Chip oxygen sensor and preparation method thereof

The technology of an oxygen sensor and a manufacturing method, which is applied in the field of oxygen sensors, can solve the problems of poor flexural strength of the sheet-type oxygen sensor, prone to cracks and warpage, complicated manufacturing process, etc., achieves easy printing and uniformity, and is beneficial to industrialized production and preparation. simple craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

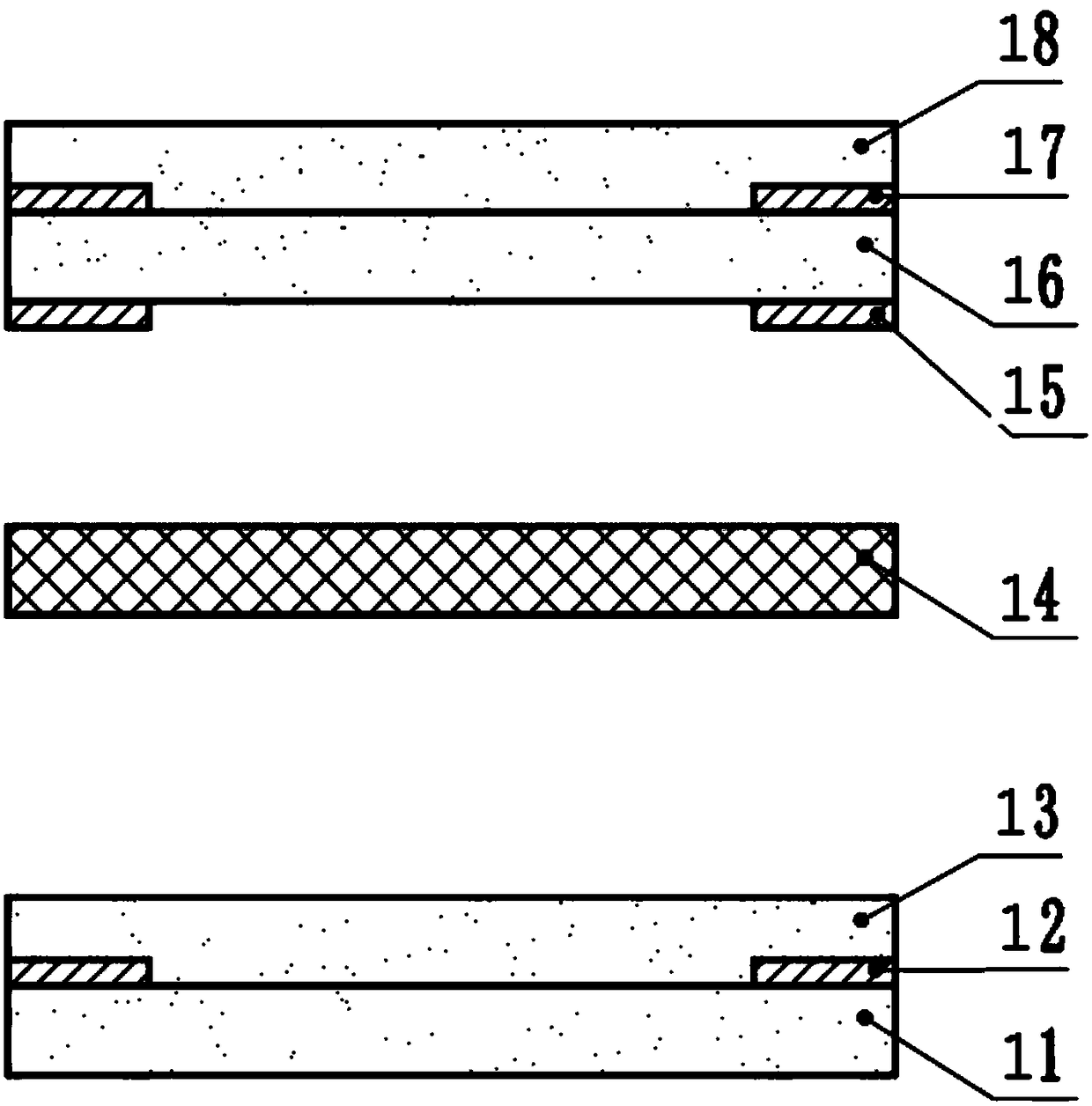

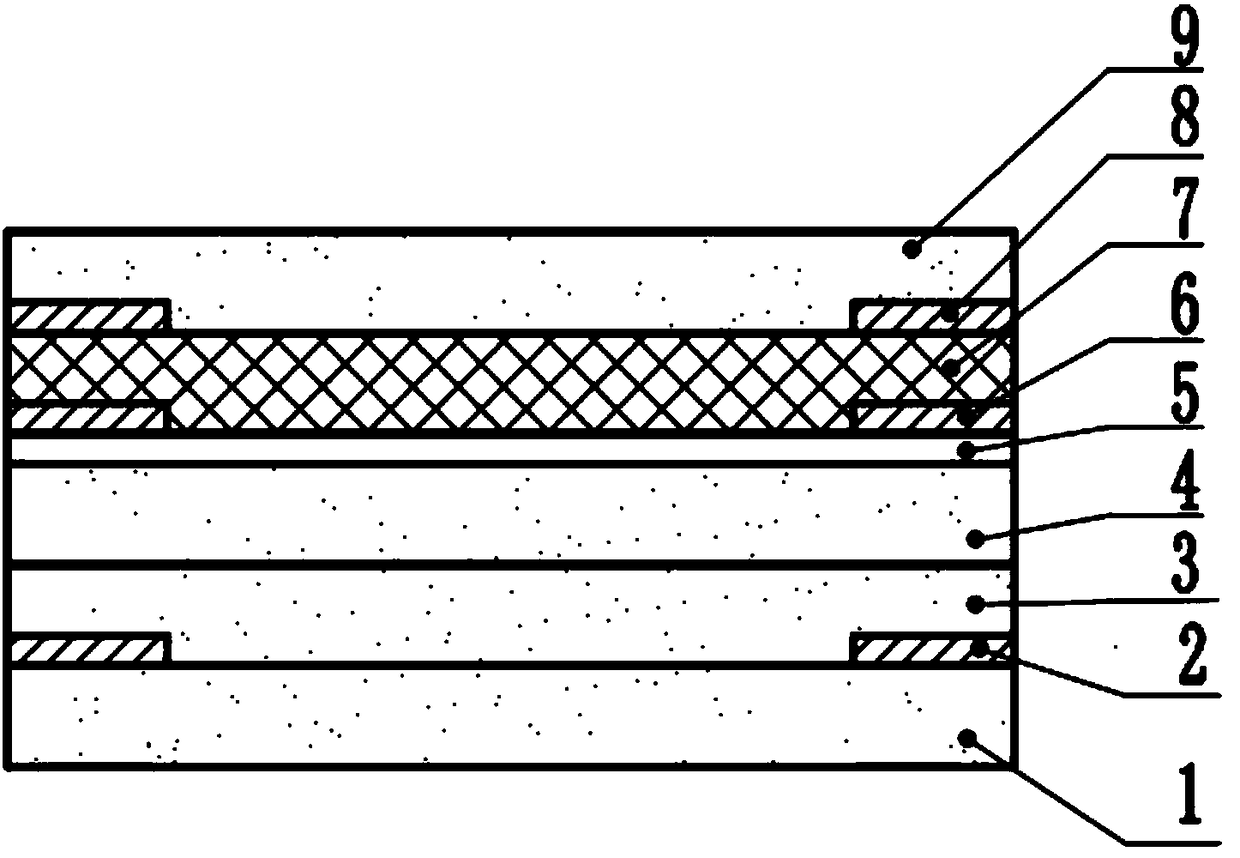

[0033] Embodiment 2 of the manufacturing method of the chip oxygen sensor, the steps are as follows:

[0034] The alumina ceramic substrate 4 that has been sintered into a dense body with a purity of 80% and a thickness of 0.5 mm is prepared, and the first insulating layer 3 is printed on one side of the ceramic substrate 4. The wet film thickness of the first insulating layer 3 printed is 30um, dry, then print the heating electrode 2, the wet film thickness printed on the heating electrode 2 is 20um, dry, then print the second insulating layer 1, the wet film thickness printed on the second insulating layer 1 is 30um, dry , and then sintering the ceramic substrate 4 at a high temperature of 1500° C. to form a heater base.

[0035] Continue to print the third insulating layer 5 on the same side of the ceramic substrate 4, the wet film thickness of the third insulating layer 5 printing is 30um, dry, and then print the first porous platinum electrode 6, and the first porous plat...

Embodiment 3

[0037] Embodiment 3 of the manufacturing method of the chip oxygen sensor, the steps are as follows:

[0038] The alumina ceramic substrate 4 that has been sintered into a dense body with a purity of 93% and a thickness of 0.635 mm is prepared, and the first insulating layer 3 is printed on one side of the ceramic substrate 4. The wet film thickness of the first insulating layer 3 printed is 80um, dry, then print the heating electrode 2, the wet film thickness printed on the heating electrode 2 is 60um, dry, then print the second insulating layer 1, the wet film thickness printed on the second insulating layer 1 is 100um, dry .

[0039] Print the third insulating layer 5 on the other side of the ceramic substrate 4, the wet film thickness of the third insulating layer 5 printing is 80um, dry, then print the first porous platinum electrode 6, the first porous platinum electrode 6 printing The wet film thickness is 60um, dry, and then print the reference layer 7, the wet film t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com