Sodium alginate, and preparation method and application of sodium alginate

A technology of sodium alginate and alginic acid, applied in dyeing, textile and paper making, etc., can solve the problem of using a large amount of urea, and achieve the effect of reducing water quality requirements, reducing costs, and being easy to implement and popularize.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

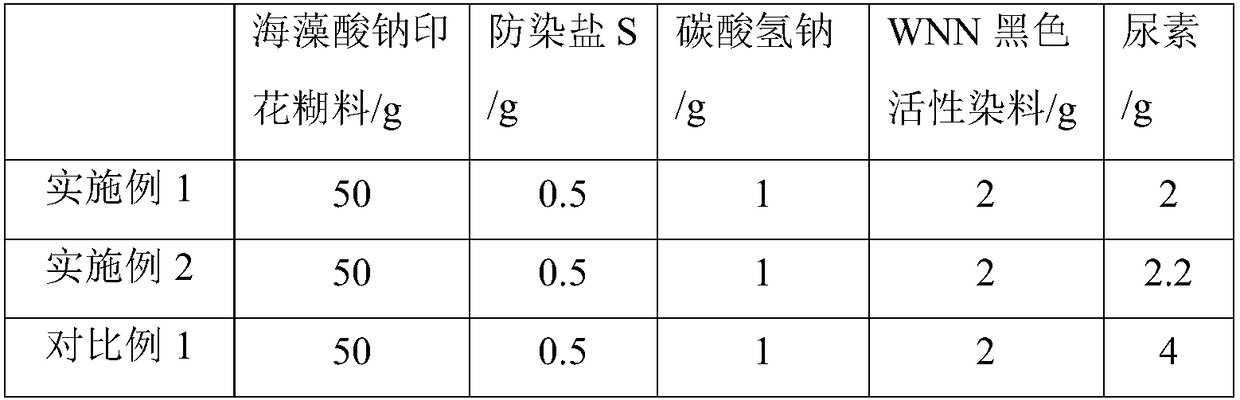

Examples

preparation example Construction

[0016] The preparation method of sodium alginate of the present invention comprises the steps:

[0017] (1) Soak and wash the brown algae with water, and then mix them evenly with an alkali agent to obtain pasty sodium alginate;

[0018] (2) Dilute the pasty sodium alginate with water and filter, then react with calcium chloride solution to obtain calcium alginate;

[0019] (3) adding the calcium alginate to hydrochloric acid for decalcification to obtain alginic acid;

[0020] (4) Pressing and dehydrating the alginic acid, then adding sodium carbonate for solid-phase neutralization to obtain neutralized sodium alginate;

[0021] (5) adding sorbitol and anhydrous sodium sulfate to the neutralized sodium alginate, mixing uniformly, kneading and granulating and drying to obtain semi-finished sodium alginate;

[0022] (6) Mix and grind the semi-finished sodium alginate with a complexing agent and a preservative to obtain sodium alginate.

[0023] In step (1), the brown algae i...

Embodiment 1

[0043] The preparation method of the sodium alginate of the present embodiment comprises the steps:

[0044] (1) Soak and wash the kelp with water, then mix it evenly with sodium carbonate to obtain pasty sodium alginate; the soaking time is 5 hours, the water consumption is 4 times of the kelp quality, the sodium carbonate consumption is 40% of the kelp quality, and the digestion temperature The temperature is 52°C, and the digestion time is 3h;

[0045] (2) Filtrate the pasty sodium alginate with water to obtain diluted sodium alginate, the dilution viscosity of the diluted sodium alginate is 105S; then react with calcium chloride solution to obtain calcium alginate; in calcium chloride solution The mass fraction of calcium chloride is 10%, the dosage of calcium chloride solution is 2% of the mass of the diluted sodium alginate, and the reaction time is 30min;

[0046] (3) adding calcium alginate to hydrochloric acid for decalcification to obtain alginic acid; the number of...

Embodiment 2

[0052] The preparation method of the sodium alginate of the present embodiment comprises the steps:

[0053] (1) Soak and wash the Ascophyllum nodosum with water, then mix it evenly with sodium carbonate to obtain pasty sodium alginate; the soaking time is 10 hours, the water consumption is 6 times of the quality of the Ascophyllum nodosum, and the amount of sodium carbonate is the quality of the Ascophyllum nodosum 40%, the digestion temperature is 54°C, and the digestion time is 5h;

[0054] (2) Filtrate the pasty sodium alginate with water to obtain diluted sodium alginate, the dilution viscosity of the diluted sodium alginate is 105S; then react with calcium chloride solution to obtain calcium alginate; in calcium chloride solution The mass fraction of calcium chloride is 10%, the dosage of calcium chloride solution is 2% of the mass of the diluted sodium alginate, and the reaction time is 30min;

[0055] (3) adding calcium alginate to hydrochloric acid for decalcificatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com