Patents

Literature

117results about How to "Uniform printing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lead-free silver conductive paste used for positive electrode of solar battery and preparation technique thereof

InactiveCN101609850AStrong adhesionLower resistanceFinal product manufactureConductive materialConductive pasteSilver electrode

The invention provides a lead-free silver conductive paste used for positive electrode of solar battery and a preparation technique thereof. The paste comprises the following materials by weight percentage: 65 to 85 percent of silver powder, 2 to 8 percent of lead-free glass powder, 10 to 25 percent of organic carrier and 0.1 to 3 percent of additive. The paste adopts the lead-free glass powder of Si-B-Bi-Al-Ti-Zn-O series to replace the traditional lead-bearing glass powder; and the series glass powder has lower softening point, can lead the silver electrode to have good adhesive force after sintering, and ensures the silver electrode to be well contacted with a silicon substrate. In addition, zinc resinate is used as the additive in the invention, not only can well improve the printing performance of the paste, but also can improve the electrical property of the electrode.

Owner:CENT SOUTH UNIV

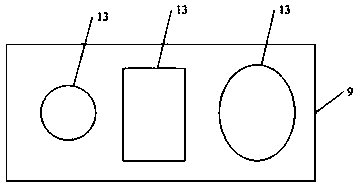

Printing relief plate

ActiveCN102069652AUniform printingAvoid side effectsPlate printingFoil printingLiquid-crystal displayEngineering

The invention discloses a printing relief plate, which comprises a bearing bottom plate and a plate body for printing, wherein the plate body for printing is provided with a bottom surface, and the bottom surface is contacted with the bearing bottom plate; and the plate body for printing comprises a central area and a marginal area, a first convex part is formed in the central area, a second convex part is formed in the marginal area, the first convex part is provided with a first top surface opposite to the bottom surface, the second convex part is provided with a second top surface opposite to the bottom surface, and the distance between the second top surface and the bottom surface is smaller than the distance between the first top surface and the bottom surface. According to the printing relief plate, an orientation material can be uniformly printed on a glass substrate so as to prevent a cured orientation film from generating marginal effect and forming a lug in the marginal area, enlarge the effective display area of a liquid crystal display screen and improve the display effect.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD

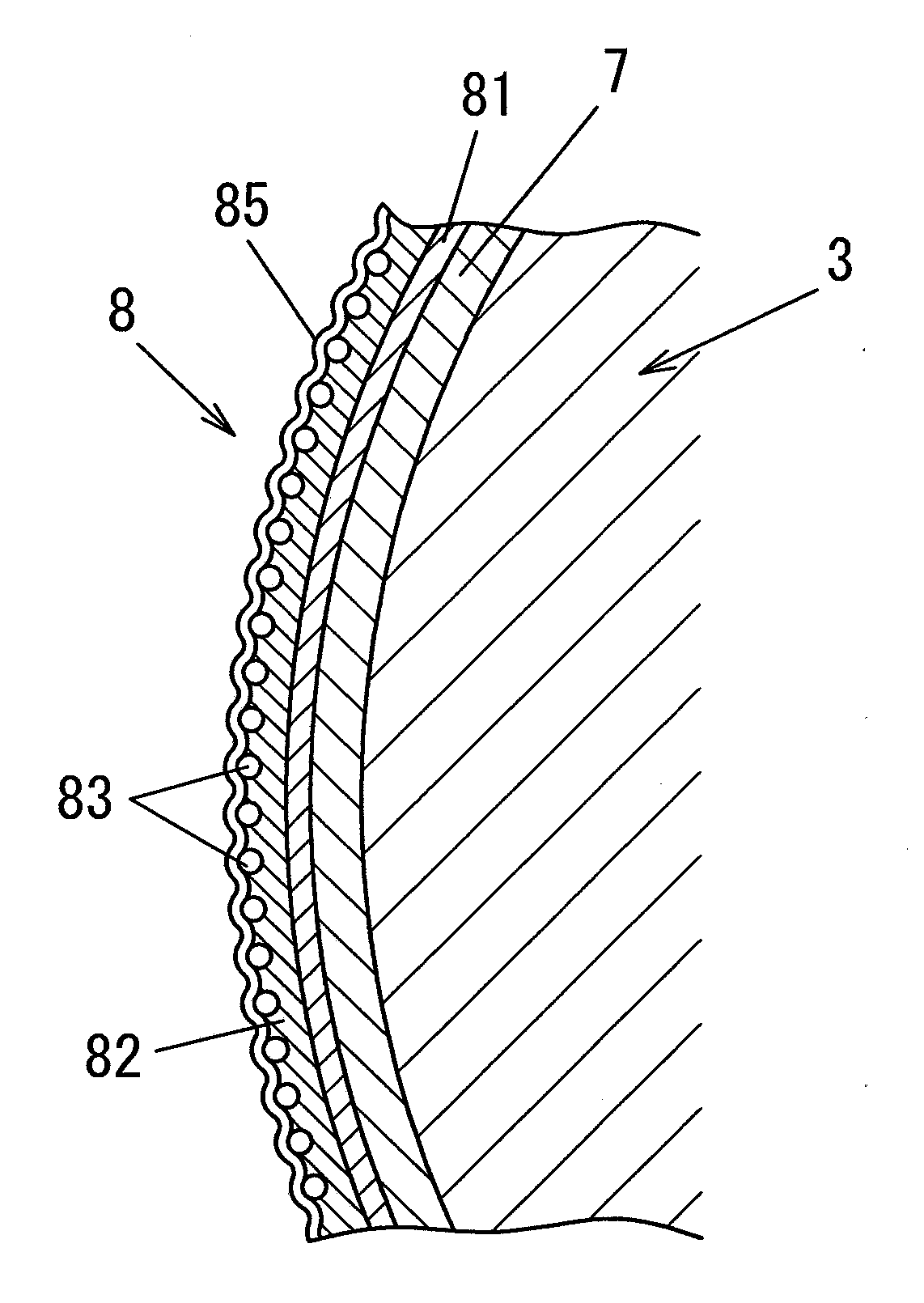

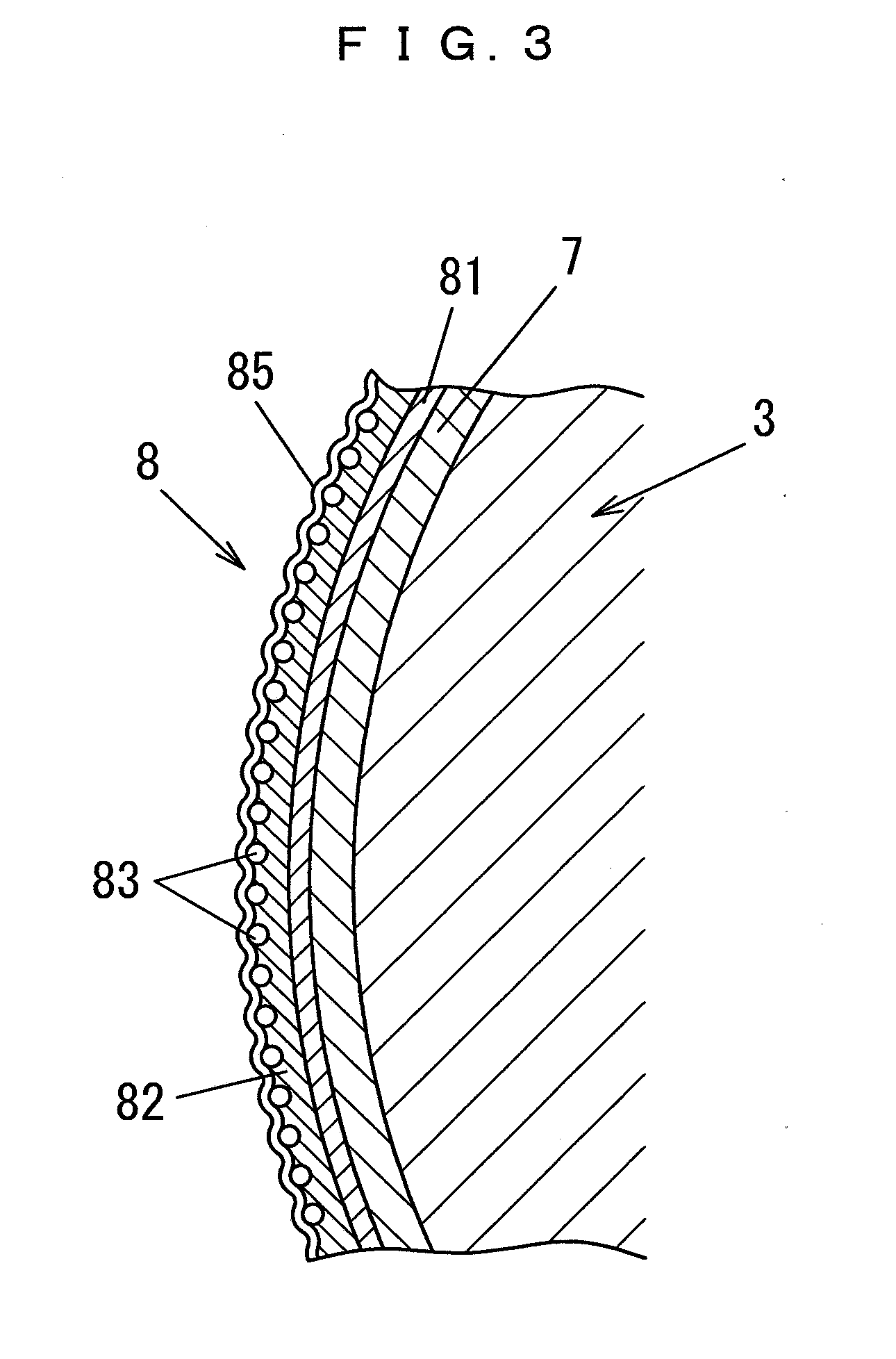

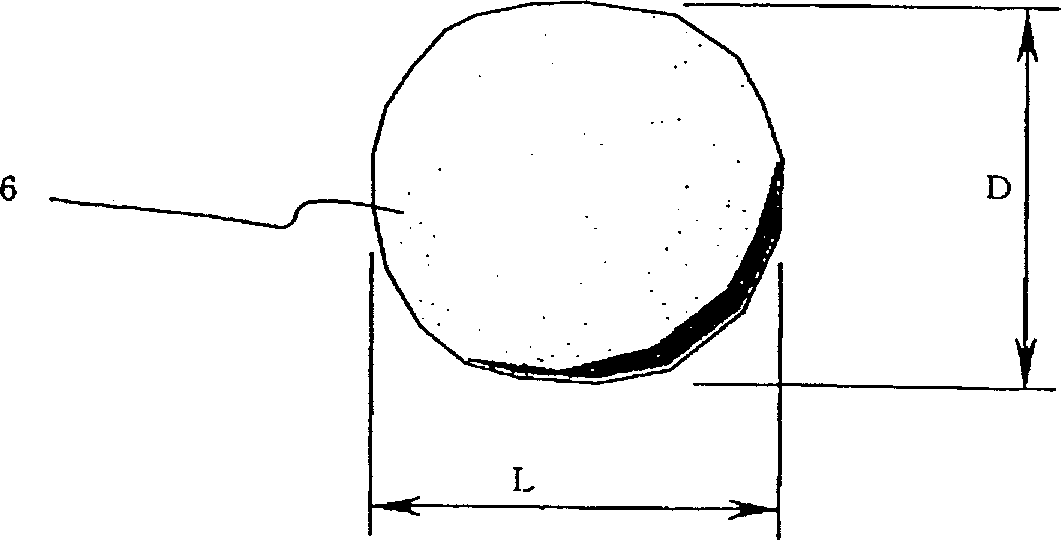

Jacket for impression cylinder or transfer cylinder and method for manufacturing the same

InactiveUS20110056397A1Good shape retentionSufficient flexibilityMetal-working apparatusRotary pressesConvex structureEngineering

A composite structure for application to an impression cylinder or a transfer cylinder includes an ink smear preventing sheet having flexibility as a whole backed by a flexible metal thin plate. The work surface of the ink smear preventing sheet has an ink smear preventing structure in the form of a concave-convex configuration. The ink smear preventing sheet is of a flexible sheet of resin having an adhesive layer thereon in which are partially embedded many small balls to form the concave-convex structure.

Owner:SHINODA

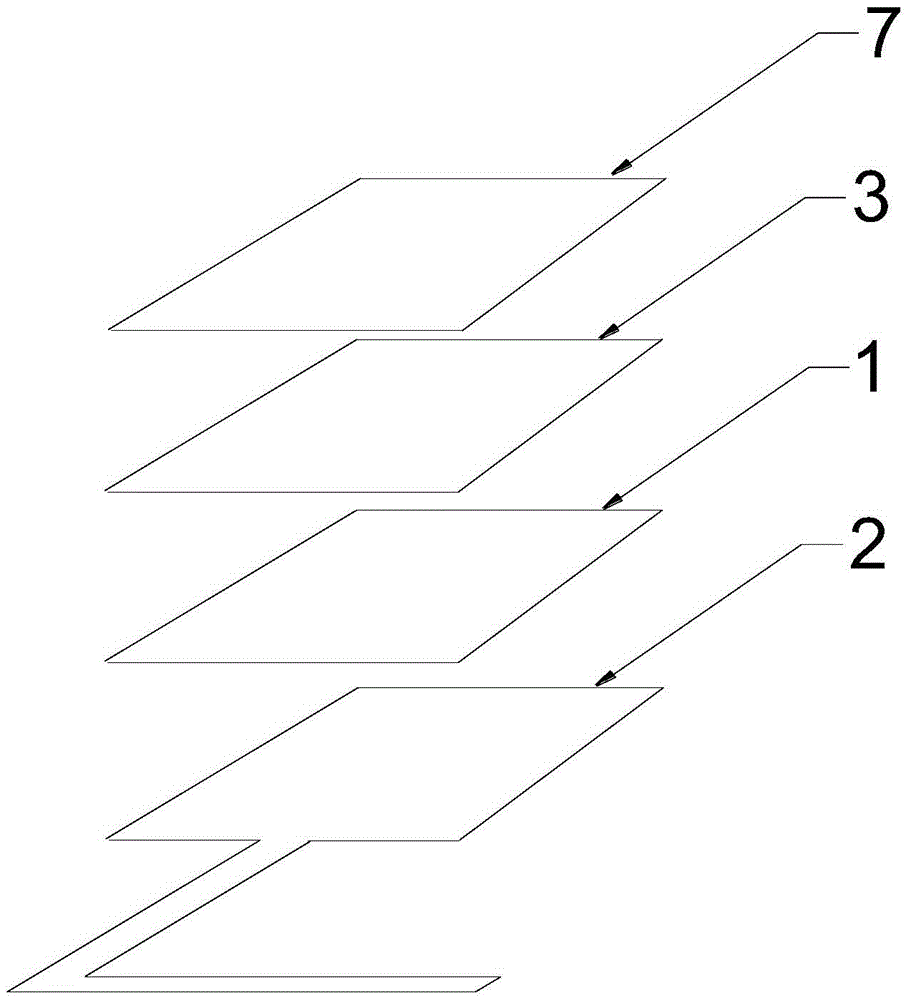

Thermal transfer image receiving sheet and manufacturing method of thermal transfer image receiving sheet

InactiveUS7223513B2High-density printing characteristicsUniform printingDiffusion transfer processesAblative recordingEngineeringThermal transfer

A thermal transfer image receiving sheet comprising a heat insulating layer and a layer adjacent to the heat insulating layer on a substrate, wherein the heat insulating layer is provided between the layer and the substrate, the heat insulating layer contains hollow particles in an amount of at least 65 percent by mass, and the heat insulating layer and the layer are formed by simultaneous multi-layer coating.

Owner:DAI NIPPON PRINTING CO LTD

Thermal transfer image receiving sheet and manufacturing method of thermal transfer image receiving sheet

InactiveUS20060046931A1High-density printing characteristicsUniform printingDiffusion transfer processesAblative recordingEngineeringThermal transfer

A thermal transfer image receiving sheet comprising a heat insulating layer and a layer adjacent to the heat insulating layer on a substrate, wherein the heat insulating layer is provided between the layer and the substrate, the heat insulating layer contains hollow particles in an amount of at least 65 percent by mass, and the heat insulating layer and the layer are formed by simultaneous multi-layer coating.

Owner:DAI NIPPON PRINTING CO LTD

Connecting material for cold transfer printing paper and preparation

ActiveUS20080280758A1Increase print qualityHigh transfer ratePattern printingAblative recordingEngineeringAcrylic coating

A connecting material for cold transfer printing paper is provided and includes an acrylic coating agent composition as an isolating layer and an acrylic coating agent composition as an ink-receiving layer. Also provided is a method for preparing the connecting material for cold transfer printing paper, a cold transfer printing paper and a method for printing a pattern or letter on a fabric by using the cold transfer printing paper.

Owner:NEWTECH TEXTILE TECH DEV SHANGHAI

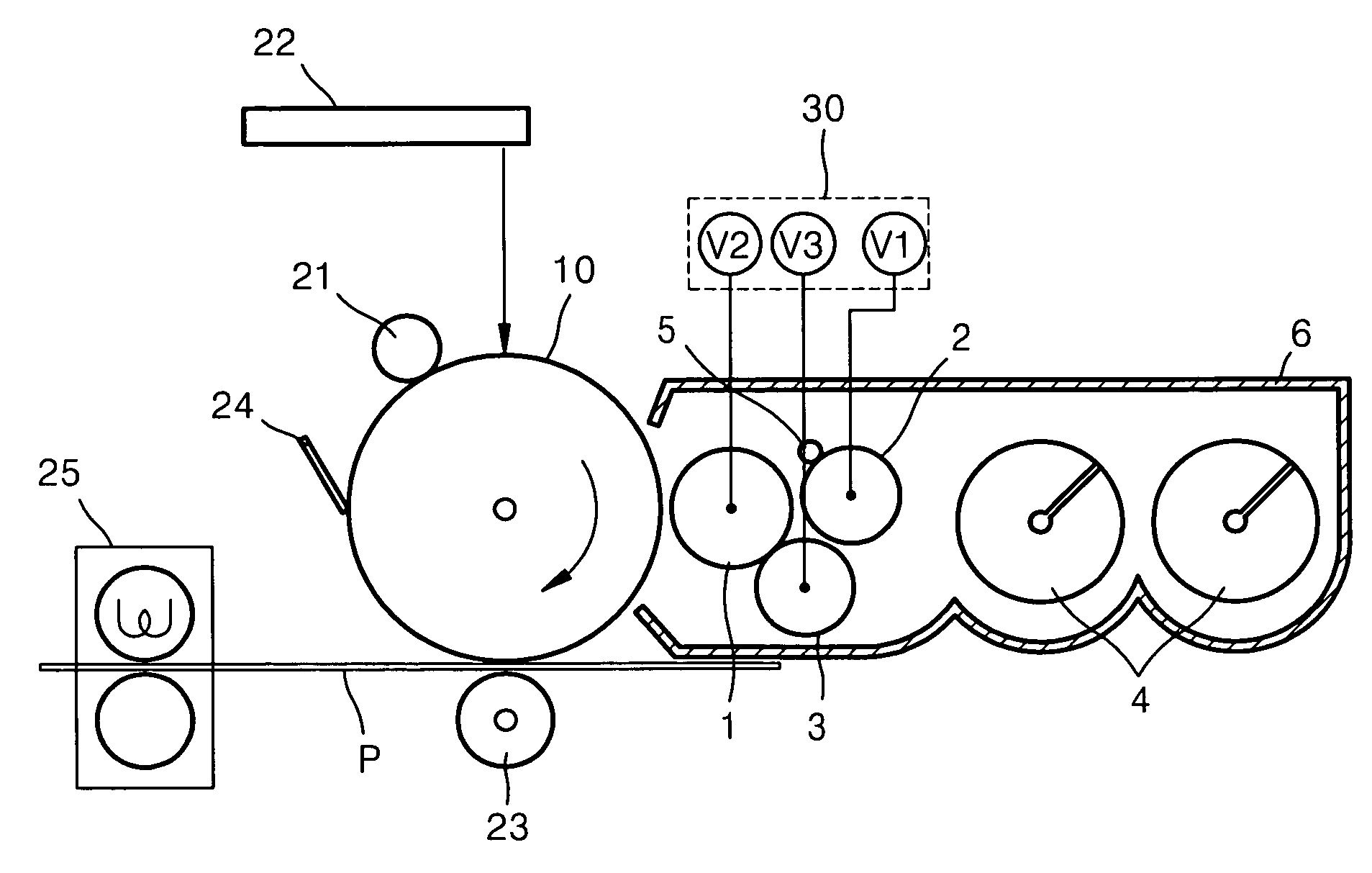

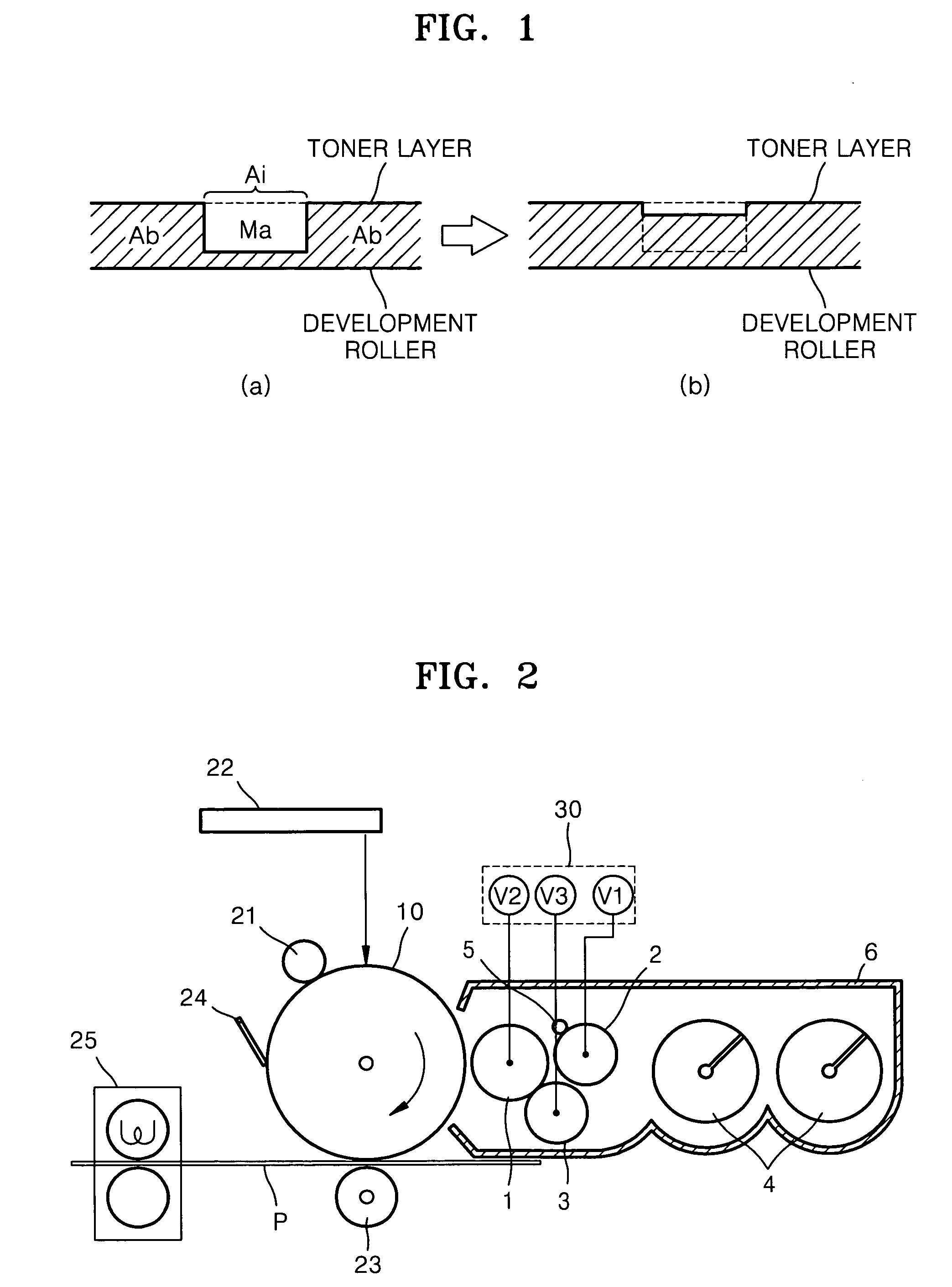

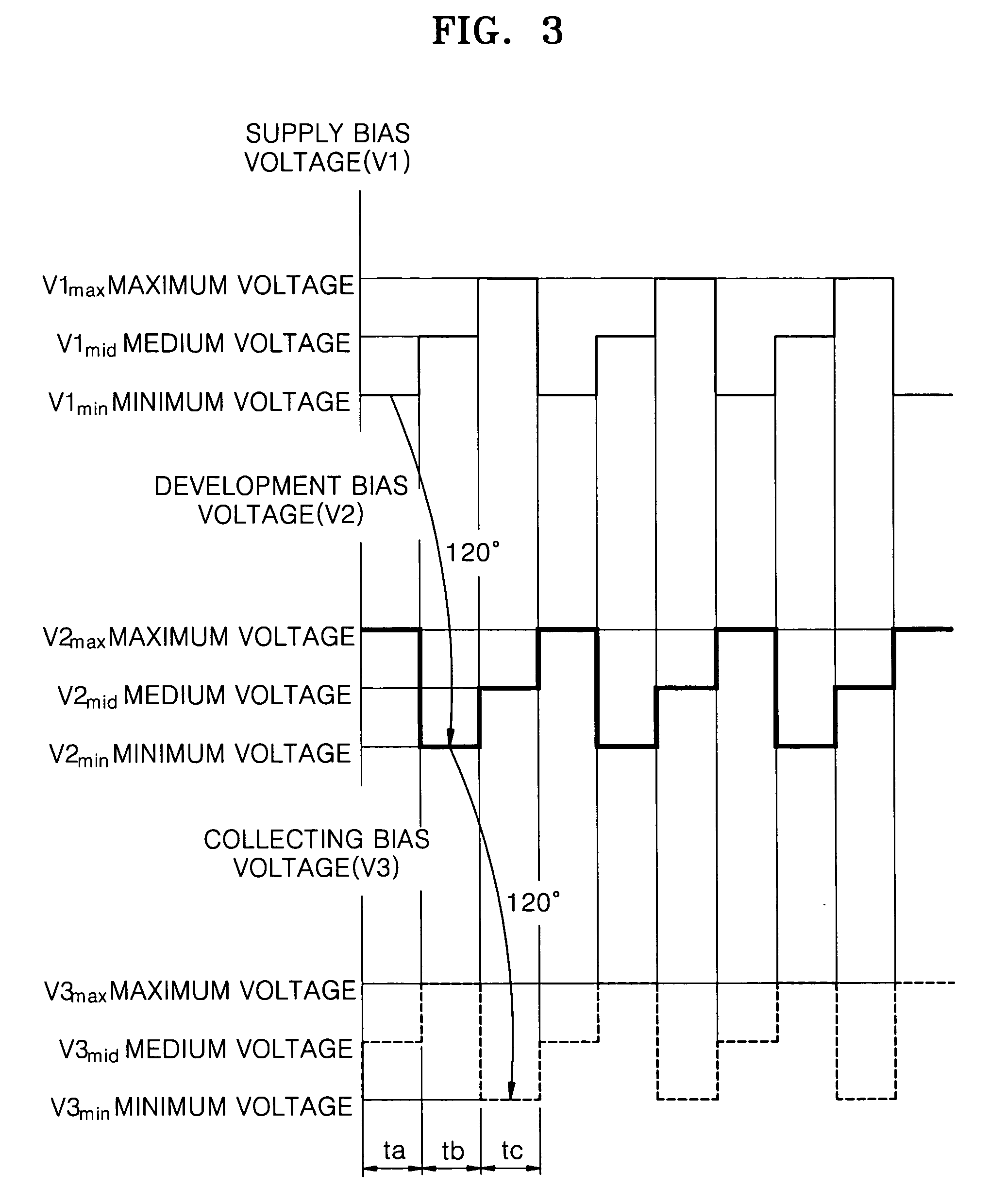

Hybrid development apparatus and development method therefor

InactiveUS20070071505A1High quality imagingInhibition formationElectrographic process apparatusEngineeringDuty cycle

A hybrid development apparatus and a development method therefor are provided. The hybrid development apparatus includes a magnetic roller, a donor roller, and a collecting roller. A supply bias voltage, a development bias voltage, and a collecting bias voltage are respectively applied to the three rollers. The three bias voltages are tri-level bias voltages having same voltage duties of maximum, medium and minimum voltages and phases thereof are different by 120 degrees from each other.

Owner:SAMSUNG ELECTRONICS CO LTD

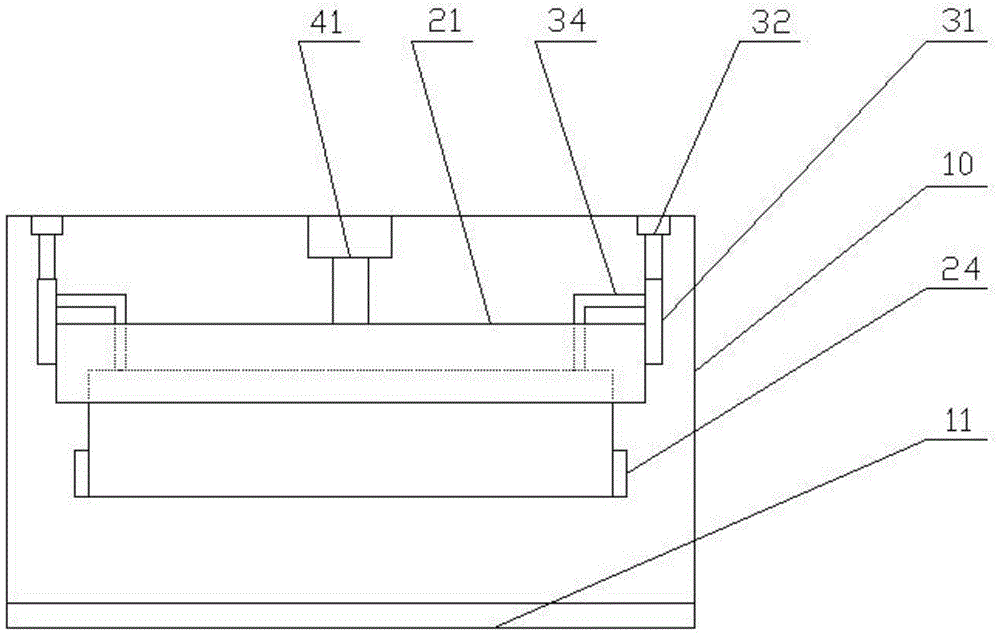

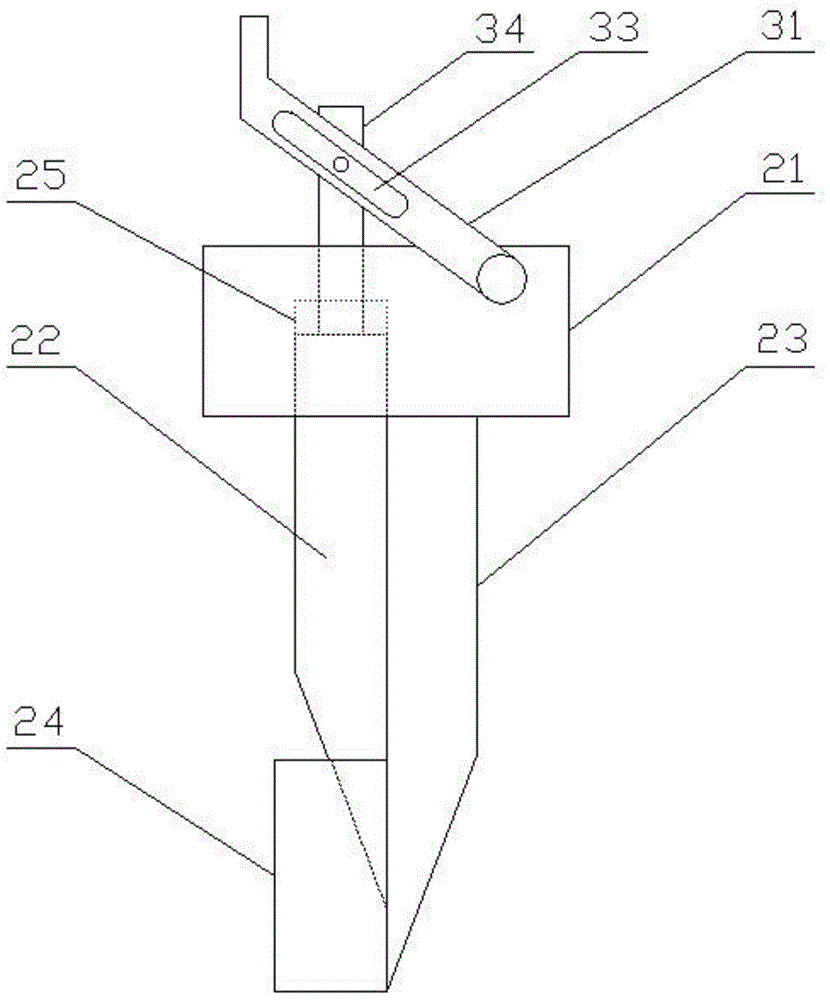

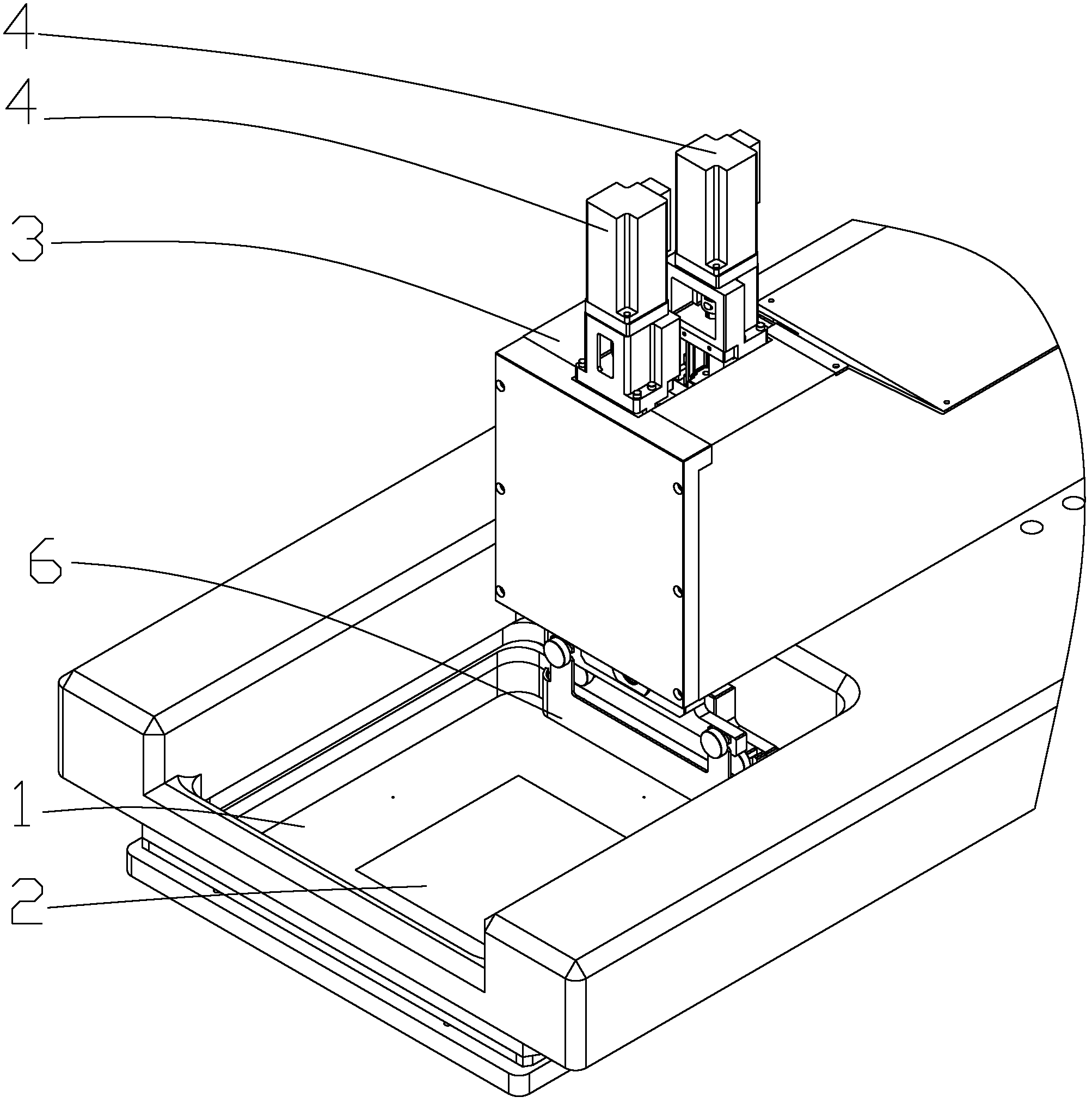

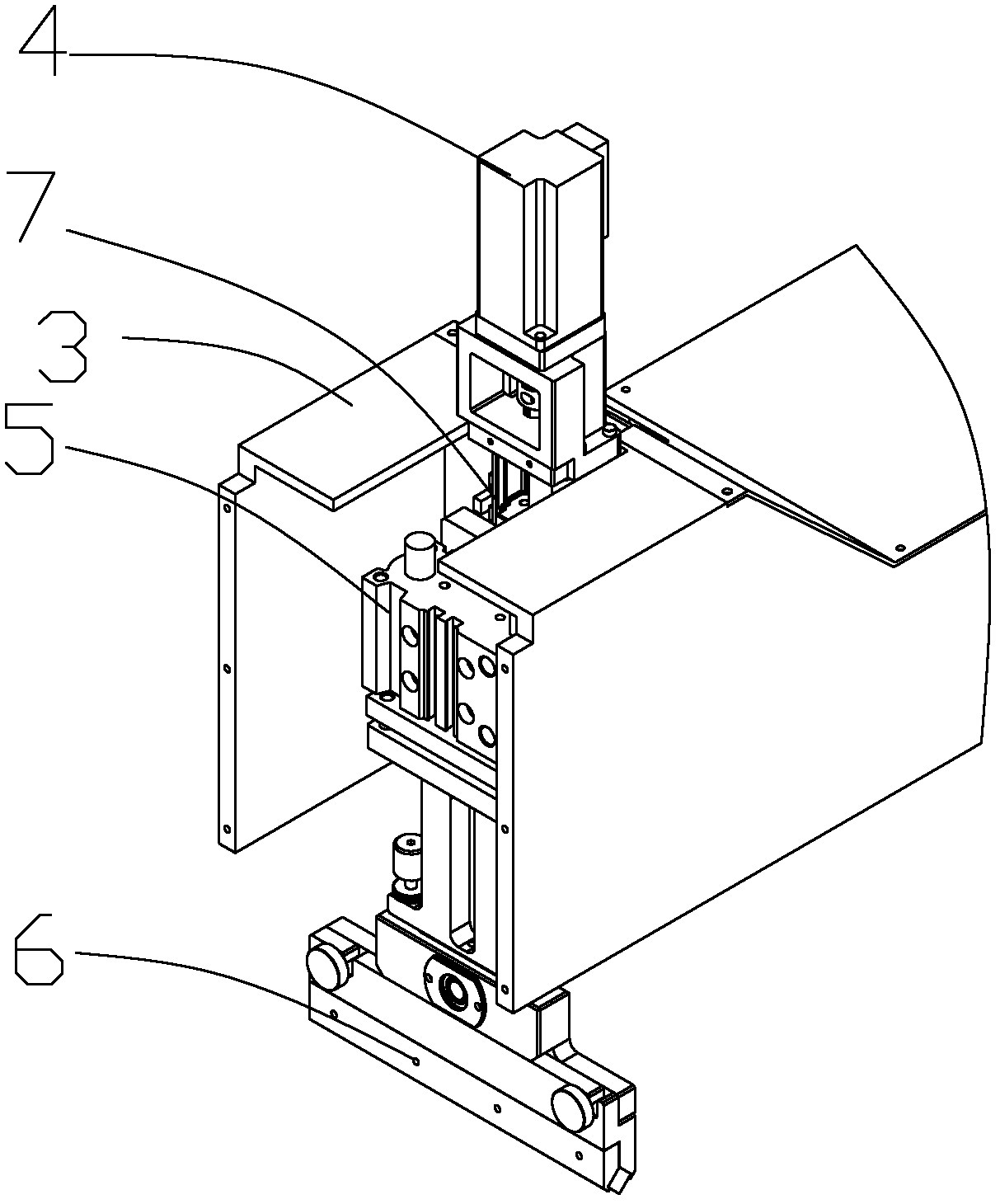

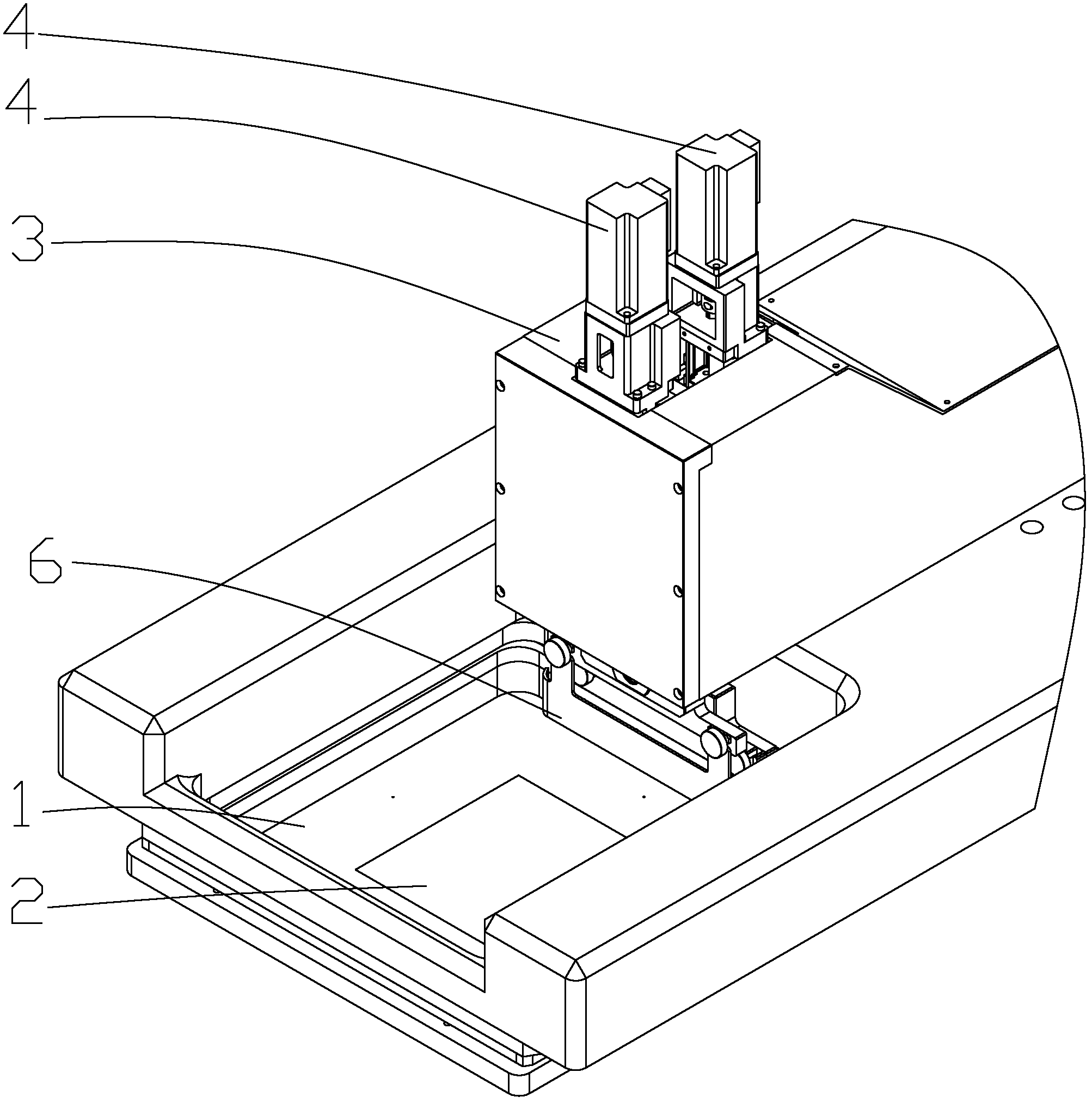

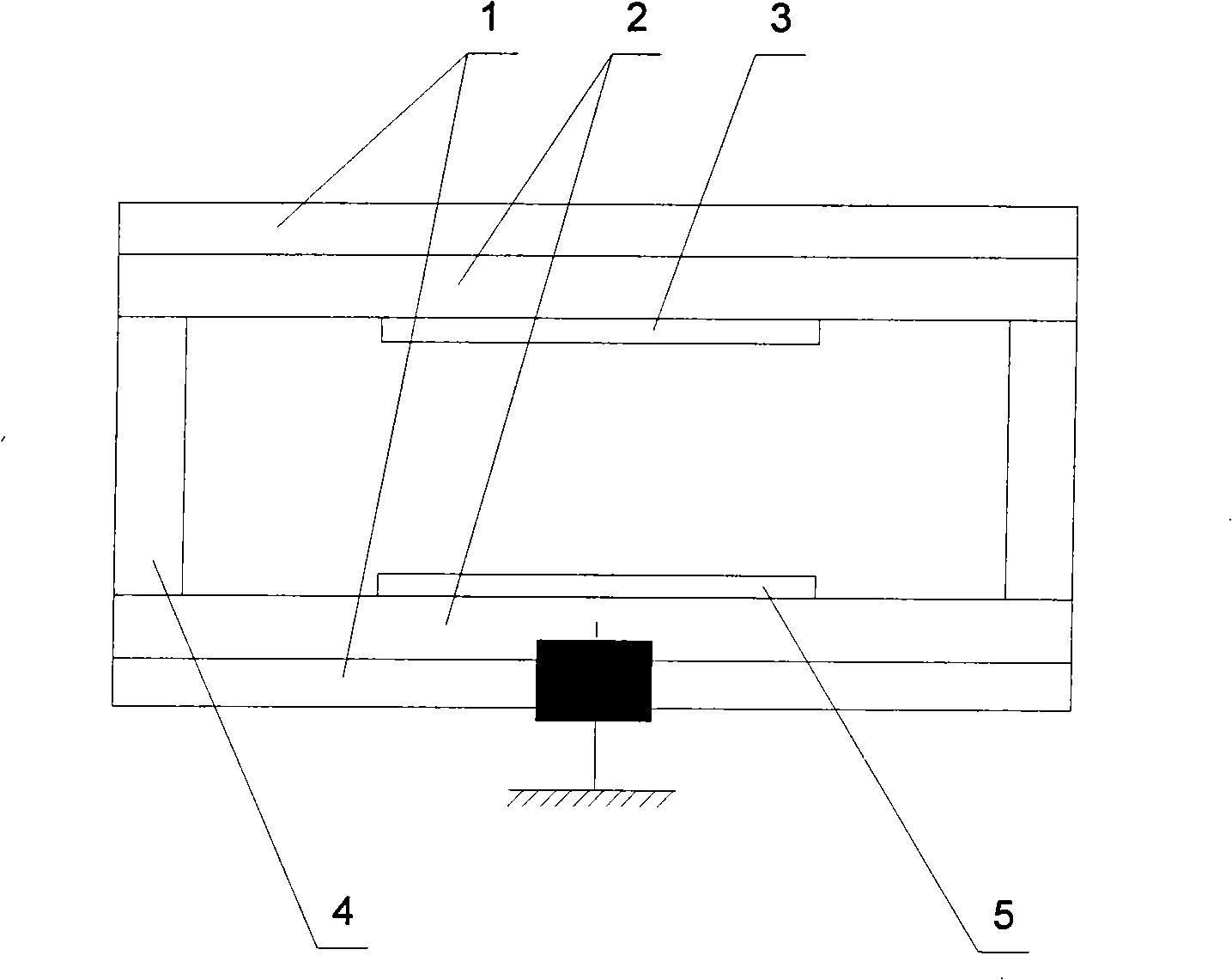

Circuit board printing machine

The invention relates to a circuit board printing machine which comprises a rack provided with a workbench. A scraper assembly which moves relative to the rack in the longitudinal direction and in the horizontal direction is arranged on the rack; the scraper assembly comprises a scraper rack; two scrapers including the first scraper and the second scraper are arranged on the scraper rack, and the back side of the first scraper and the back side of the second scraper are attached to each other; the two sides of the scraper rack are provided with a first driving mechanism used for driving the first scraper to move relative to the second scraper in the longitudinal direction; a second driving mechanism used for driving the scrapers to move in the longitudinal direction and in the horizontal direction is arranged on the rack. According to the circuit board printing machine, the first scraper and the second scraper are arranged, the back side of the first scraper and the back side of the second scraper are attached to each other, and the first scraper is made to move relative to the second scraper in the longitudinal direction, and accordingly solder paste or red glue adhering to the second scraper can be scraped off through the first scraper, the solder paste or the red glue is prevented from adhering to a printed circuit board when the scrapers retract, the circuit board is printed uniformly, and therefore the welding effect of components and parts is guaranteed.

Owner:SUZHOU ENOUXI INTELLIGENT TECH CO LTD

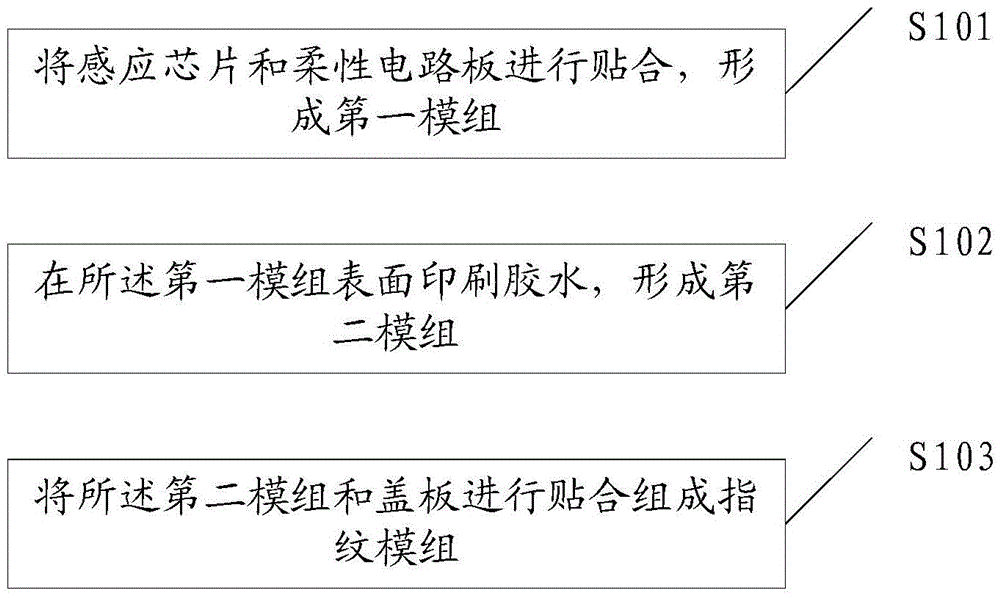

Fingerprint module manufacturing method

InactiveCN105678227AWon't spillUniform printingCharacter and pattern recognitionInput/output processes for data processingScreen printingFlexible circuits

The invention relates to the technical field, and specifically relates to a fingerprint module manufacturing method. The fingerprint module manufacturing method includes the steps: attaching an induction chip to a flexible printed circuit board so that a first module is formed; printing glue on the surface of the first module to form a second module; and attaching the second module to a cover plate to form a fingerprint module. During the process of the fingerprint module manufacturing method, a screen printing plate with hollow areas is introduced so that the glue is not overflowed and the glue can be uniformly printed on the induction chip when the glue is printed.

Owner:TOP TOUCH ELECTRONICS

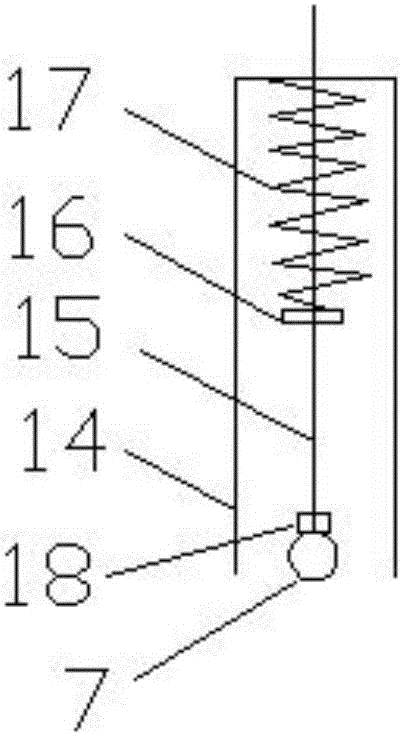

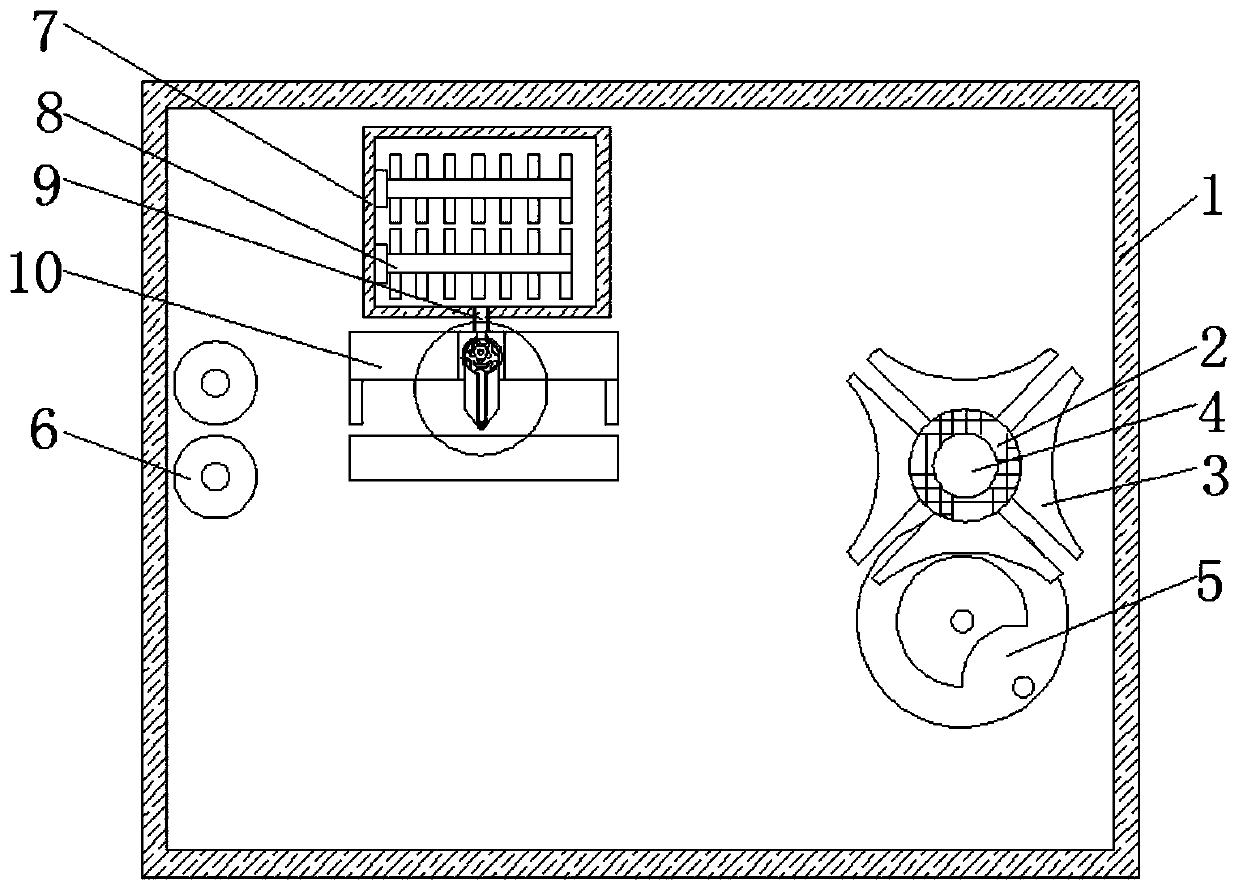

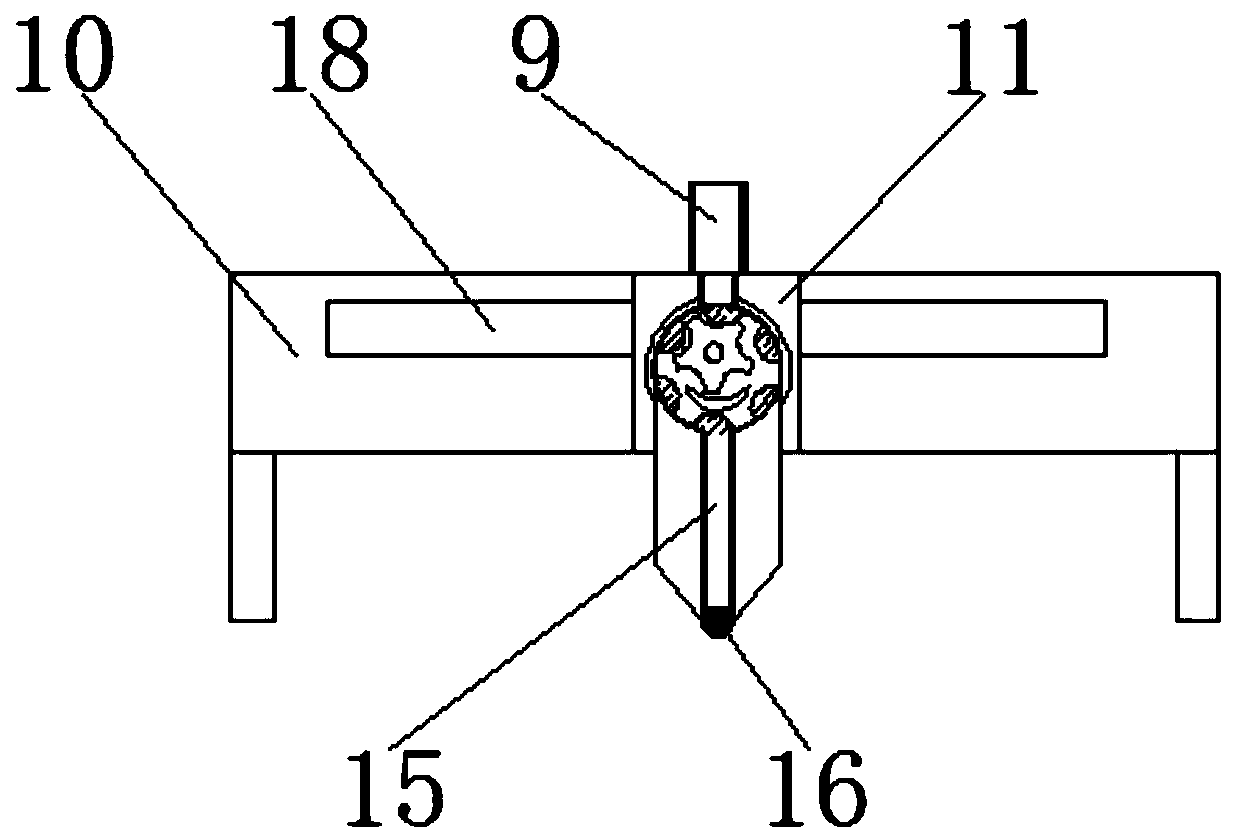

Double-mode printing device for solar cells

The invention discloses a double-mode printing device for solar cells, which comprises a pressure cylinder. A cylinder body of the pressure cylinder is fixed to a nut, a retractable rod of the pressure cylinder is downwards vertically disposed, and a scraper capable of realizing screen printing for electrodes of the silicon cells is arranged on the retractable rod. In a pressure printing mode, the retractable rod of the pressure cylinder can be compressed, the pressure cylinder is driven by a motor to downwards move to a specified working position, the scraper can be stopped by a printing screen when moving downwards, upward acting force is exerted on the retractable rod of the cylinder, when the acting force is higher than stretching force of the cylinder, the retractable rod of the cylinder is compressed, accordingly, when a printing tabletop is uneven, force exerted on the screen by the scraper is constant due to expansion and retraction of the retractable rod of the pressure cylinder, uniform printing is guaranteed, and the pressure printing mode is convenient to control.

Owner:SUZHOU MAXWELL TECH CO LTD

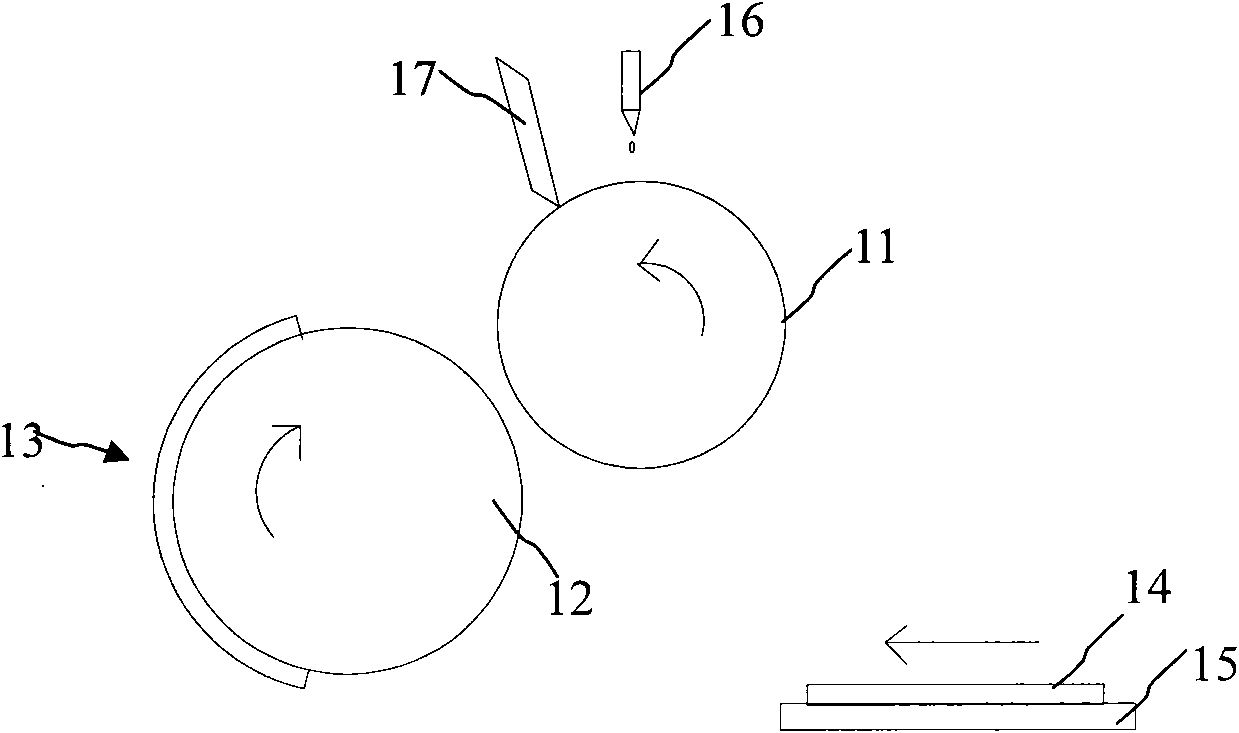

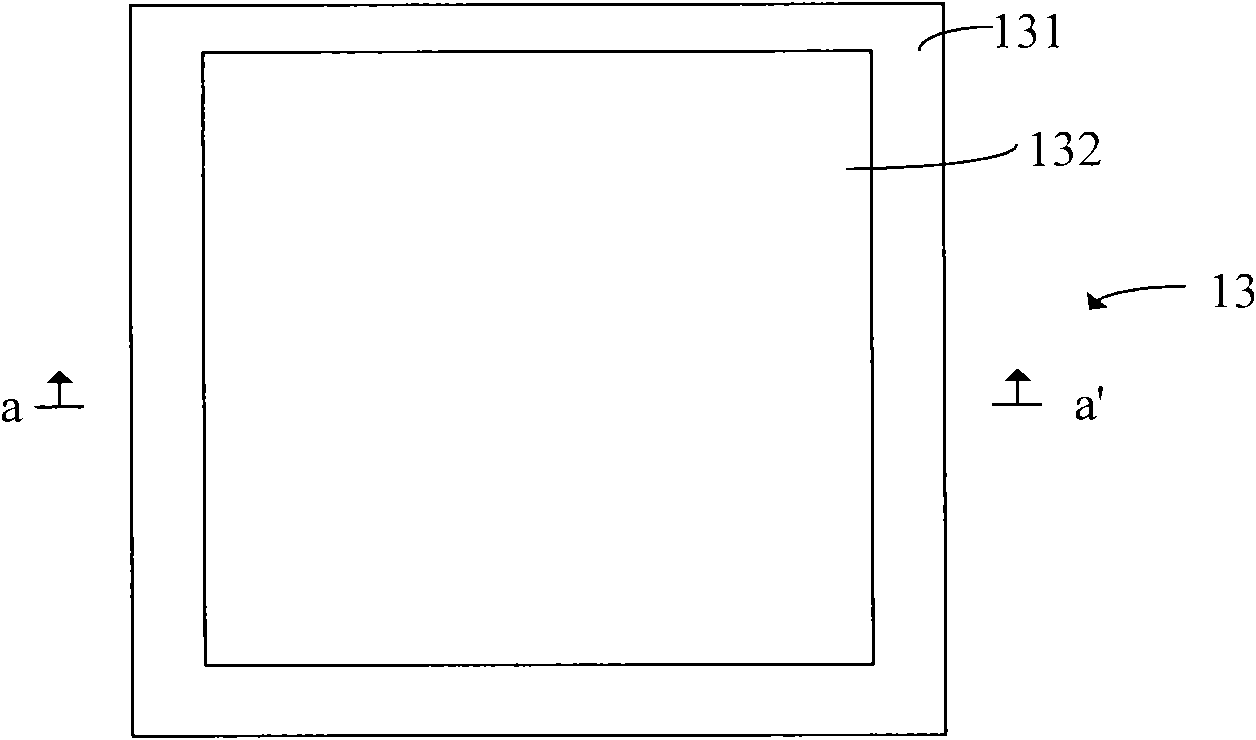

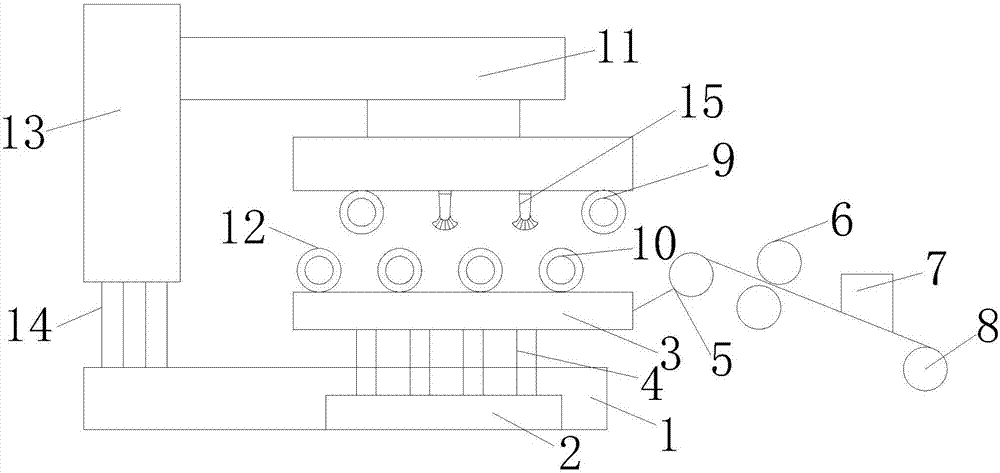

Preparation method of asymmetric plate ceramic nanofiltration membrane

PendingCN108079788ASolve for uniformitySolve the requestReverse osmosisCeramicwareWater basedEmulsion

The invention discloses a preparation method of an asymmetric plate ceramic nanofiltration membrane. According to the method, ceramic powder with different chemical composition and granular sizes is mixed with a water-based auxiliary, ceramic membrane slurry is prepared and printed on a plate ceramic membrane support body by a special porous emulsion roller, the support body is sintered at different temperatures, and the asymmetric plate ceramic nanofiltration membrane with different chemical composition and pore structures is formed on the surface of the support body. Density, diameter and depth of slurry adsorbing holes in the porous emulsion roller can be adjusted effectively with a laser drilling technology, so that thickness and uniformity of the ceramic membrane can be controlled precisely. The ceramic membrane with different thicknesses and surface pore size being 5-100 nm can be obtained with adoption of the porous emulsion roller with different pore density, pore diameter andpore depth. The asymmetric plate ceramic nanofiltration membrane is low in filtering resistance, high in filtering reflux, long in service life, energy-saving and environmentally friendly, and preparation cost is low.

Owner:肖汉宁

Sizing agent combination

ActiveCN104141248AImprove wrinkle resistanceColor depthDyeing processAgent CombinationPulp and paper industry

The invention discloses a sizing agent combination which comprises, by weight, 1-3 parts of thickener, 0.5-1.5 parts of crease-resistant agent, 2-4 parts of potato oxidized starch, 0.2-0.5 part of antifoaming agent, 0.5-1 part of leveling agent and 90-95 parts of water. By means of the synergistic effect of all the constituents, the water retention capacity and viscosity of the sizing agent combination are improved, and the dyeing effect of dye-based ink is good. Fabric subjected to digital printing by means of the sizing agent combination can be colored deeper and brighter, the color design is clear, and stain bleeding is avoided. Due to the adoption of the crease-resistant agent, the crease resistance of silk and wool blended fabric is improved greatly, the finishing process conducted after the silk and wool blended fabric is printed is omitted, and energy is saved. Due to the adoption of the antifoaming agent, even sizing is achieved by means of the sizing agent combination, no foam is generated, and the printing effect is improved.

Owner:佛山市三水嘉骏纺织染有限公司

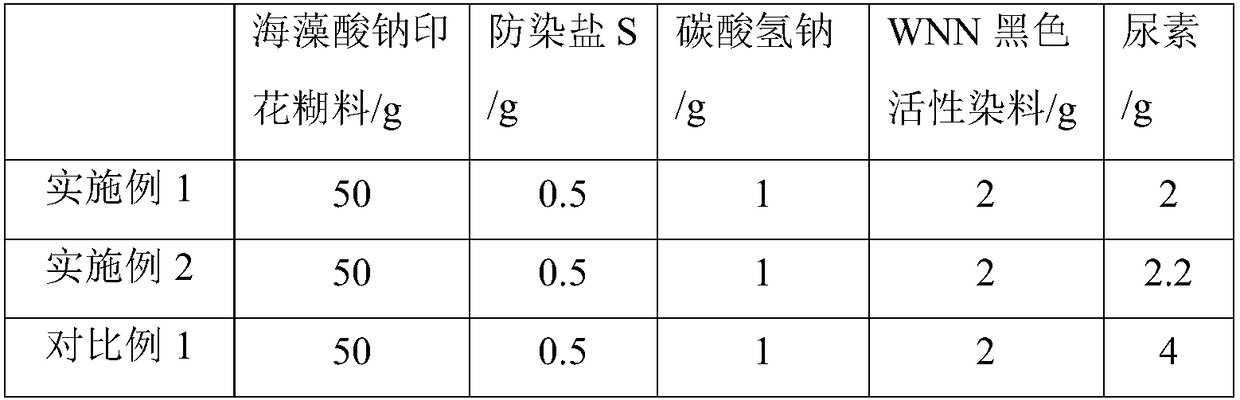

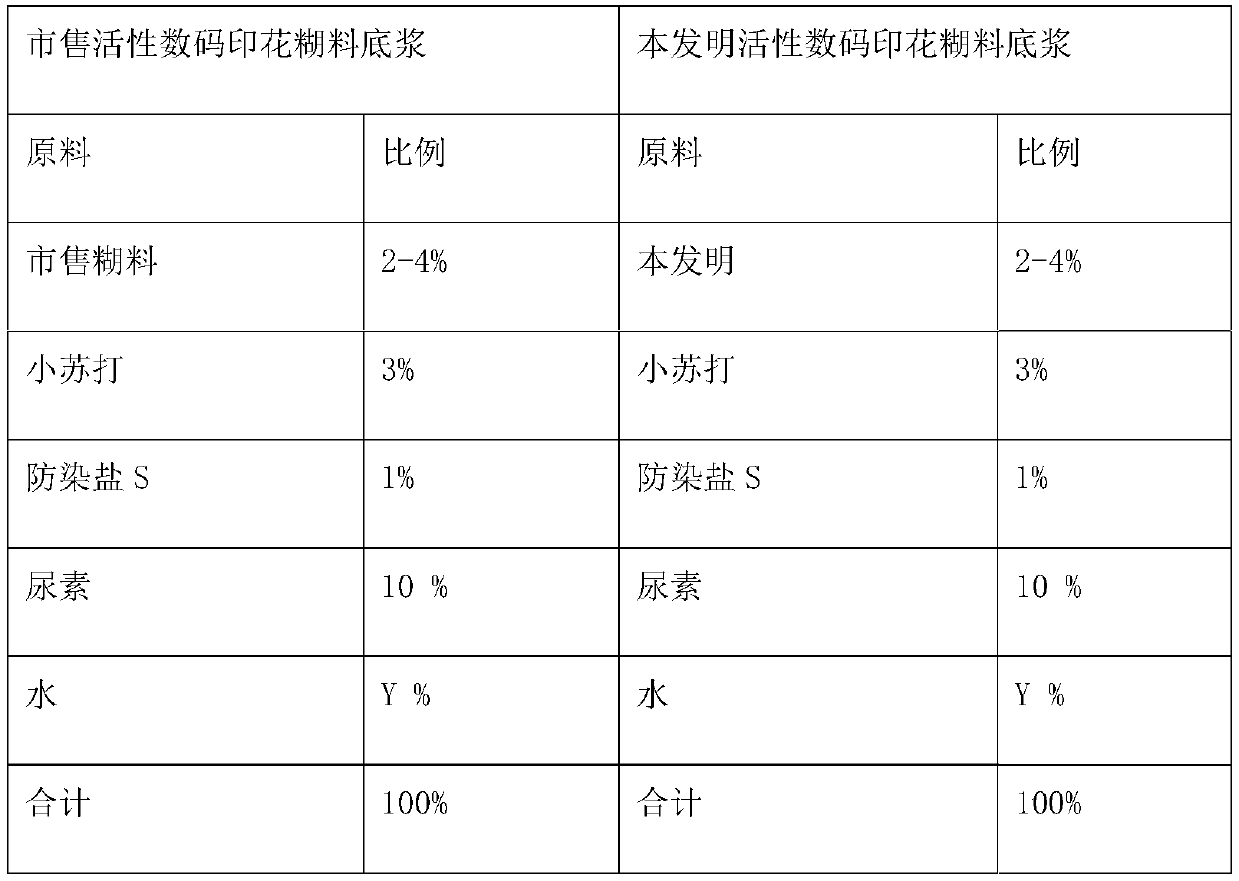

Sodium alginate, and preparation method and application of sodium alginate

The invention discloses sodium alginate, and a preparation method and an application of sodium alginate. The preparation method of sodium alginate comprises the steps of adding sorbitol after a neutralization procedure, and performing mixing, granulation, drying and grinding to form a final product. Prepared sodium alginate has the advantages of good appearance, high rheological property and the like; a preparation technology is simple and easy to implement and popularize; a PVI (polyvinyl isobutyl ether) value of printing paste of sodium alginate is 0.65-0.73; defects such as blade streaks and mesh clogging during printing can be effectively reduced; a formula of the printing paste of sodium alginate comprises sorbitol; fixation between a dye and a fabric can be promoted; the fabric is dyed uniformly; the color yield and fastness of the printing are increased, so that the consumption of urea in the printing can be reduced; the rheological property of sodium alginate can also be improved; the generation of the printing defects is reduced; the printing of the fabric is uniform; a color is bright; and a pattern is clear.

Owner:QINGDAO BRIGHT MOON SEAWEED GROUP

Connecting material for cold transfer printing paper and preparation

ActiveUS7989039B2Increase transfer rateEfficient receptionPattern printingAblative recordingEngineeringAcrylic coating

A connecting material for cold transfer printing paper is provided and includes an acrylic coating agent composition as an isolating layer and an acrylic coating agent composition as an ink-receiving layer. Also provided is a method for preparing the connecting material for cold transfer printing paper, a cold transfer printing paper and a method for printing a pattern or letter on a fabric by using the cold transfer printing paper.

Owner:NEWTECH TEXTILE TECH DEV SHANGHAI

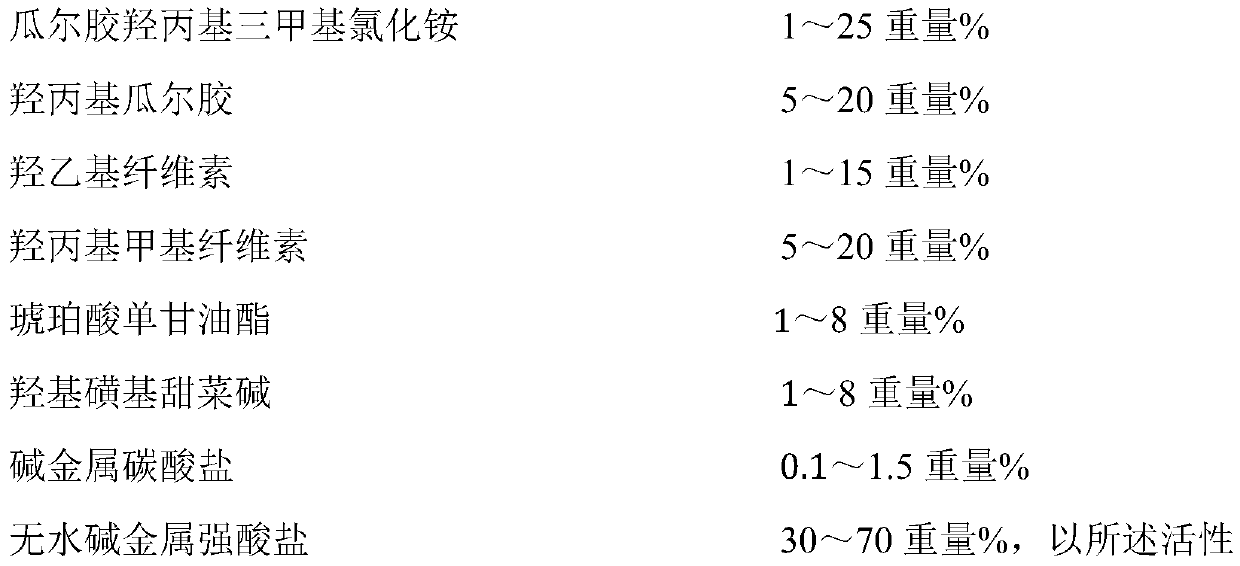

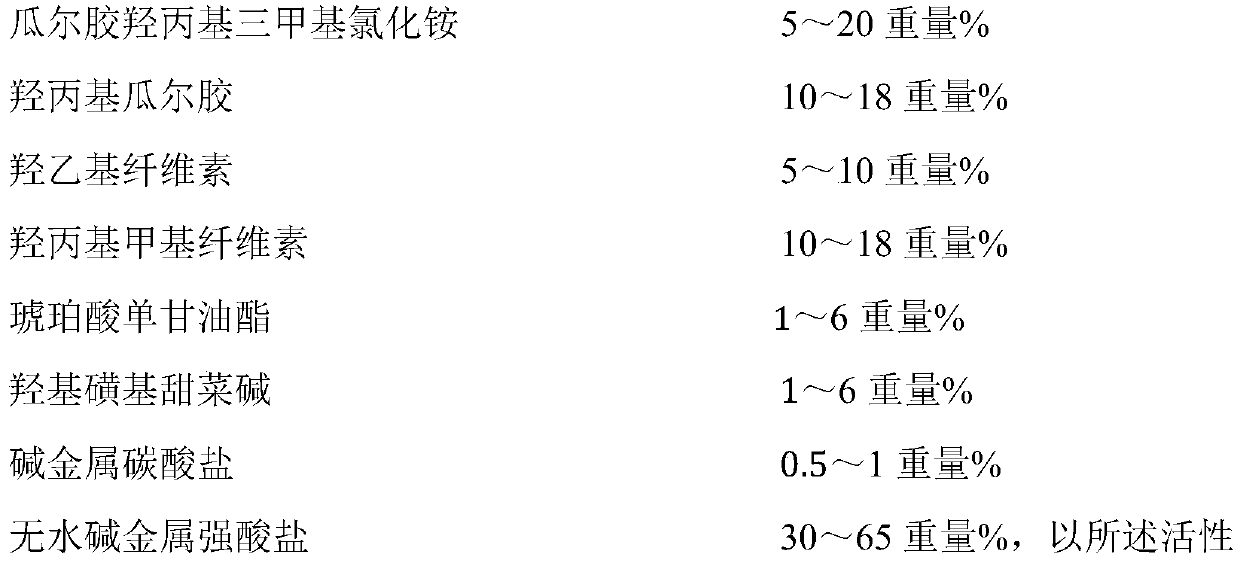

Active digital printing paste composition and preparation method thereof

The invention discloses an active digital printing paste composition and a preparation method thereof. The active digital printing paste comprises the following components: 1-25% by weight of guar hydroxypropyltrimethylammonium chloride, 5-20% by weight of hydroxypropyl guar, 1-15% by weight of hydroxyethyl cellulose, 5-20% by weight of hydroxypropyl methylcellulose, 1-8% by weight of monoglyceride succinate, 1-8% by weight of hydroxysultaine, 0.1-1.5% by weight of alkali metal carbonate and 30-70% by weight of anhydrous alkali metal strong acid salt, based on the total weight of active digital printing paste. The active digital printing paste composition has the characteristics of high color yield, soft hand feeling, uniform printing, high definition and the like, and has excellent comprehensive performance of active digital printing.

Owner:TAICANG BAONI IND CO LTD

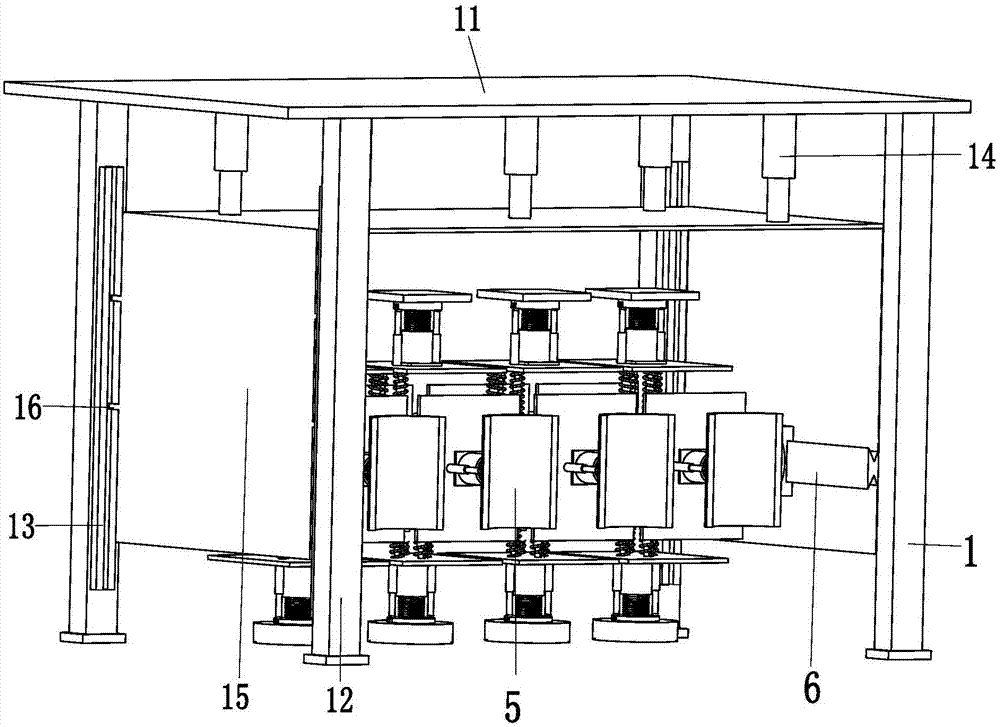

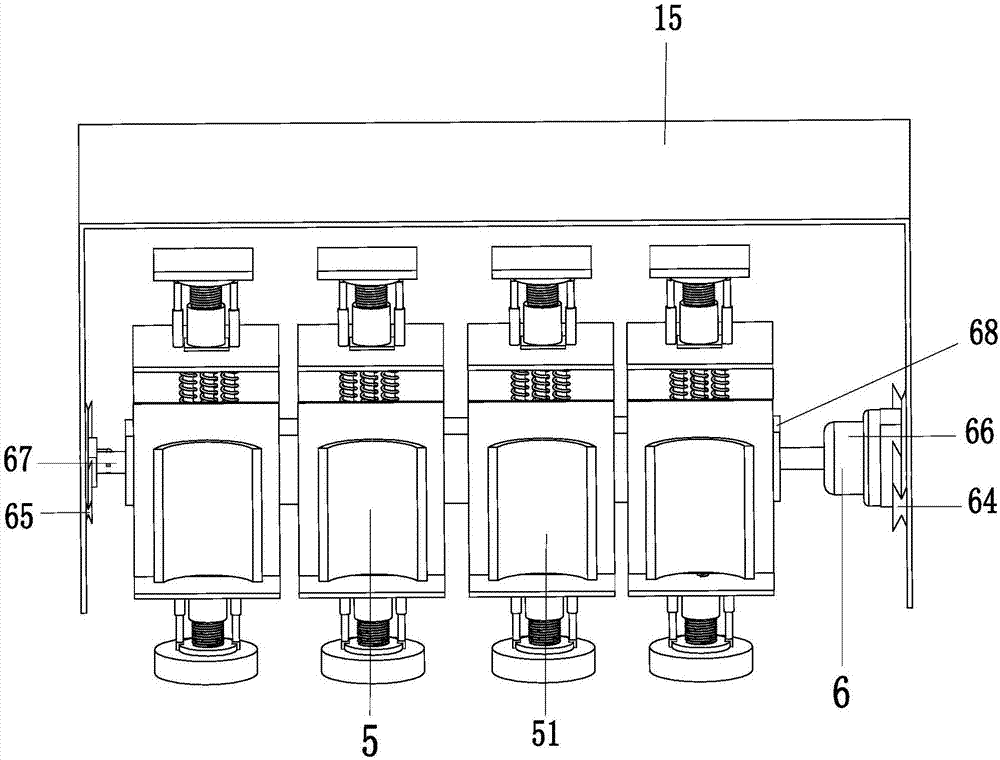

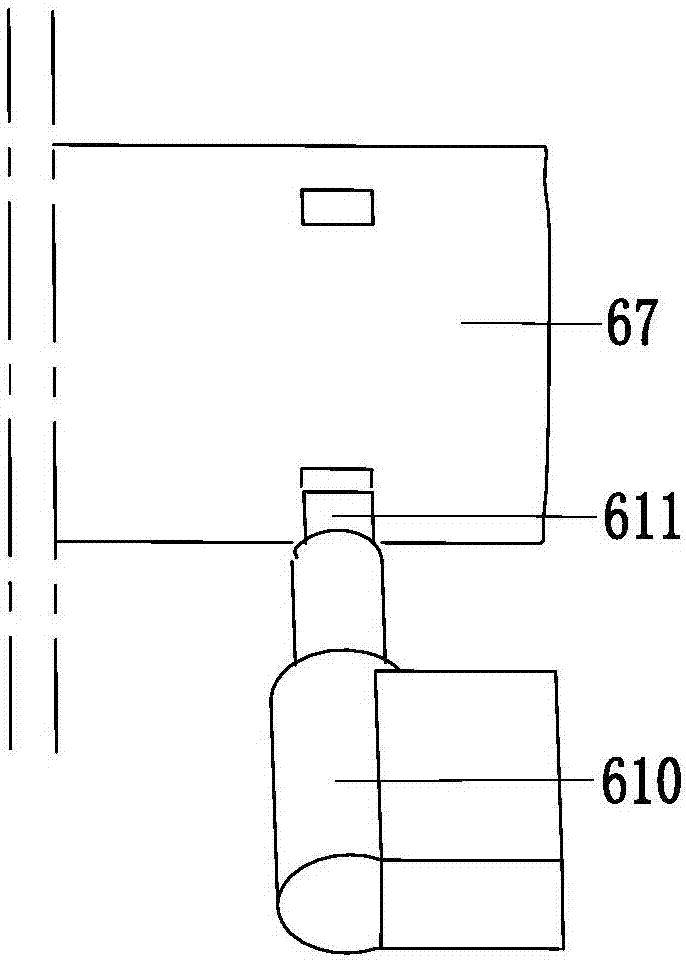

Accurate positioning type domestic ceramic unerring automatic printing equipment

InactiveCN107344449AUniform printingFast printRotary pressesOther printing apparatusComputer engineering

The invention relates to a precise positioning type daily-use ceramic non-deviation automatic printing equipment, comprising a supporting device, four printing devices and a rotating device, the rotating device is installed on the supporting device, and the four printing devices are symmetrically installed on the rotating device The supporting device includes a supporting top plate, four supporting columns, a supporting chute, five lifting electric push rods, a lifting frame and two supporting sliding rods, and the four supporting columns are symmetrically installed on the lower end surface of the supporting top plate, each A support chute is installed on the inner side of each support column. The present invention can solve the existing problems of low work efficiency, high labor intensity, uneven printing, deviation of printing position, and the need to prepare various printing plates in the existing manual printing of ceramics; it realizes precise positioning of ceramics of different shapes, rapid The printing function has the advantages of high work efficiency, low labor intensity, mechanized uniform printing, precise positioning of printing through positioning blocks, automatic rotation and switching of printing plates, etc.

Owner:俞樑兵

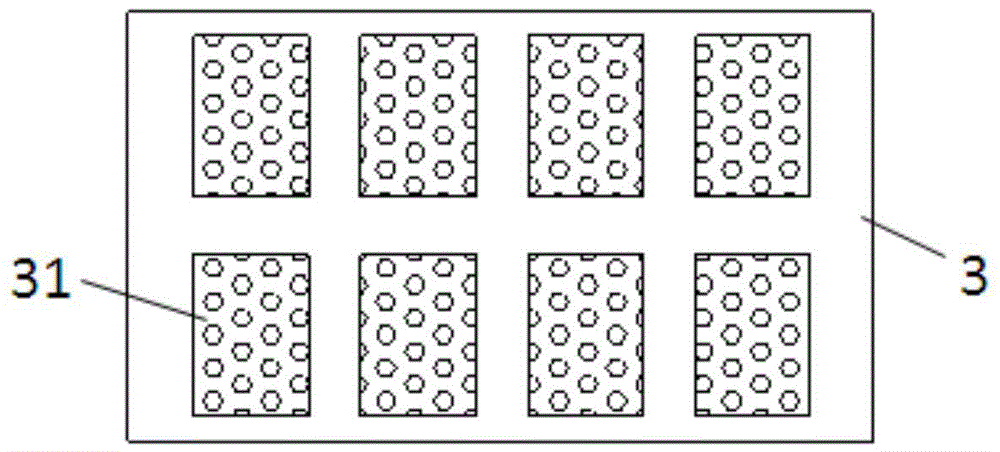

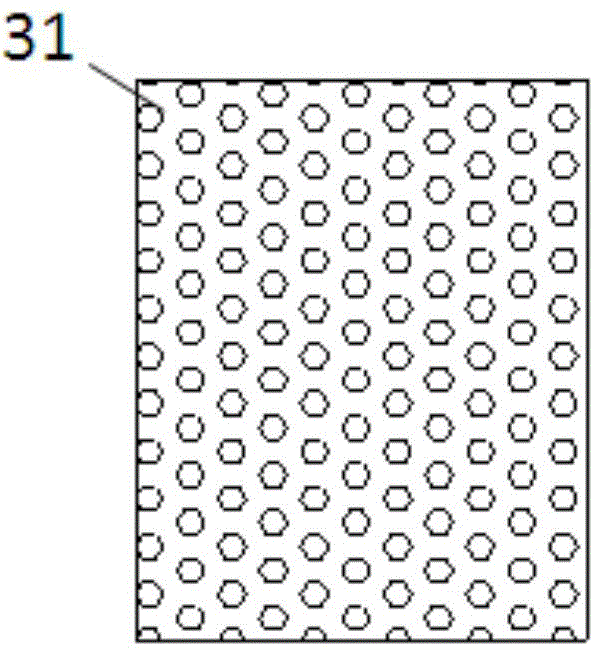

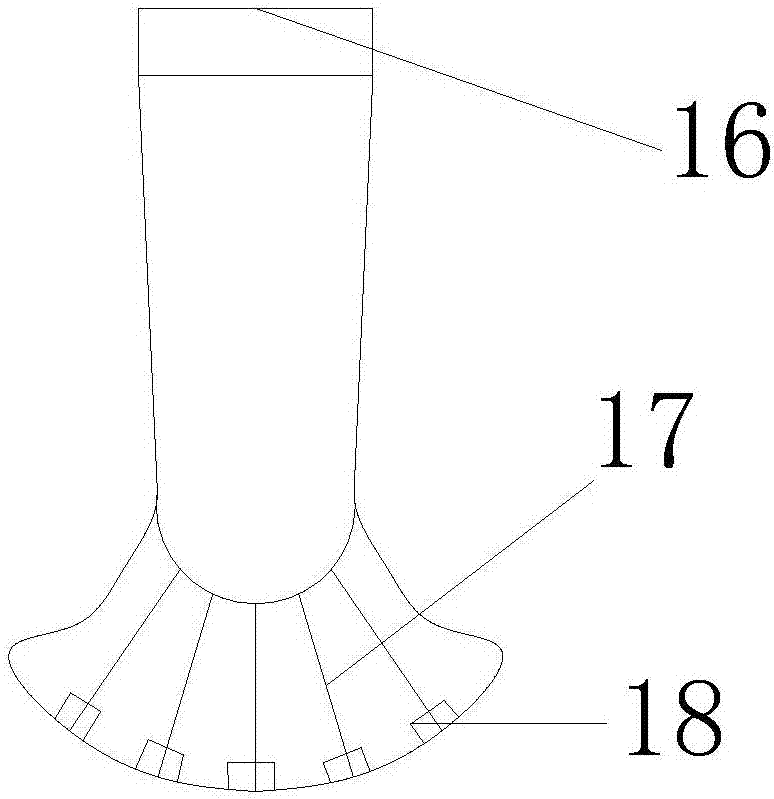

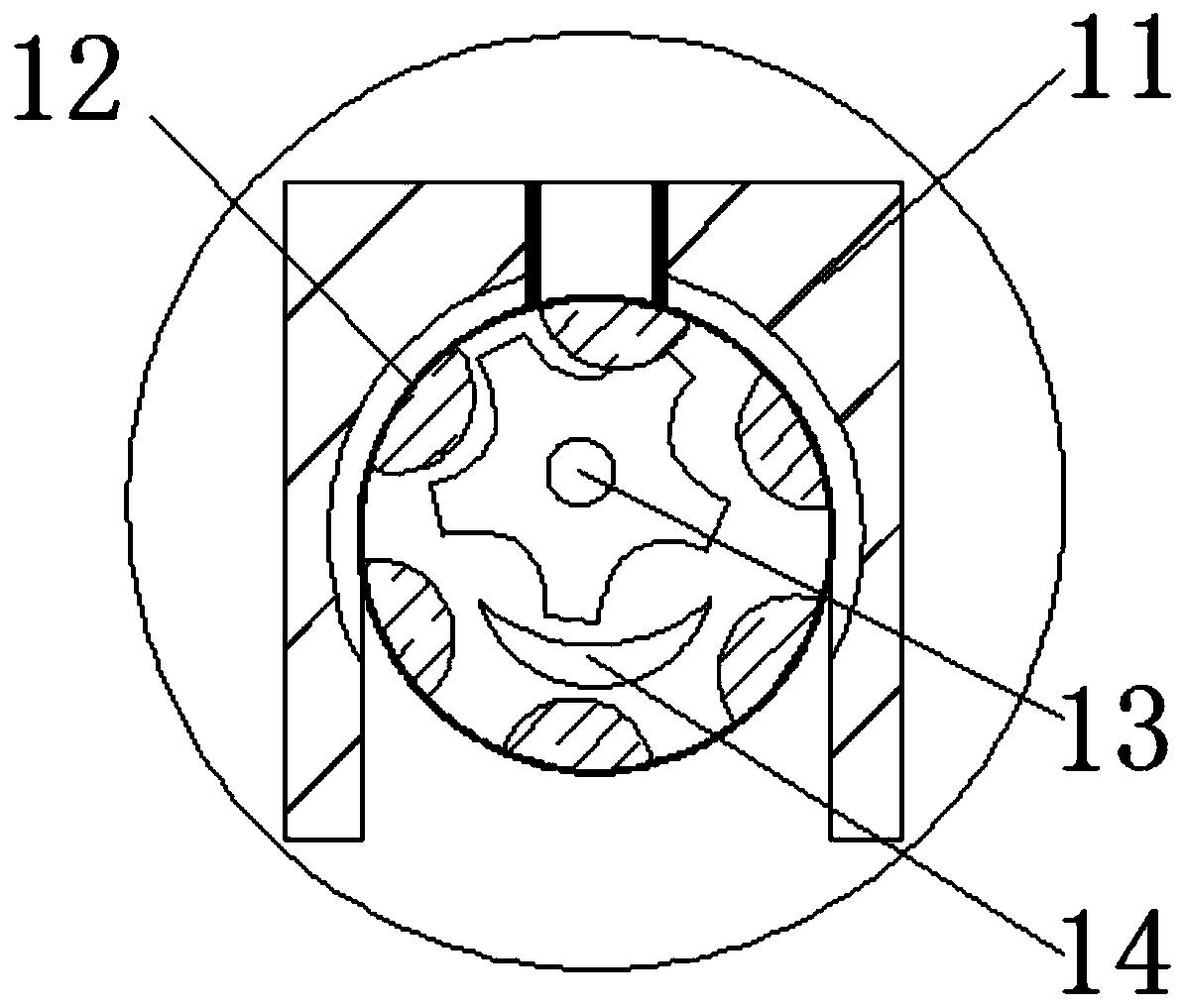

Printing relief block

InactiveCN104669772AUniform printingImprove display qualityRotary pressesEngineeringElectrical and Electronics engineering

The invention relates to the technical field of display, in particular to a printing relief block. The printing relief block comprises a plurality of valid printing areas which are arranged on the printing relief block, wherein an invalid printing area is arranged between every two adjacent valid printing areas; a pattern of a printing body in each valid printing area is quadrangular; a bump which extends outwards is arranged at each of the four top corners of the quadrangular printing body; a plurality of bump units are uniformly distributed on the printing body and bumps. According to the printing relief block provided by the invention, the bump which extends outwards is additionally arranged at each of the four top corners of the quadrangular printing body of an effective display area, an orienting material can be uniformly printed on a glass substrate, the phenomenon that poor corner displaying is caused due to the fact that an oriented film is baffled at a corner position by a metal circuit and cannot be diffused is avoided, and display quality is improved.

Owner:BOE TECH GRP CO LTD +1

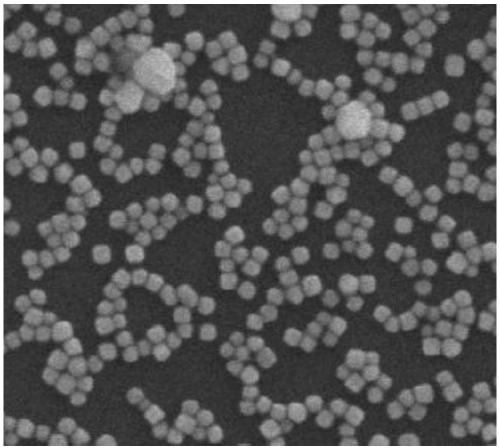

Cathode-ray tube having oxide cathode and method for producing same

InactiveCN1269053AHigh electron emissionUniform radiation distributionCathode ray tubes/electron beam tubesDischarge tube solid thermionic cathodesImage resolutionMetal substrate

It is an object to obtain a cathode ray tube having a high resolution without decreasing electron emission property. Surface of a cathode was leveled by heating during forming a vacuum in order to oxidize a carbonate salt to an oxide as an electron emissive material, after applying a paste for printing on a metal substrate by screen printing, drying the same, and incorporating an oxide cathode in a cathode ray tube, the paste having a mixture of needle-like particles of the first group and bulk particles of the second group incorporated as an alkaline earth metal carbonate forming an electron emissive material layer.

Owner:MITSUBISHI ELECTRIC CORP

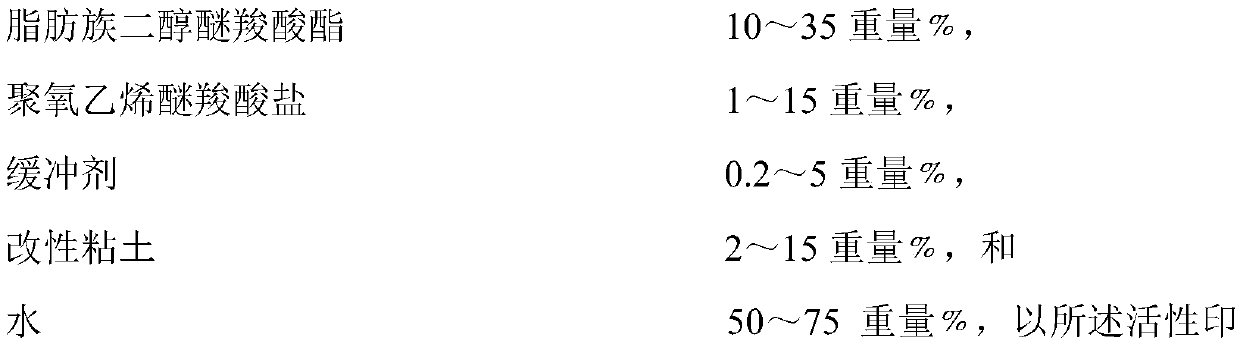

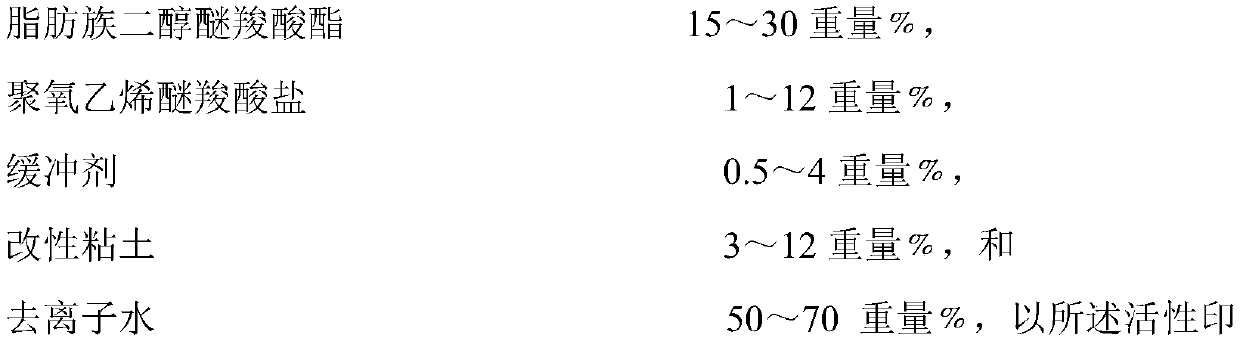

Reactive printing urea substitute and preparation method thereof

ActiveCN109594364ATo achieve printing effectHigh fixation rateDyeing processPolymer scienceCarboxylic salt

The invention discloses a reactive printing urea substitute and a preparation method thereof. Based on the total weight of the reactive printing urea substitute, the reactive printing urea substitutecomprises the following components in percentage by weight: 10 to 35 percent of aliphatic diol ether carboxylate, 1 to 15 percent of polyoxyethylene ether carboxylate, 0.2 to 5 percent of a bufferingagent, 2 to 15 percent of modified clay and 50 to 75 percent of water. The reactive printing urea substitute is high in printing depth and high in printing uniformity; the products do not comprise ammonia nitrogen.

Owner:TAICANG BAONI IND CO LTD

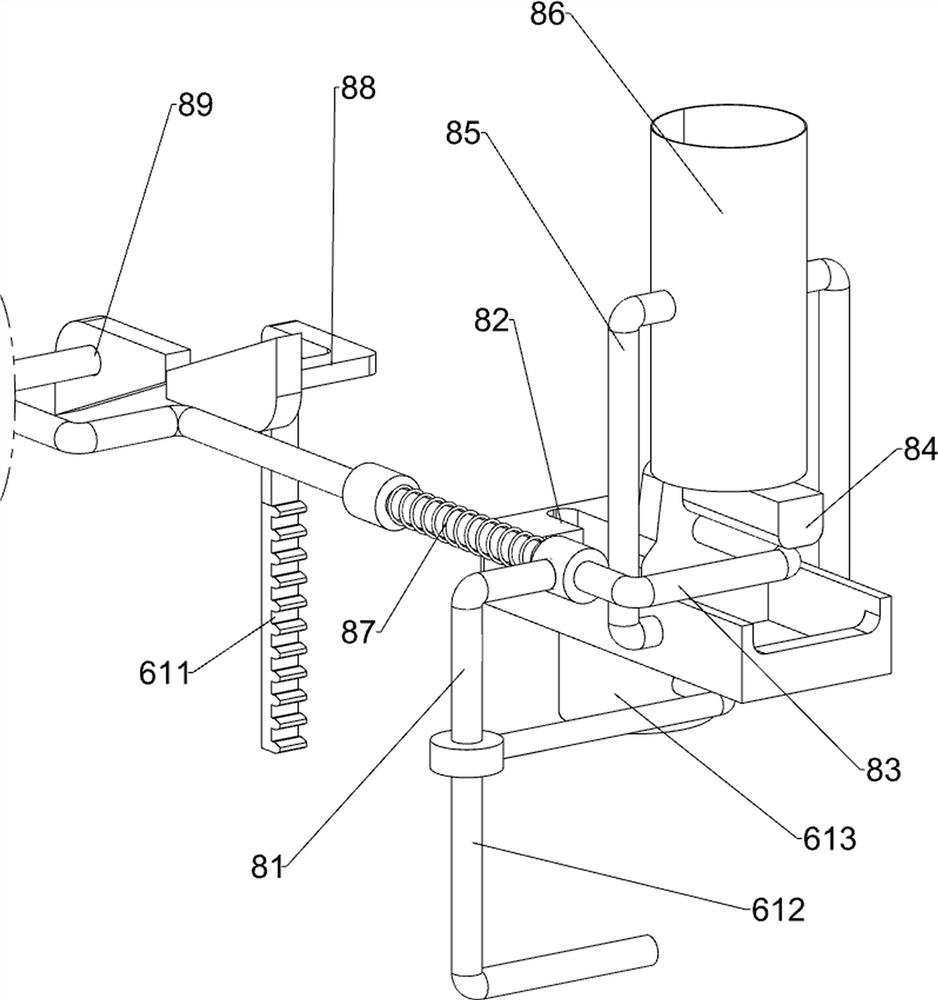

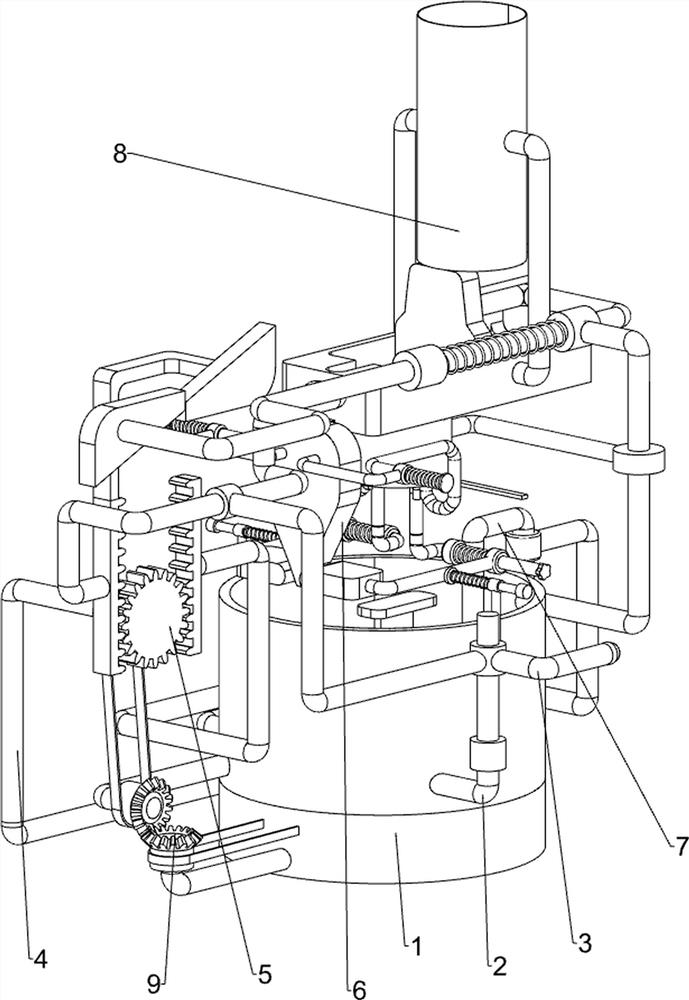

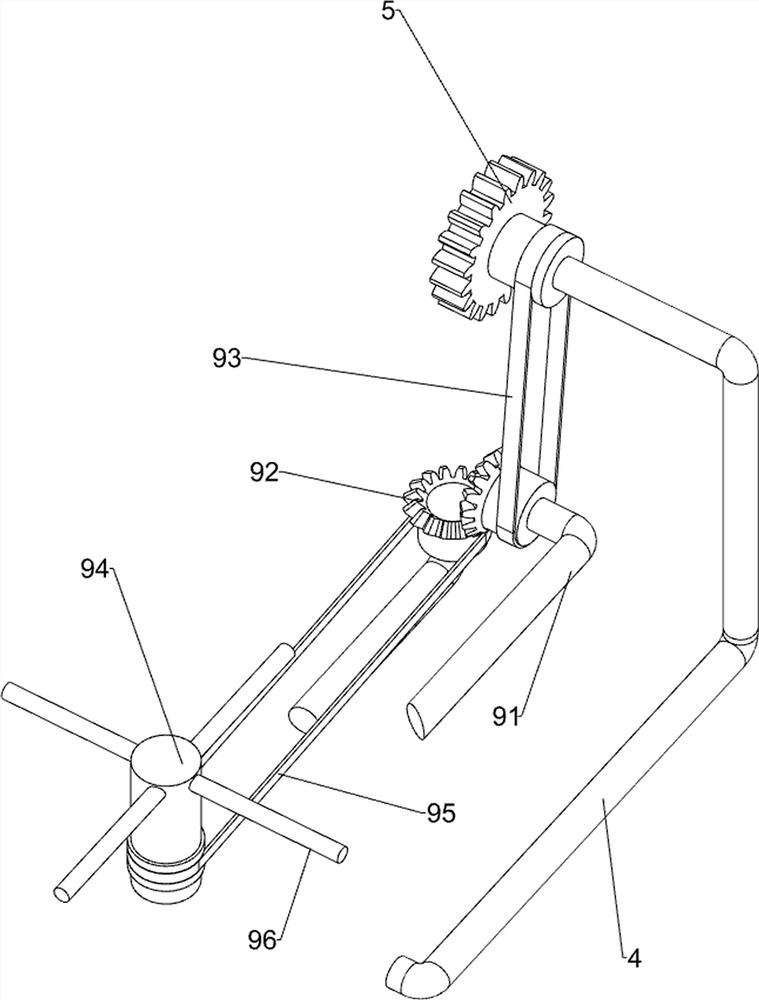

Dyeing device for mouth part of porcelain cup

InactiveCN112373183ARealize the purpose of automatic feedingEasy to useRotary pressesPrinting press partsEngineeringMechanical engineering

The invention relates to a dyeing device, in particular to a dyeing device for a mouth part of a porcelain cup. The invention provides a dyeing device for the mouth part of the porcelain cup, which can dye the mouth part of the porcelain cup automatically, and can stir pigments. The dyeing device for the mouth part of the porcelain cup comprises a supporting paint frame, a first fixed rod, a handle, a second fixed rod, a straight gear, a pressing feeding mechanism, and a discharging coating mechanism, wherein the first fixed rod is arranged on the supporting paint frame; the handle is arrangedon the first fixed rod in a sliding mode; the second fixed rod is arranged at one side of the supporting paint frame; one side of the second fixed rod is rotatably equipped with the straight gear; the pressing feeding mechanism is arranged on the supporting paint frame; and the discharging coating mechanism is arranged on the supporting paint frame. The discharging coating mechanism can be matched with the pressing feeding mechanism for pressing the porcelain cup and coloring the porcelain cup without manually coloring, so that dyeing of the porcelain cup is more uniform.

Owner:甘伟新

Portable manual curved-surface screen printing machine

The invention relates to a portable manual curved-surface screen printing machine, and belongs to the technical field of printing. The portable manual curved-surface screen printing machine mainly comprises a machine frame, a top frame, a rectangular frame, a screen printing plate and a scraping plate, wherein the top frame is located at the top of the machine frame and is in a U shape, and the two end points of a U-shaped opening are connected to a rotary shaft at the top end of the machine frame so that the U-shaped top frame can rotate around the rotary shaft; sliding guide rails are symmetrically mounted on the two sides of the U-shaped top frame, the rectangular frame is mounted in the sliding guide rails, and the rectangular frame can slide in the U-shaped top frame freely; the screen printing plate is fixed in the rectangular frame through fasteners; the two sides of a cross beam on the lower portion of the machine frame are each symmetrically provided with two bearings used for storing an article to be printed, and the article to be printed can rotate freely under the effect of friction force of the screen printing plate; and a positioning pointer is mounted on one supporting rod of the machine frame and points to the feature point of the article to be printed, and thus the initial printing position of the article to be printed is marked. The portable manual curved-surface screen printing machine is simple in structure, operation is flexible and convenient, the printing quality is good, the article to be printed can be printed and repaired on the using field, and batched printing can also be performed.

Owner:张昕宸

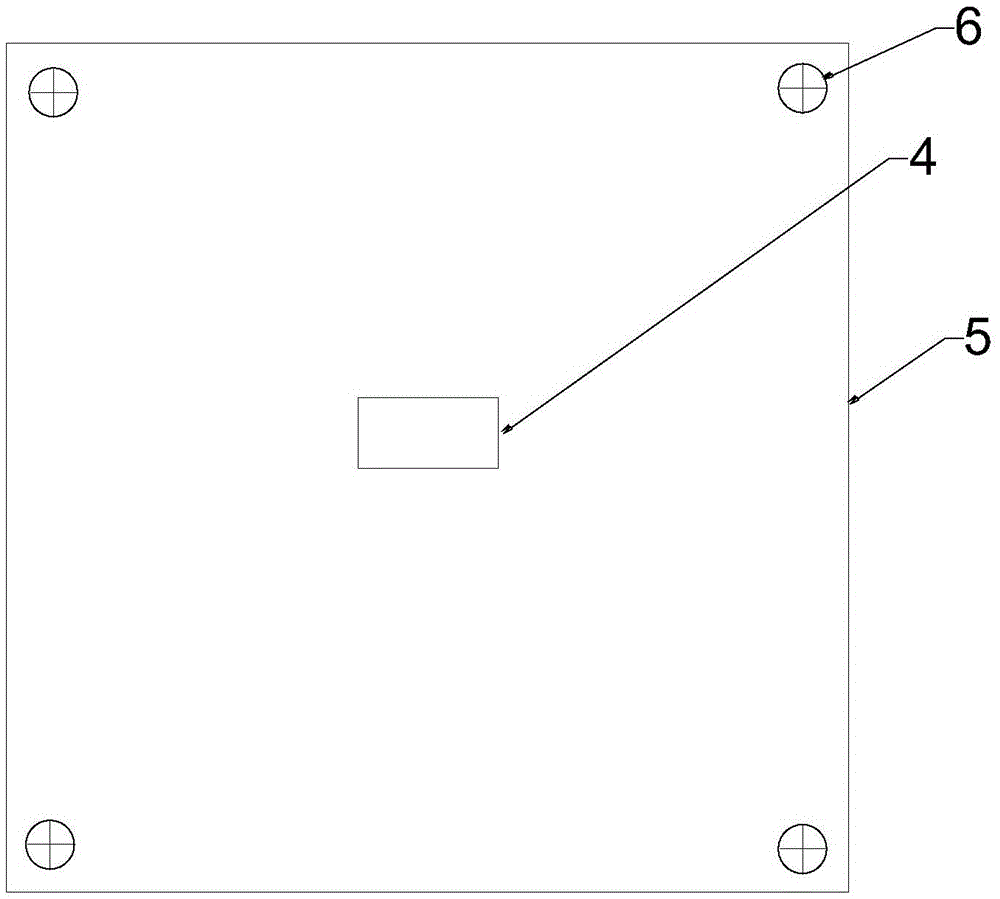

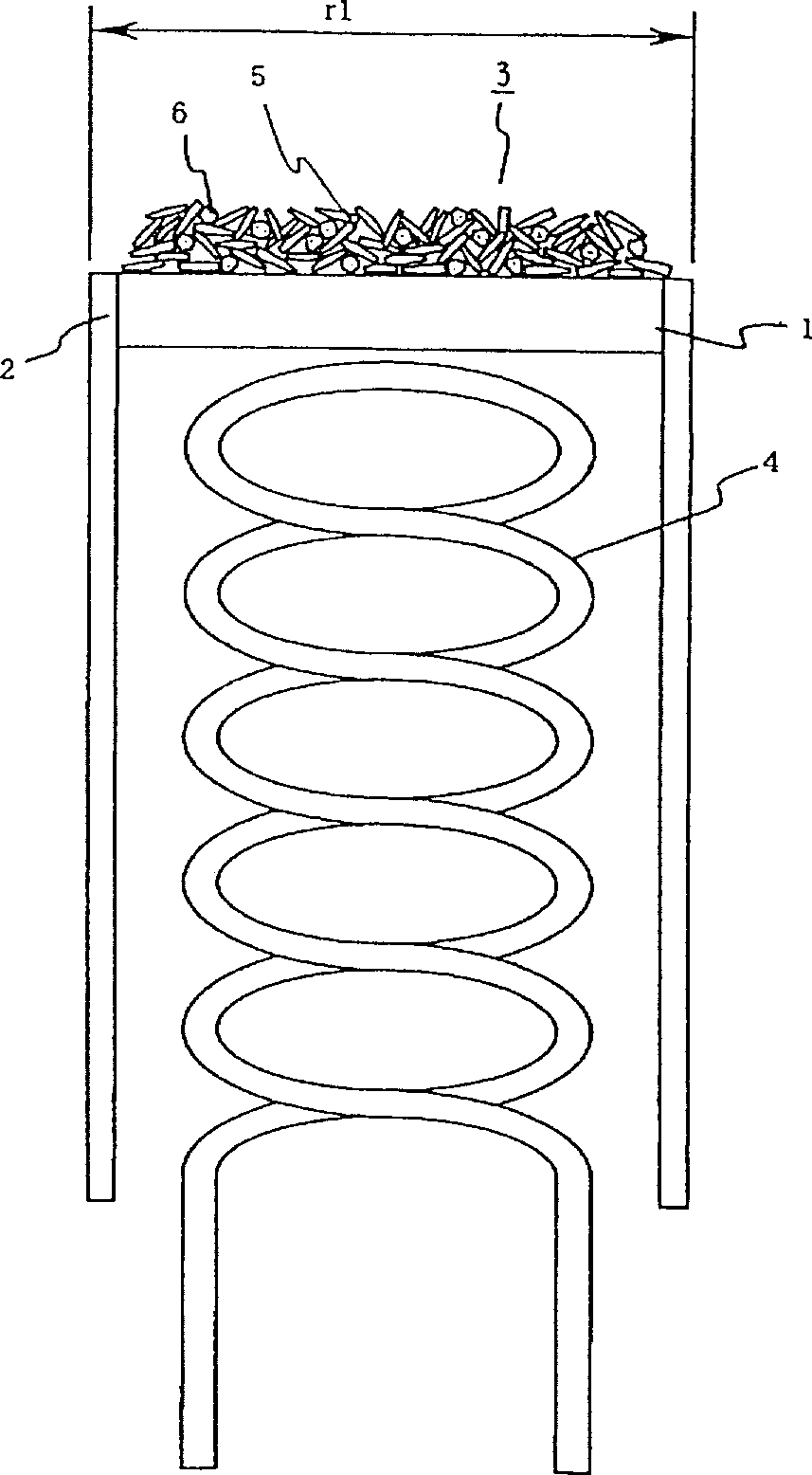

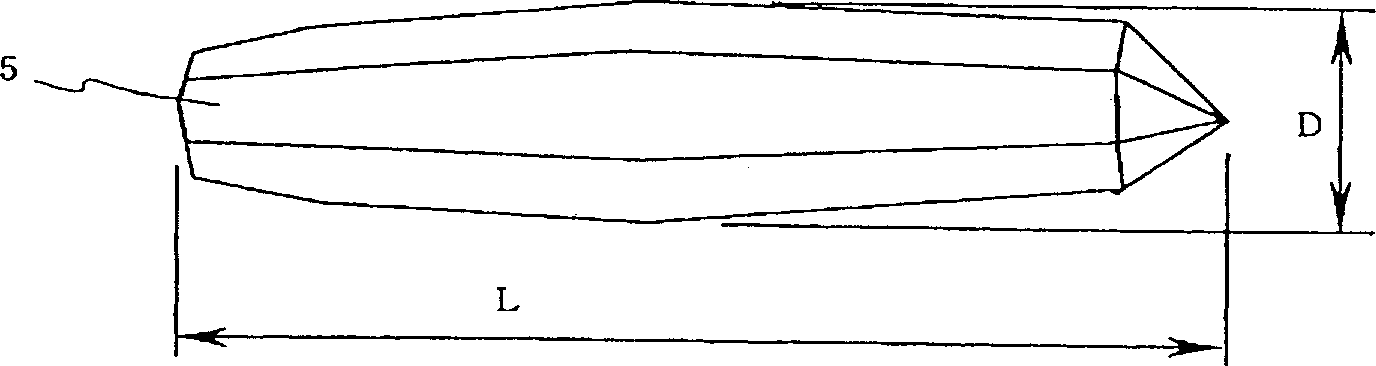

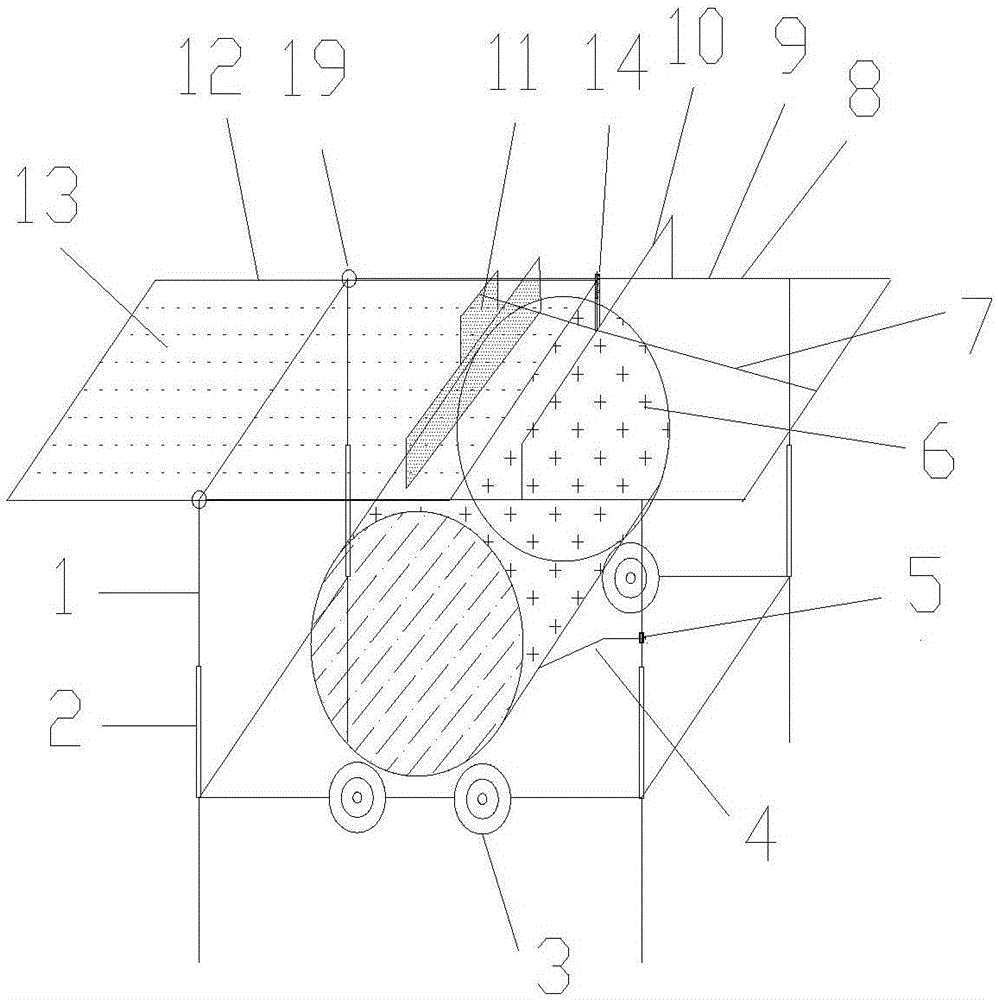

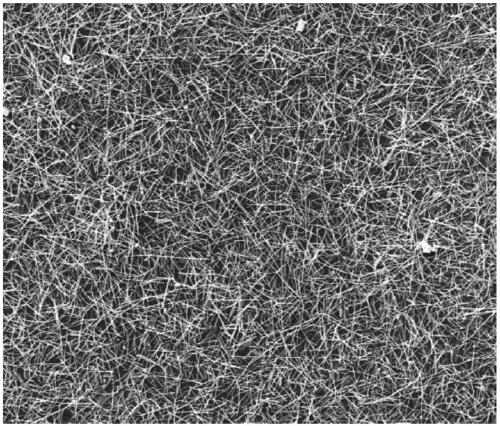

Method for nano ZnO film preparation by screen painting and luminous tubes using the film

InactiveCN101336019AUniform printingImprove featuresElectrical apparatusElectroluminescent light sourcesScreen printingField emission display

The invention relates to field emission display field, particularly a method of preparing a nm Zno film by silk-screen printing and a luminotron using the same, characterized by comprising: a. preparing ZnO paste; b. preparing the ZnO film by the silk-screen printing; c. hot sinter process after printing; d. annealing after burning and mechanical post processing. The luminotron using the film is characterized by including two parallel ITO conducting glasses (1), which is sealed, also an insulating column (4) is arranged between the two parallel ITO conducting glasses (1); a phosphor powder film (3) is on the inner surface of one ITO conducting glass (1), and a ZnO film (5) is on other glass. ITO layers of the two ITO conducting glasses (1) are respectively educed on the outside of the luminotron. The method of preparing the nm Zno film by the silk-screen printing has low cost, and the ZnO film is printed evenly with large area. The luminotron using the film is high in stability, long in service life and high in luminous efficiency.

Owner:BEIFANG UNIV OF NATITIES

Automatic cloth printing device with spraying devices

PendingCN107379753ASimple structureEasy to adjustRotary pressesPrinting press partsTextile printerEngineering

Owner:杭州依翰丝绸文化创意有限公司

Glass printing technology

InactiveCN104175733AImprove cleanlinessUniform printingOther printing apparatusProcess engineeringIndustrial engineering

The invention discloses a glass printing technology which includes the following steps: firstly, cleaning a piece of glass; then drying the cleaned glass; then fixing the dried glass on a fixture; then scouring the surface, to be subjected to printing treatment, of the glass on the fixture through a pneumatic nozzle; finally performing printing treatment on the scoured glass. According to the invention, the technical effects that the glass printing technology is reasonably designed, the rejection rate of printed products is lower, the production efficiency is higher and the production cost is reduced are realized.

Owner:成都派莱克科技有限公司

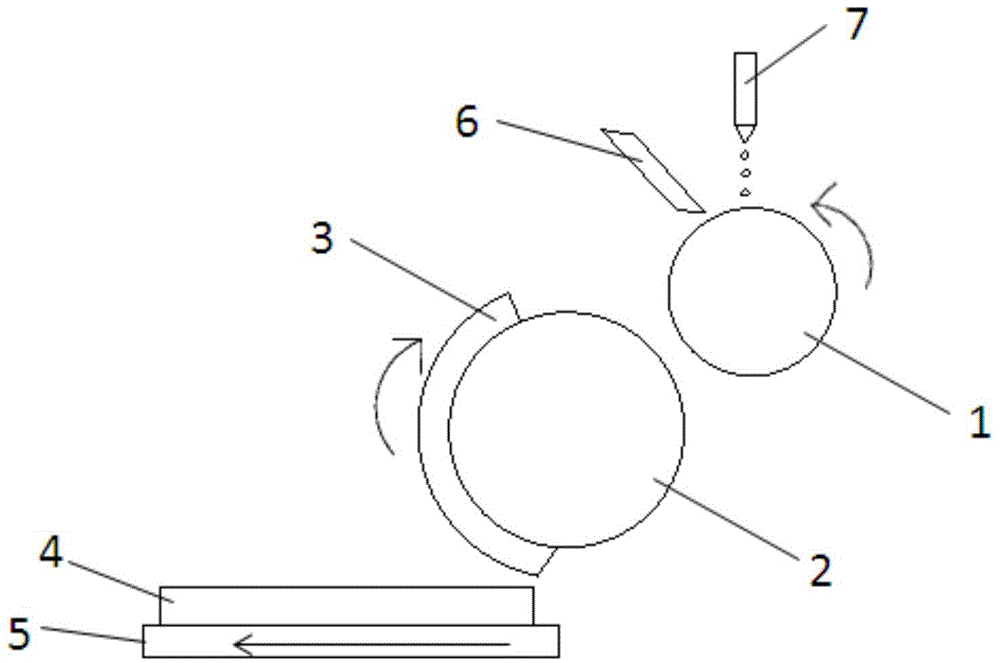

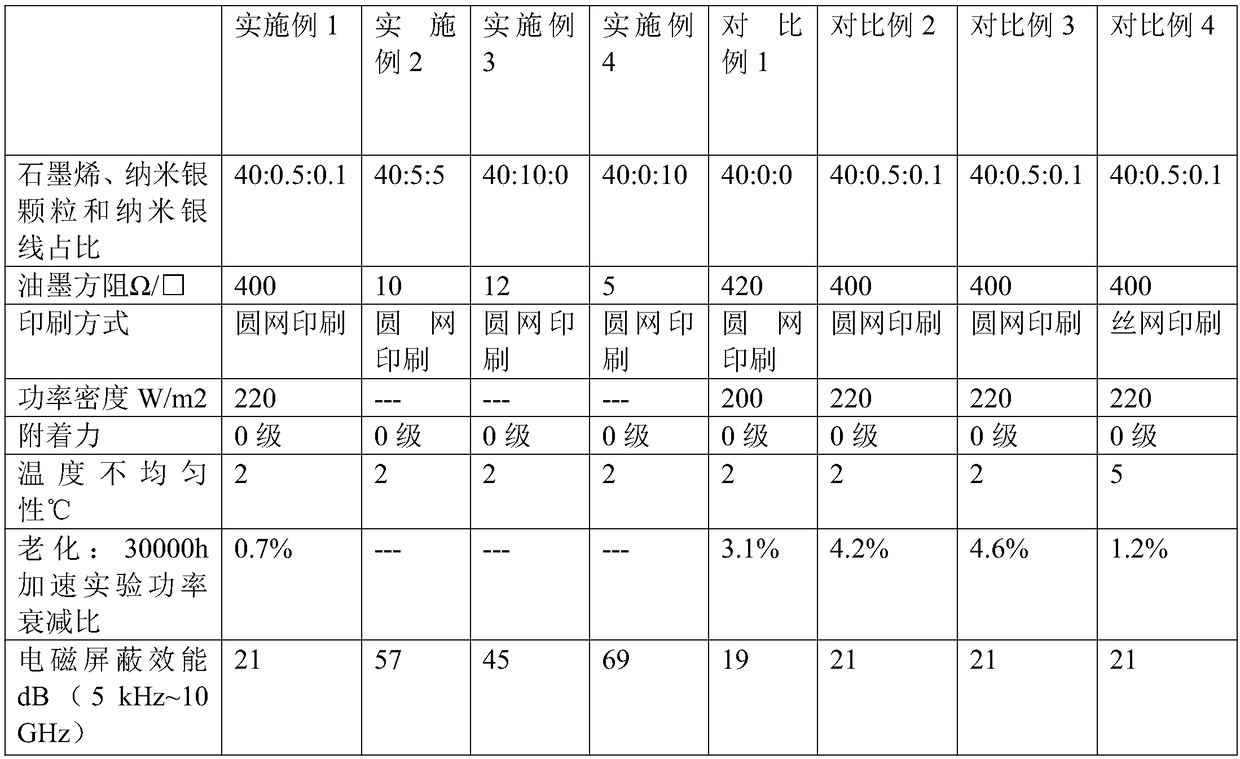

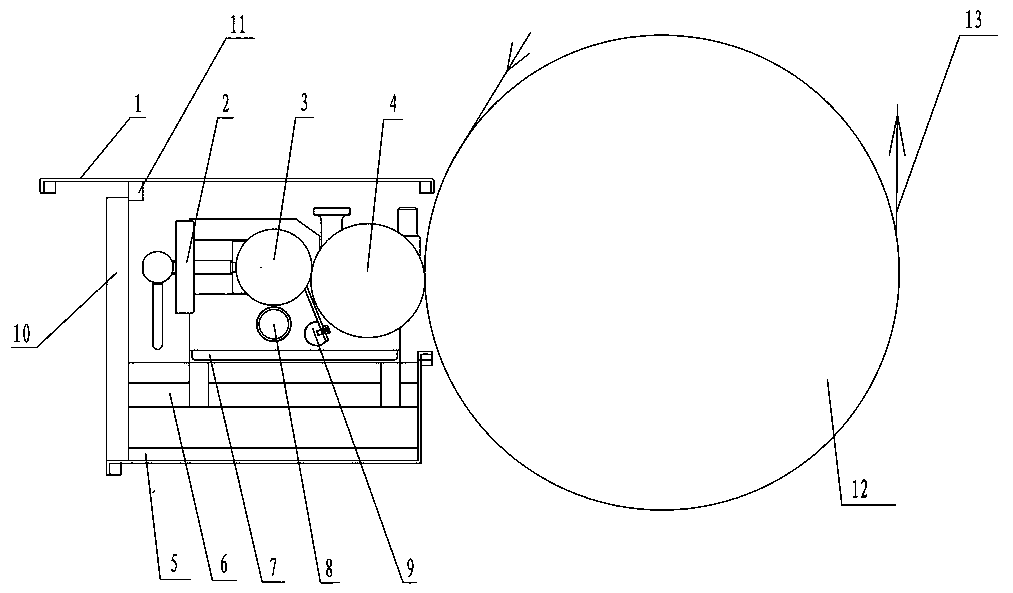

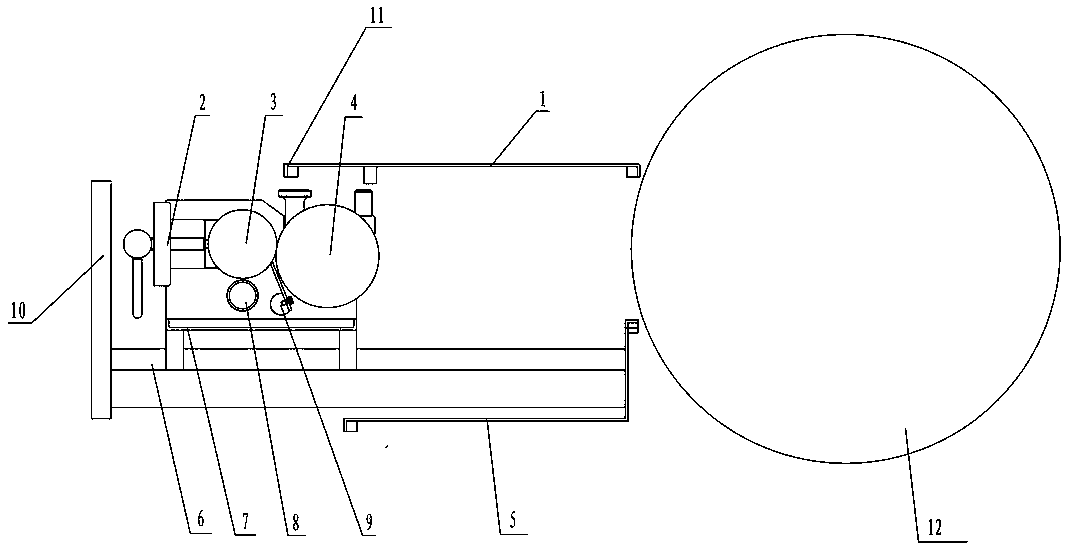

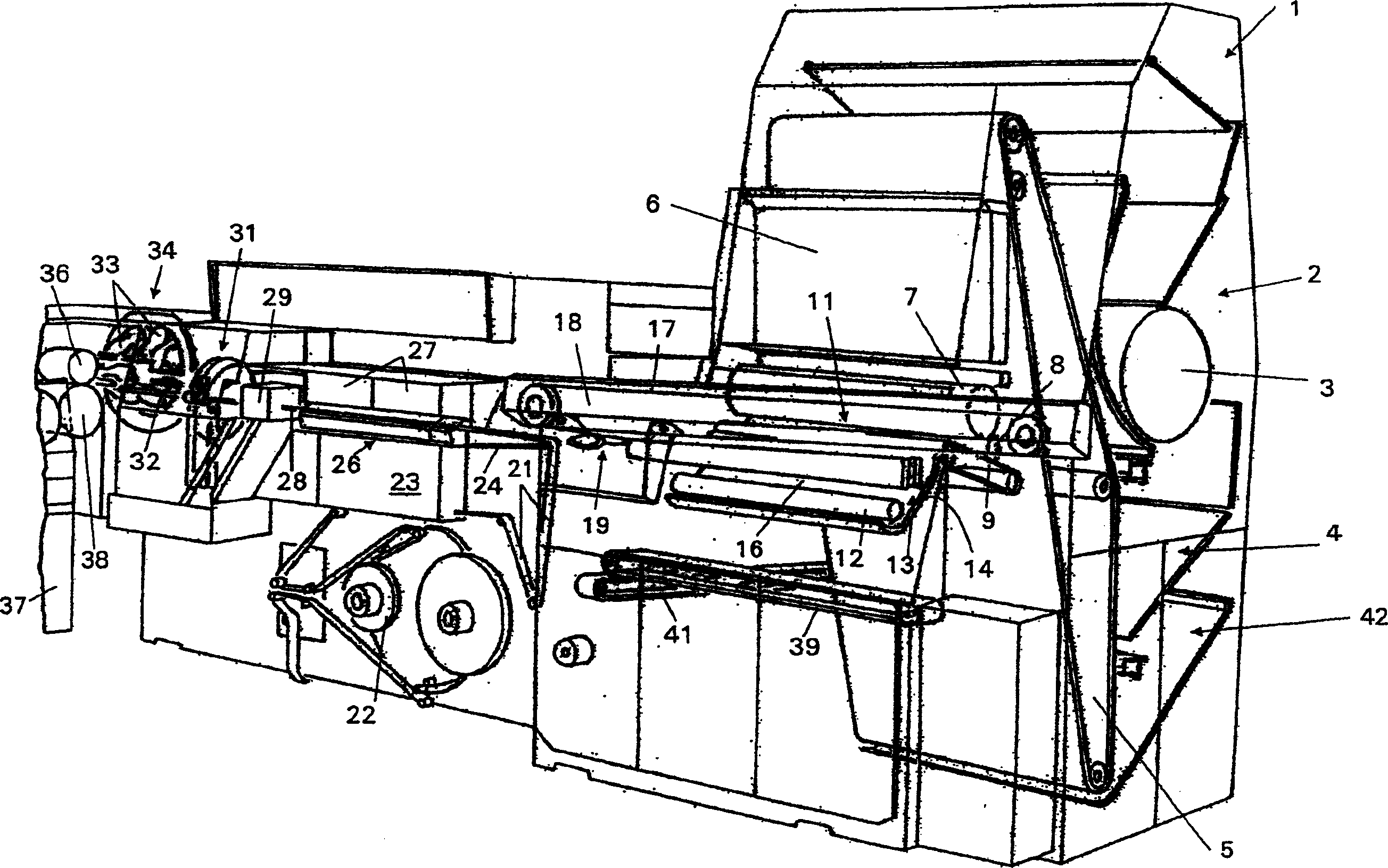

Method for preparing microchip graphene electrothermic ink, preparation method and application of electrothermic wall cloth

InactiveCN109370315ASolve the shortcomings of only choosing soft substratesEvenly heatedInksOther printing apparatusScreen printingSilver electrode

The invention provides a method for preparing a microchip graphene electrothermic ink, a preparation method and an application of an electrothermic wall cloth. The method for preparing the microchip graphene electrothermic ink comprises the following steps: preparing a silver nano-wire; preparing few-layer microchip graphene filter cake; and preparing the microchip graphene electrothermic ink. Themicrochip graphene electrothermic ink has the advantages of uniform dispersibility, high conductivity and the like. The preparation method of an electrothermic wall cloth comprises the following steps: compounding the microchip graphene electrothermic ink with a diluting agent; pumping to an ink outlet nozzle of a rotary screen printing device through a pipeline, uniformly feeding to a rotary screen inner tube under the pressure of a pump, regulating the depth, angle and position of a rotary screen printing scraper to uniformly extrude and print the ink from a rotary screen to a base material; and roasting in an oven, printing a silver electrode and preparing an electrothermic wall cloth semi-finished product. The method is simple in process and easy to operate, can overcome the limitation of a traditional printing mode to a base material. The electrothermic wall cloth can be applied to electromagnetic shielding cloth of a machine room.

Owner:江苏天创新材料科技有限公司

Safety film device

InactiveCN105513798ASimple structurePrint directThin/thick film capacitorStacked capacitorsEngineeringMechanical engineering

Owner:JIANGMEN ZHAOYE TECH

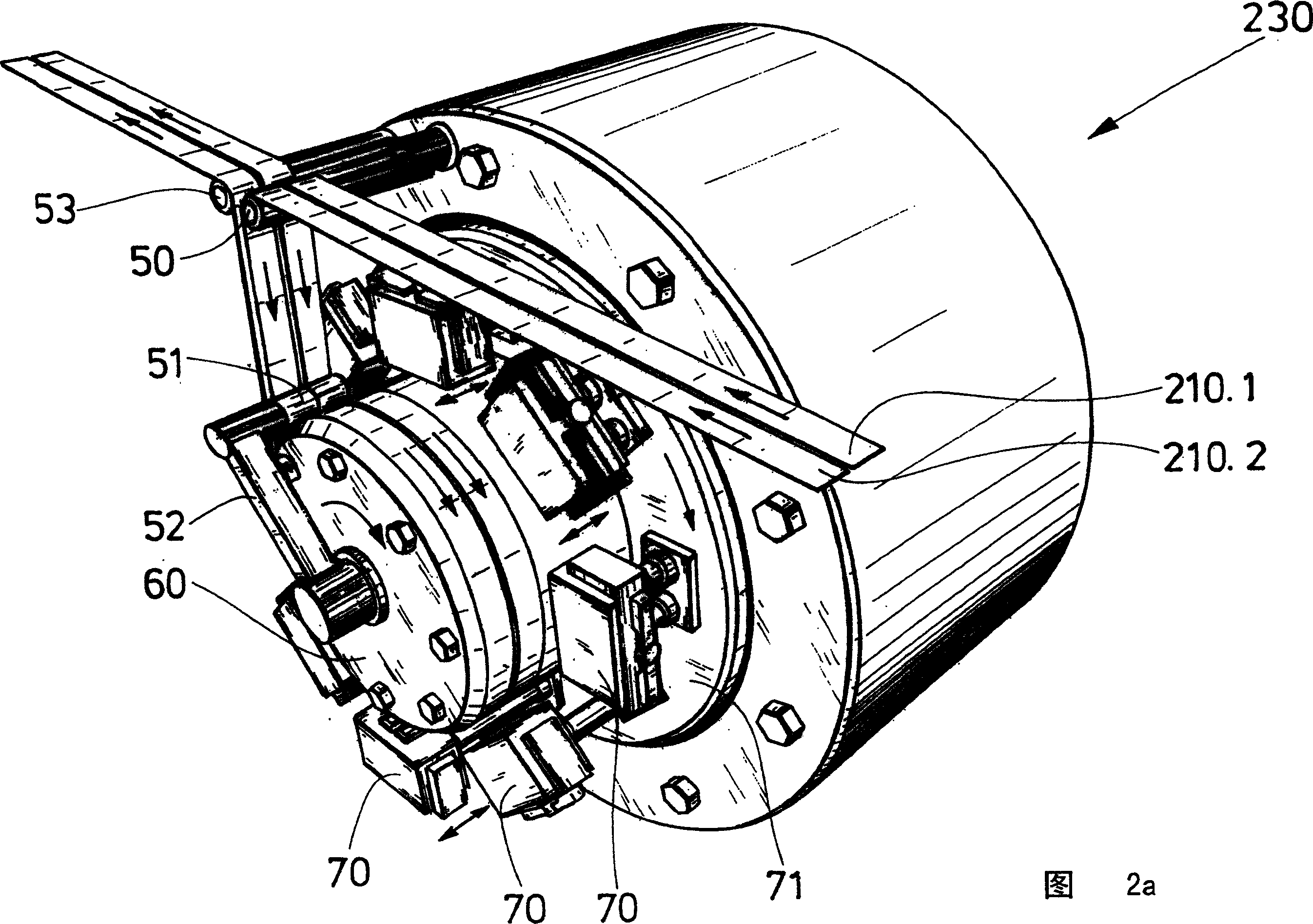

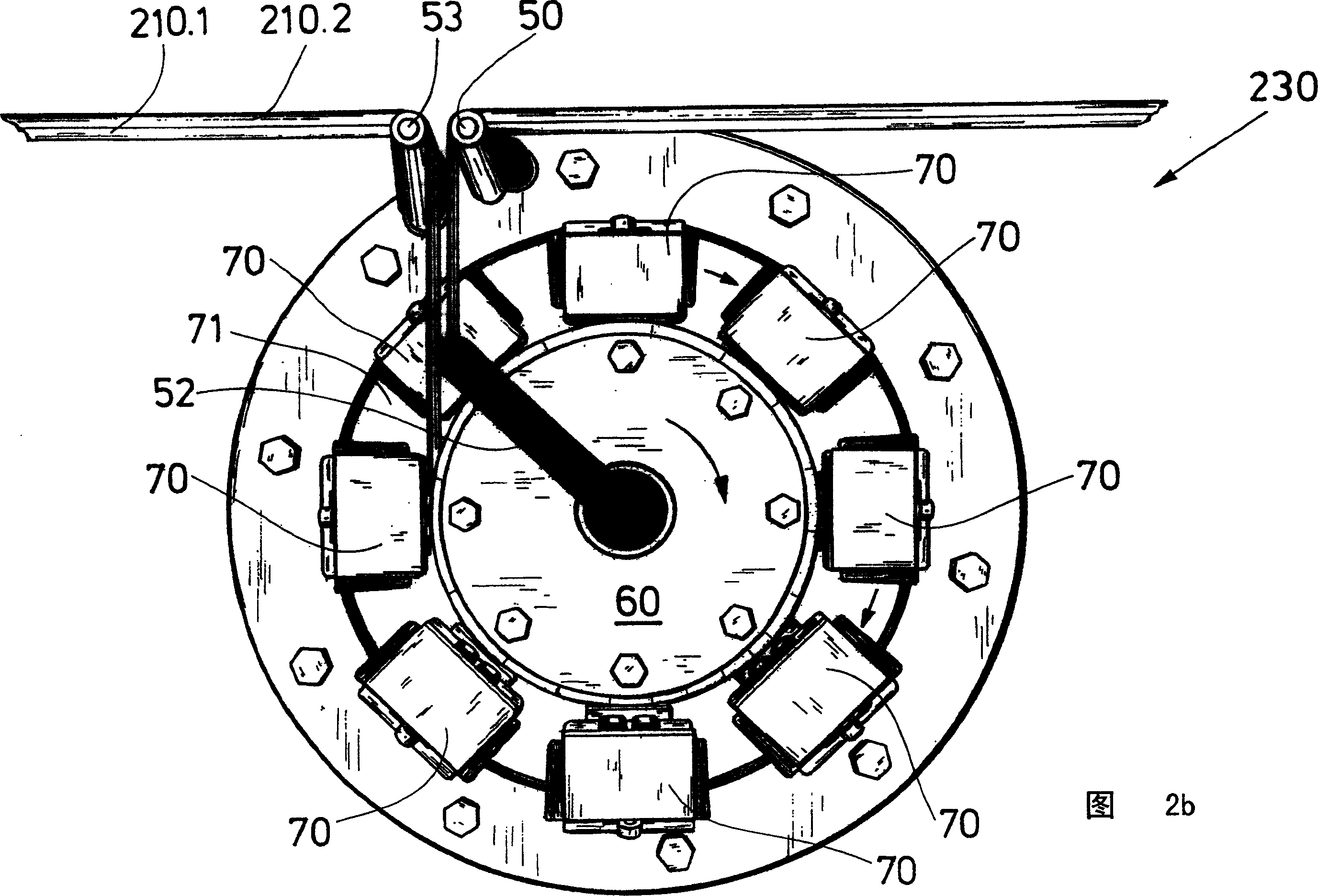

Rotating printing unit for a machine of the tobacco processing industry

InactiveCN1575670AShorten speedUniform printingCigarette manufactureTypewritersEngineeringMechanical engineering

This invention relates to the process and the devices (23, 230) for applying print marks along the conveying direction by printing elements (70, 170) on the articles (21, 210.1, 210.2; 90) conveyed in a predetermined conveyor speed of the tobacco processing industry, in particular wrapping strips (21, 210.1, 210.2), preferably cigarette paper strips or a rod-shaped smoking article (90). The method is realized by reduction of a relative speed between the printing elements (70, 170) and the articles (21, 210.1, 210.2; 90) to be printed in the printing process along the conveying direction. The invention relates to a machine in the tobacco processing industry, in particular cigarette rod forming machine or a filter installing machine.

Owner:HAUNI MASCHINENBAU AG

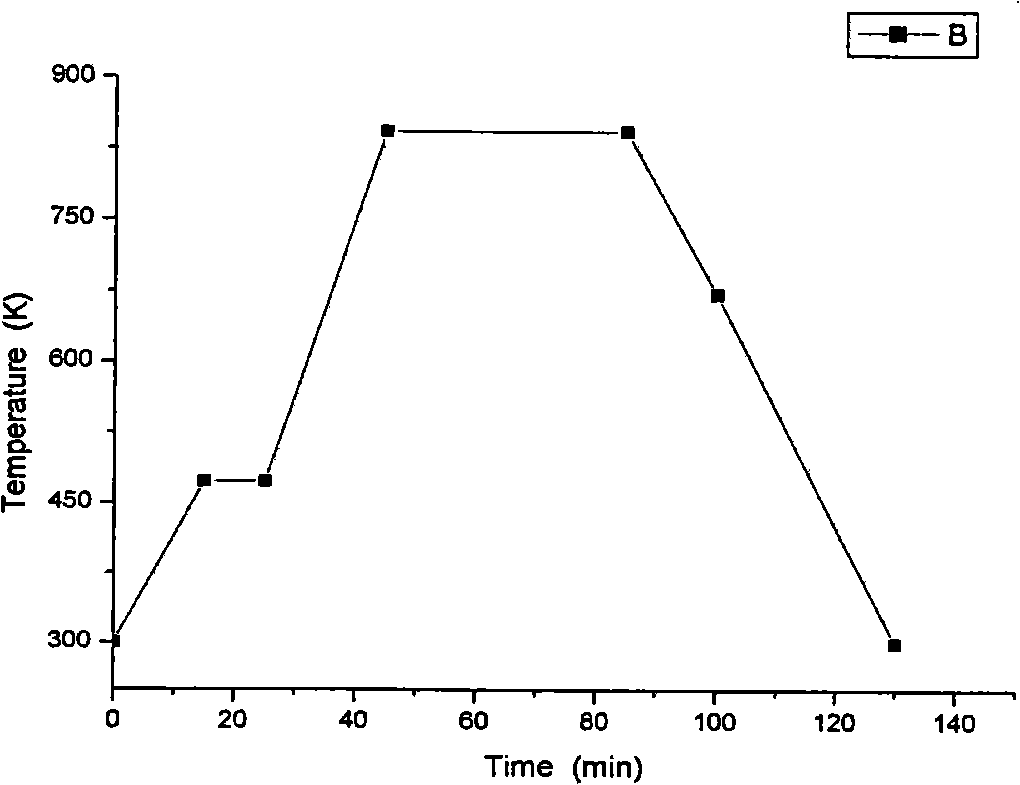

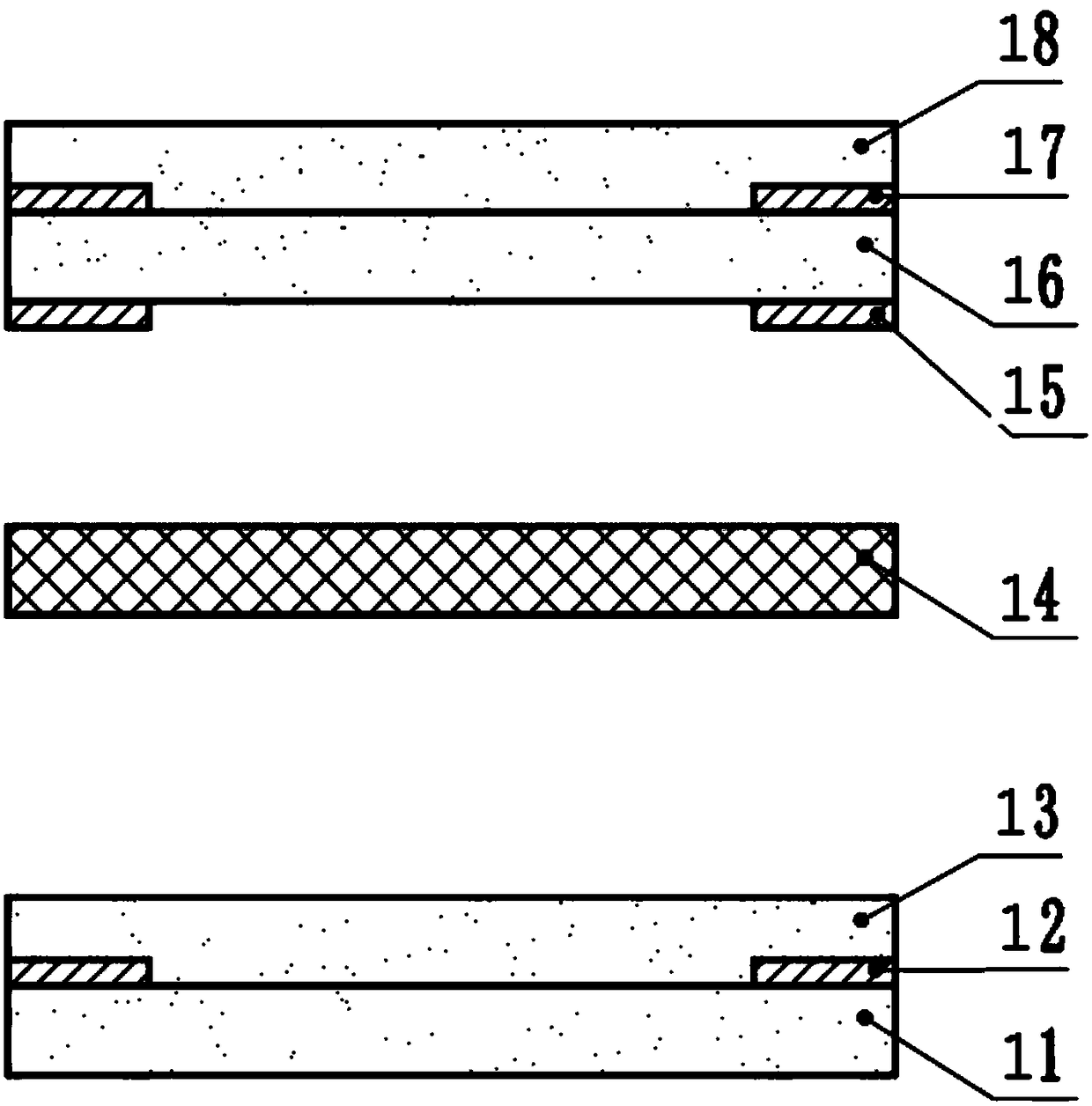

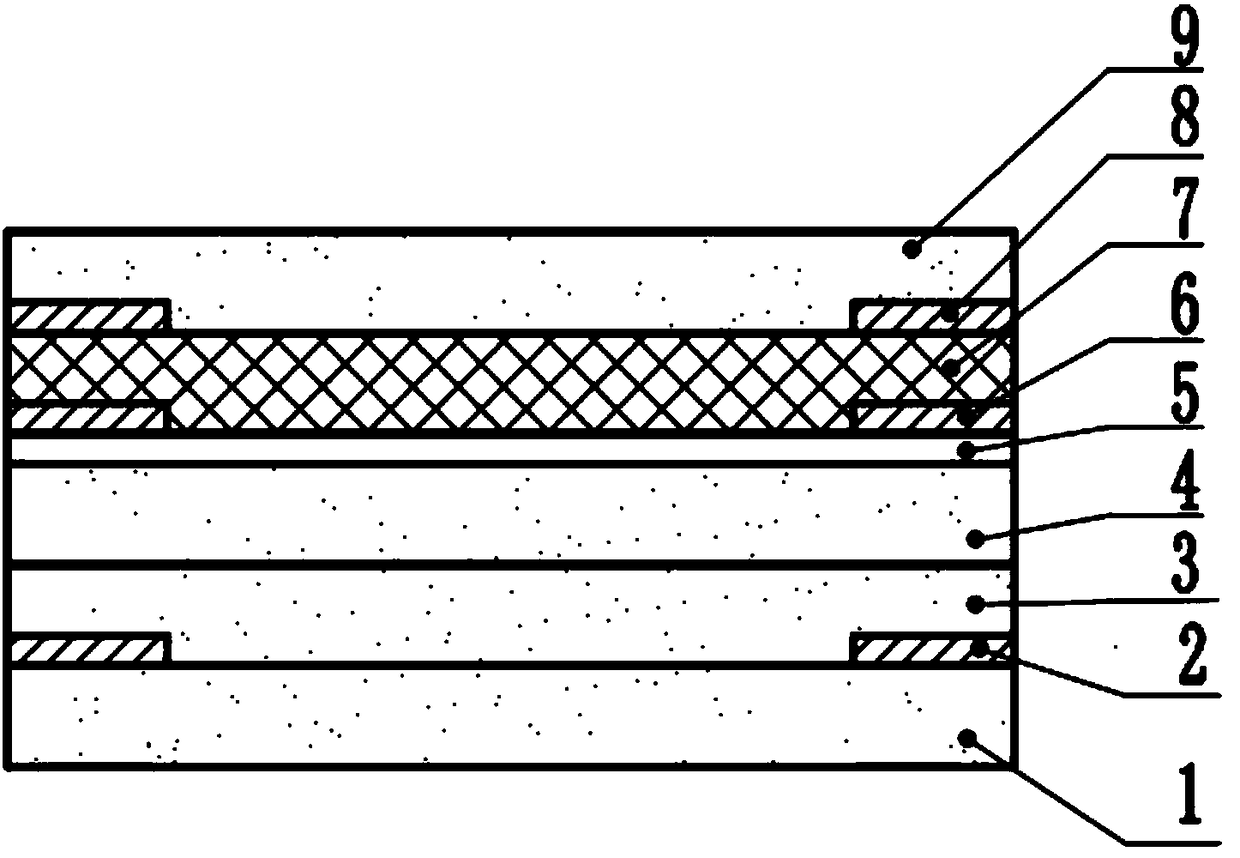

Chip oxygen sensor and preparation method thereof

PendingCN108254430AUniform printingGuaranteed yieldMaterial analysis by electric/magnetic meansPlatinumDense body

The invention discloses a preparation method of a chip oxygen sensor and the chip oxygen sensor prepared by the method. The preparation method comprises the following steps: preparing a ceramic substrate sintered into a dense body to serve as a support body; sequentially printing a first insulating layer and drying the printed first insulating layer at one side of the ceramic substrate through a thick film printing mode, printing a heating electrode and drying the printed heating electrode and printing a second insulating layer and drying the printed second insulating layer at the other side of the ceramic substrate or on the second insulating layer through the thick film printing mode; sequentially printing a third insulating layer and drying the printed third insulating layer, printing afirst porous platinum electrode and drying the printed first porous platinum electrode, printing a reference layer and drying the printed reference layer, printing a second porous platinum electrodeand drying the printed second porous platinum electrode and printing a porous protection layer and drying the printed porous protection layer; and sintering the printed ceramic substrate at high temperature so as to be molded. The chip oxygen sensor disclosed by the invention has no need of being thermally pressed and is simple in process, less in deformation and cracks and high in finished product yield.

Owner:卢忠勇 +1

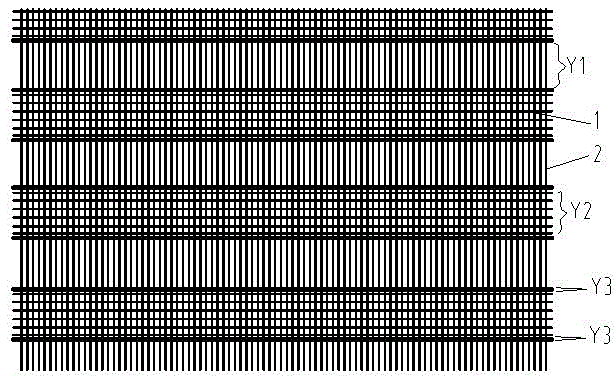

A knitting method of a silk screen with a moved screen silk yarn structure

InactiveCN105463692AExtended service lifeNot easy to fall offScreen printersBraidYarnScreen printing

A knitting method of a silk screen with a moved screen silk yarn structure is disclosed. The method includes (1) roughening silk yarn used for knitting the silk screen before silk screen knitting to increase roughness of the silk yarn, (2) moving weft silk yarn in two groups of third width zones to allow a first zone to only contain warp silk yarn arranged longitudinally, (3) arranging the silk yarn in the first zone, the first third zone, a second zone and the other third zone orderly and evenly at intervals, and (4) knitting in a circulating manner according to the silk yarn layout in the step (3) to form the silk screen. According to the silk screen knitted by the method, adhesive force of a sensitive emulsion on the silk screen is high, the sensitive emulsion is not liable to shed during a printing process, the service lifetime of a screen printing plate can be prolonged, ink permeating is made evener, and printing lines are more uniform in height, straighter, small in broadened width, low in ups and downs and good in printing effects.

Owner:赫日光电(苏州)有限公司

Automatic loading and drying printing device for shoe upper fabric producing

ActiveCN110588153AEasy to printGuaranteed uptimeRotary pressesOther printing apparatusEngineeringMechanical engineering

The invention relates to the technical field of printing, and discloses an automatic loading and drying printing device for shoe upper fabric production. The device comprises a machine body, a feedingroller, an adjusting wheel and a dye box are arranged in the machine body, the front face of the adjusting wheel is fixedly connected with a connecting shaft, the end, away from the adjusting wheel,of the connecting shaft is fixedly connected with a fixed wheel, the outer portion of a connecting block is fixedly connected with an adjusting rod, a rotating wheel is movably mounted at the position, blow the adjusting wheel, in the machine body, a stirring shaft is arranged in the dye box, and a conveying pipe is fixedly mounted below the dye box. According to the automatic loading and drying printing device for shoe upper fabric production, a convex block and an adjusting block are arranged on the rotating wheel, a clamping opening is formed in the adjusting wheel, a power source drives the rotating wheel to rotate, the rotating wheel rotates, the adjusting wheel is driven to rotate through the adjusting block, indirect rotation of the adjusting wheel is achieved, the product can be better printed, and stable running of the device is ensured.

Owner:温州卡派鞋业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com