Intelligent shoe sole glue spraying process for avoiding overflow of glue liquid from edge, and glue spraying equipment thereof

A glue-spraying and glue-liquid technology, which is applied to footwear, shoe parts, and shoe-making machinery, can solve problems such as difficult control of spraying angle, glue overflow, and uneven glue distribution, so as to improve the quality of shoemaking and the market. Competitiveness, solving technical limitations, beneficial to the effect of fitting and fixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

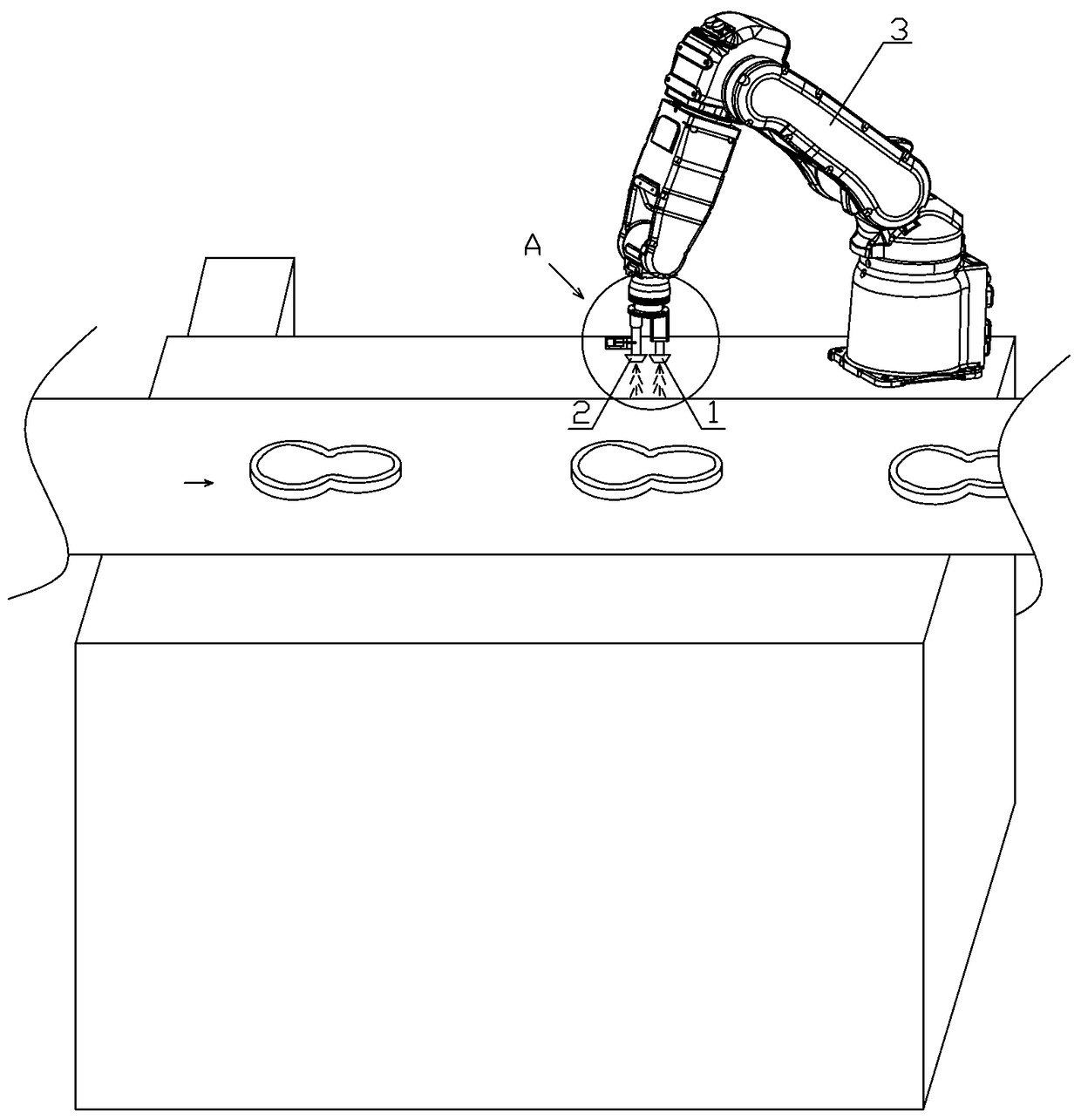

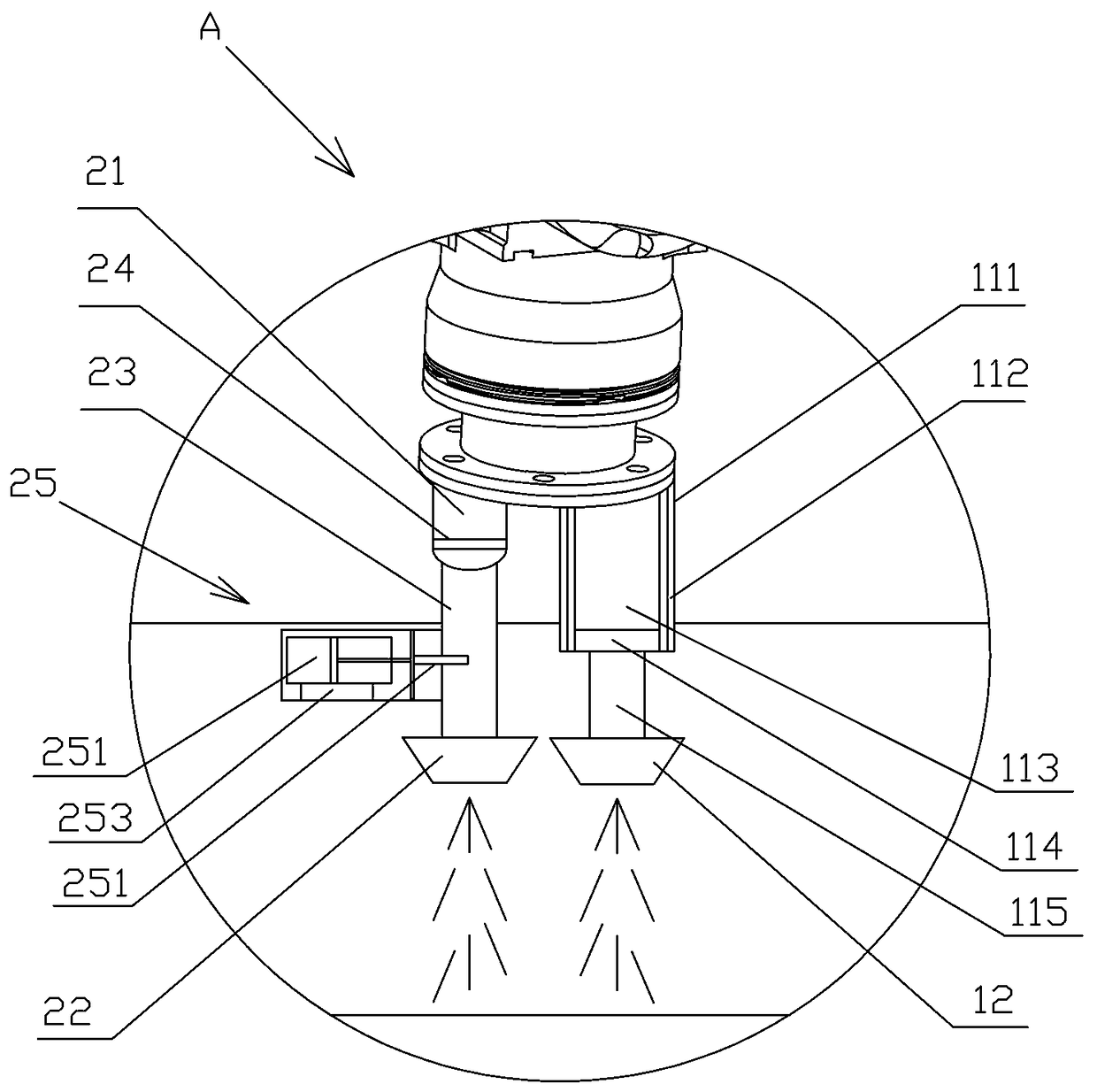

[0025] The specific implementation manners of the present invention will be further described below with reference to the accompanying drawings.

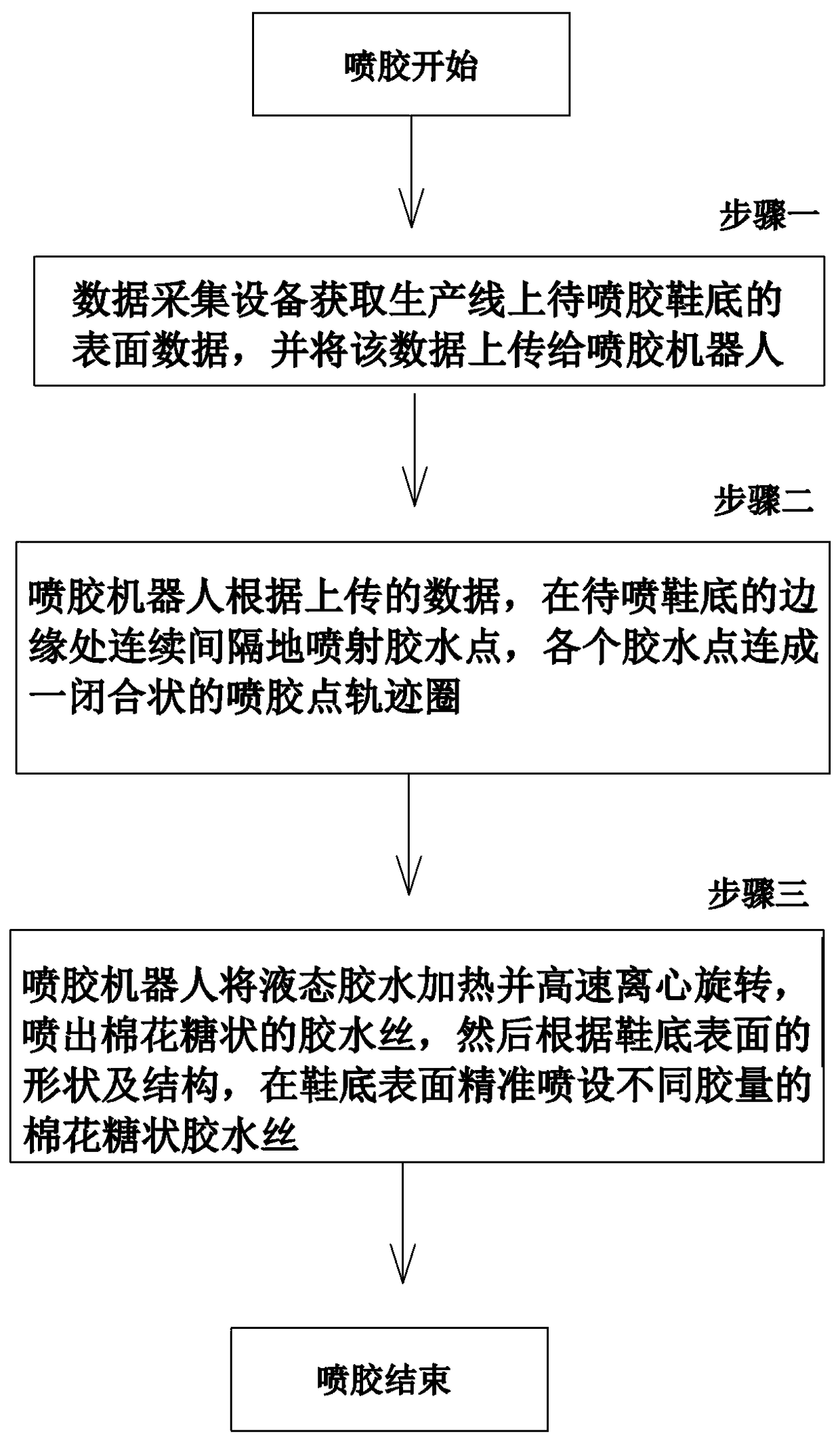

[0026] like figure 1 Shown, a kind of shoe sole intelligent glue spraying technology that avoids glue liquid from overflowing from the edge, described technology comprises the following specific steps:

[0027] Step 1: The data acquisition equipment obtains the surface data of the sole to be glued on the production line, and uploads the data to the glue spraying robot;

[0028] Step 2: According to the uploaded data, the glue spraying robot continuously sprays glue dots at intervals on the edge of the sole to be sprayed, and each glue dot is connected to form a closed trajectory circle of glue spray dots;

[0029] Step 3: The glue spraying robot heats the liquid glue and spins it centrifugally at high speed, sprays out marshmallow-like glue threads, and then accurately sprays marshmallow-like glue threads of different glue amounts ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com