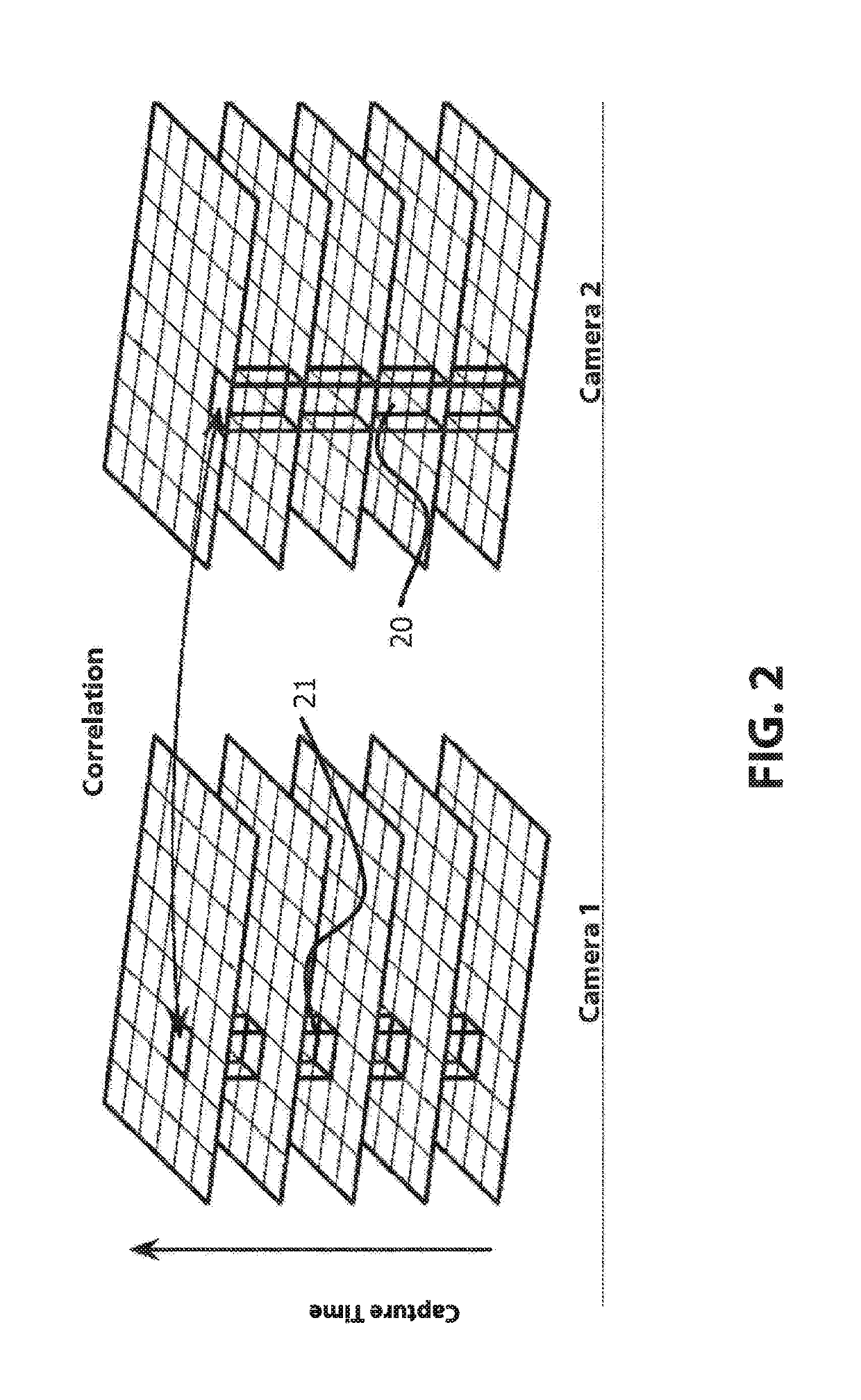

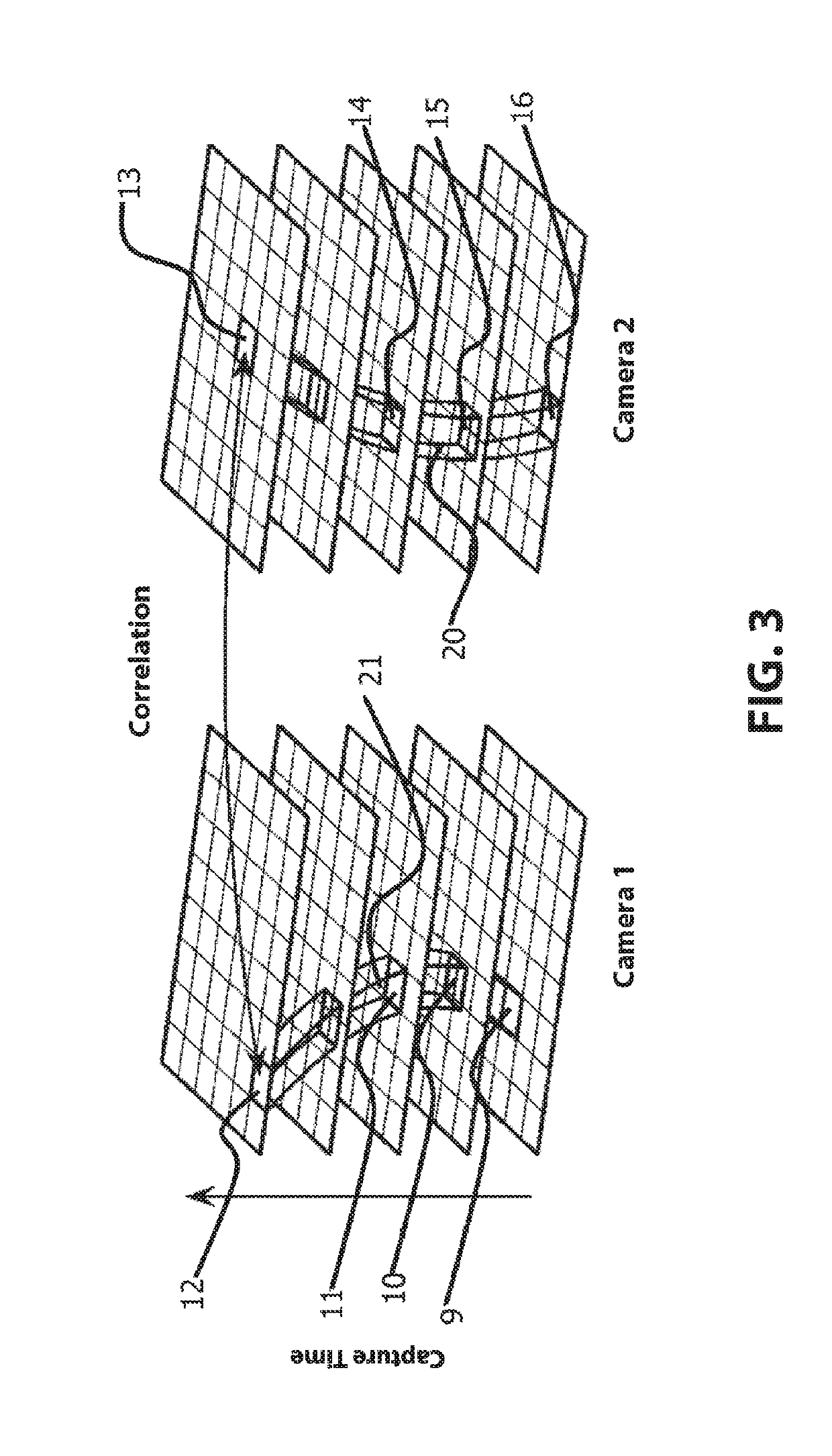

Method for the three dimensional measurement of a moving objects during a known movement

ActiveUS20190128665A1Overcome disadvantagesImage enhancementImage analysisPattern sequenceTriangulation

A 3D measurement method including; projecting a pattern sequence onto a moving object; capturing a first image sequence with a first camera and a second image sequence synchronously to the first image sequence with a second camera; determining corresponding image points in the two sequences; computing a trajectory of a potential object point from imaging parameters and from known movement data for each pair of image points that is to be checked for correspondence, The potential object point is imaged by both image points in case they correspond. Imaging object positions derived therefrom at each of the capture points in time into image planes respectively of the two cameras. Corresponding image points positions are determined as trajectories in the two cameras and the image points are compared with each other along predetermined image point trajectories and examined for correspondence; lastly performing 3D measurement of the moved object by triangulation,

Owner:COGNEX CORP

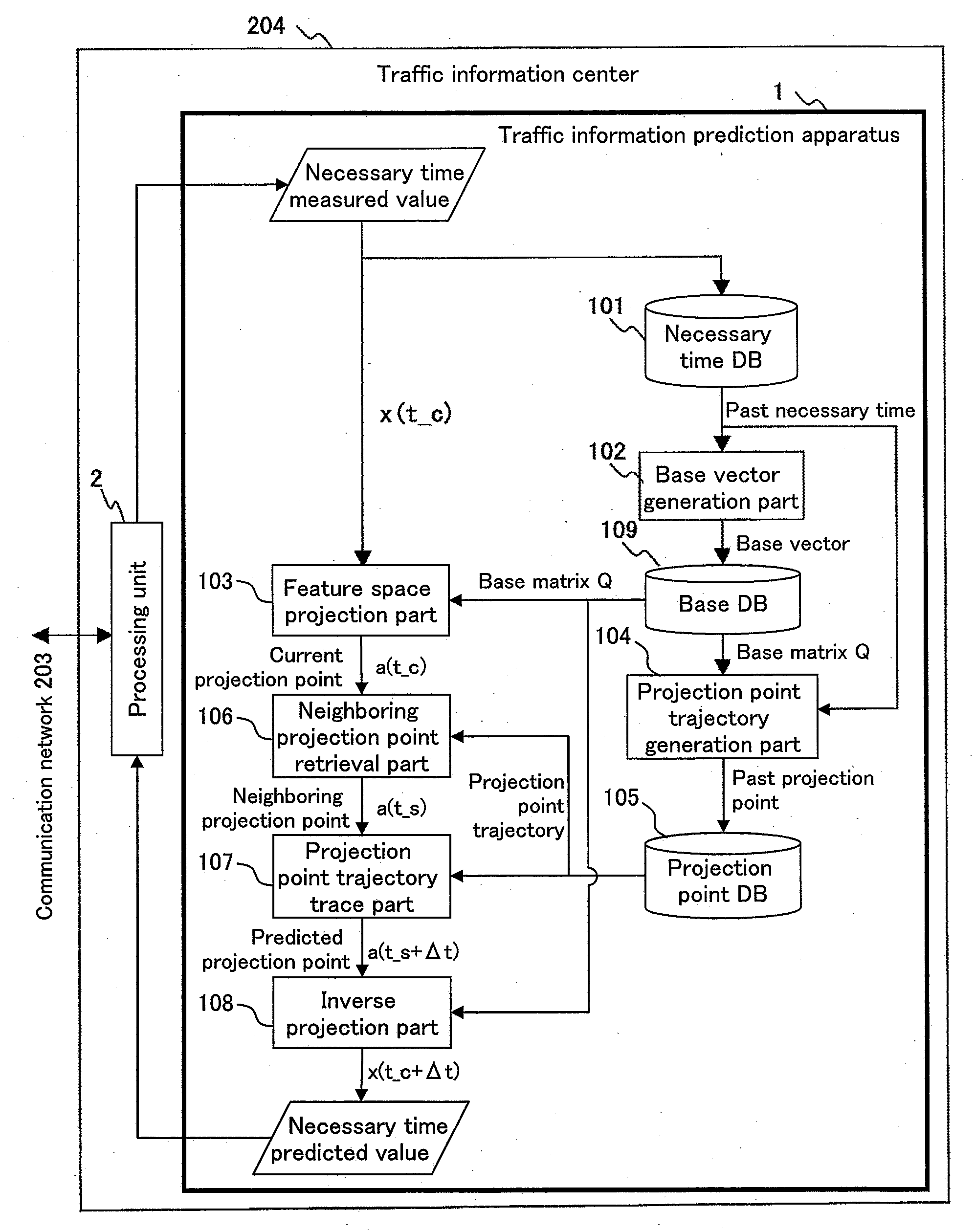

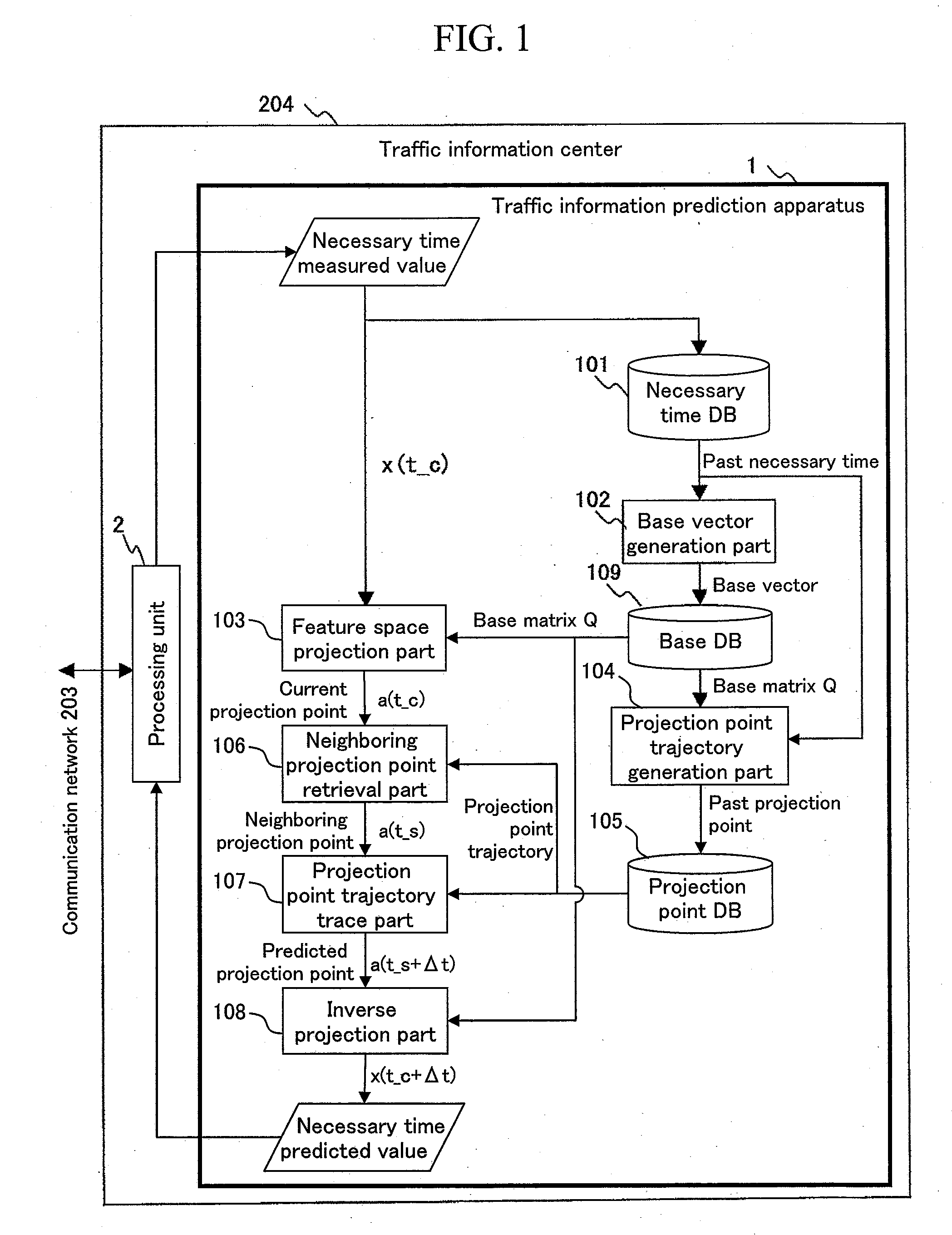

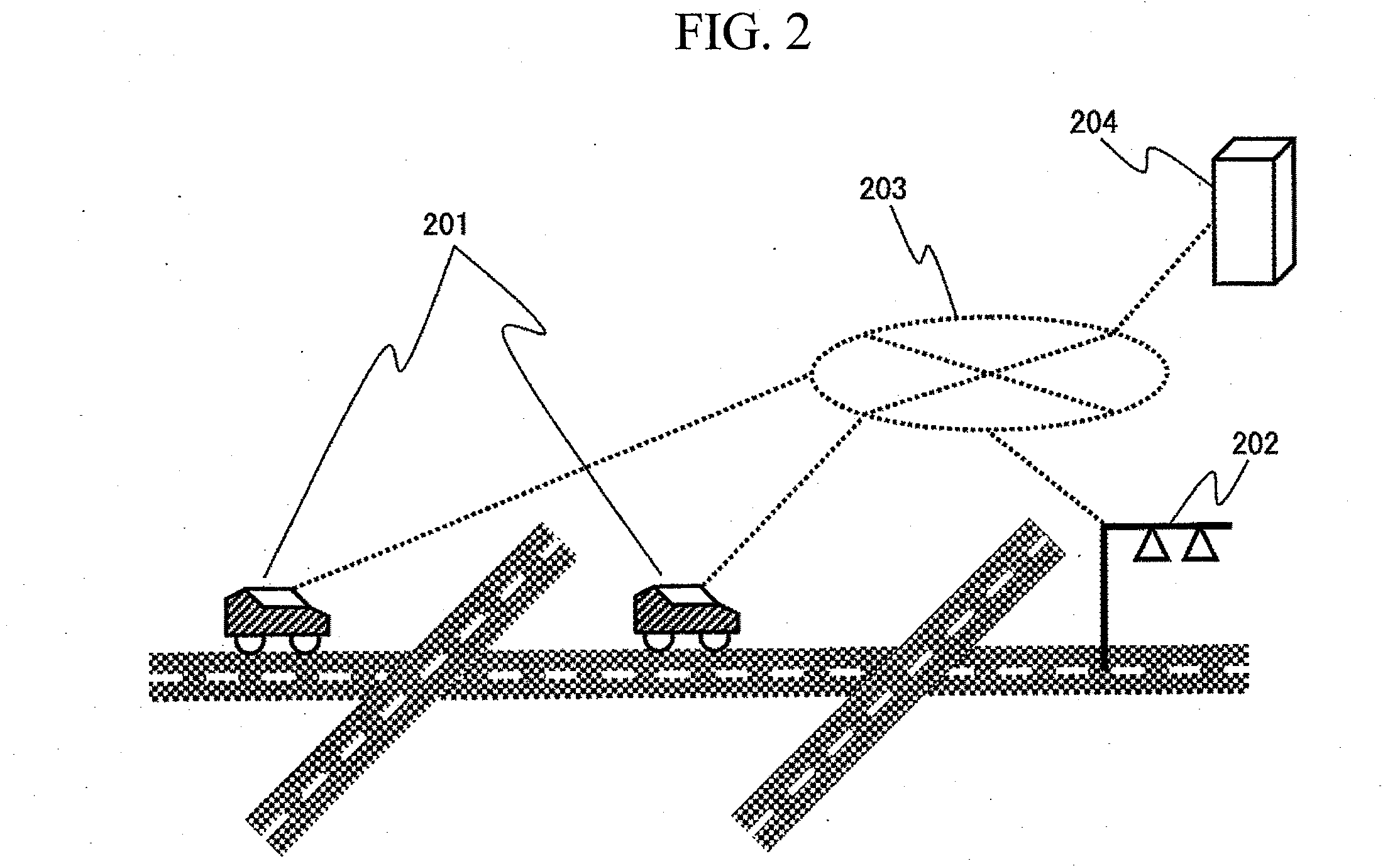

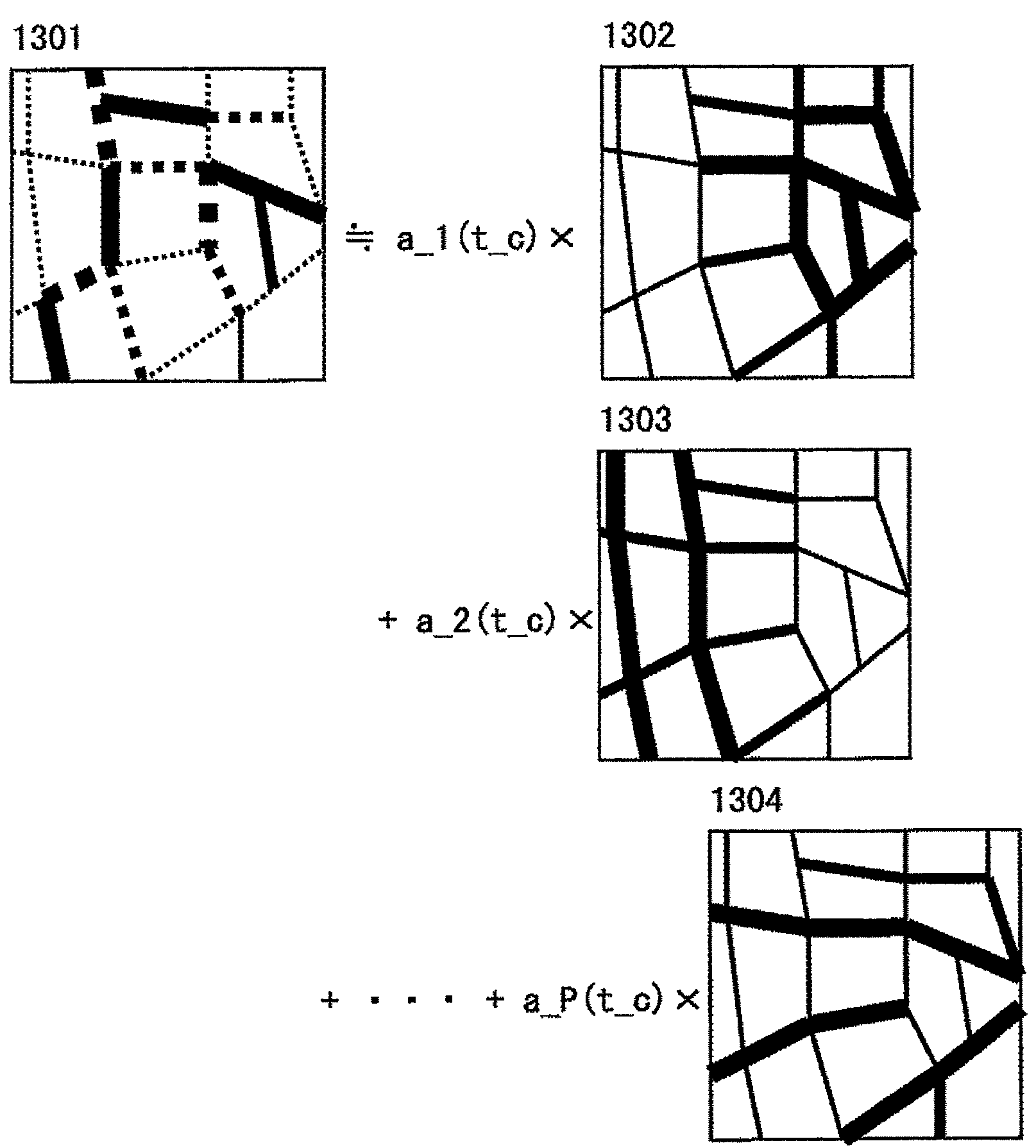

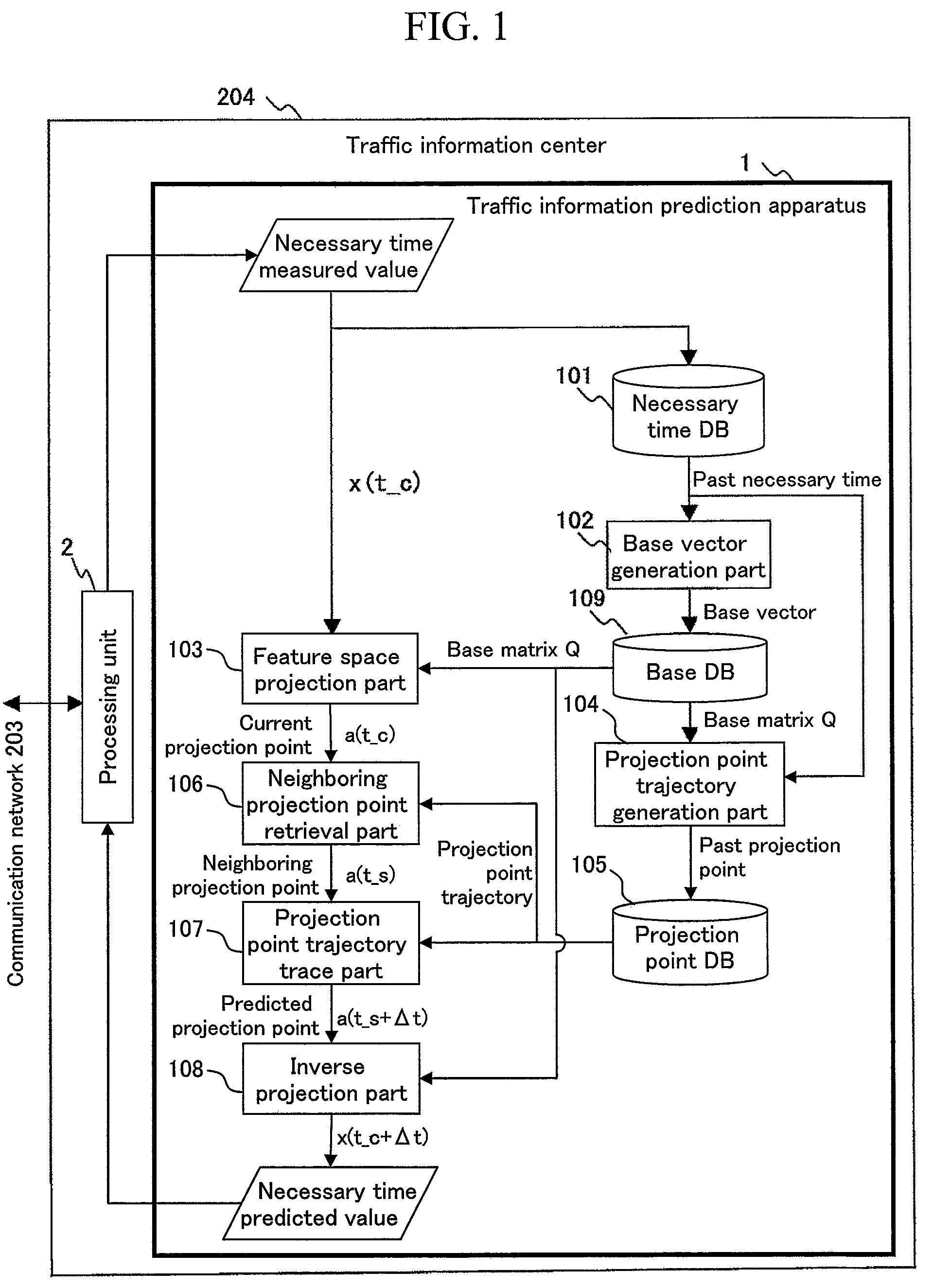

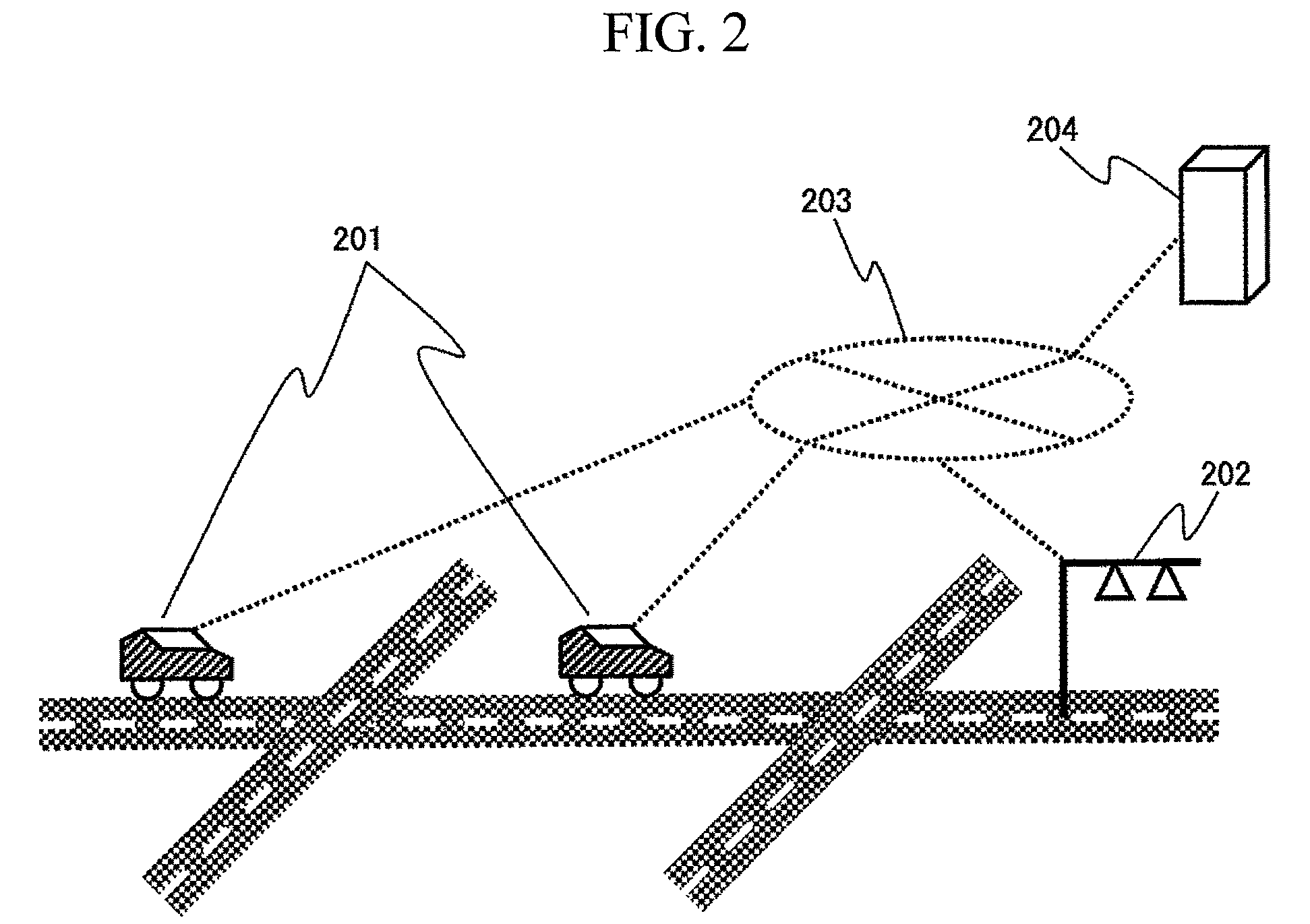

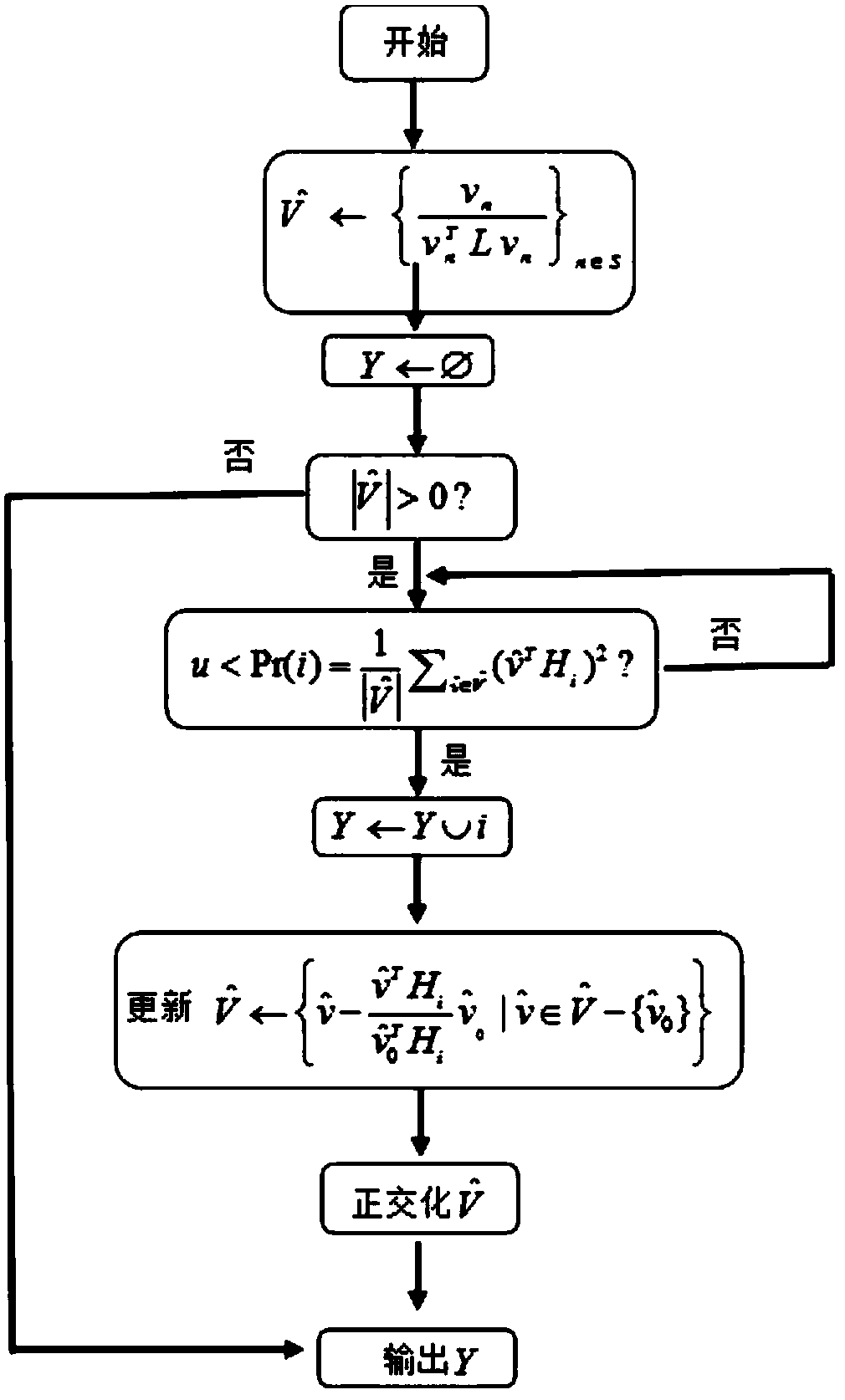

Dynamic Prediction of Traffic Congestion by Tracing Feature-Space Trajectory of Sparse Floating-Car Data

InactiveUS20090070025A1Analogue computers for vehiclesAnalogue computers for trafficTemporal databasePrincipal component analysis

A traffic situation is predicted based on the correlation in the traffic situation between road sections. A base vector generation unit generates the base vectors constituting a feature space representing the correlation between a plurality of links by making a principal component analysis for the necessary time in the past recorded in a necessary time database. A projection point trajectory generation unit records a projection point trajectory of projecting the necessary time in the past recorded in the necessary time database to the feature space in a projection point database. A feature space projection unit projects the necessary time at present to the feature space, and a neighboring projection point retrieval unit retrieves a past projection point in the neighborhood of the concerned projection point from the projection point database, and a projection point trajectory trace unit traces the trajectory of past projection points starting from the retrieved neighboring projection point for a prediction target time width, and an inverse projection unit inversely projects the end point of the concerned trajectory to calculate the predicted value of the necessary time.

Owner:HITACHI LTD

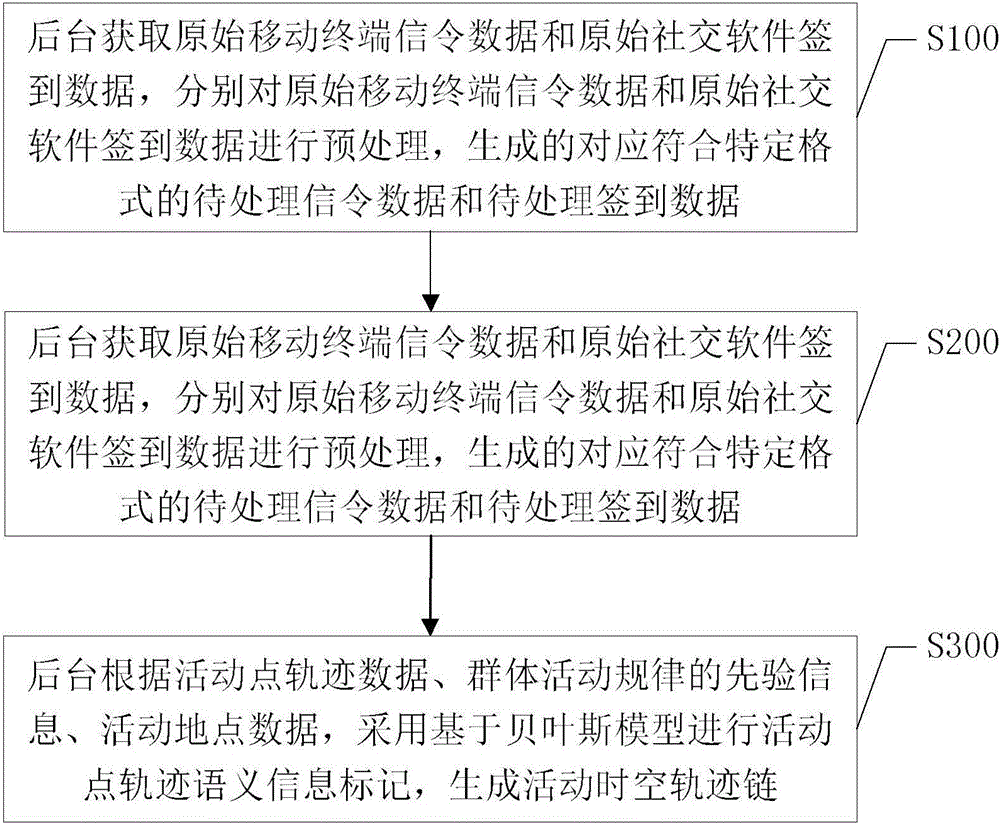

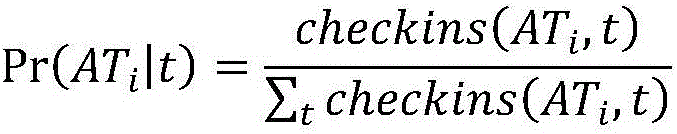

Group activity data collection method and system based on multisource space-time trajectory data

ActiveCN106211071AAccurate extractionAccurate collectionLocation information based servicePrior informationComputer science

The invention discloses a group activity data collection method and system based on multisource space-time trajectory data. The method comprises the steps that a background obtains and preprocesses original mobile terminal signal data and original social software signature data and generates to-be-processed signal data and to-be-processed signature data in consistent with specific formats; the background obtains activity point trajectory data from the to-be-processed signal data, establishes and learns prior information of group activity rules, obtains activity point trajectory data, and obtains activity location data; the background marks activity point trajectory semantic information by employing a Bayesian model and generates an activity space-time trajectory chain according to the activity point trajectory data, the prior information of group activity rules and the activity location data. According to the method and the system, individual activities are deduced by employing the Bayesian model; the influence of the activity type of a former moment on the activity type of a latter moment in the space-time activity trajectory is taken into consideration; and accurate, fast and efficient extraction and collection of wide-range and massive group activities are realized.

Owner:SHENZHEN UNIV

Dynamic prediction of traffic congestion by tracing feature-space trajectory of sparse floating-car data

InactiveUS7542844B2Analogue computers for vehiclesAnalogue computers for trafficTemporal databasePrincipal component analysis

A traffic situation is predicted based on the correlation in the traffic situation between road sections. A base vector generation unit generates the base vectors constituting a feature space representing the correlation between a plurality of links by making a principal component analysis for the necessary time in the past recorded in a necessary time database. A projection point trajectory generation unit records a projection point trajectory of projecting the necessary time in the past recorded in the necessary time database to the feature space in a projection point database. A feature space projection unit projects the necessary time at present to the feature space, and a neighboring projection point retrieval unit retrieves a past projection point in the neighborhood of the concerned projection point from the projection point database, and a projection point trajectory trace unit traces the trajectory of past projection points starting from the retrieved neighboring projection point for a prediction target time width, and an inverse projection unit inversely projects the end point of the concerned trajectory to calculate the predicted value of the necessary time.

Owner:HITACHI LTD

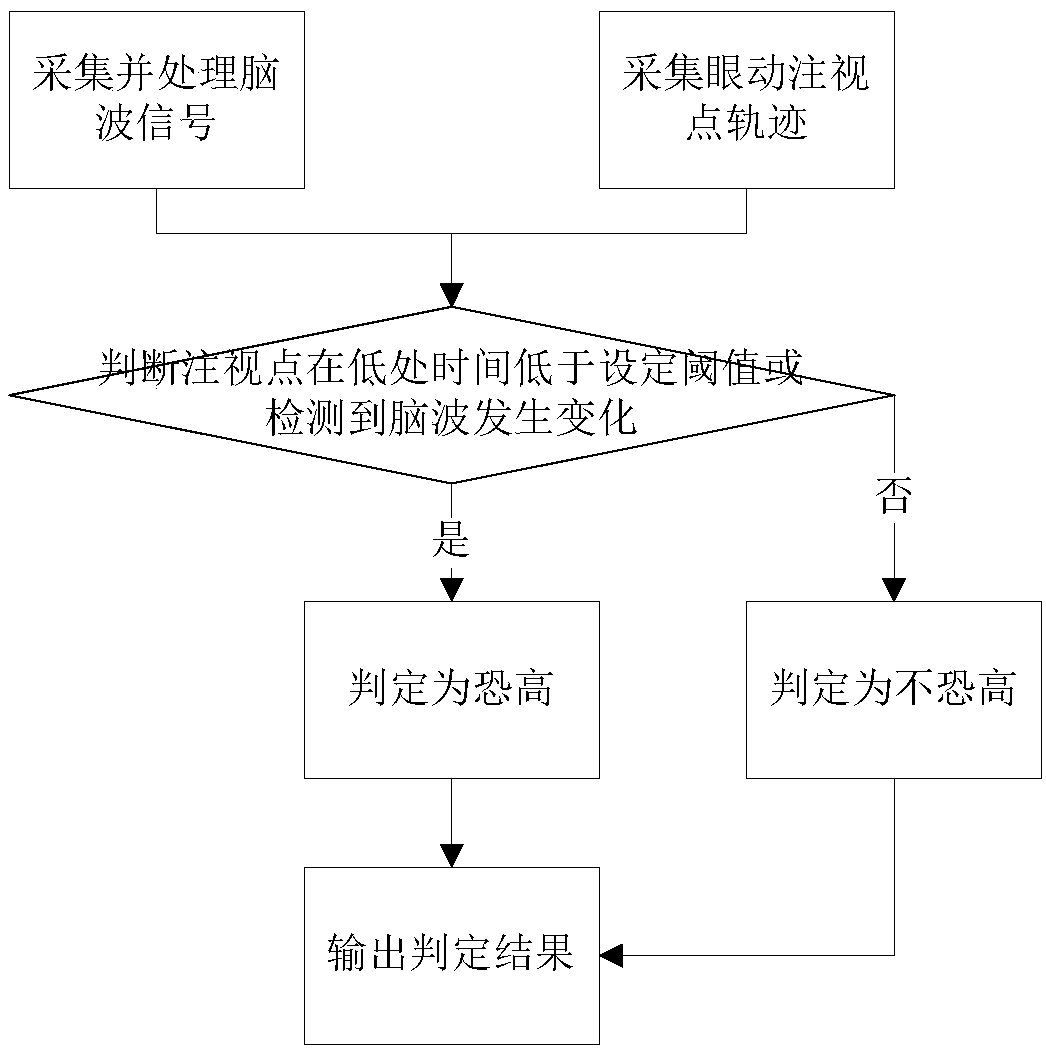

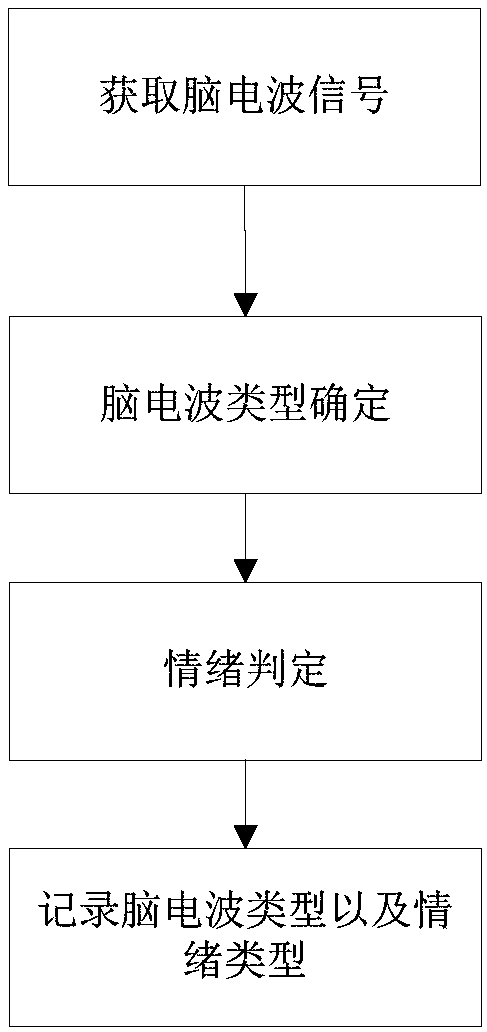

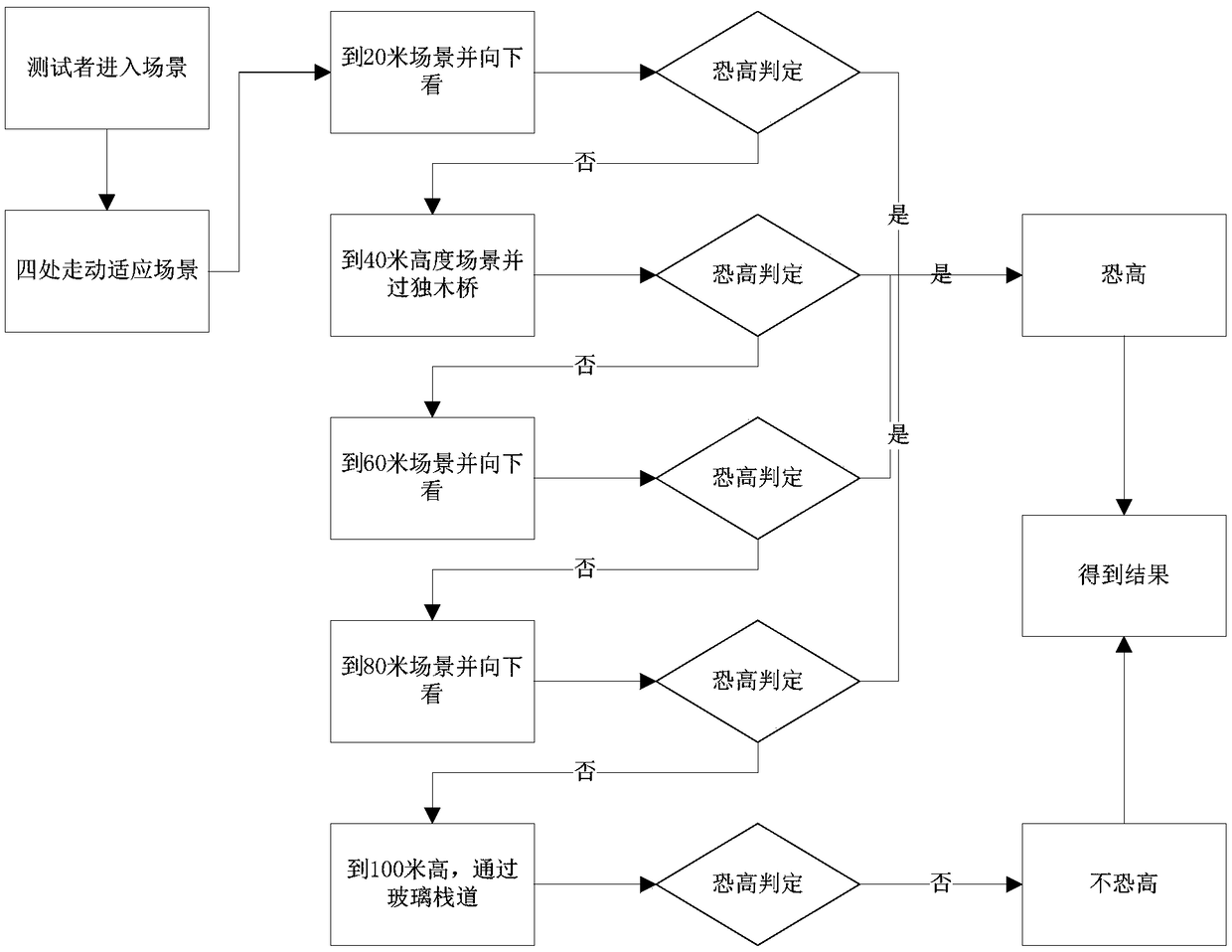

Acrophobia evaluation system based on virtual reality and eye movement brain wave detection

ActiveCN109044373AAddressing field of view limitationsEnsure safetySensorsPsychotechnic devicesData collectingEvaluation system

The invention discloses an acrophobia evaluation system based on virtual reality and eye movement brain wave detection. The system comprises a test scene design module, a test scene selection module,a data collecting and processing module and an acrophobia judgment module; the data collecting and processing module collects the real-time eye movement gaze point trajectory of a testee entering different test scenes through an eye movement detector, collects the real-time brain wave signal of the testee entering different test scenes through a brain wave detector, processes the brain wave signal, and performs emotion judgment according to the processing result; the acrophobia judgment module judges that the testee has acrophobia and outputs the judgment result if the time duration of an eyemovement gaze point in a set height range is smaller than a set time threshold or the motion judgment indicates that the testee is scared, otherwise, the acrophobia judgment module judges that the testee has no acrophobia, the test scene selection module runs again to select a next test scene until all test scenes are selected, and the judgment result is output.

Owner:JINAN BOTU INFORMATION TECH CO LTD

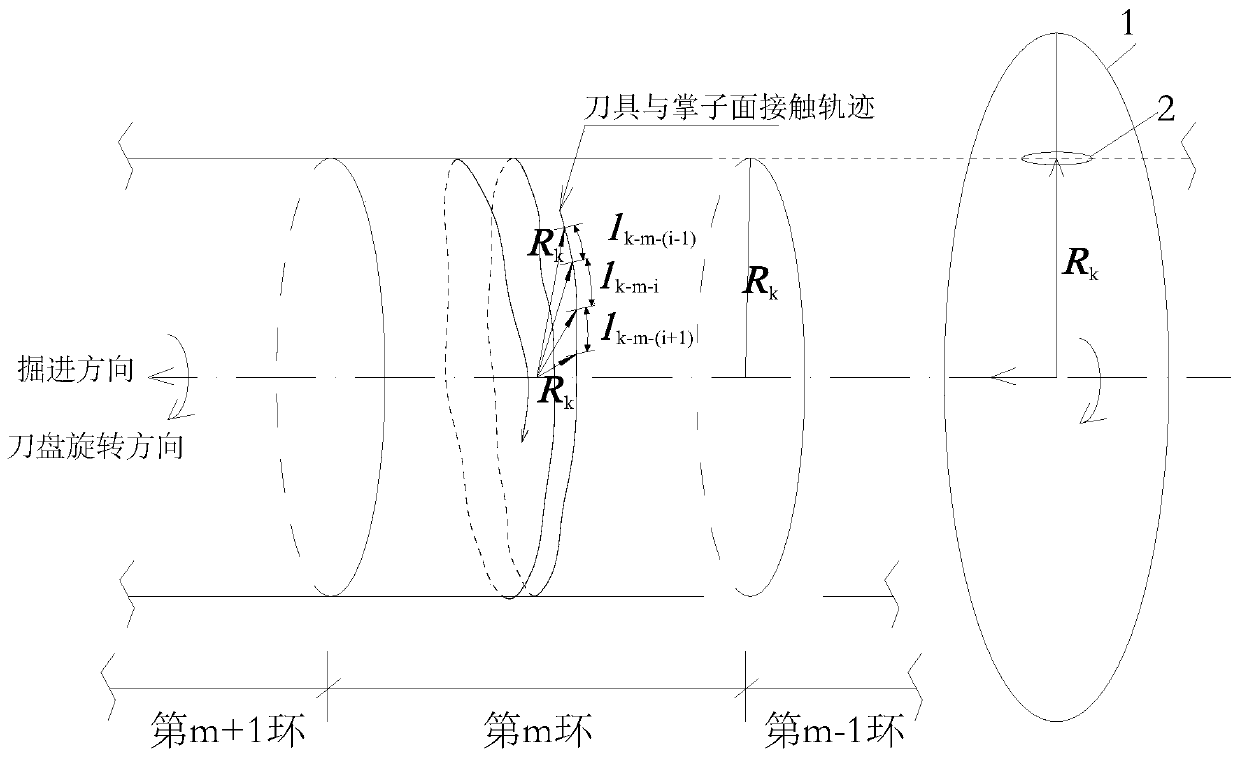

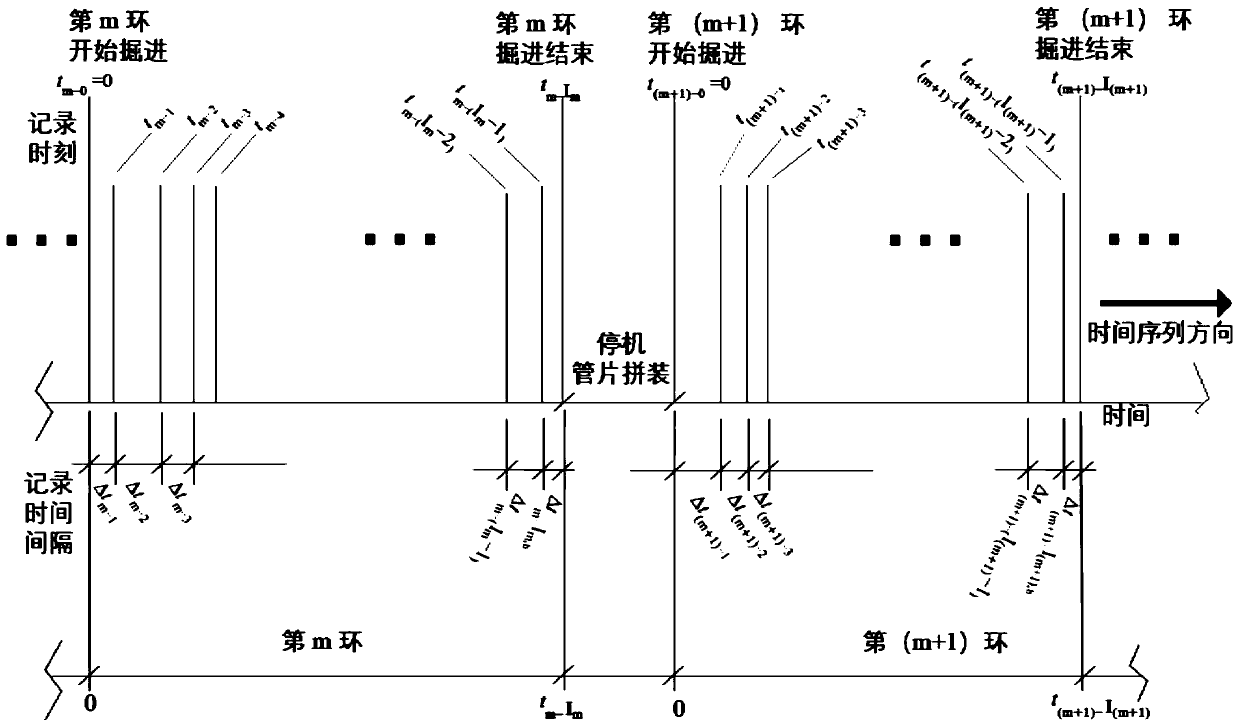

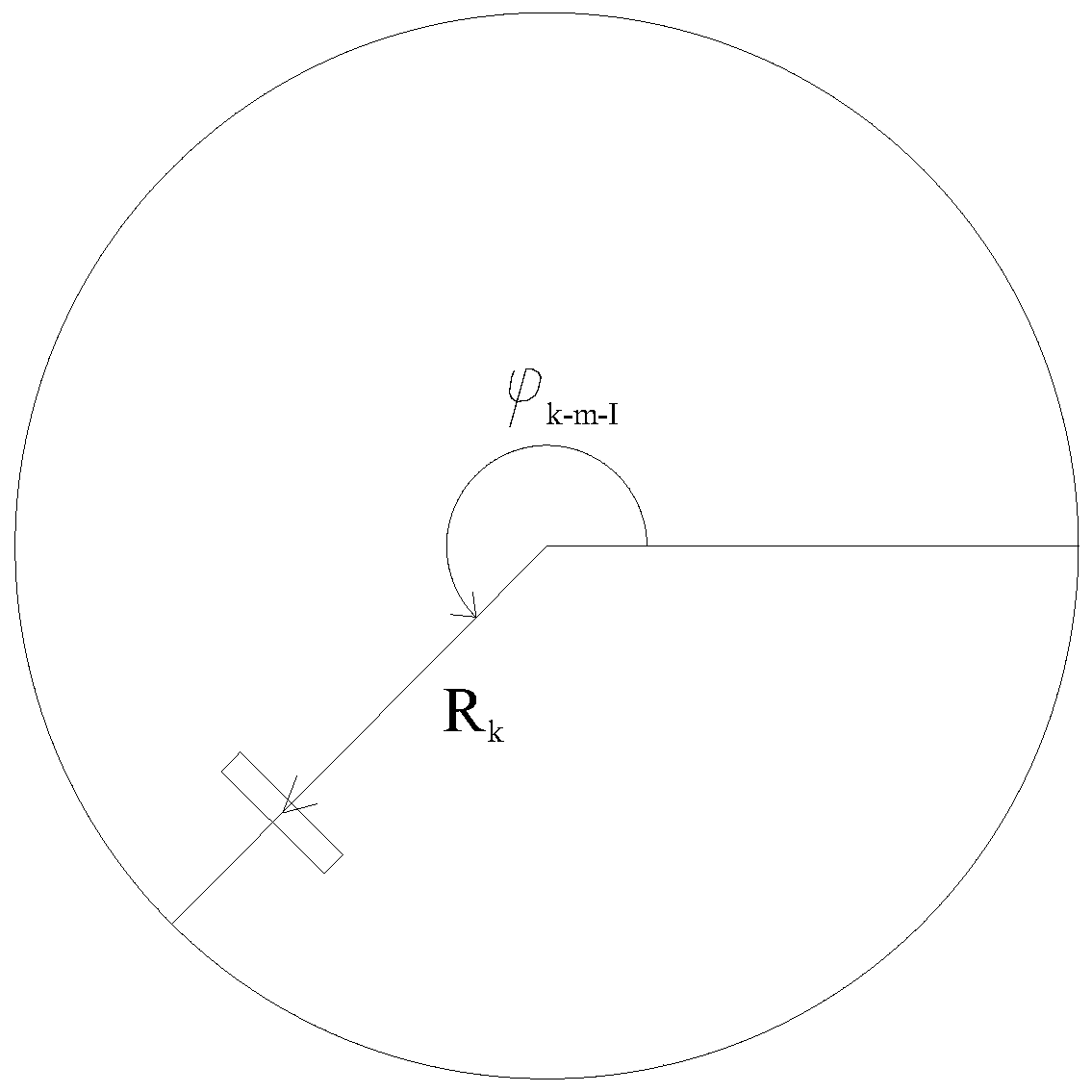

Method for predicting accumulated mass loss rate of heading machine cutter

ActiveCN110378069AImprove tunneling efficiencyReasonable methodDesign optimisation/simulationComplex mathematical operationsLoss rateUnderground tunnel

The invention belongs to the technical field of underground tunnel engineering construction and provides a method for quantitatively predicting the cutter abrasion quality of the heading machine cutter during composite stratum heading. On the basis of tool mass measurement and corresponding tool and tunnel face contact point trajectory calculation, mass line loss indexes MLI of tools at differentpositions are subjected to classification statistics according to strata. After the MLI is normalized into equivalent mass line loss indexes EMLI, a universal prediction model for the equivalent massline loss indexes of homogeneous strata is obtained. The MLI and the corresponding EMLI are clear in physical significance. The equivalent mass line loss index universal prediction model considers both the shareability of independent variables and the prediction precision. The cutter wear quality prediction method based on the equivalent mass line loss index general prediction model is provided. The calculation process is simple and clear. The prediction precision is high. Based on engineering investigation data and construction data, the method is reasonable, high in practicability and beneficial to quantitatively predicting the tool abrasion state, scientifically and reasonably arranging bin opening and tool changing and improving the tunneling efficiency.

Owner:NANJING KENTOP CIVIL ENG TECH +1

Simulation checking method for deep-space optical navigation image processing algorithm

ActiveCN102116633AGuaranteed Prior ResearchGood for error analysisInstruments for comonautical navigationFixed starsImaging processing

The invention provides a simulation checking method for finishing deep-space optical navigation image processing algorithm by virtue of a simulation function. The method comprises the following steps: image processing is carried out on an obtained star point trajectory simulation image, a series of attitude matrixes generated randomly and a node predicted value with errors; in the image processing, the node predicted value with errors is corrected; matching templates are obtained at the periphery of each corrected node pixel by taking each corrected node pixel coordinate as a center, so as to carry out cross correlation to obtain a coordinate of relative pixels among a plurality of fixed star targets, and then the corrected value is compared with a true value to evaluate pixel error for image processing; then, a relative angular moment is calculated, recognition of background fixed stars is carried out by adopting a ditrigon fixed star recognition method according to the relative angular moment, a calculation matrix is formed by a fixed star vector according to the recognition result of the background fixed star, and then according to the matrix operation, the azimuth of target planetoids can be calculated; and finally, the calculated azimuth of the target planetoids is compared with the true azimuth of the target planetoids to obtain deviation.

Owner:BEIJING INST OF CONTROL ENG

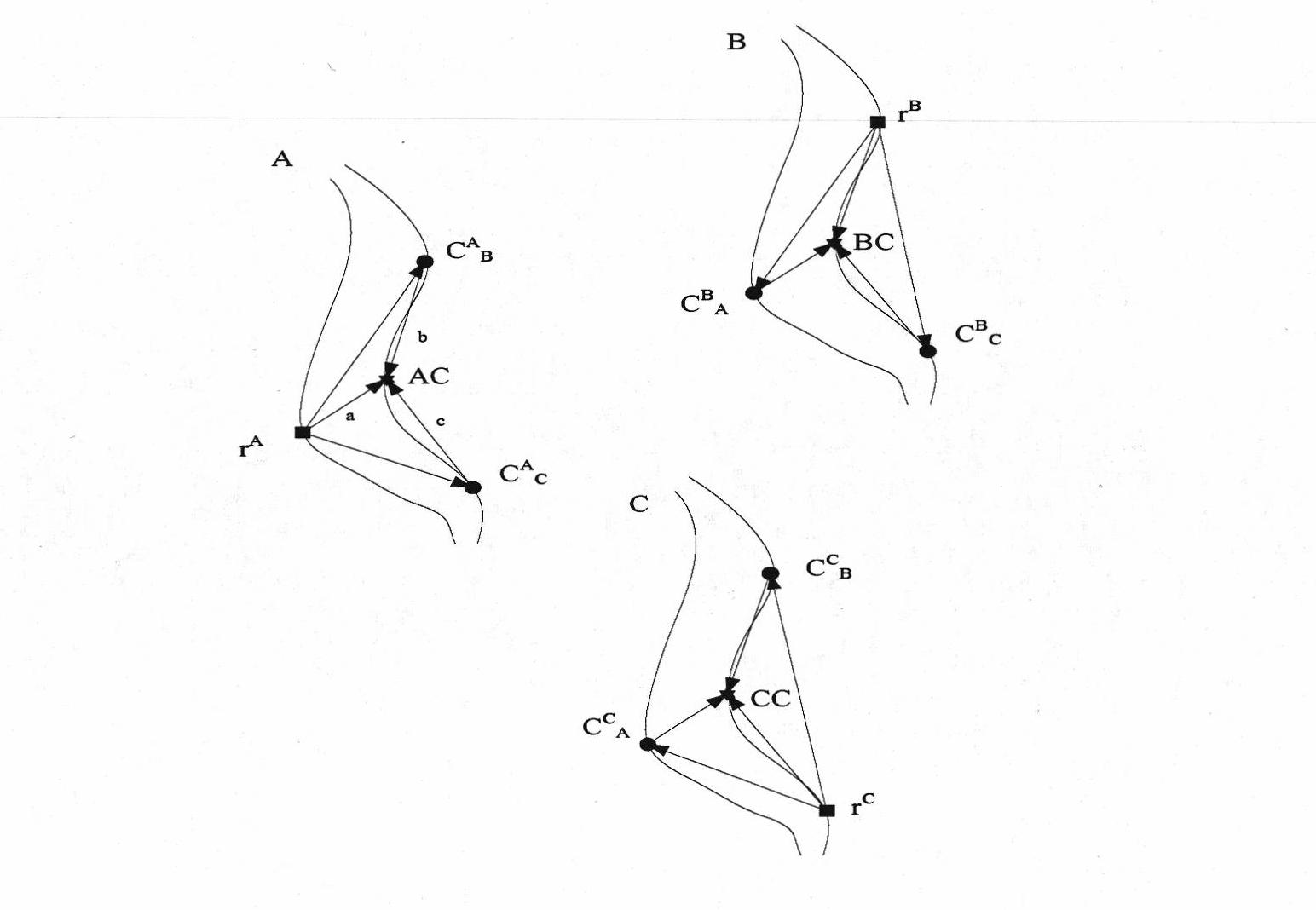

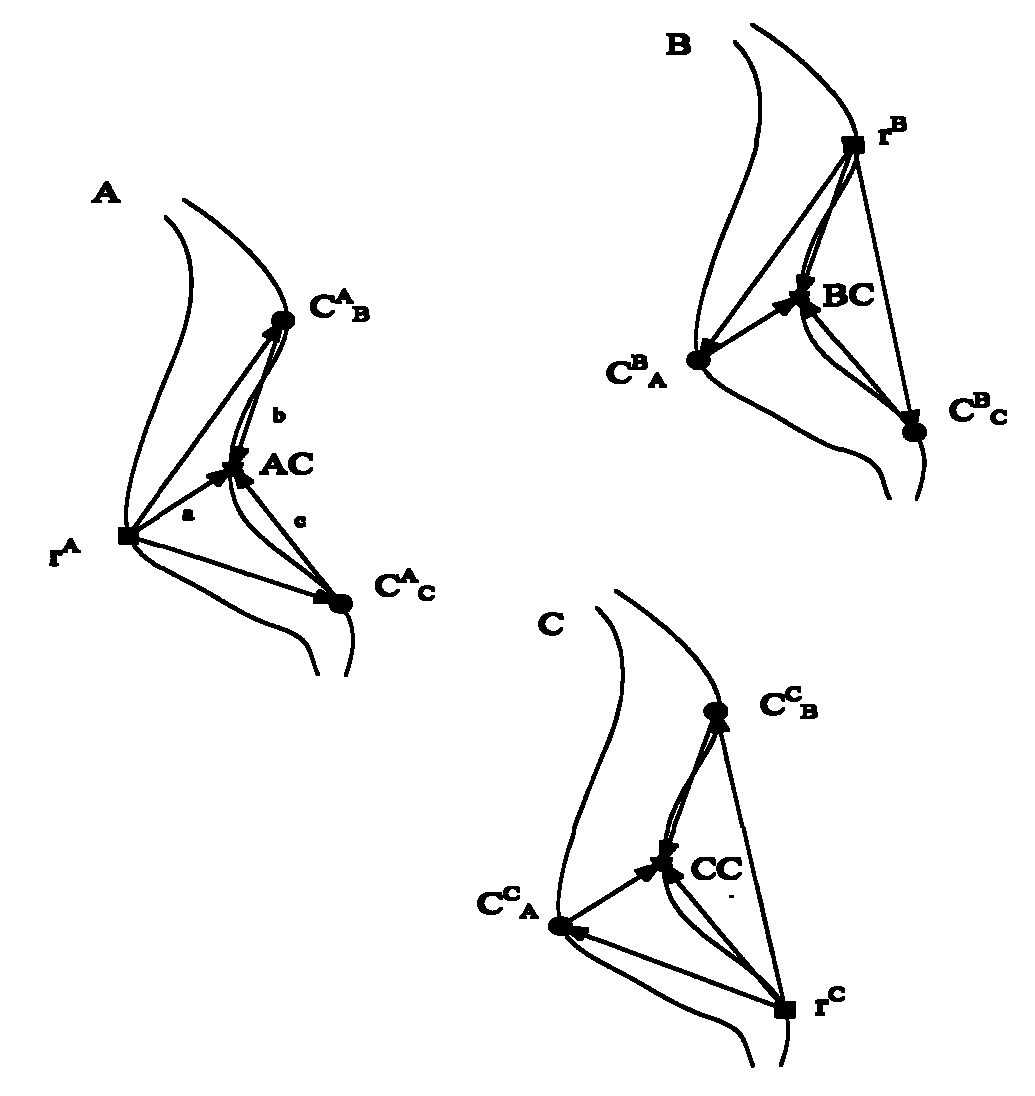

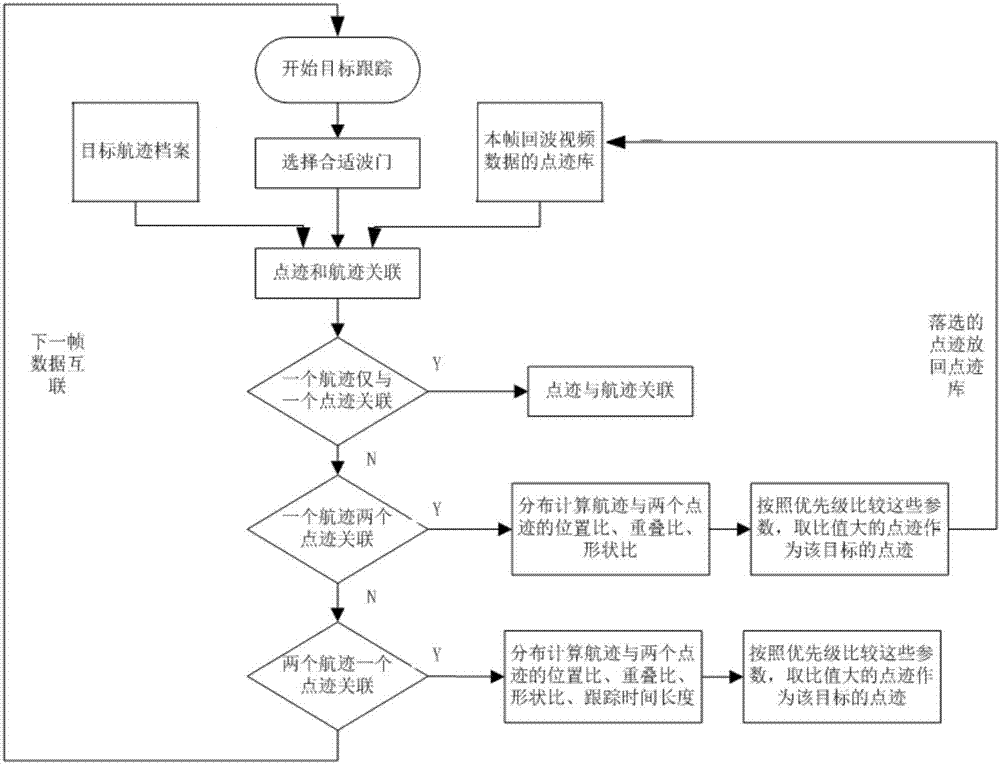

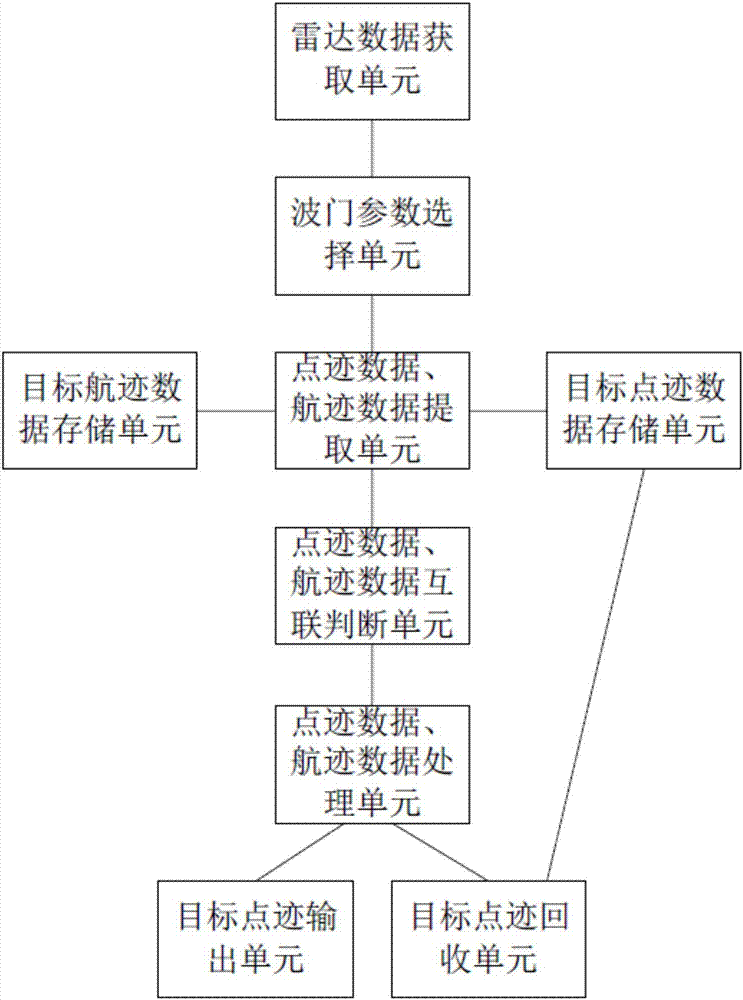

Marine navigation radar data interconnection-based multi-target tracking method and system

ActiveCN107144837AGuaranteed target tracking accuracyReduce false match rateRadio wave reradiation/reflectionMulti target trackingRadar

The invention belongs to the radar technical field and relates to a marine navigation radar data interconnection-based multi-target tracking method and system. The method includes the following steps that: a plurality of groups of radar data are collected from a radar; appropriate wave gate parameters are selected according to a tracking duration and a tracking state; the overlap ratio, distance ratio, shape ratio and energy ratio of navigation trajectory data and a plurality of point trajectory data are calculated through a point trajectory data and navigation trajectory data processing unit, so that an interconnection condition can be obtained; and a target point trajectory data tracking result is obtained through a target point trajectory output point. According to the marine navigation radar data interconnection-based multi-target tracking method and system of the invention, besides position information, the features of targets, such as the shape ratio and energy ratio are utilized; and multidimensional information judgment is utilized, and therefore, when multi-target tracking is performed in a dense clutter environment, the tracking accuracy of the targets can be ensured, and the probability of false matching can be decreased.

Owner:BEIJING HIGHLANDER DIGITAL TECH +1

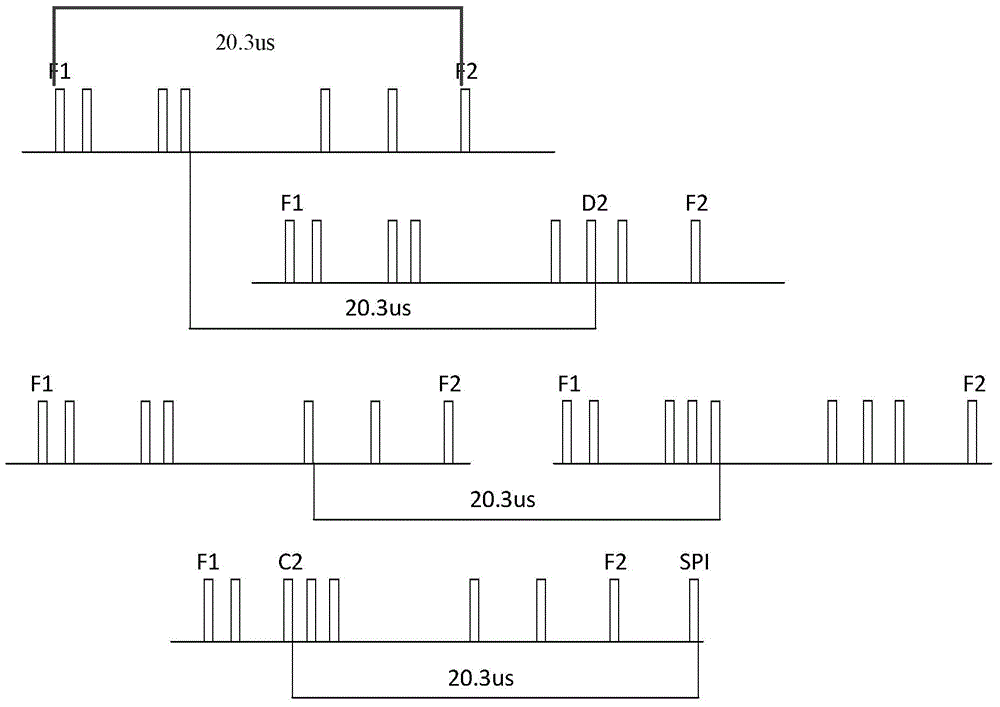

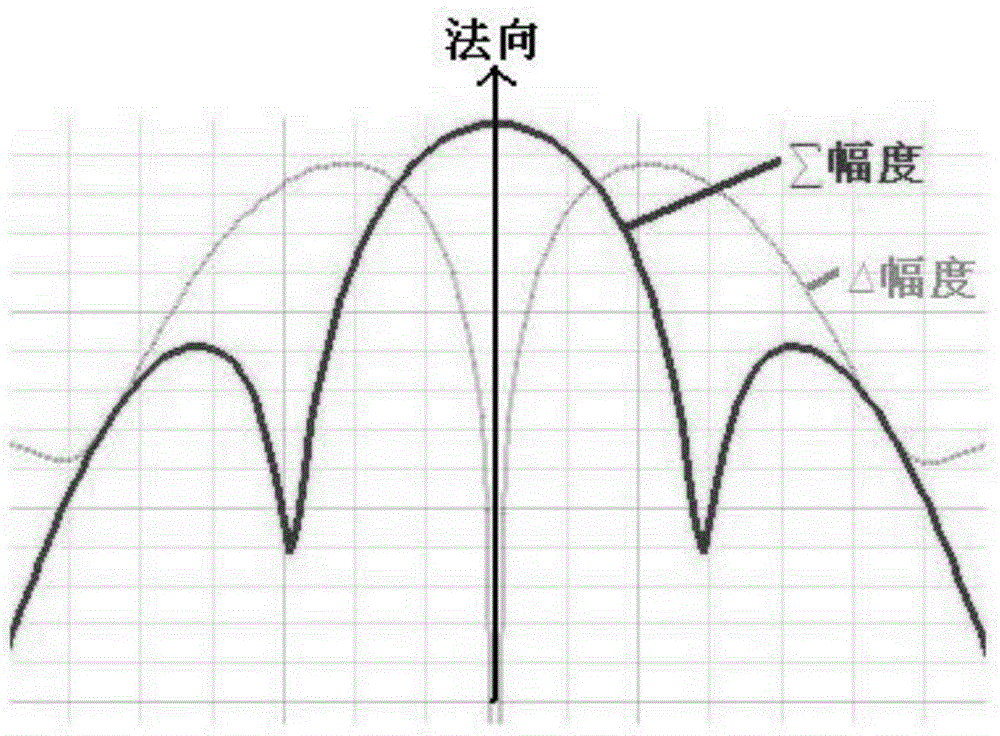

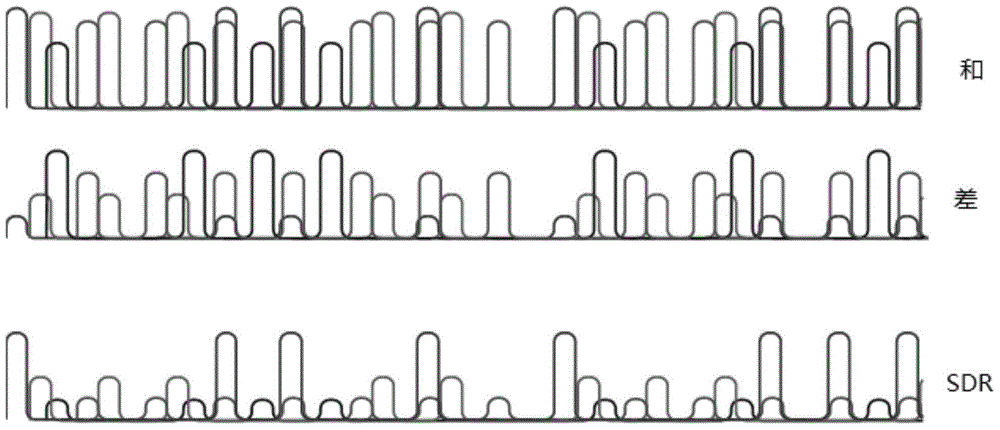

Multi-target point trajectory gathering method for forming target point trajectory

InactiveCN104931959AAccurate removalAvoid mutual influenceRadio wave reradiation/reflectionMultipath interferenceSide lobe

The invention provides a multi-target point trajectory gathering method for forming a target point trajectory, and aims to provide a multi-target point trajectory gathering method which can be used to effectively separate multiple targets, eliminate interference signals, and accurately form a target point trajectory. The method of the invention is realized by the following technical scheme: after a response signal is received by an interrogation antenna, an interrogator separates overlapping signals based on the sum-difference ratio and the amplitude difference between the front and back edges of signal pulse, and the interrogator uses the amplitude ratio SDR of sum and difference signals to eliminate sidelobe interference signals and part of multipath interference signals according to the characteristics of an antenna pattern; whether two framework pulses are overlapping pulses is judged, and the over-wide pulse of which the front and back edges are inconsistent in amplitude is separated into two framework pulses; a set of data with correct framework and low confidence is decoded; and finally, multiple interrogation results of the same target within the scope of one beam are gathered by a density point trajectory association method. By adopting the method of the invention, the problem that it is impossible to identify all targets as the targets are too dense is solved.

Owner:10TH RES INST OF CETC

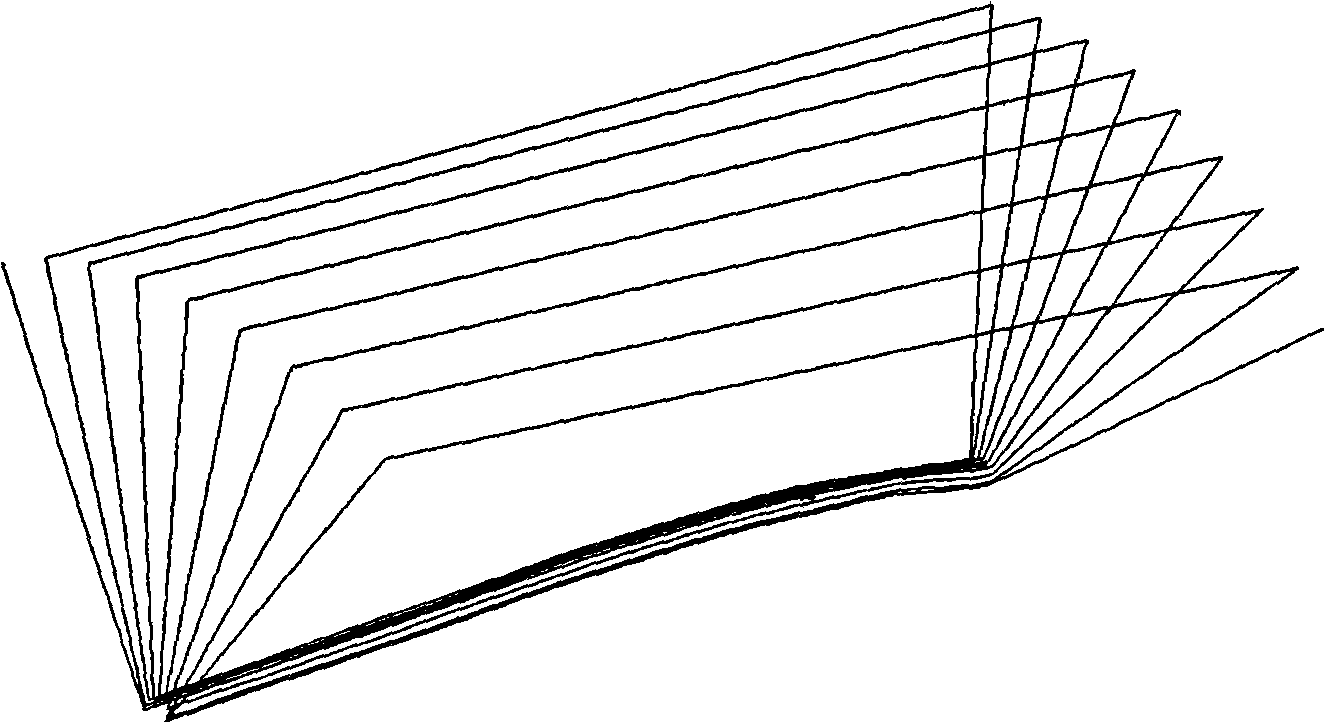

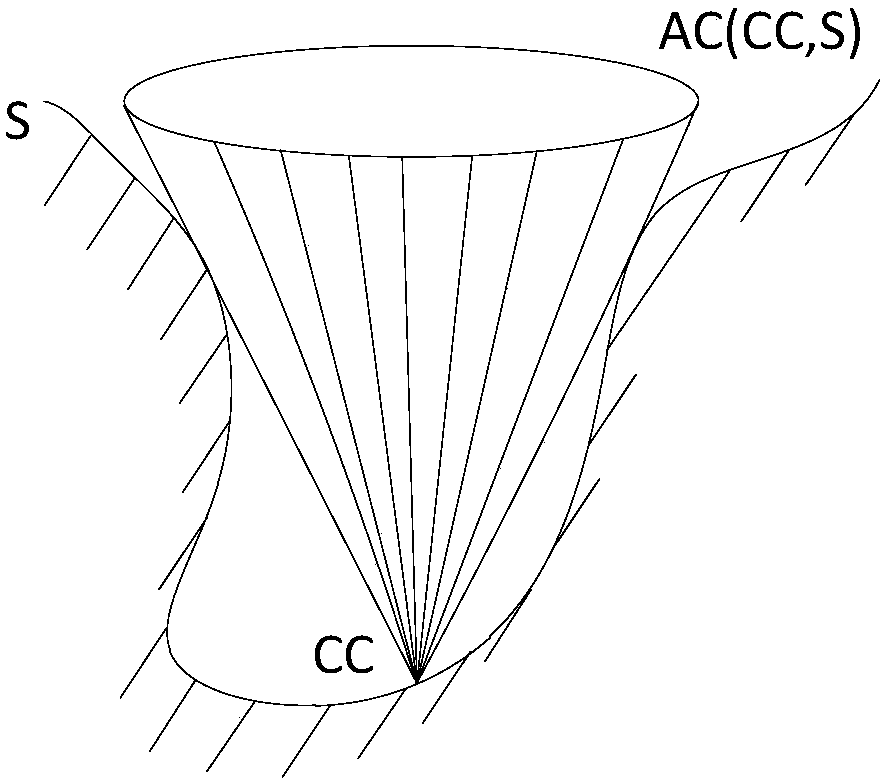

Impeller machining tool path global optimization method

The invention discloses an impeller machining tool path global optimization method, which comprises the following steps: S1) carrying out discrete triangularization on an impeller model and a tool model; S2) planning a trajectory of contact points between tools and an impeller, and calculating a tool position point trajectory; S3) judging a reachable direction cone of each tool position point by utilizing interference checking; S4) establishing a global optimization objective function of cutter-axis vector, construction a constrained single-source directed graph and converting the optimization solving problem of the objective function into the shortest path finding problem; and S5) solving the objective function by utilizing a shortest path finding algorithm to obtain an optimal tool orientation. The method can quickly calculate the reachable direction cone of each tool and realizes overall fairing of the cutter-axis vector.

Owner:HUAZHONG UNIV OF SCI & TECH +1

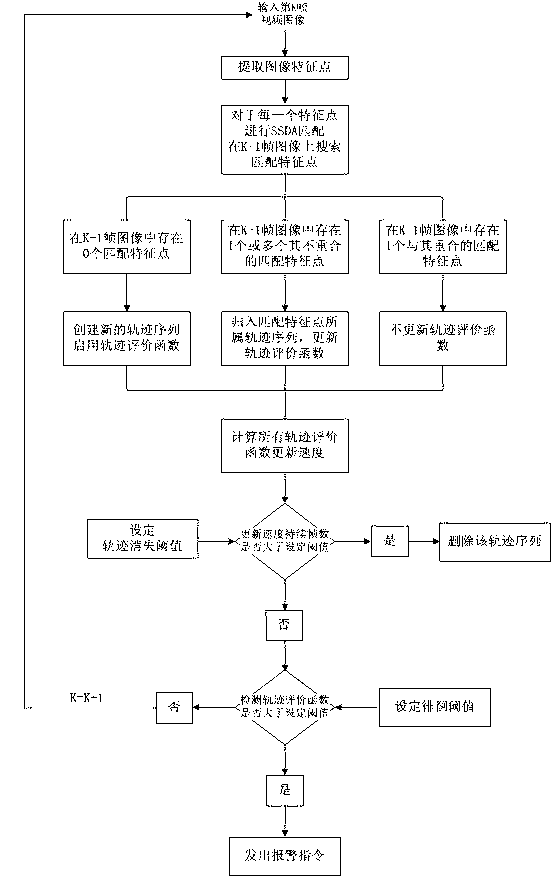

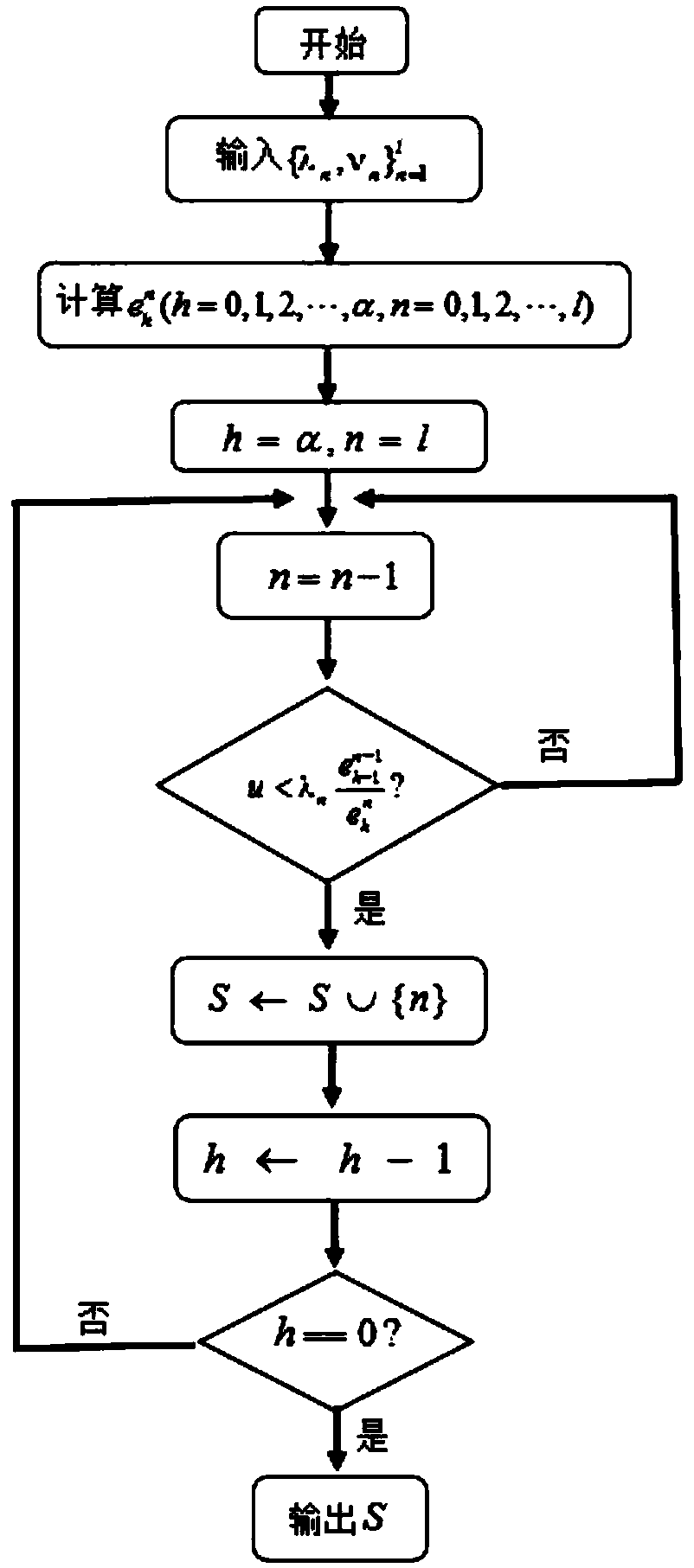

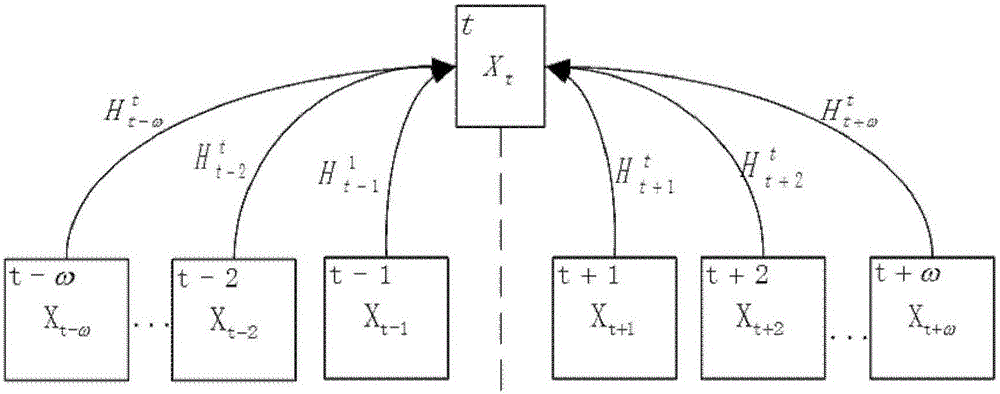

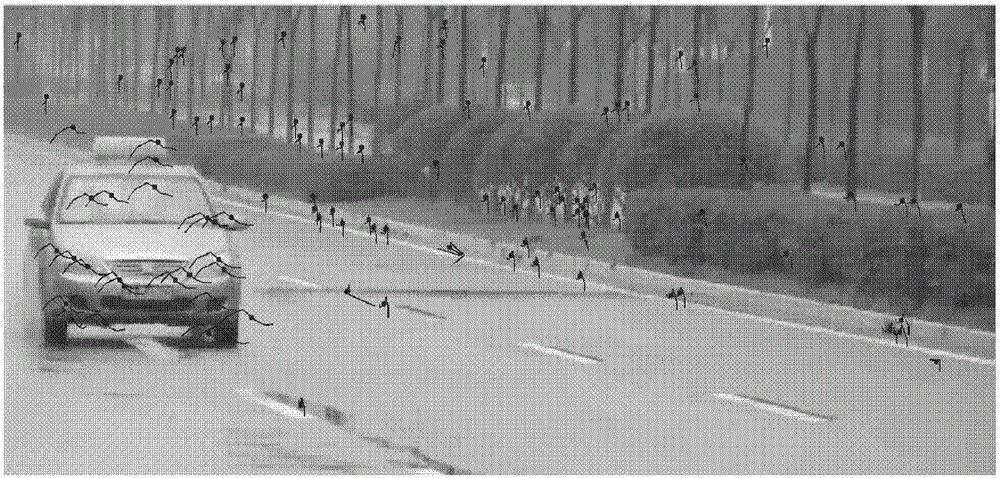

Real-time loitering detection method based on dynamic programming

InactiveCN102810206AImprove detection rateImprove real-time performanceImage analysisPattern recognitionPrior information

The invention discloses a real-time loitering detection method based on dynamic programming, which belongs to the field of real-time video detection. The method comprises: firstly, extracting the feature points of an image of the current frame; secondly, carrying out SSDA (sequential similarity detection algorithm) matching between the extracted feature points and an image of the previous frame to detect the corresponding matched feature points; then, carrying out feature point trajectory tracking of dynamic programming; evaluating each trajectory by an evaluation function; detecting the evaluation function value of each trajectory; determining that a loitering target occurs in the monitored area if the evaluation function value exceeds a set loitering threshold; and displaying the loitering trajectory and sending an alarm instruction. The method provided by the invention can effectively improve the loitering target recognition capability without needing a large amount of prior information, is easy to realize, is less influenced by the background of the monitored area, and has the advantages of stable and reliable performance and less calculation amount.

Owner:NANJING UNIV OF SCI & TECH

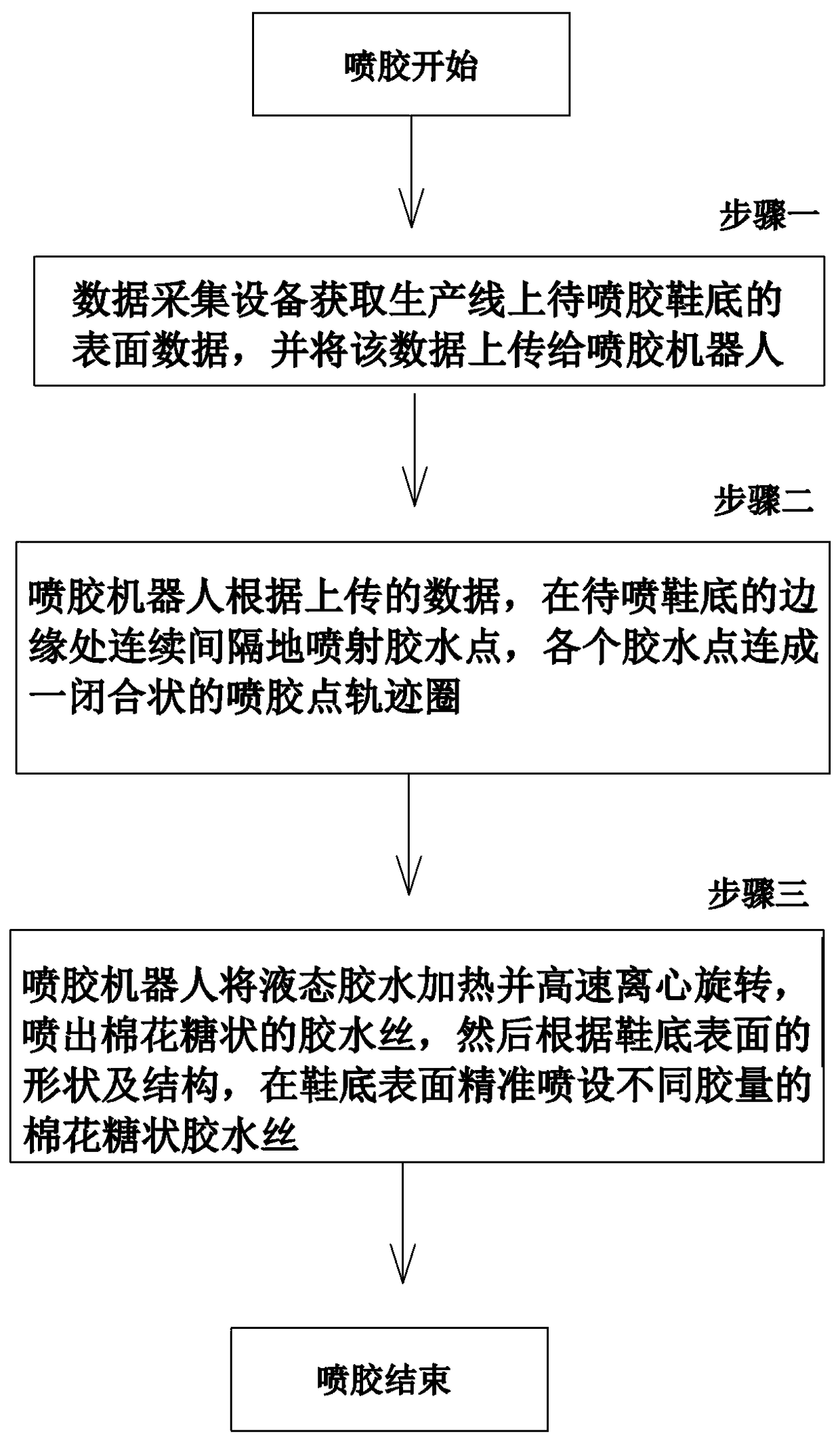

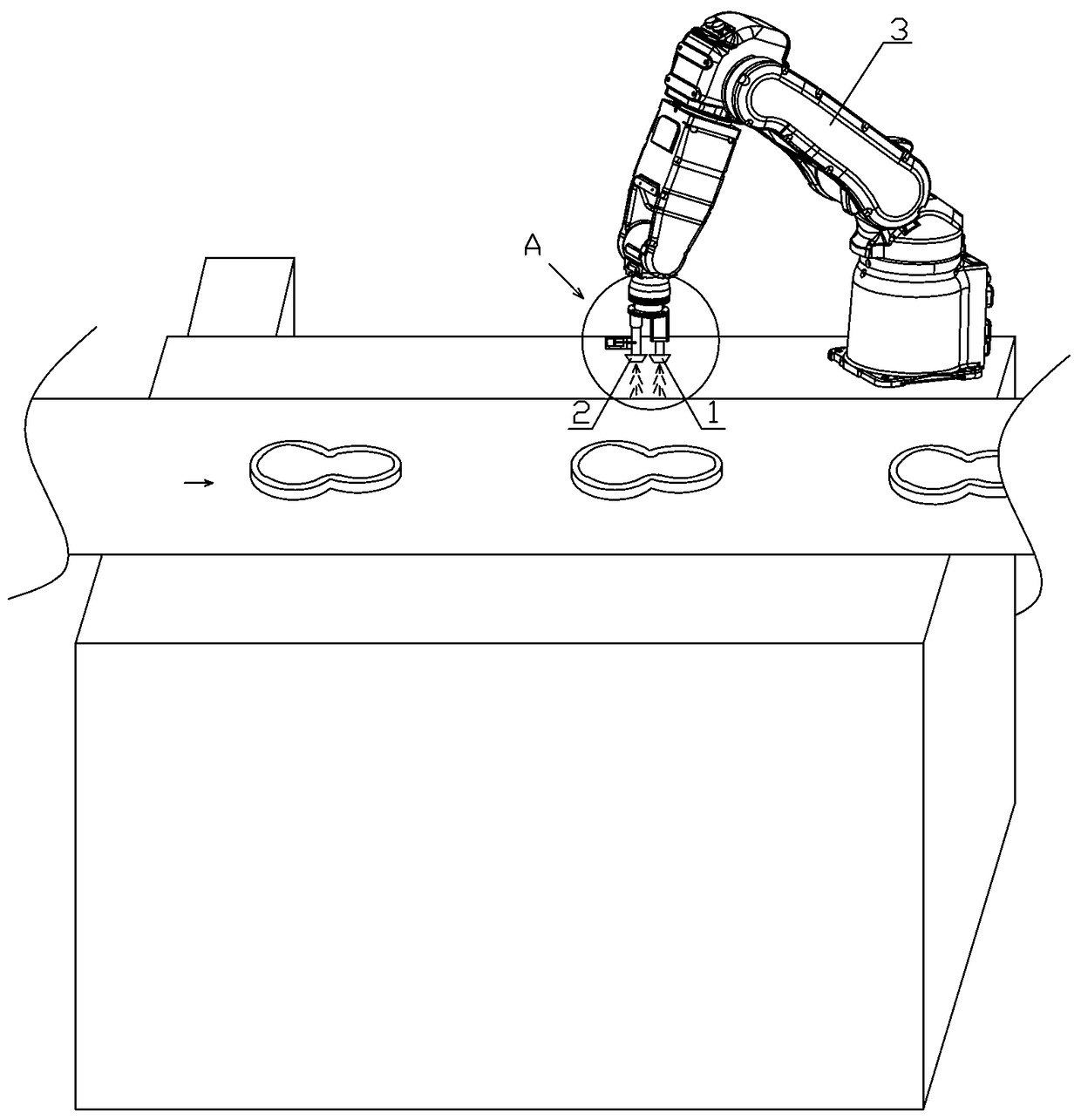

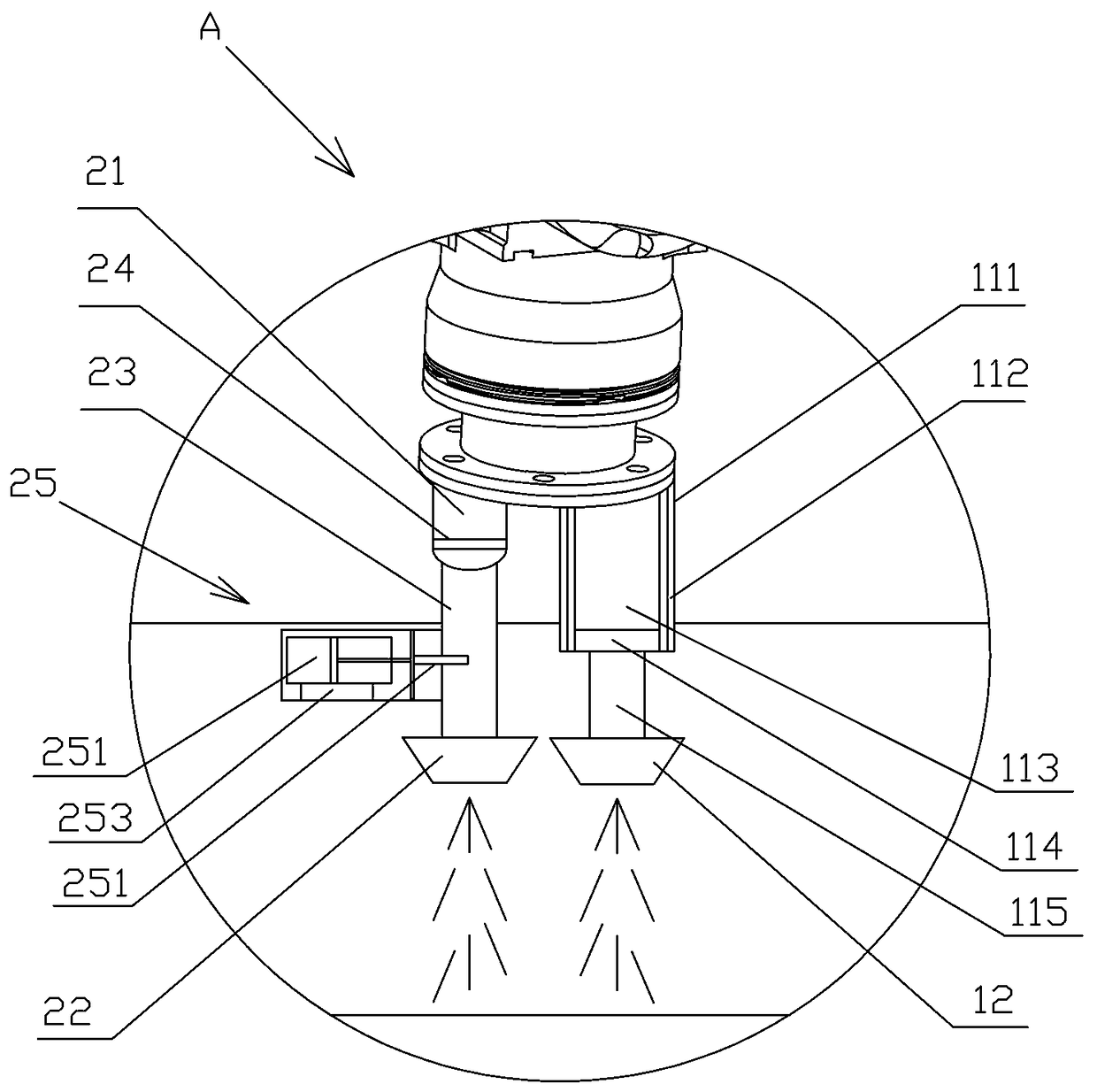

Intelligent shoe sole glue spraying process for avoiding overflow of glue liquid from edge, and glue spraying equipment thereof

PendingCN108991655AWon't spillImprove bonding efficiencyShoe gluingProduction lineAgricultural engineering

The invention discloses an intelligent shoe sole glue spraying process for avoiding overflow of a glue liquid from an edge. The intelligent shoe sole glue spraying process comprises the specific stepsthat: step 1, data acquisition equipment acquires surface data of a shoe sole to be sprayed with glue on a production line; step 2, a glue spraying robot sprays glue points at the edge of the shoe sole to be sprayed with glue successively at intervals according to uploaded data, wherein the glue points form a closed glue spraying point trajectory circle; step 3, the glue spraying robot sprays glue wires in a shape of candy floss, and sprays different amounts of the candy-floss-shaped glue wires on the surface of the shoe sole precisely according to the shape and structure of the surface of the shoe sole; step 4, and the glue spraying robot completes a spraying operation on the shoe sole. The invention further discloses glue spraying equipment of the intelligent shoe sole glue spraying process. The intelligent shoe sole glue spraying process and the glue spraying equipment can be better applied to glue spraying on shoe soles in different bottom part shapes by utilizing properties of the glue wires, solve the technical limitation of direct use of a spray gun for glue spraying in the prior art, and improve the shoemaking quality and market competition of the production enterprise.

Owner:BLACK GOLD STEEL AUTOMATION TECH FUJIAN

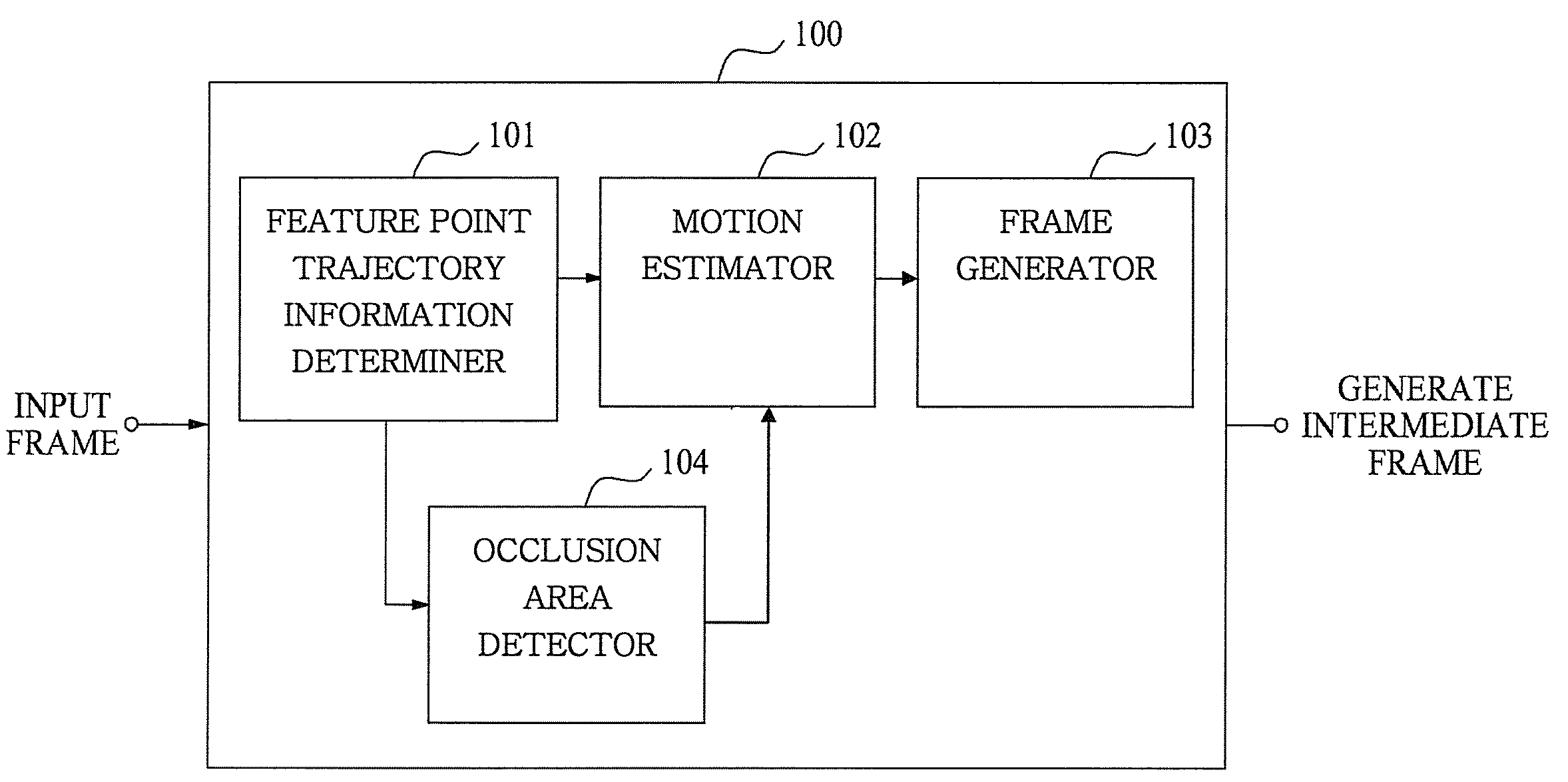

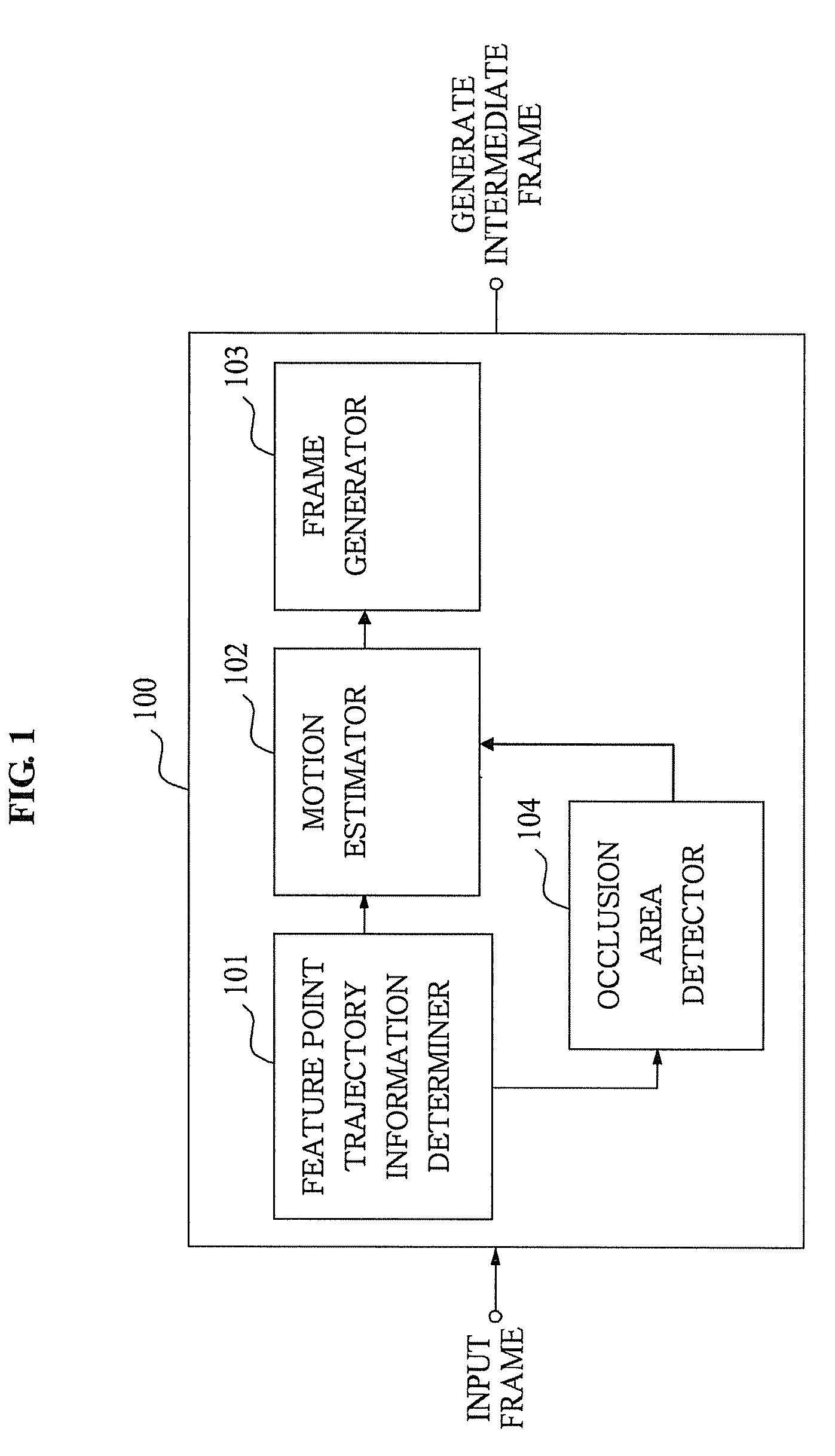

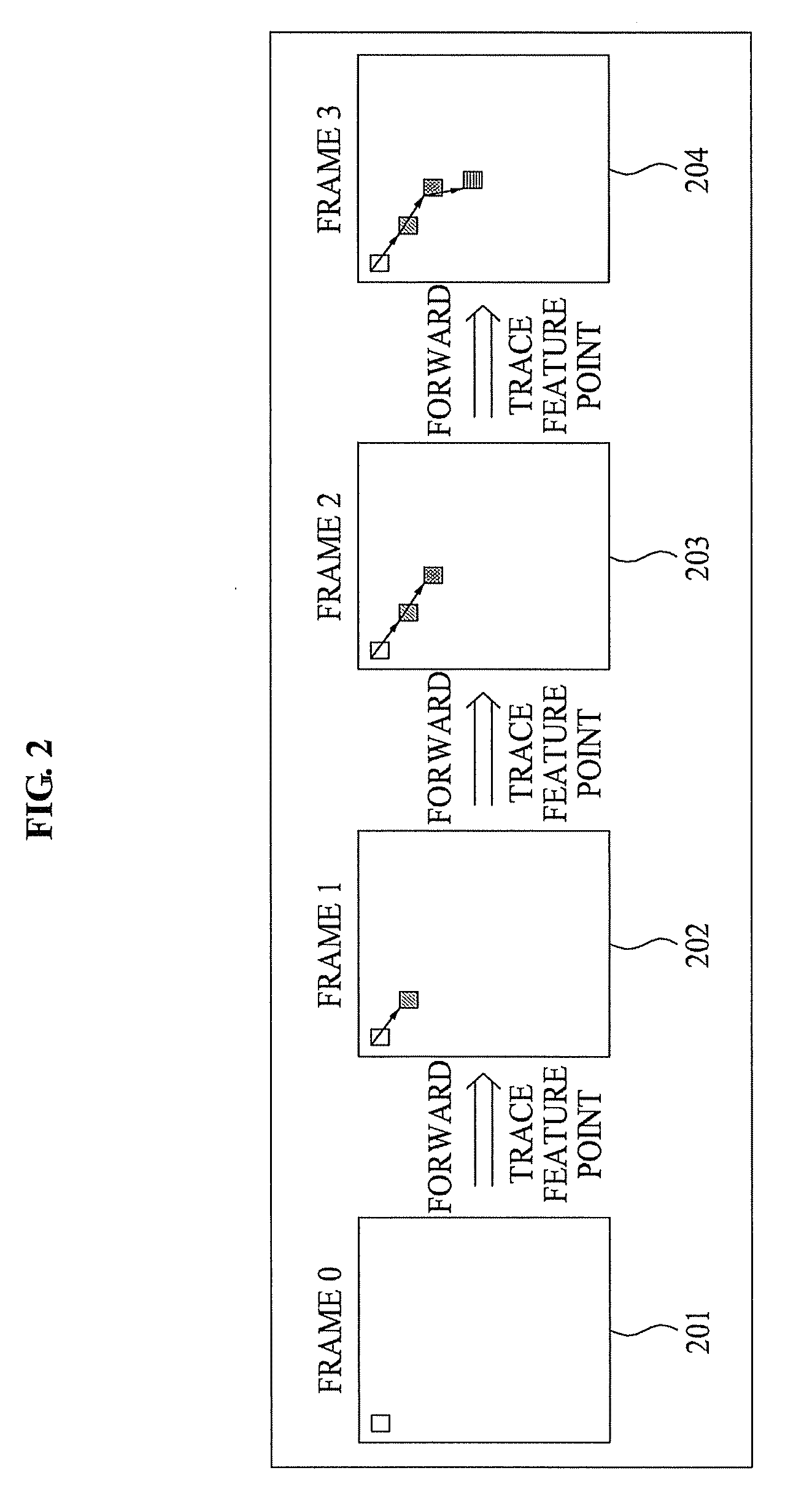

Apparatus and method for improving frame rate using motion trajectory

ActiveUS20100104140A1Increase frame rateCharacter and pattern recognitionDigital video signal modificationComputer scienceFrame rate

A frame rate improving apparatus and method use a motion trajectory. The frame rate improving apparatus determines forward feature point trajectory information through a feature point, and generates a new intermediate frame by performing backward motion estimation through the feature point trajectory information, thereby generating an interpolated image with high quality.

Owner:SAMSUNG ELECTRONICS CO LTD

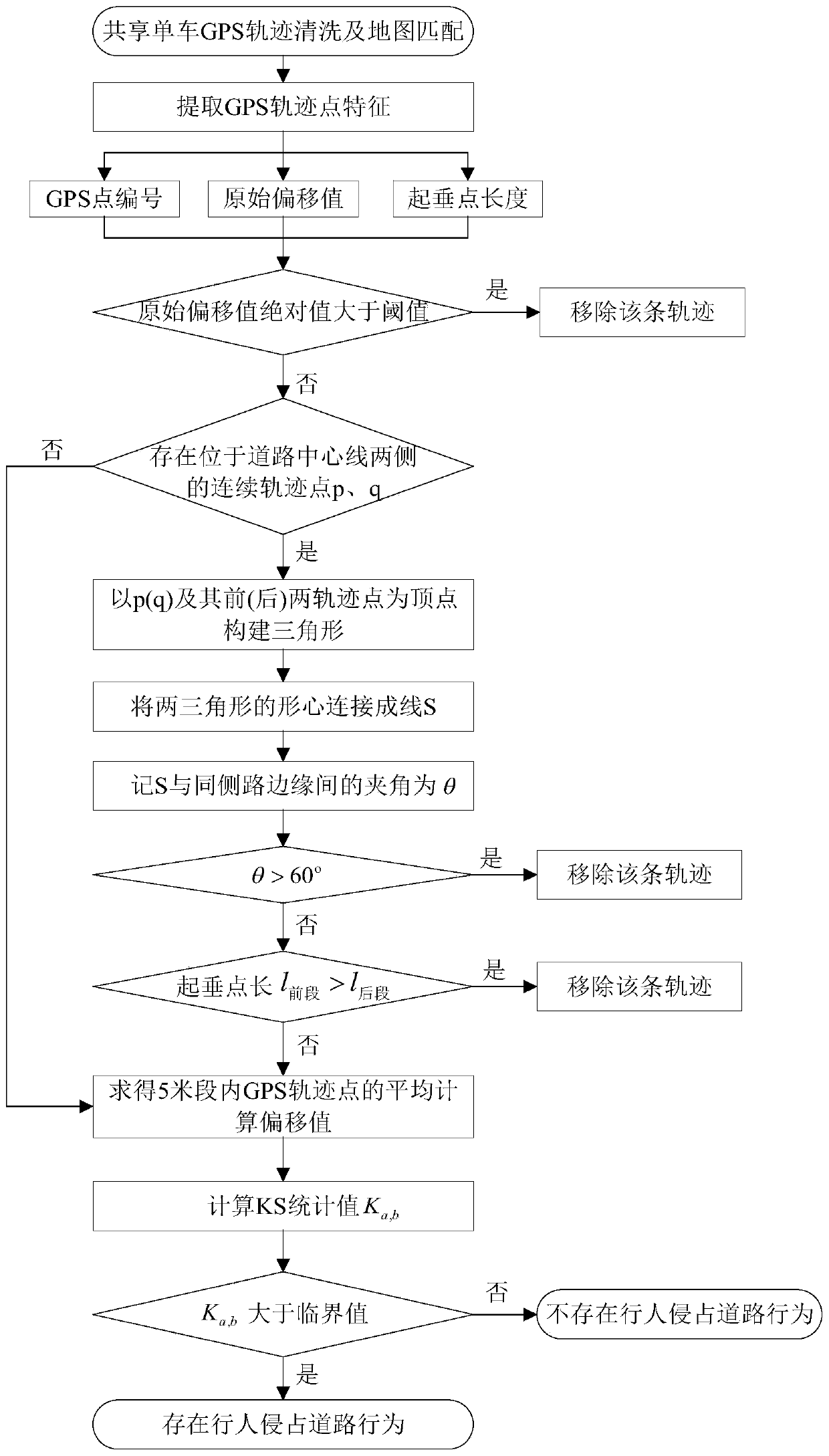

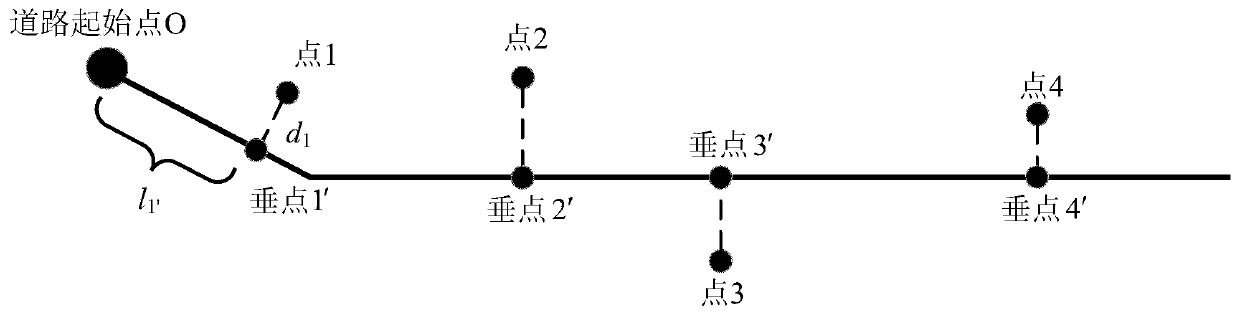

Identification method for road occupation behavior of pedestrian on the basis of bicycle sharing GPS (Global Positioning System) trajectory data

InactiveCN110136442AImplement road encroachmentImprove traffic efficiencyDetection of traffic movementSatellite radio beaconingData matchingSingle vehicle

The invention discloses an identification method for road occupation behavior of a pedestrian on the basis of bicycle sharing GPS (Global Positioning System) trajectory data. The method comprises thefollowing steps that: firstly, carrying out bicycle sharing GPS trajectory data cleaning to remove abnormal speed trajectory data and low-sampling-point trajectory data; then, carrying out map matching and processing on the bicycle sharing GPS trajectory data; matching the bicycle sharing GPS trajectory data to a road to extract GPS trajectory point characteristics, and on the basis of trajectorygeometric characteristics, correcting the bicycle sharing trajectory data to remove the trajectory data of reverse riding; and finally, detecting the road occupation behavior of the pedestrian, calculating a calculation deviation value between a trajectory to be detected and a standard trajectory, carrying out fitting calculation on deviation value distribution, and using Kolmogorov-Smirnov to check and judge whether the road occupation behavior of the pedestrian occurs in the road section or not. By use of the method, the advantage that the GPS trajectory data is real-time and effective can be fully utilized, the timeliness and the effectiveness of an identification process can be achieved, and manpower, material resources and financial resources are saved. The road occupation behavior ofthe pedestrian is identified in time and can be intervened in time, and the traffic safety level of pedestrian passage and non-motor vehicle riding can be improved.

Owner:SOUTHEAST UNIV

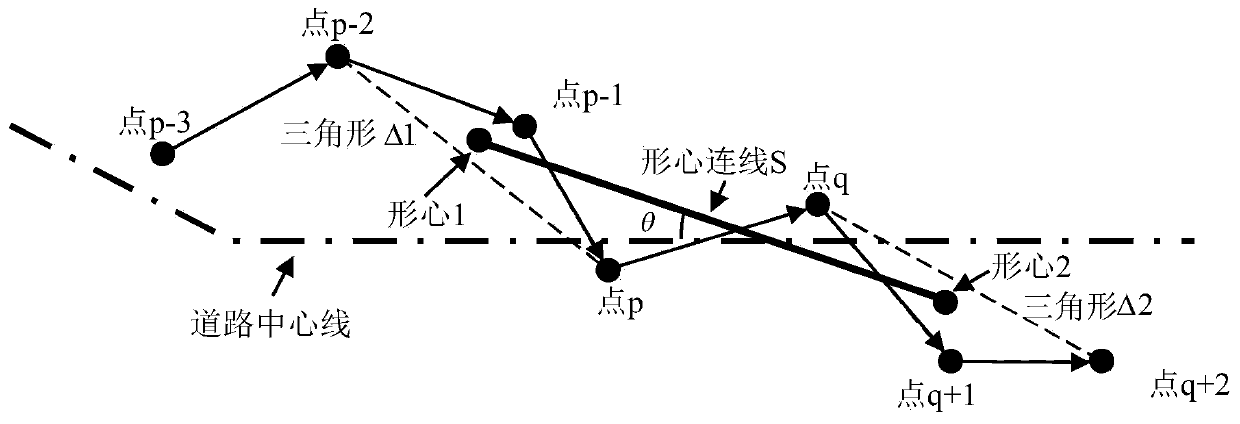

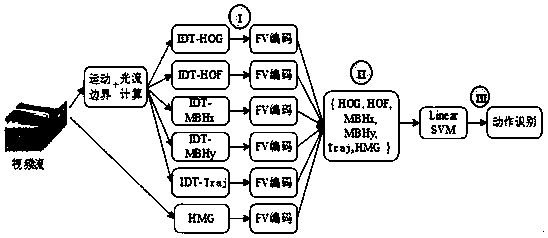

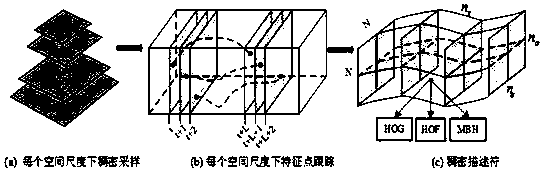

Human motion identification method based on dense sampling of motion boundary and motion gradient histogram

ActiveCN108629301AReduce the number of tracesEnhance feature expressionImage enhancementImage analysisFeature vectorHuman body

The invention discloses a human motion identification method based on dense sampling of the motion boundary and a motion gradient histogram. The method mainly comprises steps that 1), a video stream is inputted; 2), the optical flow field of the inputted video is calculated, feature point sampling is carried out, and dense feature points are extracted; 3), the trajectory of the feature points is calculated; 4), dense descriptors along the feature point trajectory are calculated; 5), two adjacent frames of video images are derived in time to obtain time series motion images, and the spatial gradient of the motion images is calculated to obtain a motion gradient descriptor HMG; 6), feature encoding is performed separately for each descriptor; 7), after regularization of each descriptor, thedense descriptors and the motion gradient descriptor are connected in series to form a feature vector; 8), the feature vector is trained and learned to obtain a human motion identification model; and9), the human body motion is identified through utilizing the human motion identification model. The method is advantaged in that motion identification precision is improved, and calculation cost is further reduced.

Owner:CHONGQING UNIV

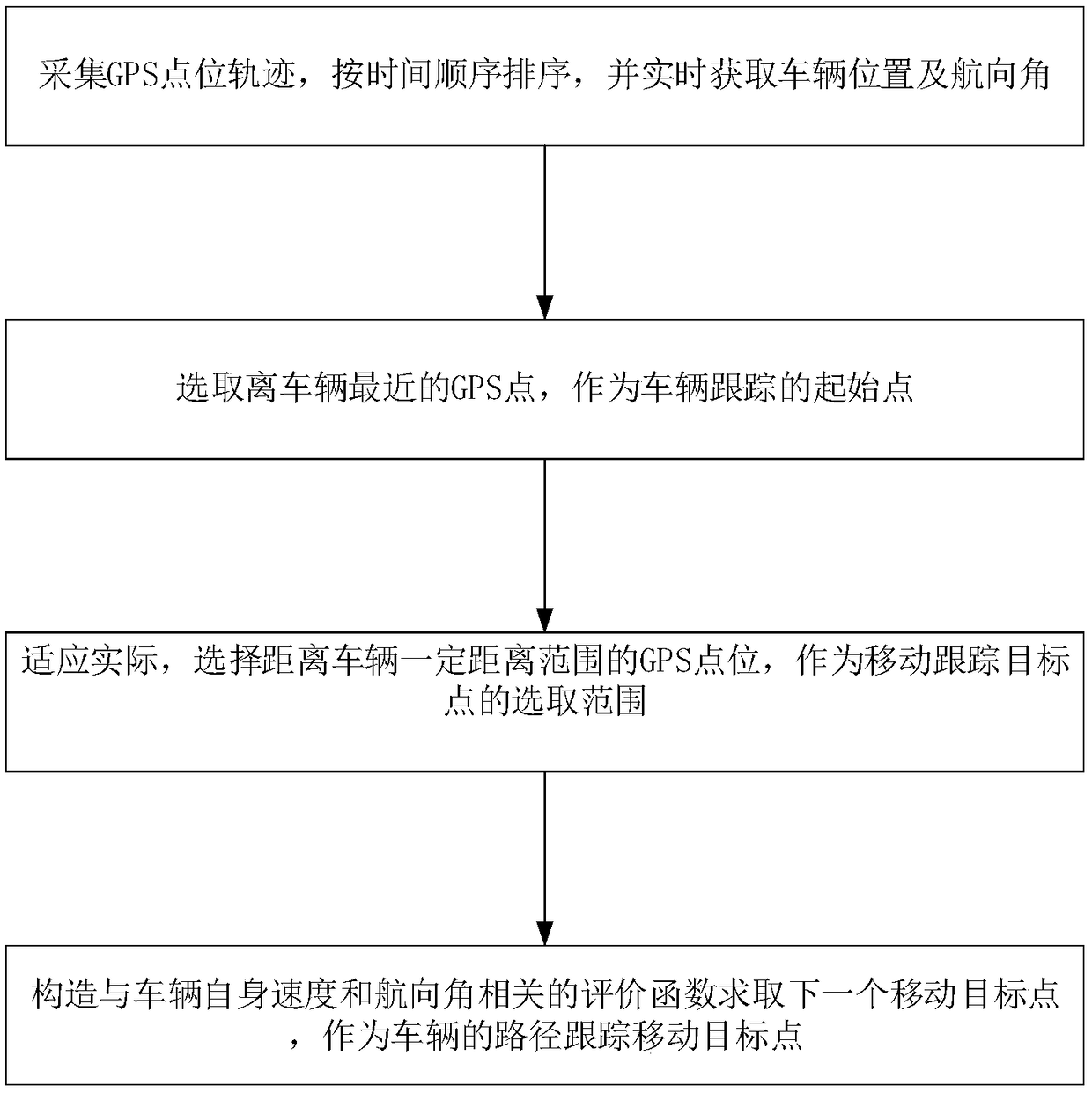

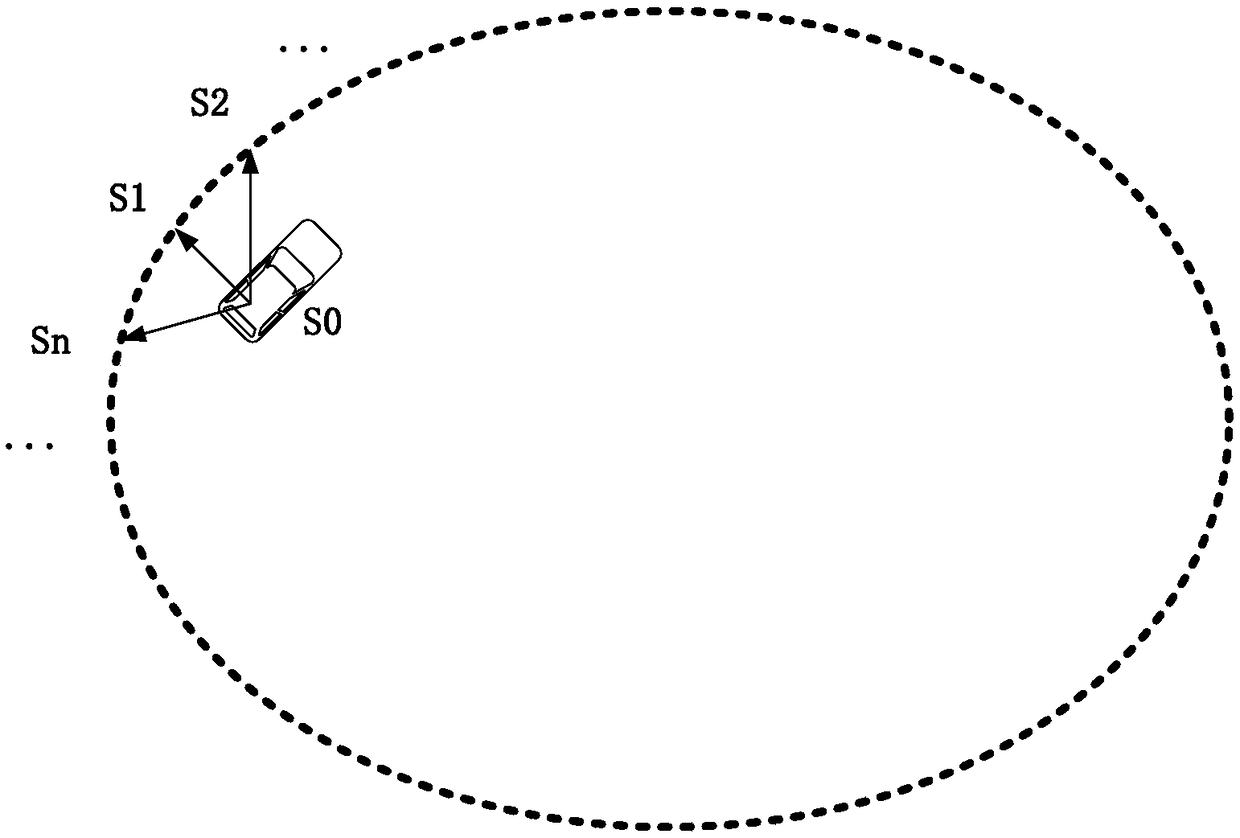

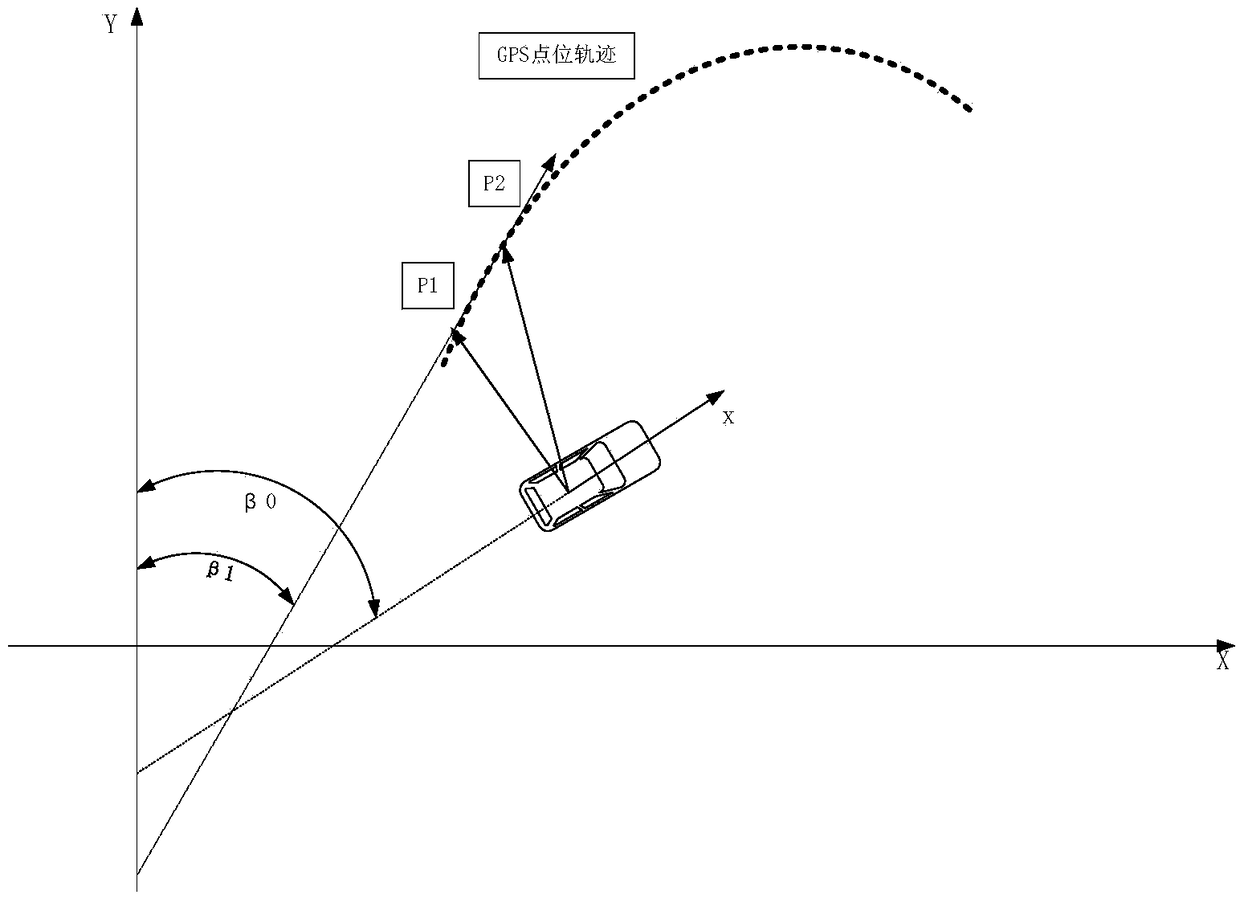

Method for selecting unmanned vehicle path tracking movement target point

InactiveCN108983782AImprove accuracySmall amount of calculationPosition/course control in two dimensionsComputer scienceReal-time computing

The invention relates to a method for selecting an unmanned vehicle path tracking movement target point. The method comprises the steps of collecting GPS point trajectories, sorting in a chronologicalorder, acquiring position coordinates and heading angle of a current position of an unmanned vehicle on a map in real time, selecting a GPS point closest to the vehicle as a starting point of vehicletracking, selecting a GPS point from a certain distance of the vehicle as the selection range of the tracking movement target point so as to adapt to an actual situation, obtaining a next movement target point by constructing an evaluation function related to the speed and heading angle of the vehicle, and finally, solving a suitable path tracking movement target point as a target point in unmanned vehicle path tracking. According to the method, the changes of the vehicle speed and the path heading angle are comprehensively considered to obtain the movement target point of the unmanned vehicle path tracking, the stability of the unmanned vehicle path tracking can be improved, and the safety of unmanned driving is improved.

Owner:JILIN UNIV

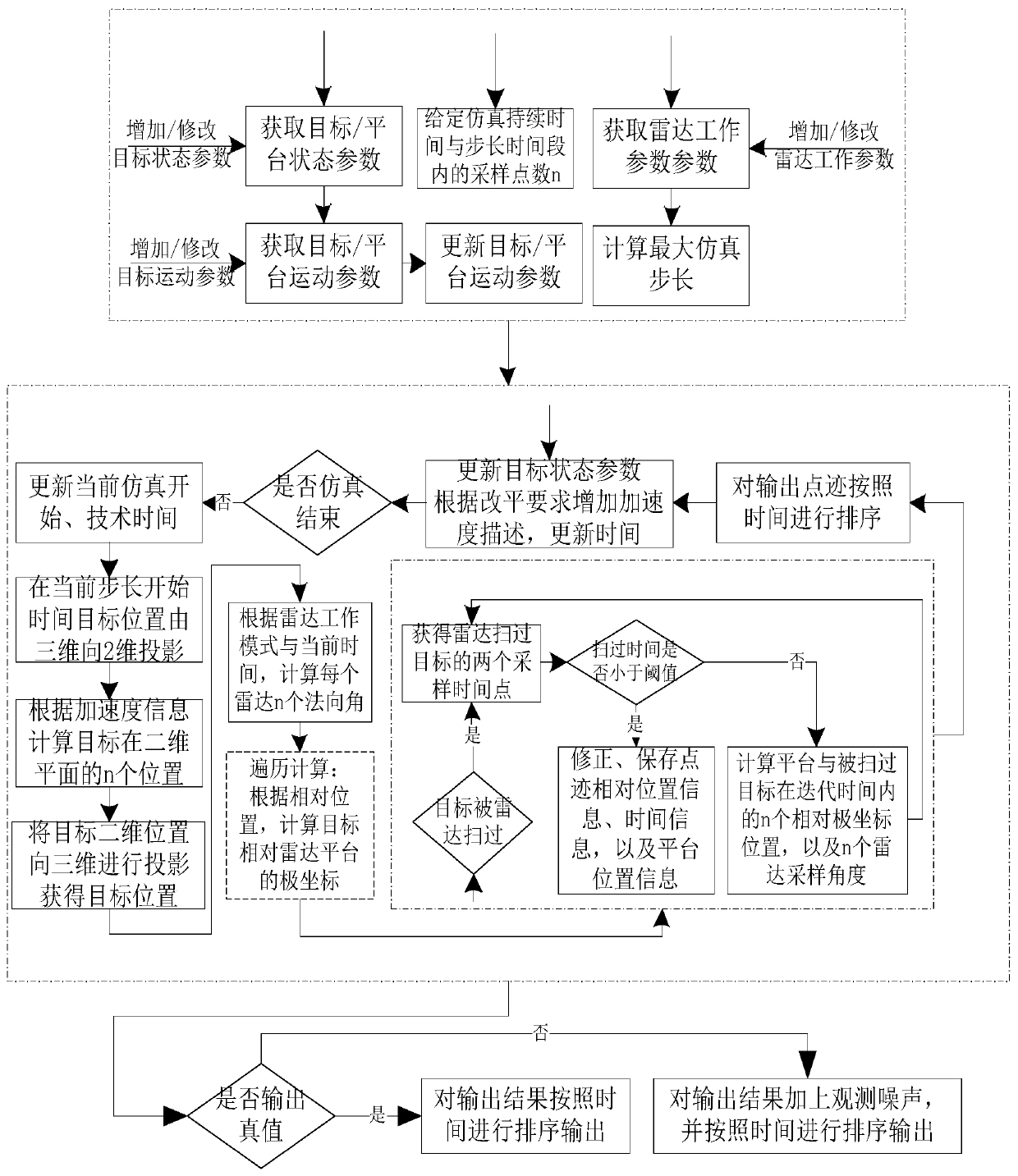

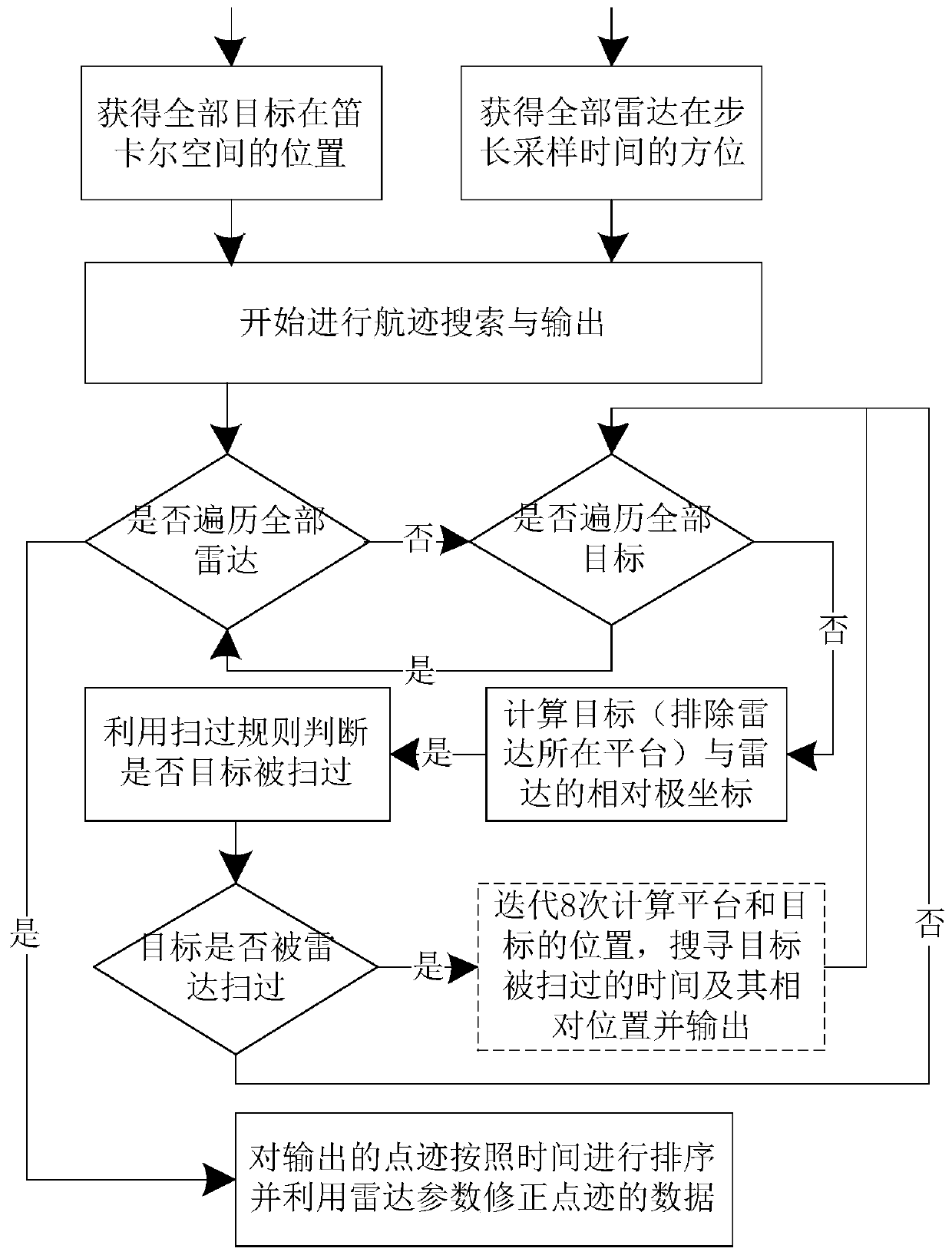

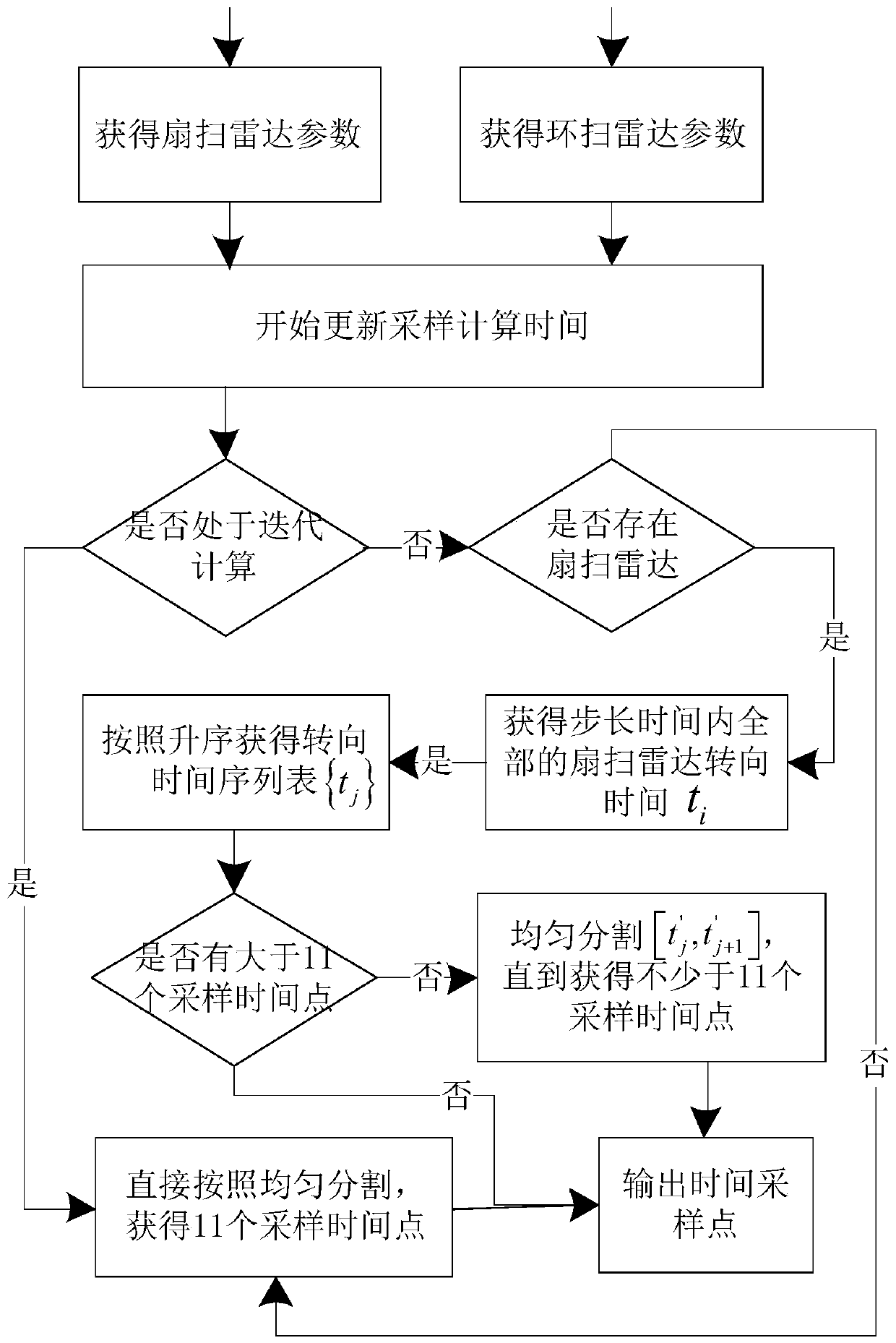

Scanning radar-based target three-dimensional acceleration motion model calculating method

The invention proposes a scanning radar-based target three-dimensional acceleration motion model calculating method. According to the method, theoretical analysis is carried out at first, and then, adata processing flow is designed. According to the theoretical analysis, the mathematical formula of two-dimensional space target free motion is derived based on acceleration factor analysis; a targetthree-dimensional position information-to-two-dimensional projection matrix and a target two-dimensional position-to-three-dimensional space transformation matrix are obtained by means of derivation;and the influence of calculation step length selection and sampling time point selection on data precision under multi-platform and multi-radar working modes is analyzed. According to the design of the data processing flow, after target motion state and radar working parameter initial setting is completed, the relative polar coordinate position of a target relative to a radar at a sampling time point is calculated through using a target motion model formula, and the normal direction of the radar at the sampling time point is further calculated; whether it is necessary to output a point trajectory is judged through a post-scanning judgment criterion; and after each calculation step length is terminated, target point trajectory position information is corrected based on the error information of the radar, and is sequenced and outputted according to time.

Owner:中国船舶集团有限公司第七二四研究所

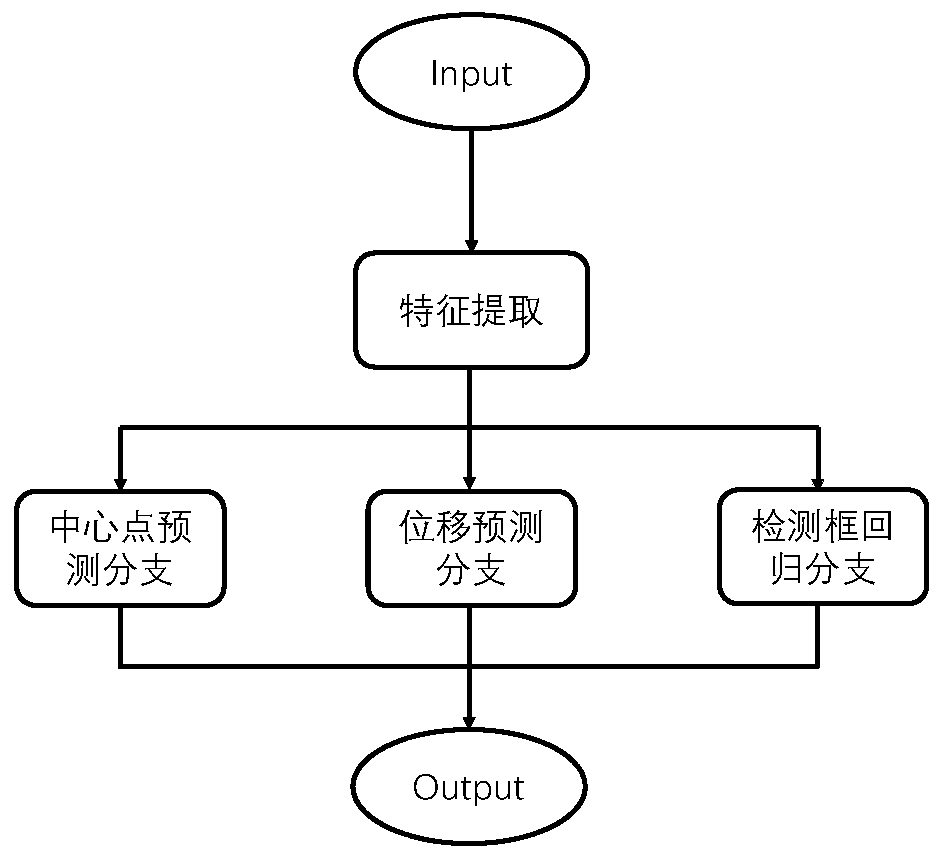

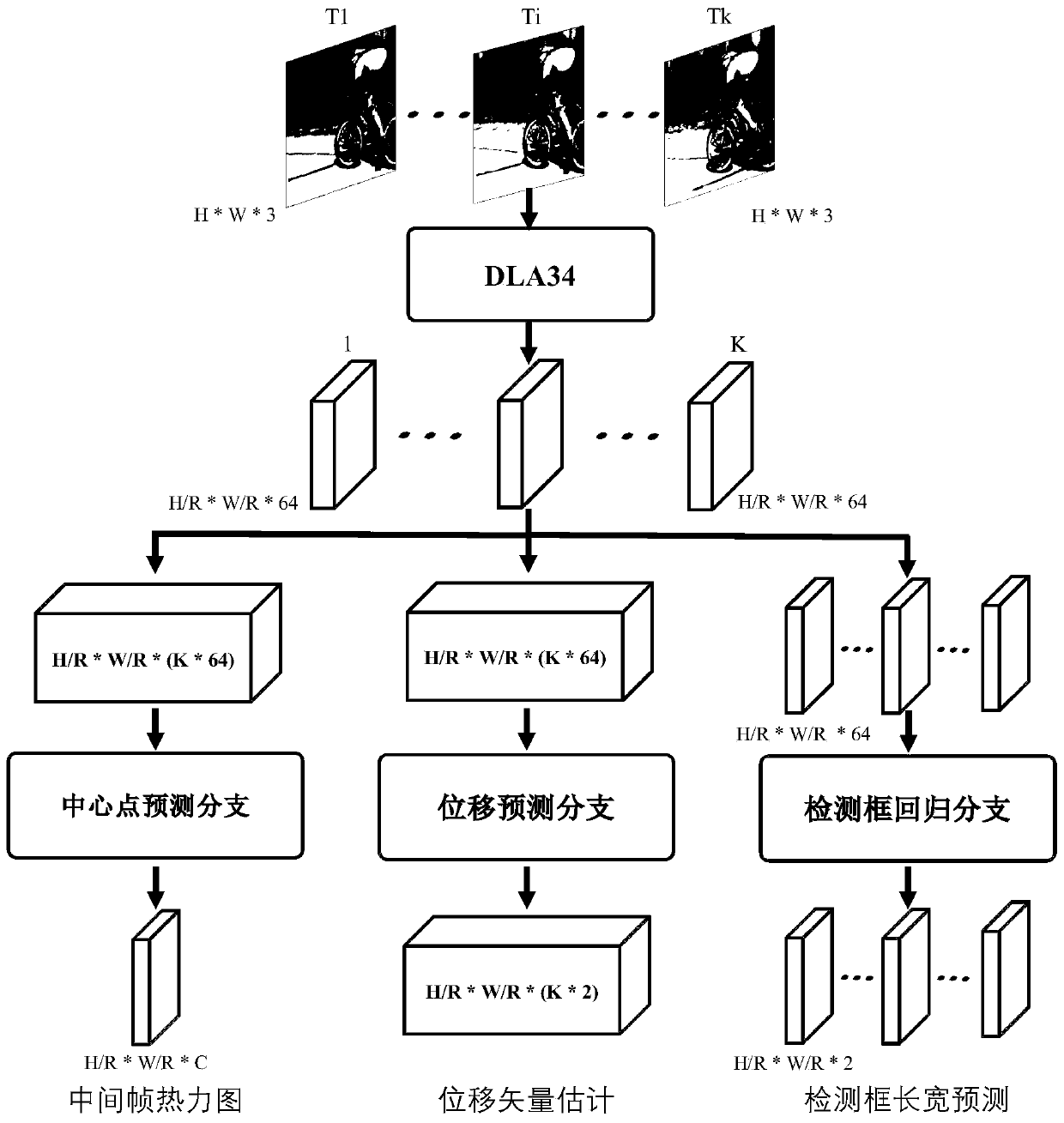

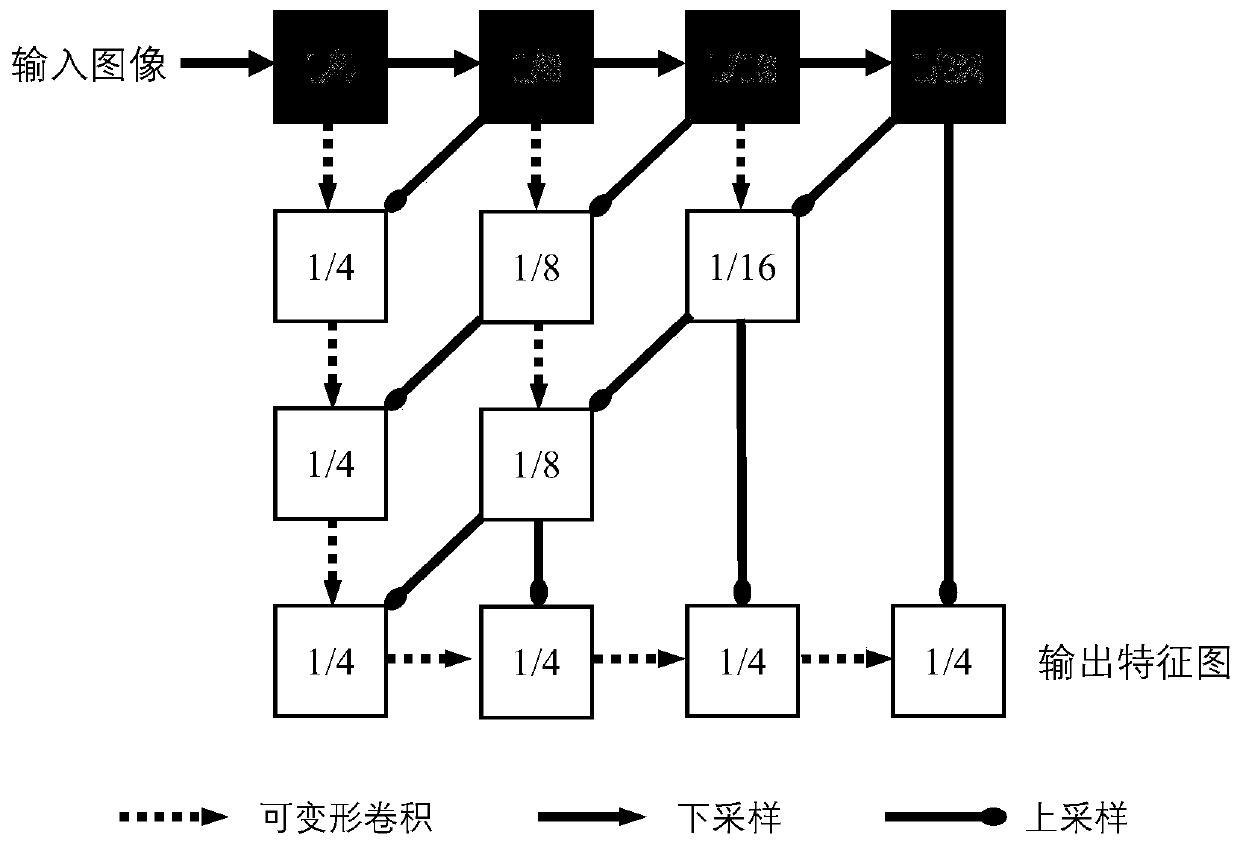

Video action detection method based on central point trajectory prediction

ActiveCN111259779AQuick and easy categorySimple and quick positioning resultsCharacter and pattern recognitionNeural architecturesFrame sequenceComputer graphics (images)

The invention discloses a video action detection method based on central point trajectory prediction. In video spatio-temporal motion detection, each action instance is regarded as a movement track ofthe central point of the action initiator; wherein the trajectory is represented by motion vectors of the central point of the intermediate frame action and the central points of other frame actionsrelative to the central point of the intermediate frame; firstly, features are extracted from a video frame sequence for obtaining central point position prediction and action category prediction of an intermediate frame, then obtaining a motion trail from the central point of the intermediate frame to central points of other frames, and finally generating a detection box of each frame central point to obtain position positioning, thereby obtaining an action category and a positioning result, and completing a space-time detection task on a video clip. According to the anchor-frame-free video action detection method provided by the invention, time-space positioning and classification tasks of actions are completed in the video along a time sequence, and compared with video action detectionwith an anchor frame in the prior art, the anchor-frame-free video action detection method is simpler and more efficient, embodies robustness and high efficiency, and has very strong expansibility andportability at the same time.

Owner:NANJING UNIV

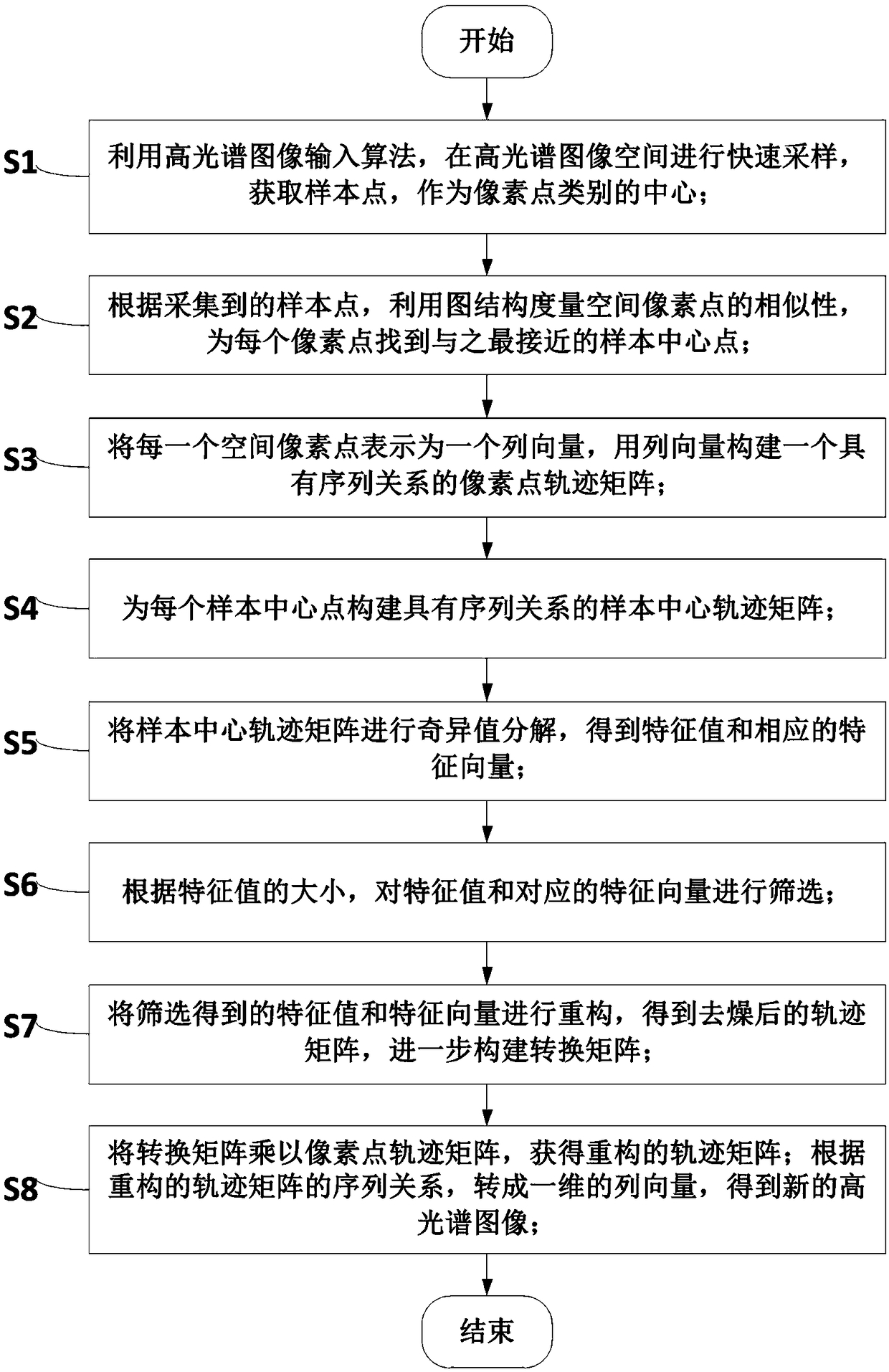

A feature extraction method of hyperspectral image based on fusion of spatial and spectral information

ActiveCN109271874AQuality improvementGood for classification tasksScene recognitionFeature vectorFeature extraction

Owner:GUANGDONG UNIV OF TECH

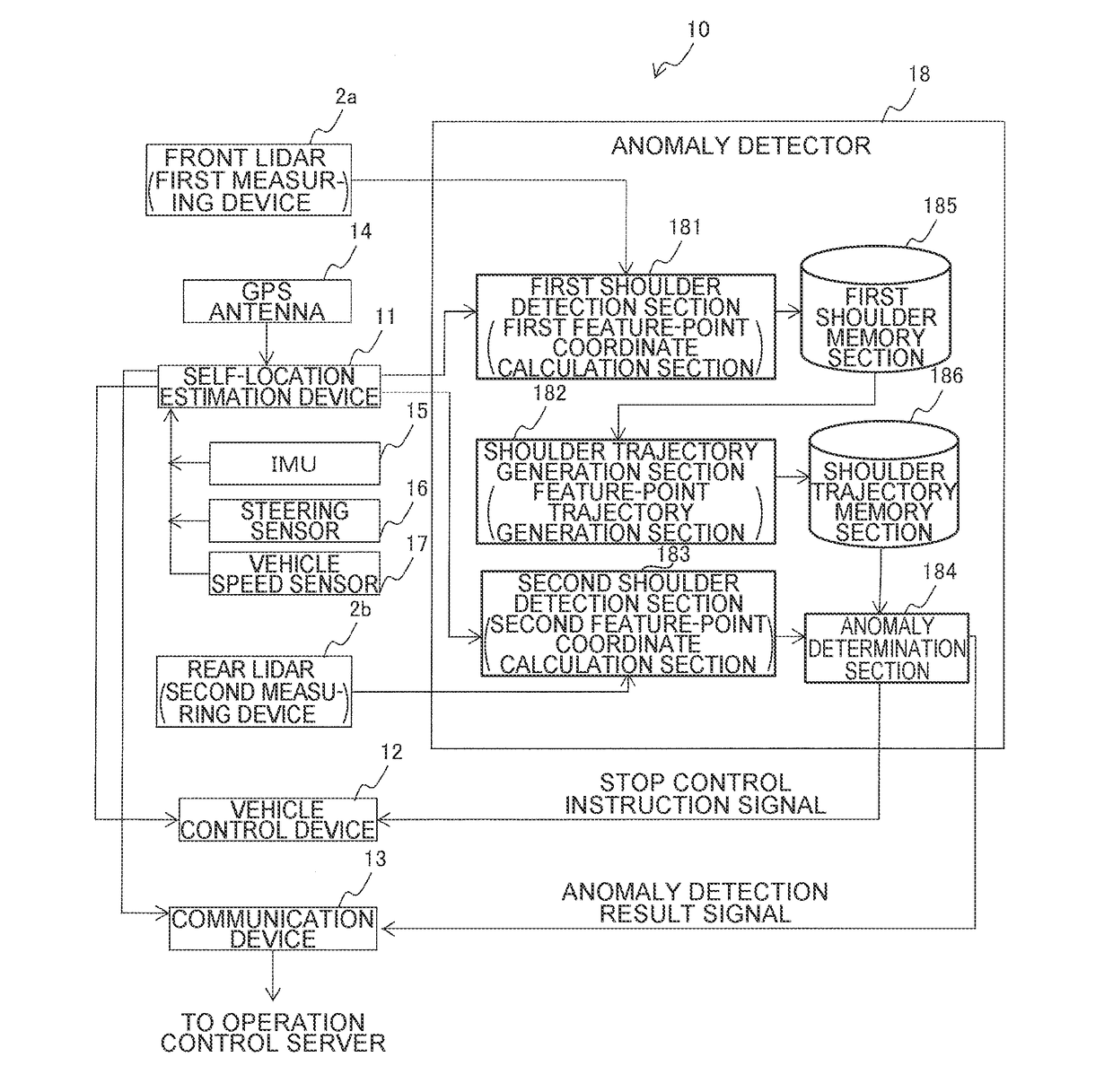

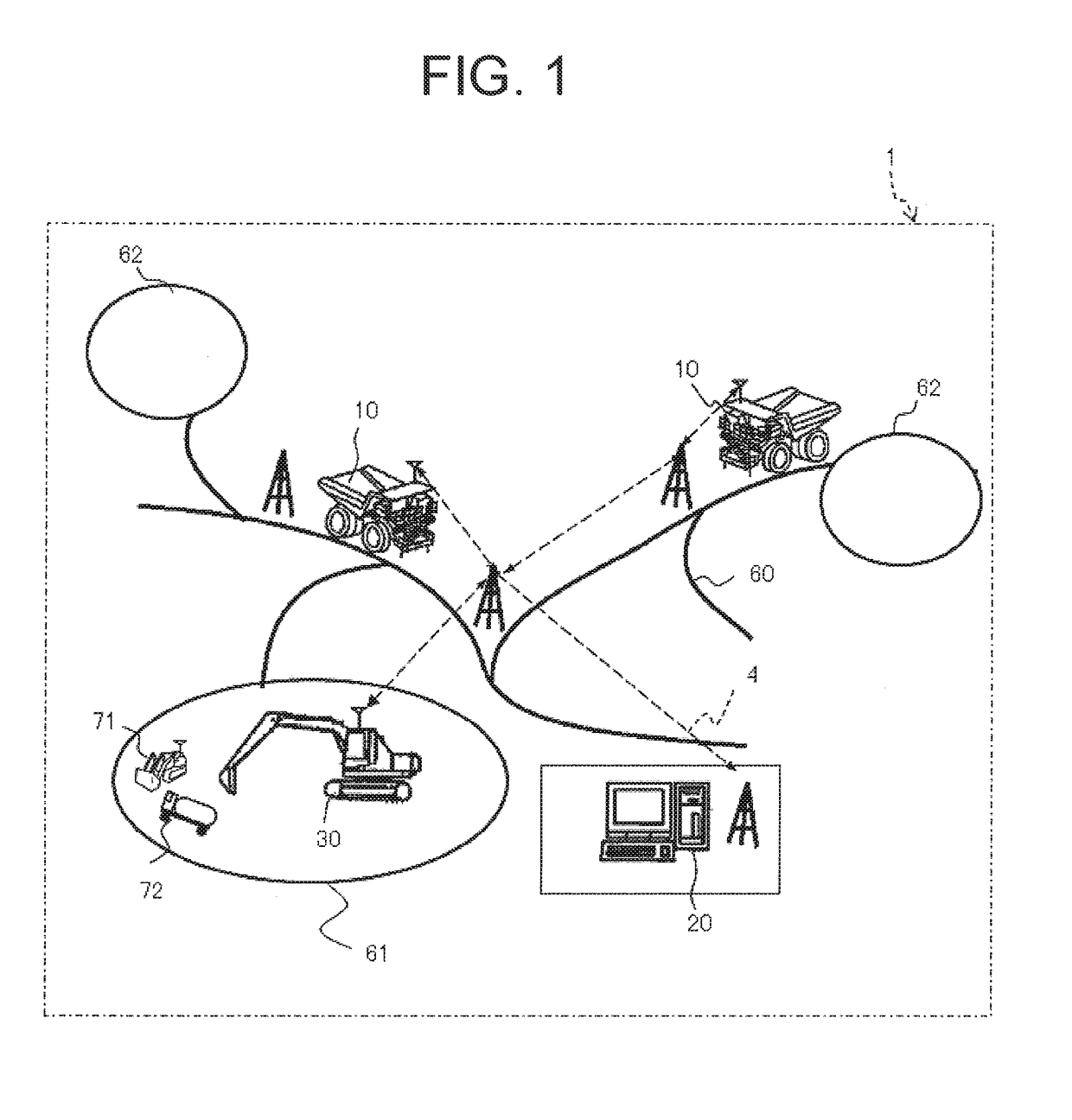

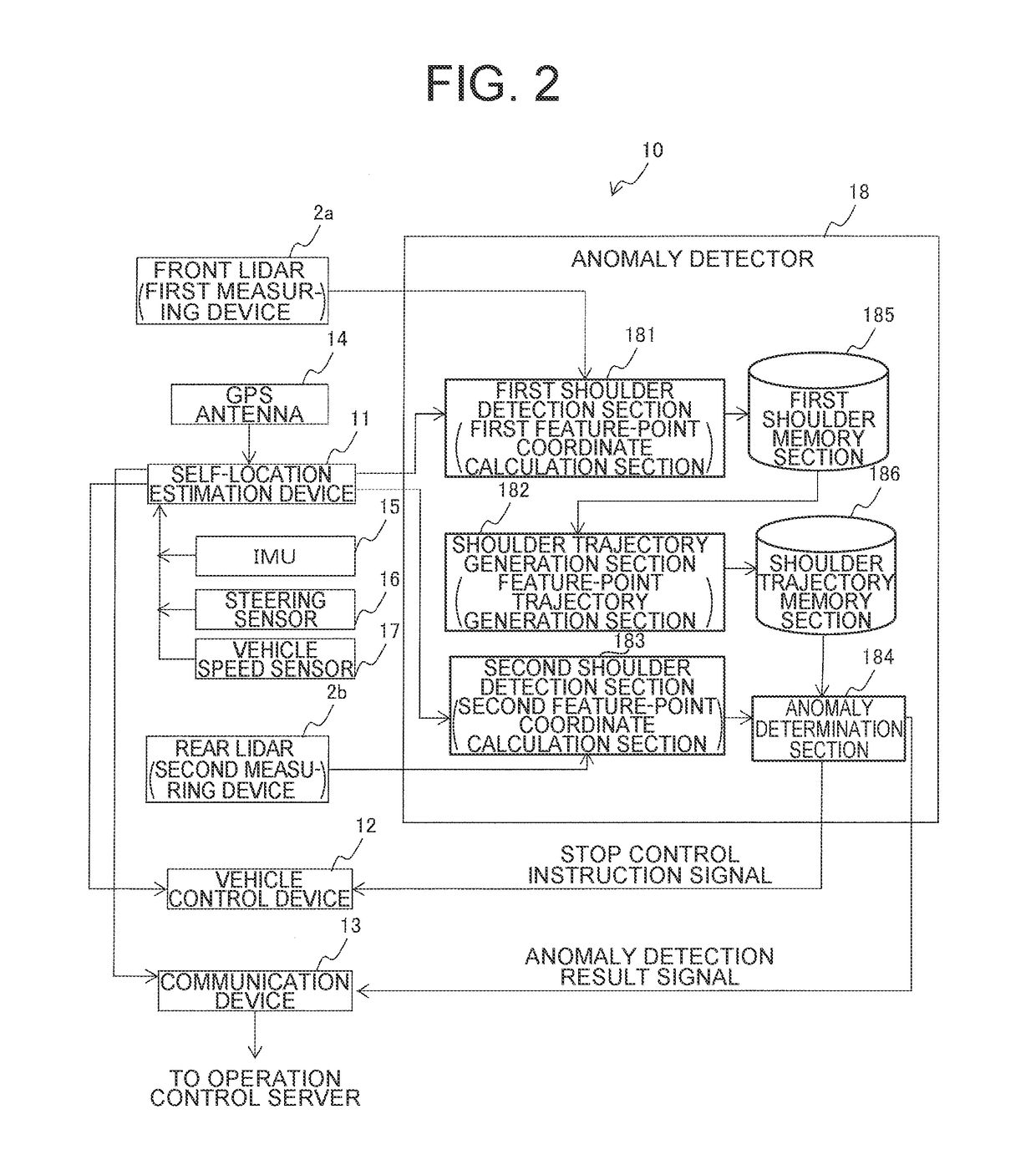

Anomaly detector for self-location estimation device and vehicle

ActiveUS20180284292A1Satellite radio beaconingElectromagnetic wave reradiationMeasurement deviceAnomaly detection

A first measuring device measures a location of its own vehicle relative to each feature point on a surrounding structure around a road surface on which the vehicle. A first feature-point is provided which, based on output from the first measuring device, acquires coordinates of the each feature point expressed in a coordinate system of the first measuring device, and uses a self-location to convert the coordinates into an external coordinate. A feature-point trajectory generation section is provided to generate, based on the first coordinates, a trajectory of the feature point group. A second measuring device measures a location of its own vehicle relative to a feature point located rearward of the feature point measured by the first measuring device. An anomaly determination section is provided to determine that anomaly occurs in a self-location estimation device if the second coordinates are on the trajectory.

Owner:NIHON KENKI CO LTD

Plane detection and tracking for structure from motion

Plane detection and tracking algorithms are described that may take point trajectories as input and provide as output a set of inter-image homographies. The inter-image homographies may, for example, be used to generate estimates for 3D camera motion, camera intrinsic parameters, and plane normals using a plane-based self-calibration algorithm. A plane detection and tracking algorithm may obtain a set of point trajectories for a set of images (e.g., a video sequence, or a set of still photographs). A 2D plane may be detected from the trajectories, and trajectories that follow the 2D plane through the images may be identified. The identified trajectories may be used to compute a set of inter-image homographies for the images as output.

Owner:ADOBE SYST INC

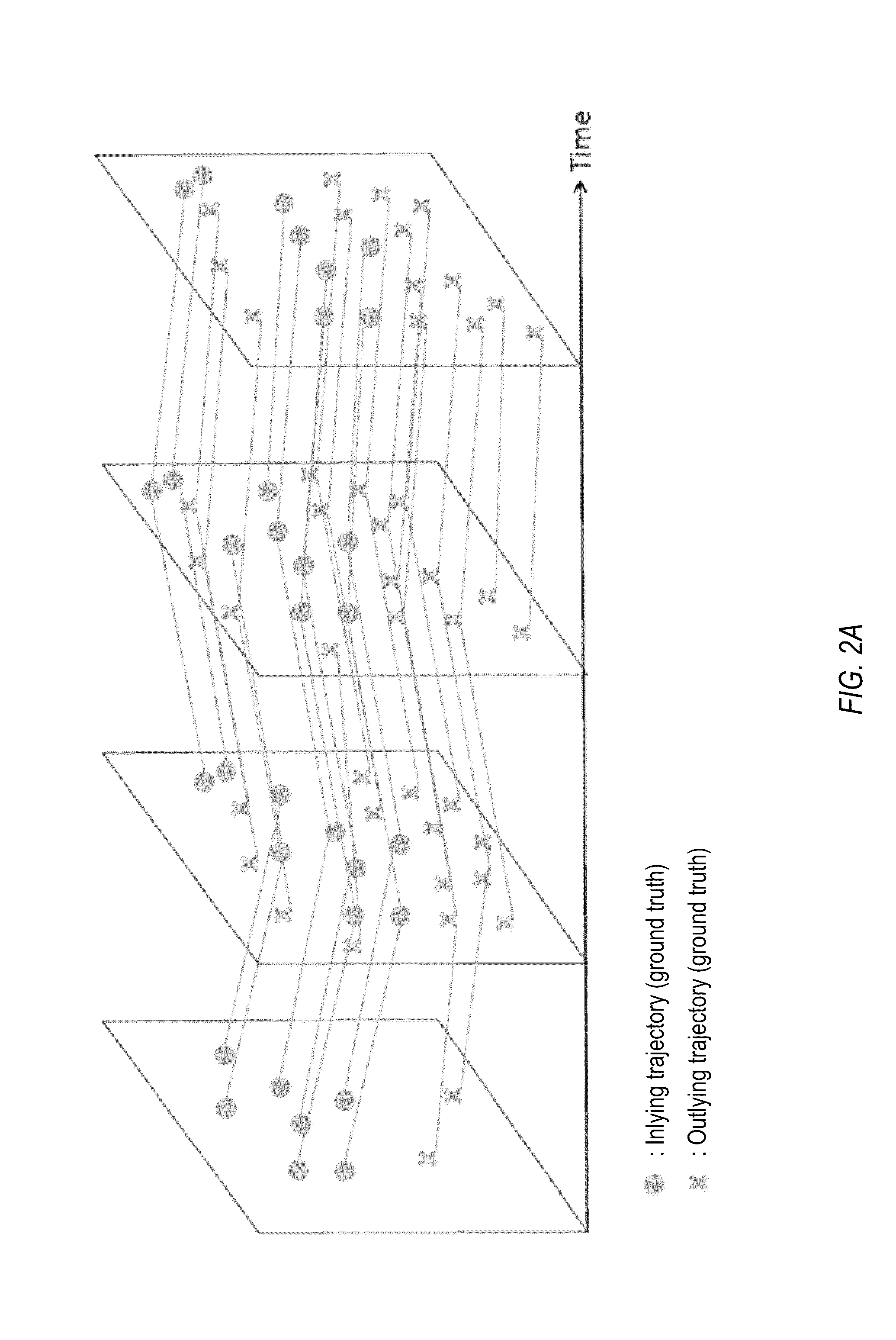

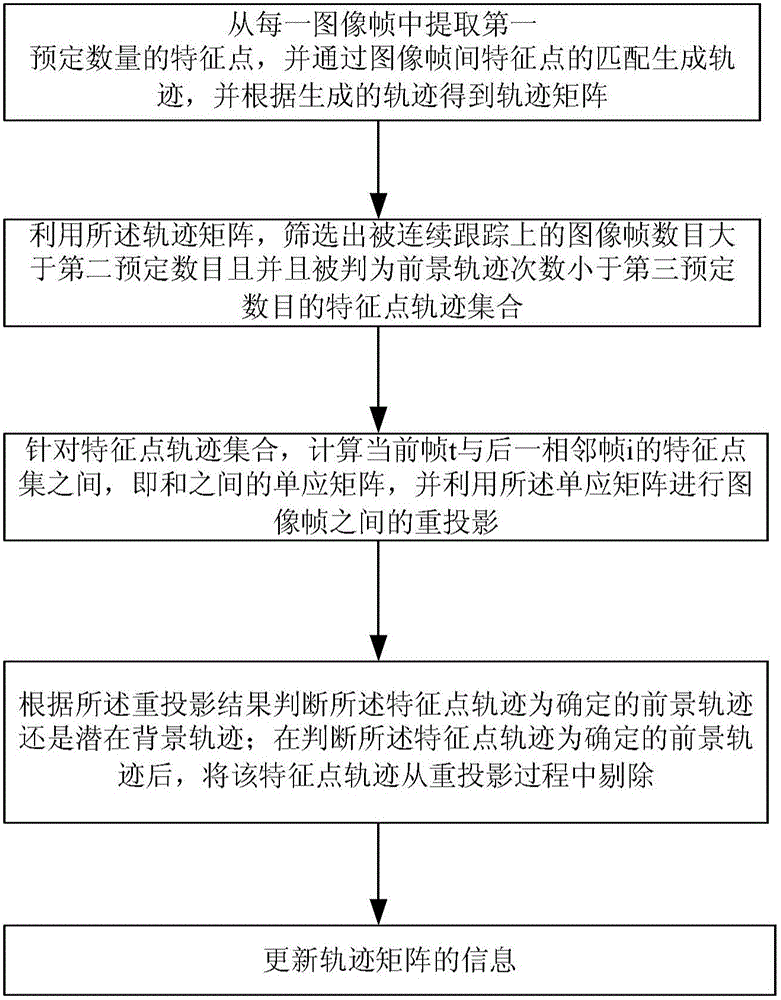

Foreground trajectory determination method and device based on feedback

ActiveCN106101485ADebounce AlgorithmTelevision system detailsColor television detailsPattern recognitionHomography

The invention discloses a foreground trajectory determination method and device based on feedback. The method comprises the following steps: extracting a first predetermined number of feature points from each image frame, and generating feature point trajectories by the match between image frames; screening a feature point trajectory set in which the number of continuously tracked image frames is greater than or equal to a second predetermined number and a foreground trajectory time is determined to be less than a third predetermined number from the feature point trajectories; for the feature point trajectory set, calculating a homography matrix between a current frame and an adjacent frame staring from the first frame, and re-projecting coordinates of each feature point in the feature point trajectory set in the adjacent frame by using the homography matrix; and determining, after the second predetermined number of re-projections, whether the feature point trajectories are determined foreground trajectories according to the re-projection results. By adopting the foreground trajectory determination method and device disclosed by the invention, the feature point trajectories belonging to a foreground object and subjecting to parallax interference can be determined and are determined as the foreground trajectories.

Owner:UNIV OF SCI & TECH OF CHINA

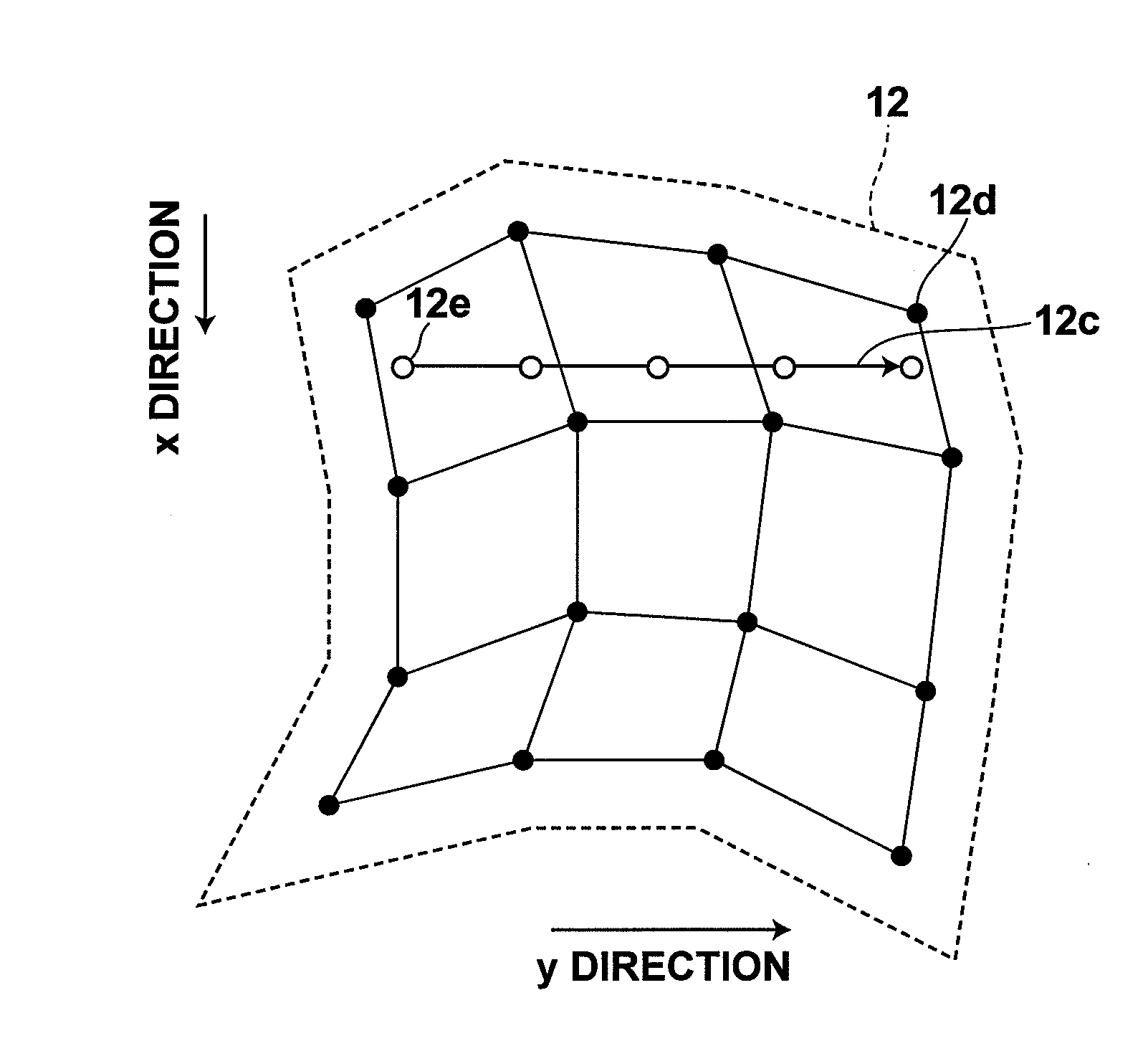

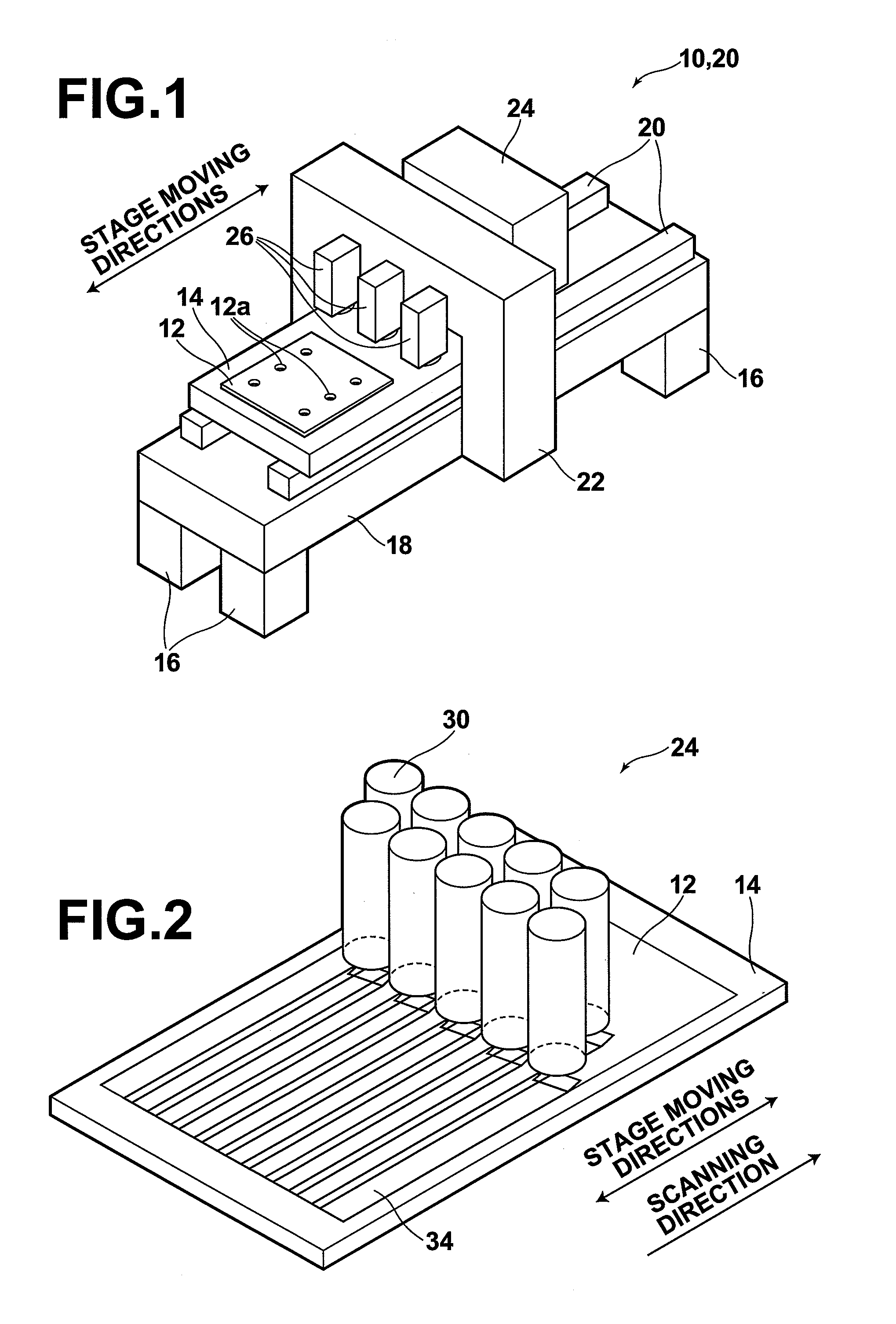

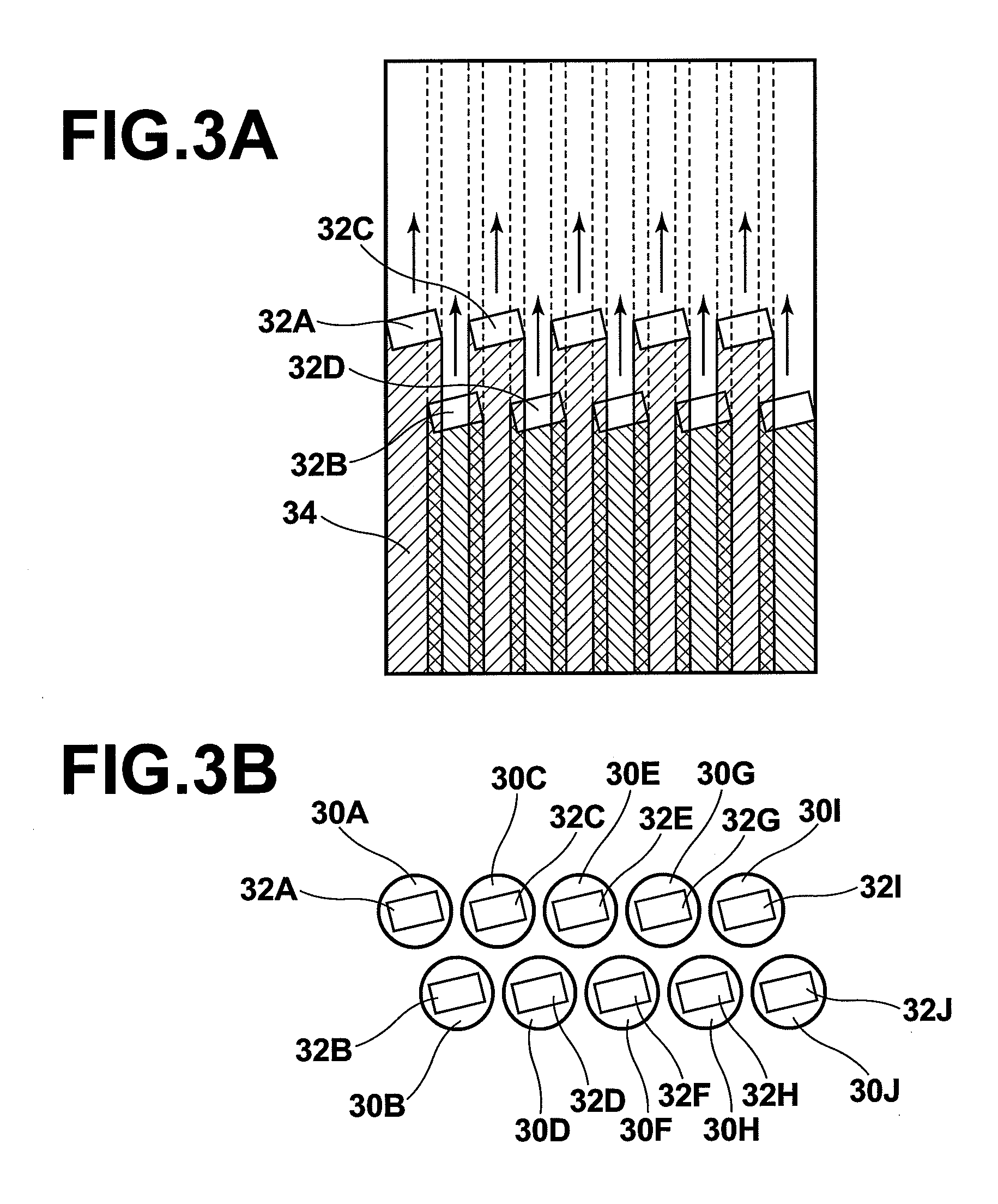

Image plotting data obtaining method and apparatus, and image plotting method and apparatus

InactiveUS8014585B2Low efficiencyReduce data volumePhotomechanical apparatusCharacter and pattern recognitionComputer visionImaging data

Obtaining hypothetical image plot point trajectories in original image data corresponding to predetermined hypothetical image plotting trajectories on a substrate; obtaining and storing in advance hypothetical image plotting data corresponding to the hypothetical image plot point data trajectories from the original image data; selecting hypothetical image plot point data trajectories corresponding to the image plotting trajectory on the substrate when an image is plotted, and obtaining information indicating the area corresponding to the image plot point data trajectory in each hypothetical image plot point data trajectory indicated by the selected hypothetical image plot point data trajectories; identifying hypothetical image plotting data corresponding to the hypothetical image plotting data trajectories; obtaining partial hypothetical image plotting data based on the information indicating the area corresponding to the image plot point data trajectory; and obtaining image plotting data based on each partial hypothetical image plotting data.

Owner:FUJIFILM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com