Method for predicting accumulated mass loss rate of heading machine cutter

A mass loss rate and roadheader technology, which is applied in the field of full-face tunnel boring machine tool wear prediction, can solve the problems of large errors, load conditions, boundary conditions, thermodynamic conditions, and site differences, and key parameters are difficult to measure reliably and accurately And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0151] Aiming at the deficiencies of the prior art, the present invention proposes a method for predicting the accumulative mass loss rate of the cutting tool of the roadheader based on the mass line loss index.

[0152] Steps 1 to 10 are methods for obtaining the general prediction model of equivalent mass line loss index based on field data. Step 11 to step 15 are methods for predicting the cumulative mass loss rate of roadheader cutters in real time by using the general prediction model of equivalent mass line loss index.

[0153] The present invention is the method for predicting the accumulative quality loss rate of boring machine cutting tool based on mass line loss index, and it comprises the following steps:

[0154] step one

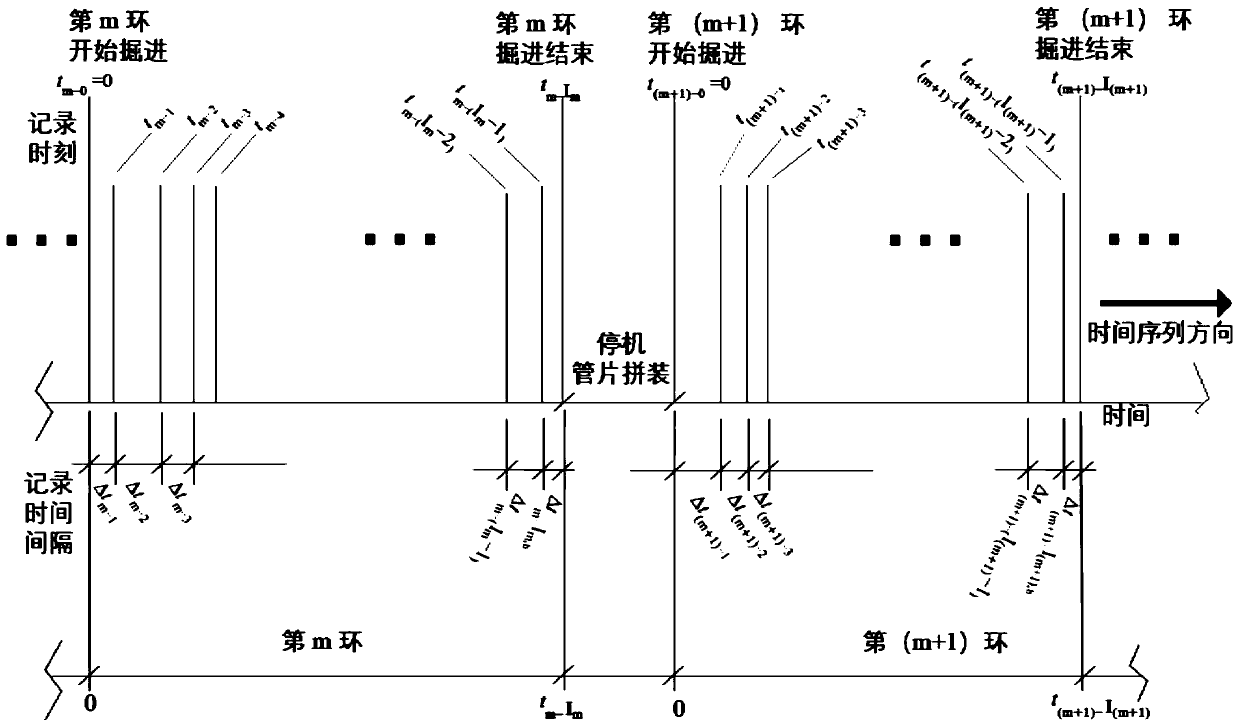

[0155] Record and sort out various construction parameters of the roadheader and group and code them by ring.

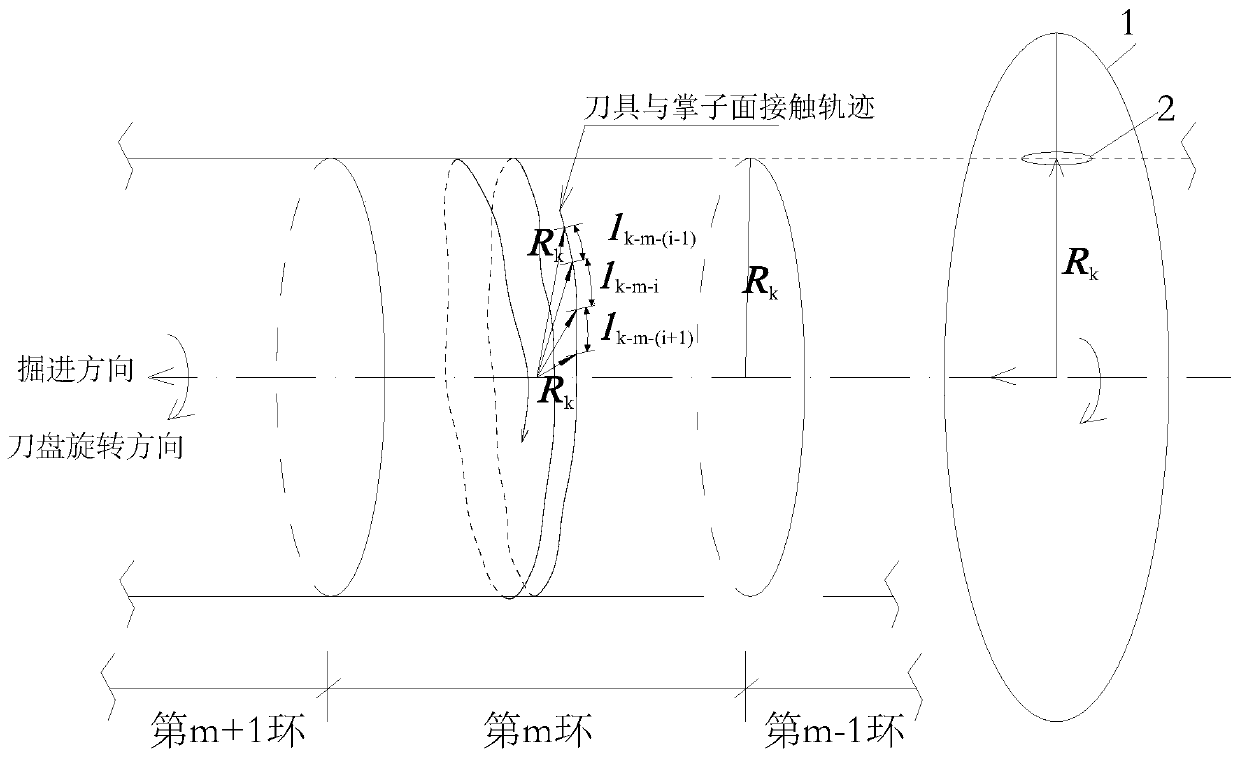

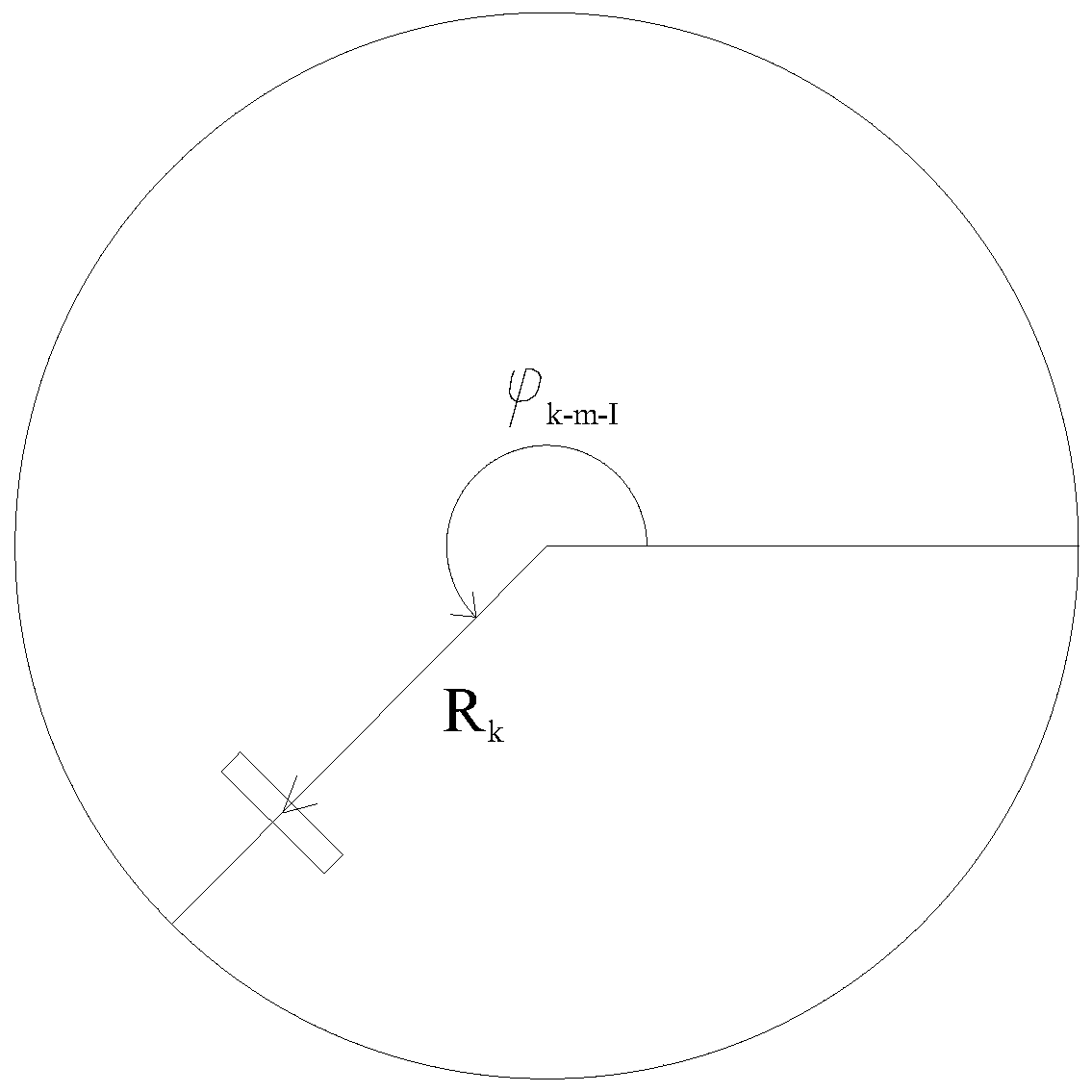

[0156] Such as figure 1 , 1 is the plane of the cutter head, and 2 is the number k tool. There are K knives distributed on the fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com