Method for preparing microchip graphene electrothermic ink, preparation method and application of electrothermic wall cloth

An electrothermal ink and graphene technology, applied in ink, applications, household appliances, etc., can solve the problems of affecting the efficiency of ink transfer to the substrate, the uneven thickness of the printed heating layer, and limiting the development of screen printing, etc., to achieve excellent long-term Diameter ratio, improved safety and service life, the effect of fewer layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0057] A preparation method of microsheet graphene electrothermal ink, comprising the steps of:

[0058] S1: Preparation of nano-silver particles and nano-silver wires:

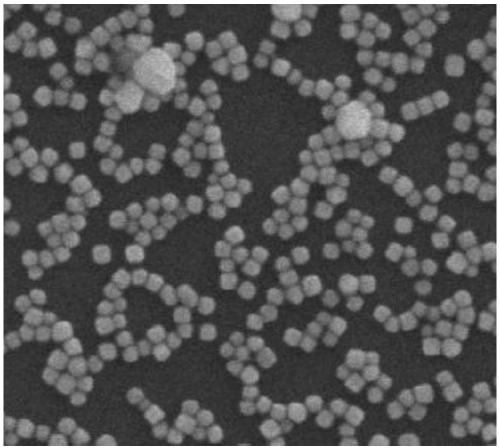

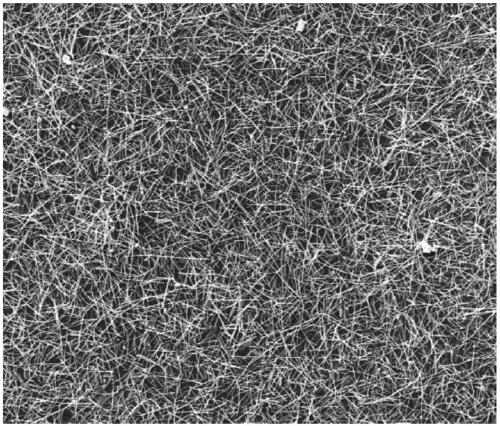

[0059] a1: Using the chemical reduction method, in deionized water, the silver salt solution is reduced by a reducing agent to prepare nano-silver colloids, the pH value of the colloid is adjusted by a pH regulator, and a dispersant is added to obtain spherical silver particles of different particle sizes. Agents to obtain long-term storage of nano-silver particles; Among them, the volume ratio of deionized water, silver salt, pH regulator, reducing agent and stabilizer is 0.1-80: 0.1-20: 0.1-5: 0.1-20: 0.1-20; The salt is one or a mixture of silver nitrate and silver sulfate, preferably silver nitrate; the pH regulator is KOH, and the pH value is 7 to 10, preferably 10; the reducing agent is ascorbic acid, sodium citrate, glucose, A mixture of one or more of sodium borohydride or amino acids (including tyro...

Embodiment 1

[0076] One, the preparation method of a kind of microchip graphene electrothermal ink in the present embodiment, comprises the steps:

[0077] S1: Preparation of nano-silver particles and nano-silver wires:

[0078] a1: Add 10mL of tyrosine to 70mL of deionized water, heat the oil bath to 90°C, stir for half an hour, remove excess tyrosine in deionized water, add 10mL of silver nitrate (0.5mM) under stirring, and the color Turn into light yellow, add 1mL of KOH (1M) under stirring, continue to stir for 1 hour, the color of the solution turns from light yellow to gray black, stop stirring, after cooling down to room temperature, add 10mL of water-based polyurethane emulsion, stir at room temperature for half an hour, stand-by;

[0079] a2: Heat 30mL of ethylene glycol oil bath to 160°C, keep stirring at constant temperature for 1 hour, add 420μL of sodium sulfide nonahydrate (solvent is ethylene glycol, 3mM), after 5 minutes, add 7.5mL of polyethylene Pyrrolidone (k30, solven...

Embodiment 2

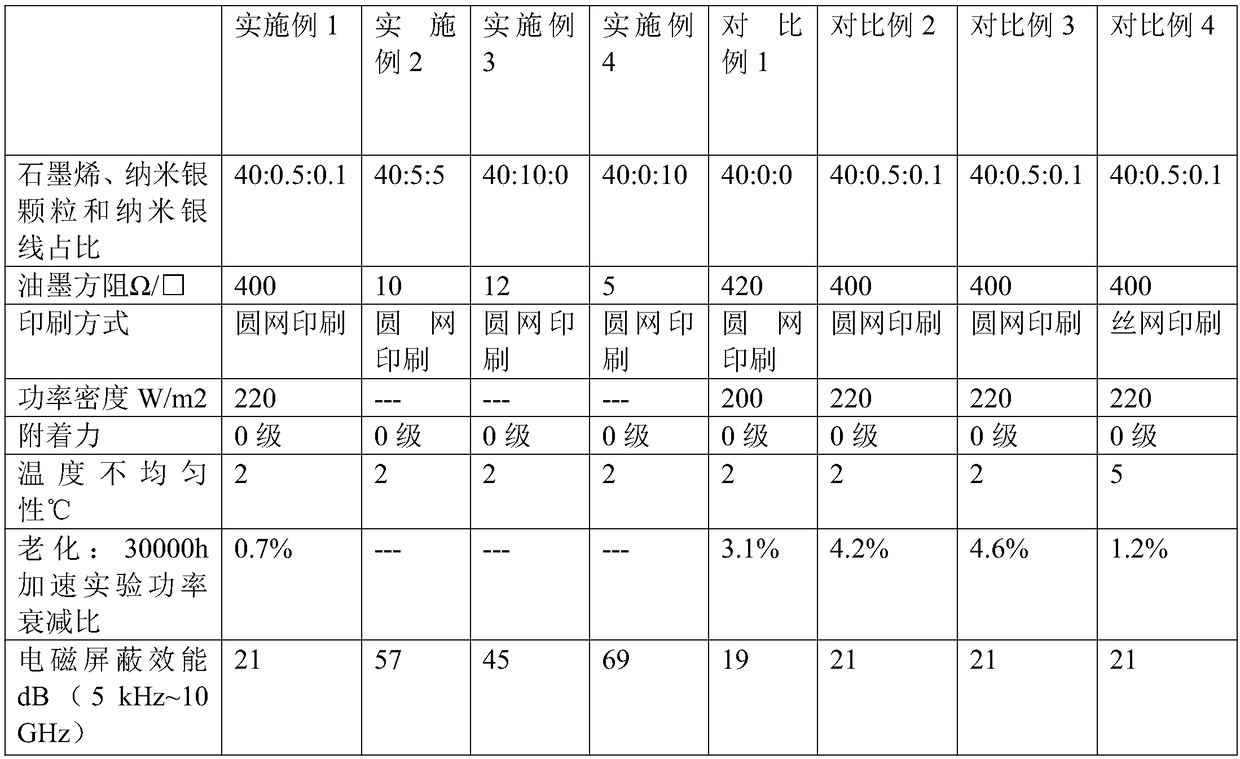

[0090] One, steps S1 and S2 in the preparation method of a kind of microflake graphene electrothermal ink in the present embodiment are all identical with S1 and S2 in embodiment 1;

[0091] The specific content of step S3 in the preparation method of a kind of microsheet graphene electrothermal ink in the present embodiment is:

[0092] Take 43 parts of water-based polyurethane emulsion (mass ratio of thermoplasticity: thermosetting = 1:2), 5 parts of polymer dispersant core chemical S19 and Tego 760W mixture (combining ratio 30:70), 0.5 part of defoamer and mix and stir. The rotation speed is 800rpm, and 40 parts of graphene filter cake (solid content 17%), 0.5 part of leveling agent BYK-349, 0.5 part of Tego 270 substrate wetting agent, 0.5 part of preservative KD3000, 5 parts of nano Silver particles, 5 parts of nano-silver wires, stirred for 0.5 hours to obtain graphene microflakes / nano-silver electrothermal ink, that is, the preparation of microflake graphene electrother...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com