Negative pressure equal liquid level height control liquid filling device

A negative pressure filling and filling device technology, applied in liquid bottling, liquid filling, liquid processing and other directions, can solve the problems affecting the purchase rate, difficulty, and inability to achieve liquid level filling of different bottles, etc. Eliminate the problem of environmental pollution and eliminate the effect of cost increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

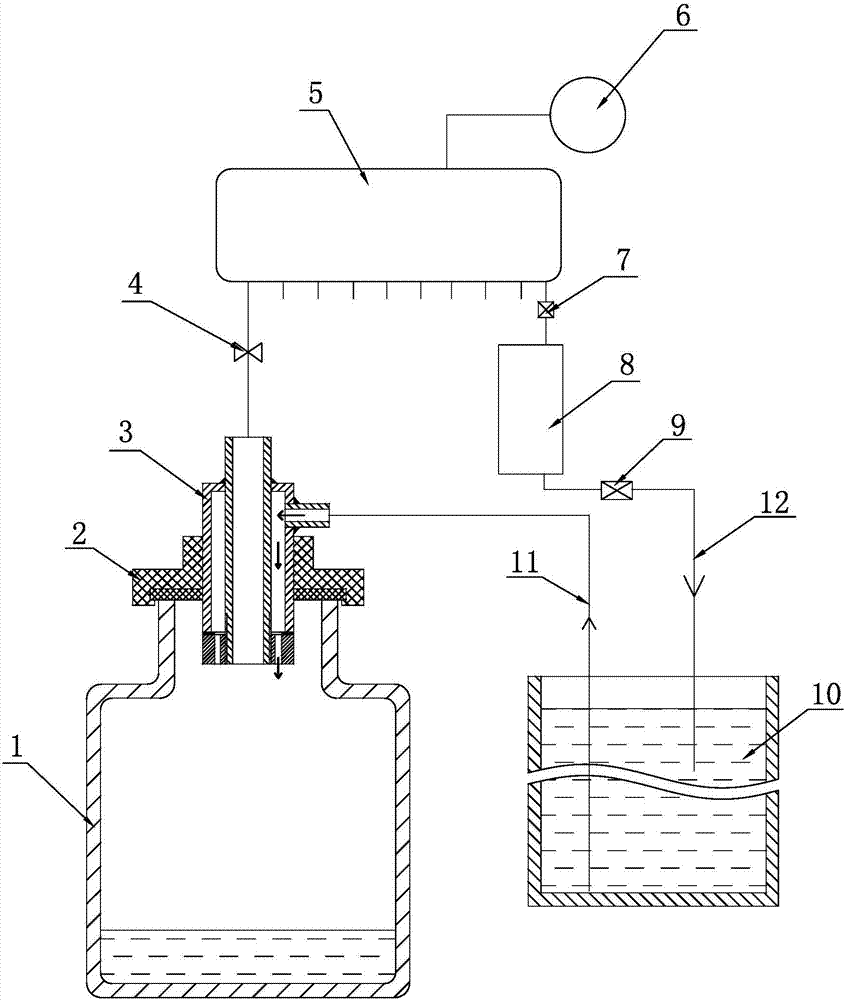

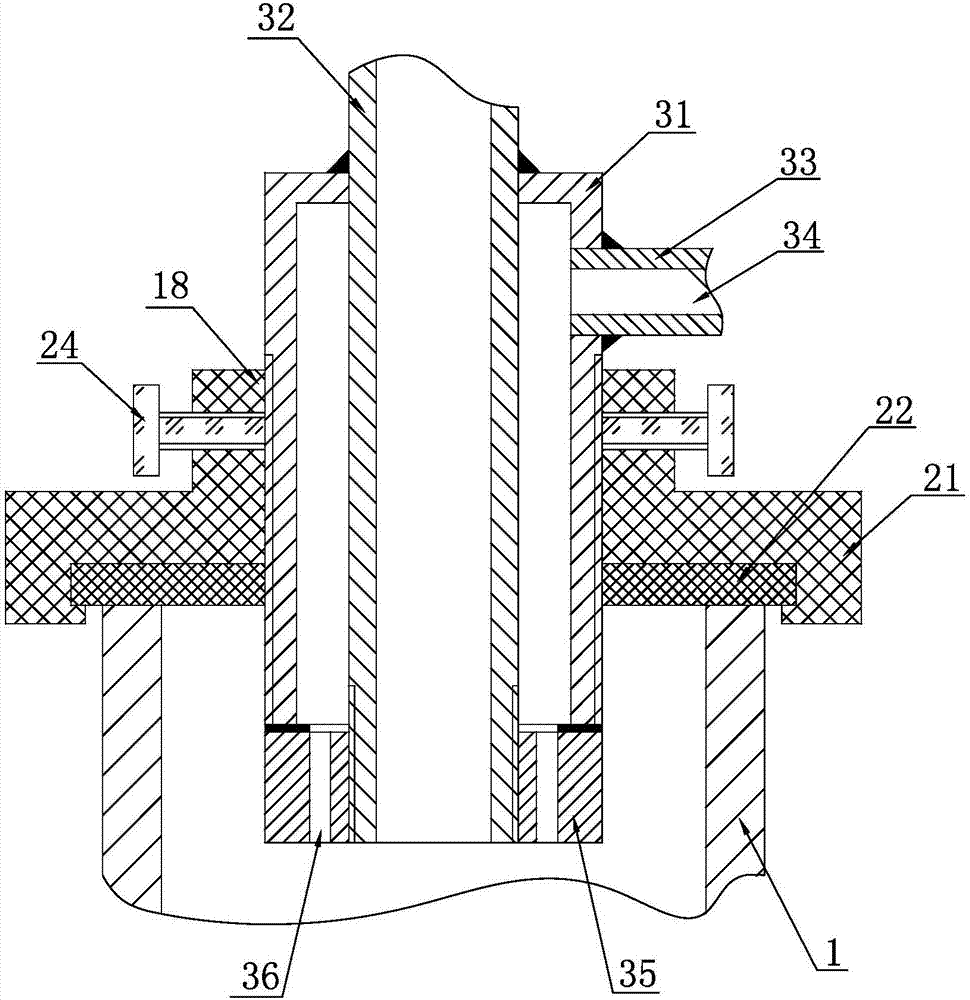

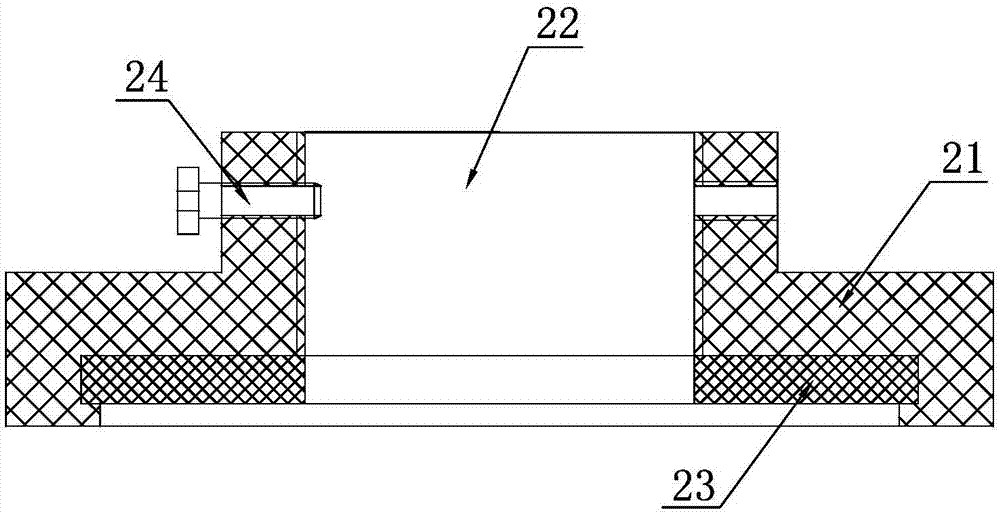

[0028] A liquid level control liquid filling device such as negative pressure, such as Figure 1-7 As shown, it includes bottle body 1, bottle mouth sealing gland 2, negative pressure filling head 3, suction valve 4, negative pressure chamber 5, vacuum pump 6, upper liquid discharge valve 7, transitional liquid storage tank 8, lower liquid discharge The valve 9 and the material liquid box 10, the bottle mouth sealing gland 2 includes a gland body 21, a connecting inner hole 22, a bottle mouth sealing gasket 23 and an adjusting screw 24, and the connecting inner hole 22 is arranged at the center of the gland body 21 , used to install the negative pressure filling head 3, the bottle mouth gasket 23 is arranged on the lower end surface of the gland body 21, and the adjusting screw 24 is screwed on the shoulder of the gland body 21 to limit the negative pressure filling head 3 extend the length of the bottle mouth sealing gasket 23, the negative pressure filling head 3 includes an...

Embodiment 2

[0030] On the basis of Example 1, the negative pressure filling head 3 is optimized, that is, a liquid level control end cap 35 is arranged at the lower end of the negative pressure filling head 3, and a central threaded hole is arranged at the center of the liquid level control end cap 35 , the outer circle of the lower section of the inner casing 32 is provided with an external thread, and the liquid level control end cap 35 is screwed on the external thread of the inner casing 32 through the central threaded hole, and the upper end surface of the liquid level control end cap 35 is connected to the outer casing The lower end surface of 31 is sealed and butted, and a liquid injection hole 36 is arranged on the lower end surface of the liquid level control end cover 35, and the liquid injection hole 36 communicates with the liquid inlet channel.

Embodiment 3

[0031]Embodiment 3: On the basis of embodiment 1, the negative pressure filling head 3 is optimized, namely the liquid level control end cap 35 is set at the lower end of the negative pressure filling head 3, and the upper end of the liquid level control end cap 35 is set There is an inner concave ring and a smooth center hole, and the side wall of the inner concave ring is provided with a side internal thread, and the outer circle of the lower section of the outer casing 31 is provided with an external thread, and the liquid level control end cap 35 is screwed on the side through the side internal thread hole. On the external thread of the outer sleeve 31.

[0032] In order to facilitate the installation and adjustment between the bottle mouth sealing gland 2 and the negative pressure filling head 3, the connecting inner hole 22 of the bottle mouth sealing gland 2 is designed as a threaded hole, and the outer circle of the negative pressure filling head 3 is provided There ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com