Method for nano ZnO film preparation by screen painting and luminous tubes using the film

A technology of screen printing and light-emitting tubes, applied in the field of field emission display, to achieve the effects of increased stability and service life, low production cost, and easy large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

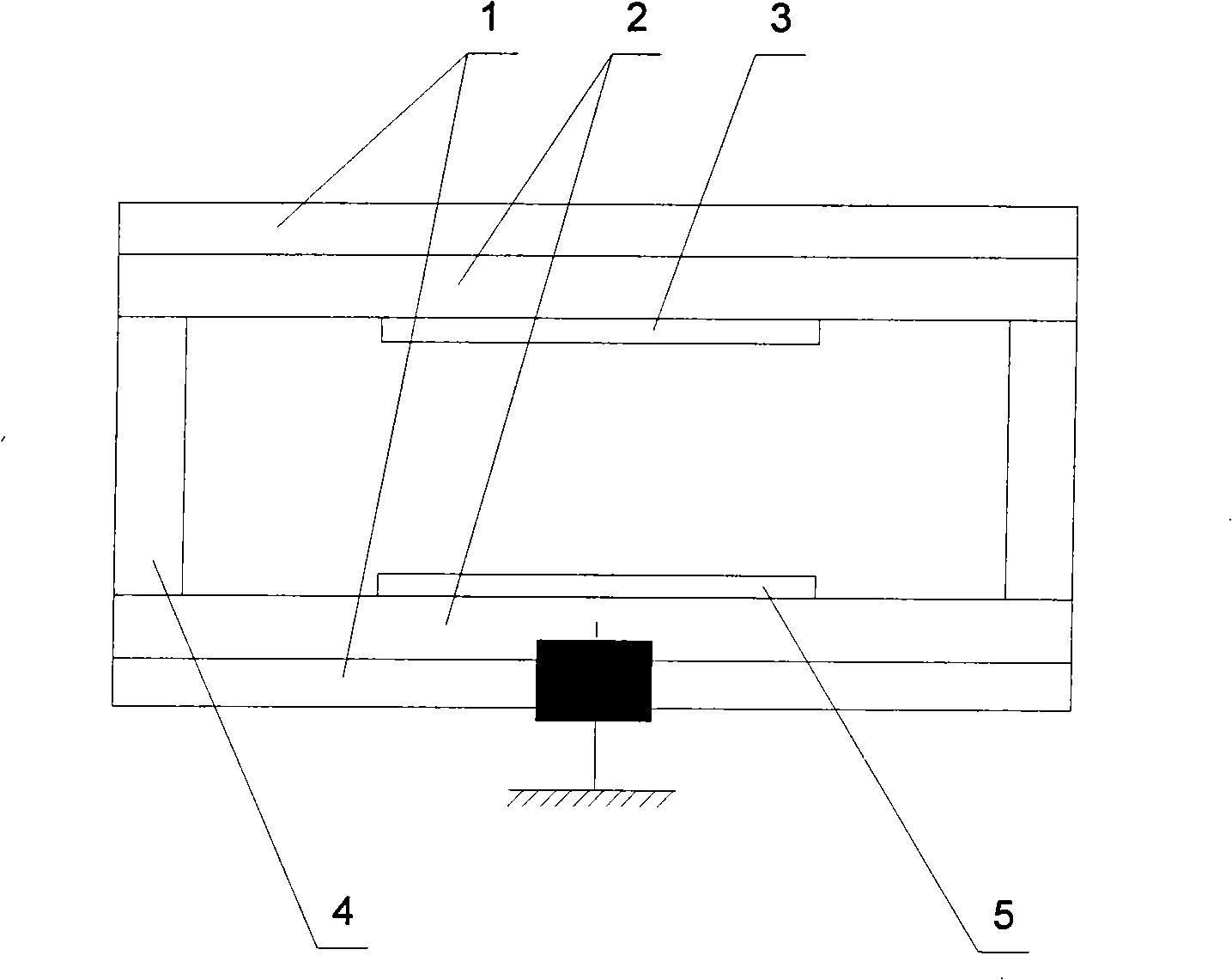

preparation example Construction

[0042] The preparation method of the above-mentioned luminous tube is as follows:

[0043] (1) cathode preparation, with the inventive method on the ITO layer of ITO conductive glass 1, print ZnO thin film 5;

[0044] (2) Anode preparation, on the ITO layer of another ITO conductive glass 1, according to the photolithography of lead wire and assembly requirements, phosphor powder is coated on it to form phosphor film 3;

[0045] (3) Fix two pieces of ITO conductive glass 1 with insulating column 4 and keep it parallel to each other;

[0046] (4) Finally, the anode and the cathode are respectively drawn out from the two ITO layers by firing the silver paste, and then the two pieces of ITO conductive glass 1 are sealed and vacuumized before being packaged.

[0047] The working principle of the ZnO thin film field emission luminous tube of the present invention is:

[0048]Ground the cathode of the field emission light-emitting tube, and apply a positive voltage to the anode. W...

Embodiment 1

[0050] A kind of screen printing prepares the method for nanometer ZnO film, comprises the following steps:

[0051] a. Preparation of ZnO slurry

[0052] Add nanometer ZnO in terpineol by weight ratio 3: 10, ultrasonic dispersion 8 hours or to nanometer ZnO fully disperse in terpineol, after crossing 130 mesh sieves, press pulping agent and aforementioned mixture (nano ZnO and terpineol alcohol) in a weight ratio of 3:10, add methyl cellulose, then heat and stir at 400K, then pass through a 420 mesh sieve again, and cool naturally to room temperature for use;

[0053] b. Preparation of ZnO thin films by screen printing

[0054] Select the mesh number as 350 mesh wire mesh or polyester mesh, and use the ZnO slurry obtained in the previous step to screen print on the ITO conductive glass by a screen printing machine;

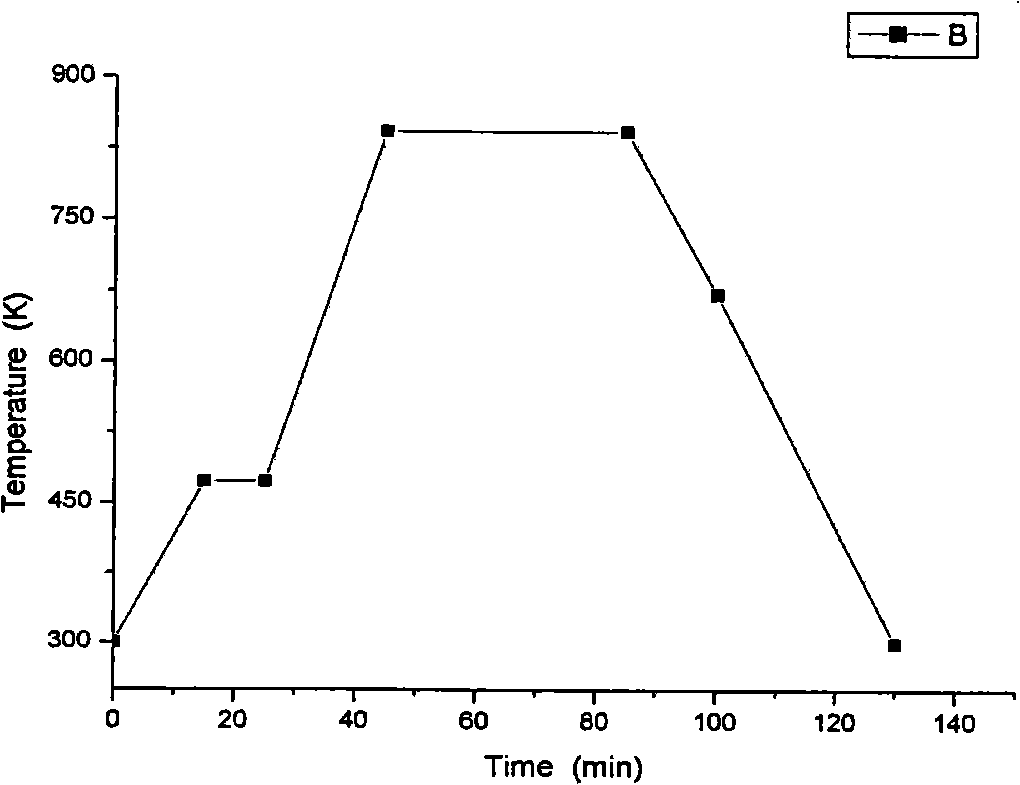

[0055] c. Thermal sintering treatment after printing

[0056] Heat up to 470K in the smart sintering furnace and keep it for 15 minutes, then raise the temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com