Safety film device

A safety film and thin film technology, which is applied in the direction of thin film/thick film capacitors, capacitor manufacturing, electrical components, etc., can solve the problems of technical effect application restrictions, metallized film production technology restrictions, etc., to achieve uniform printing, good market prospects, printing direct effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

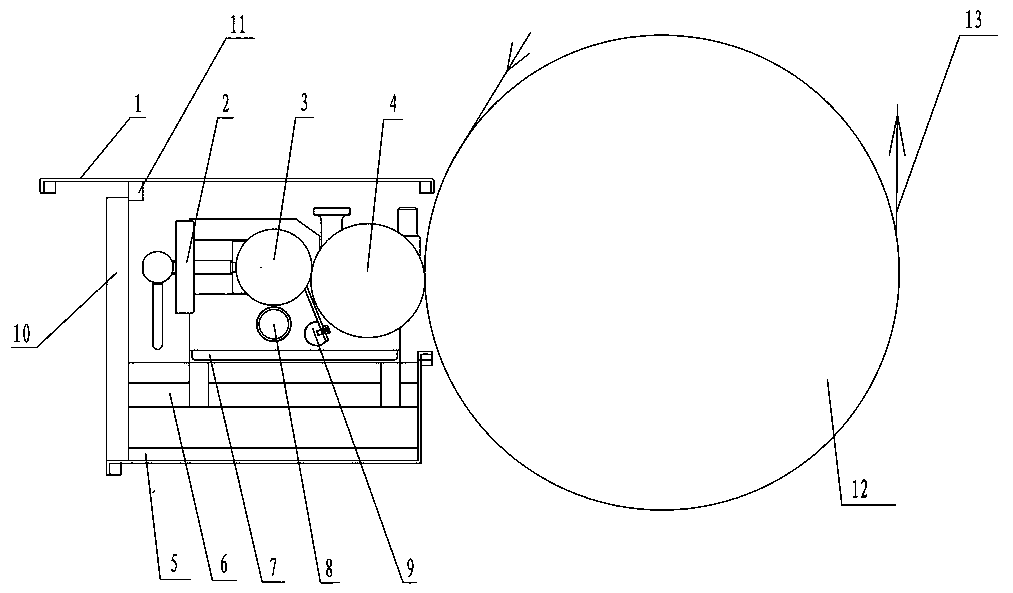

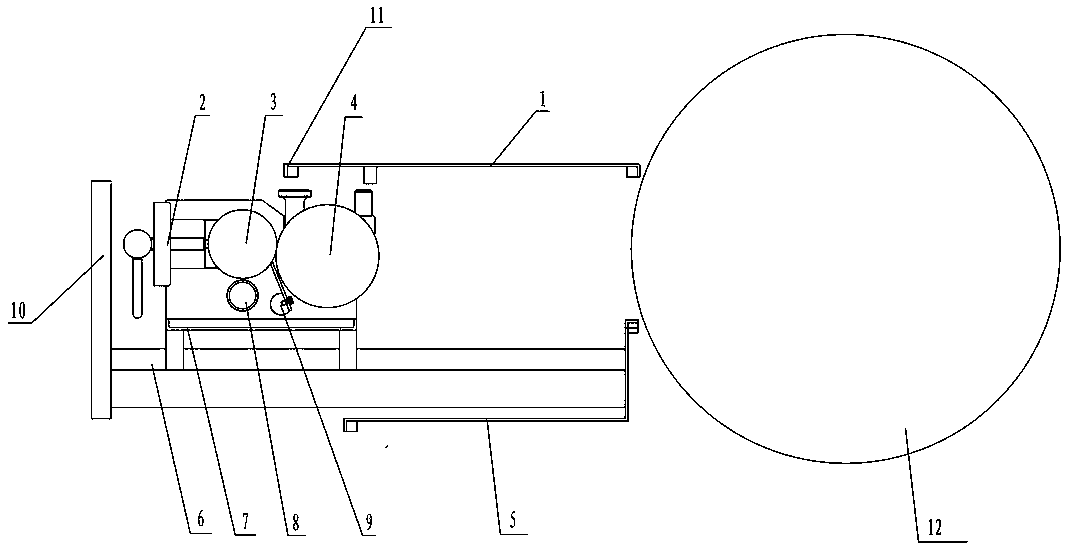

[0010] A safety film device described in Embodiment 1, such as figure 1 with figure 2 As shown, it includes an upper guard plate 1 and a lower guard plate 5 close to the main drum 12, a movable and telescopic guide rail 6 is installed on the lower guard plate, and a feed mechanism 2 for controlling the telescopic movement of the guide rail is provided on the guide rail; The feeding mechanism is provided with an oil supply roller 8 with shielding oil, a transfer roller 3 that is tangent to the oil supply roller and transfers the shield oil, and a printing roller 4 that is tangent to the transfer roller and adheres to the shield oil on the transfer roller. In the state, the printing roller is tangent to the film 13 wound by the main drum and prints shielding oil on the film; The scraper 9 for scraping off the shielding oil; the guide rail is also provided with a recovery tank 7 located under the oil supply roller, transfer roller, printing roller and scraper to recover excess ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com