Printing relief plate

A technology for printing letterpress and embossed parts, applied in the field of letterpress printing, which can solve problems such as complex design and marginal effect, and achieve the effects of avoiding marginal effect, improving display effect, and increasing effective display area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

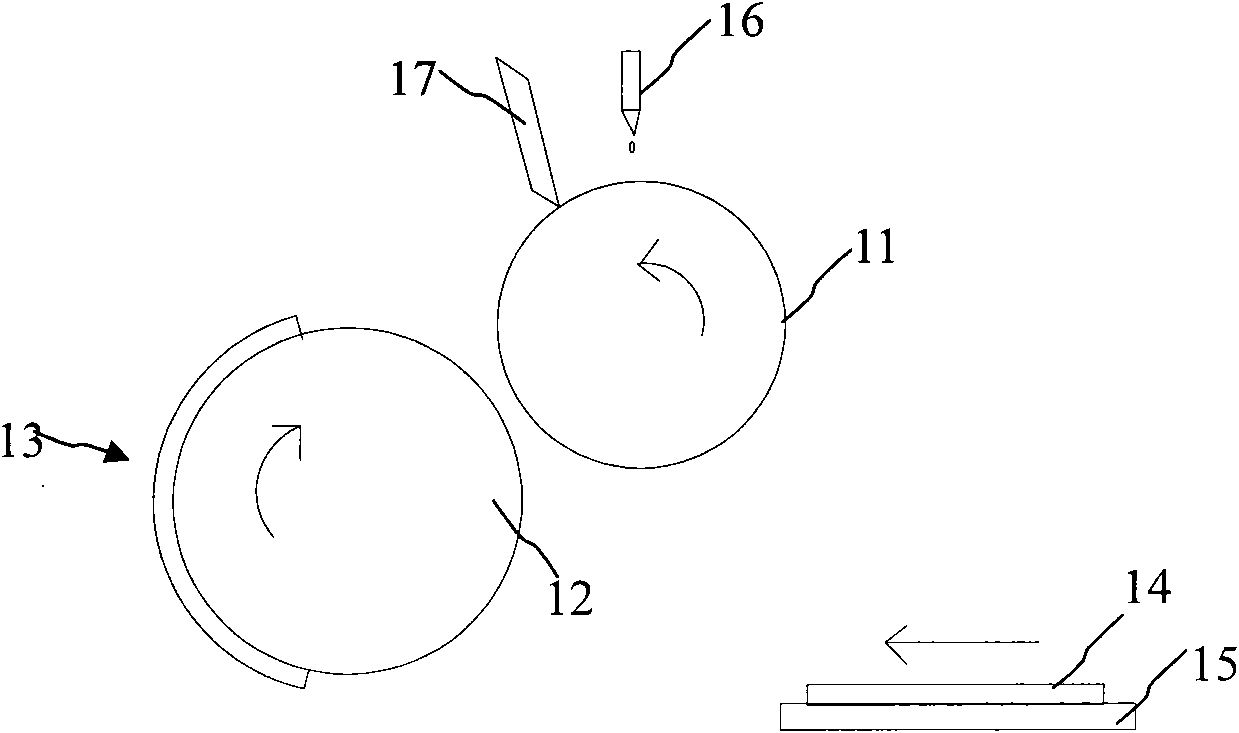

[0031] In order to have a detailed understanding of the letterpress of the present invention and enable those skilled in the art to understand the spirit of the present invention more clearly, the letterpress of a specific embodiment of the present invention is described in detail with reference to the accompanying drawings.

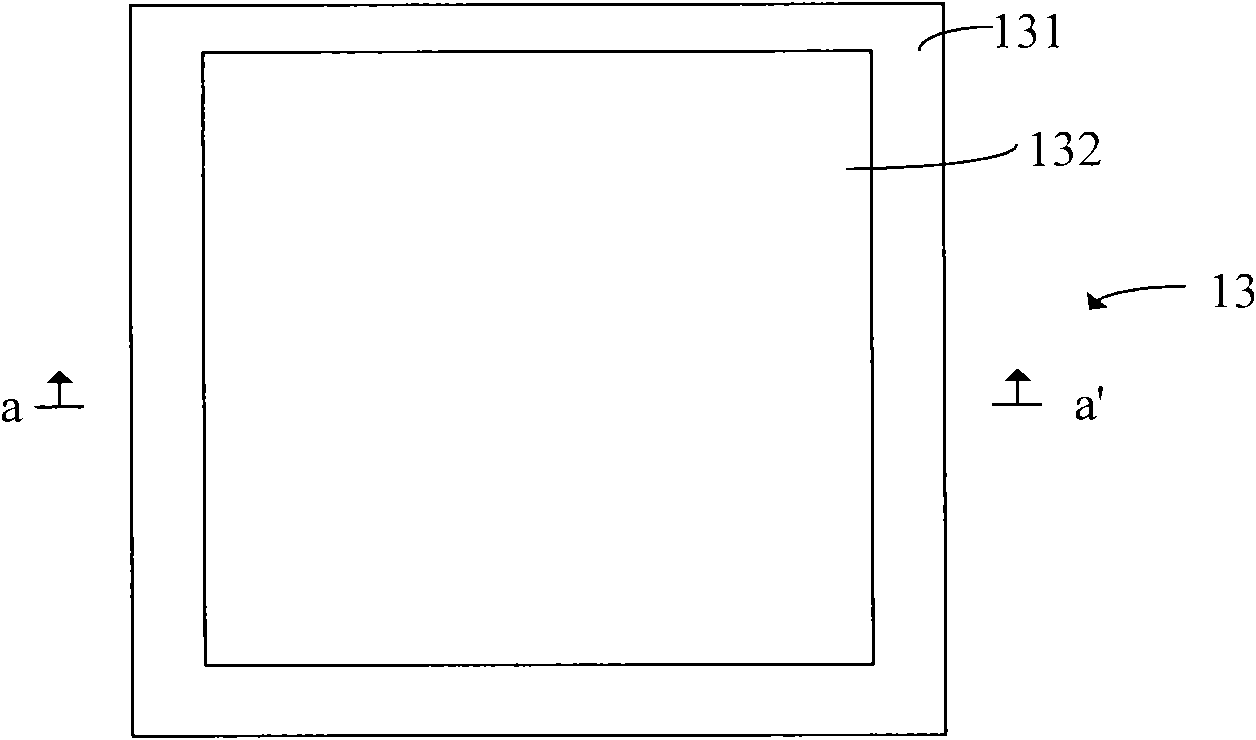

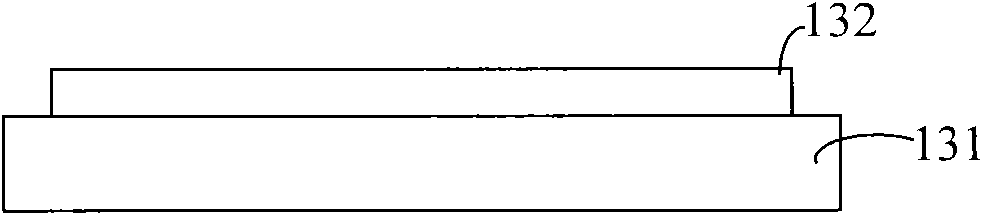

[0032] Figure 6 is a schematic plan view of a printing relief plate of a specific embodiment of the present invention, Figure 7 yes Figure 6 A schematic cross-section along b-b' of a printing relief plate according to an embodiment of the present invention is shown in . The relief printing plate 30 of the present invention includes a carrier base plate 31 and a printing plate body 32 . The printing plate body 32 has a bottom surface 325, and the bottom surface 325 is in contact with the carrying base plate 31, wherein both the carrying base plate 31 and the printing plate body 32 are plate-shaped, specifically, in a certain embodiment of the present...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com