Printing relief block

A technology for printing letterpress and printing area, which is applied in printing, printing machines, rotary printing machines, etc., and can solve problems such as inability to spread alignment liquid, poor corner display, and affecting display quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

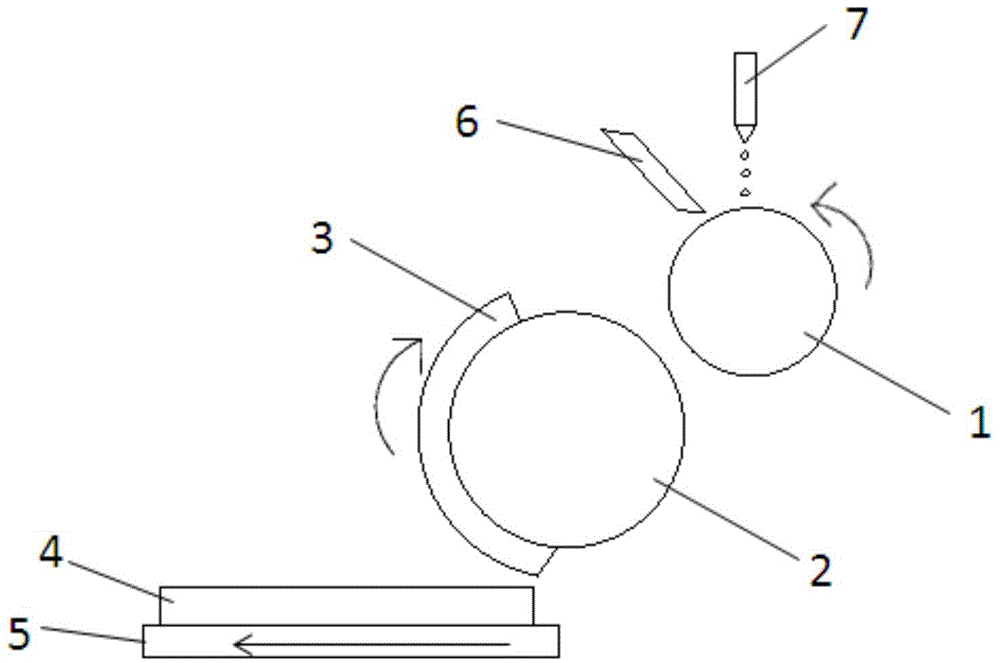

Method used

Image

Examples

Embodiment 1

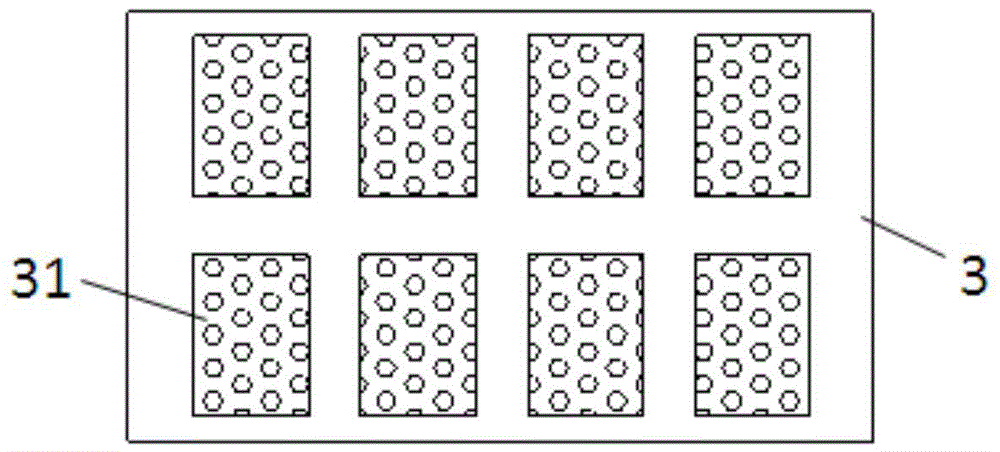

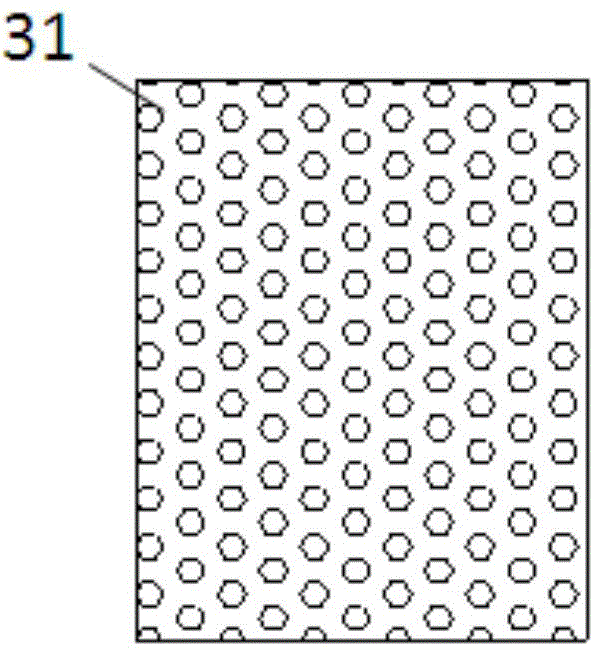

[0028] Such as Figure 5 As shown, the present invention provides a printing relief, which includes: a plurality of effective printing areas 32 are arranged on the printing relief, an ineffective printing area is arranged between the two adjacent effective printing areas, and in the effective printing area The pattern of the printed body is quadrilateral, and the four vertices of the quadrilateral printed body have protrusions extending outward;

[0029] Several protrusion units are distributed on the printing body and the protrusions. Wherein, the protrusion in this embodiment is in the shape of a semicircle, and the radius of the semicircle is preferably 0.5 mm to 20 mm.

[0030] If the radius of the semicircle is too small, the protruding position is easily blocked by the metal circuit, and the effect of diffusing the alignment liquid cannot be achieved; if the radius of the semicircle is too large, the area of the effective printing area will be exceeded, resulting in a...

Embodiment 2

[0033] Such as Image 6 As shown, the difference between this embodiment and Embodiment 1 is that the pattern of the printed body in the effective printing area 33 is a quadrangle, and the four vertices of the quadrangular printed body have protrusions extending outward; the protrusions in this embodiment It is quadrilateral, wherein the side length of the protrusions ranges from 0.1 mm to 20 mm.

[0034] If the side length of the protrusion is too small, the position of the protrusion is easily blocked by the metal circuit, and the effect of diffusing the alignment liquid cannot be achieved; if the side length of the protrusion is too large, the area of the effective printing area will be exceeded, resulting in a waste of printing alignment liquid.

[0035] In this embodiment, quadrilateral protrusions extending outward are added to the four vertices of the quadrilateral printing body. Since the quadrilateral protrusions extending outward are far from the effective display ...

Embodiment 3

[0037] Such as Figure 7 As shown, the difference between the embodiment of the present invention and embodiment 1 is that the printing body in the effective printing area 34 is a quadrangle, and the four sides of the quadrangle are arcs protruding toward the inside of the quadrangle, and the protrusions are arc-shaped, wherein, The radius of the arc is 2 mm to 100 m, and the radius of the arc is 0.5 mm to 20 mm.

[0038] In this embodiment, the printing body adopts a quadrilateral with a specific shape, and arc-shaped protrusions extending outward are added on the four corners. Since the arc-shaped protrusions extending outward are far from the effective display area, they can play a role in diffusing the alignment liquid. Function, it can effectively avoid defects caused by the corner position not being printed due to the blockage of the metal circuit, and ensure the display quality of the effective display area to the greatest extent.

[0039] The printing relief provided ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

| Side length | aaaaa | aaaaa |

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com