Laundry tablet

A technology for laundry tablets and non-woven fabrics, which is applied in the directions of detergent powder/sheet/sheet, detergent composition, soap detergent composition, etc. Transportation cost, effectiveness of protective clothing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

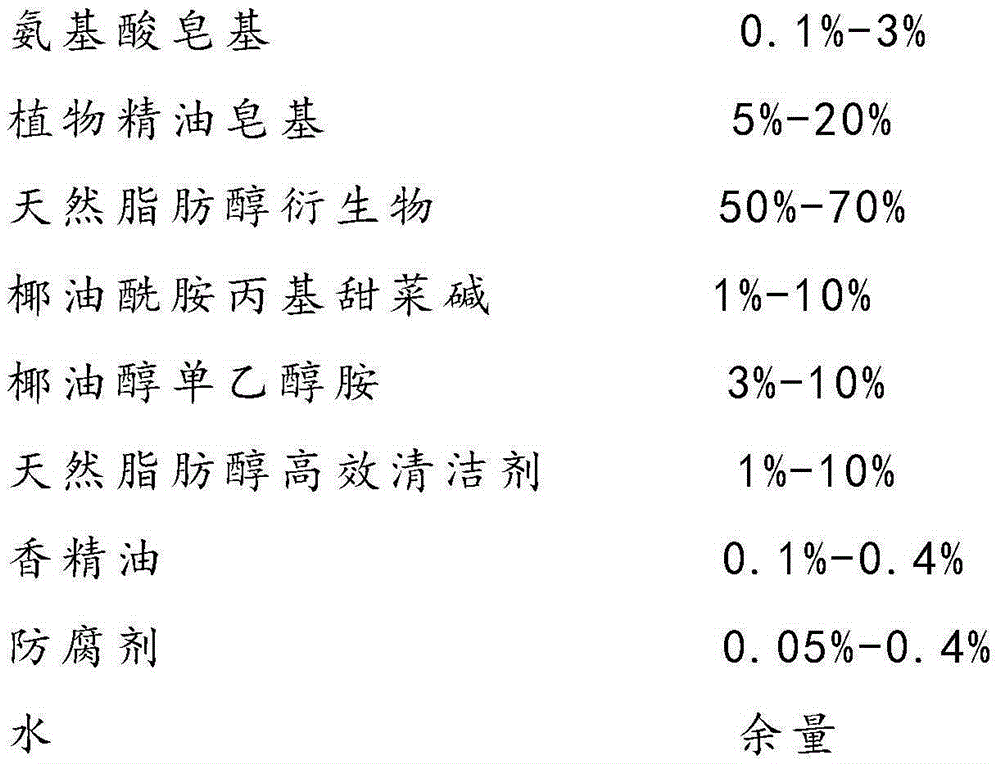

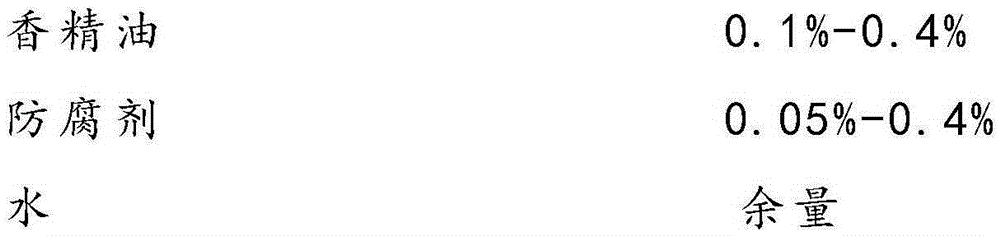

[0029] A kind of laundry sheet, it comprises non-woven fabric and the washing material attached on the non-woven fabric, and described washing material comprises: amino acid soap base 0.2%, plant essential oil soap base 10%, natural fatty alcohol derivative 60%, cocamide Propyl betaine 2%, coco alcohol monoethanolamine 5%, natural fatty alcohol high-efficiency cleaner 10%, essential oil 0.2%, preservative 0.2%, water 12.4%.

[0030] The production process is as follows: first add 12.4 parts of water to the mixer, add amino acid soap base and plant essential oil soap base, heat the mixer to 50°C, and stir for 10 minutes to completely melt the soap base. Add natural fatty alcohol derivatives, cocamidopropyl betaine and cocoal monoethanolamine, stir well, then add natural fatty alcohol high-efficiency cleaners, essential oils and preservatives, stir well, put in non-woven fabric, above The components are mixed to form a binder, and then the above binder is put into a mold to form...

Embodiment 2

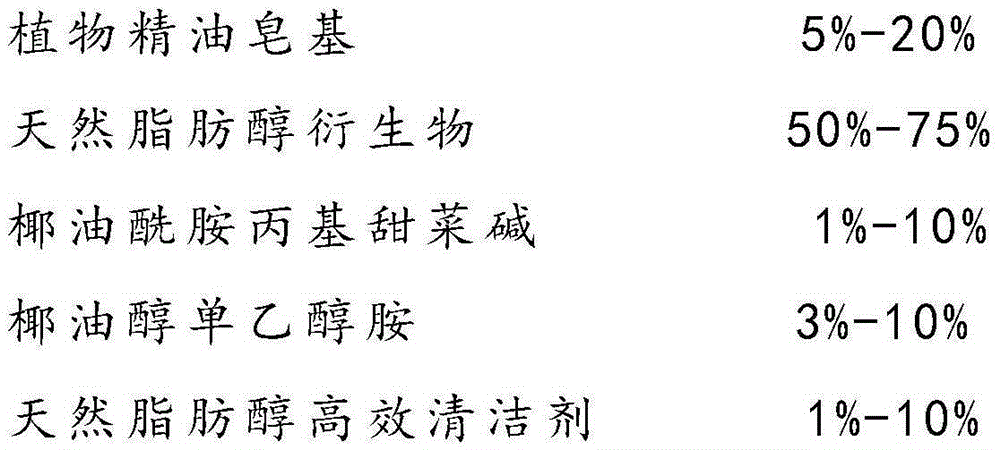

[0032] A kind of laundry sheet, it comprises non-woven fabric and the washing material attached on the non-woven fabric, and described washing material comprises: plant essential oil soap base 15%, natural fatty alcohol derivative 55%, cocamidopropyl betaine 5% , coconut oil monoethanolamine 5%, natural fatty alcohol high-efficiency cleaner 6%, essential oil 0.4%, preservative 0.1%, water 13.5%.

[0033] The production process is as follows: first add 13.5 parts of water to the mixer, then add vegetable essential oil soap base according to the weight ratio, heat the mixer to 60°C, and stir for 12 minutes to completely melt the soap base. Add natural fatty alcohol derivatives, cocamidopropyl betaine and cocoal monoethanolamine, stir well, then add natural fatty alcohol high-efficiency cleaners, essential oils and preservatives, stir well, put in non-woven fabric, above The components are mixed to form a binder, and then the above binder is put into a mold to form a tablet, the ...

Embodiment 3

[0035] A kind of laundry sheet, it comprises non-woven fabric and the washing material attached on the non-woven fabric, and described washing material comprises: amino acid soap base 1%, plant essential oil soap base 15%, natural fatty alcohol derivative 55%, cocamide Propyl betaine 4%, coco alcohol monoethanolamine 5%, natural fatty alcohol high-efficiency cleaner 8%, essential oil 0.1%, preservative 0.2%, water 11.7%.

[0036] The production process is as follows: first add 11.7 parts of water to the mixer, add amino acid soap base and plant essential oil soap base, heat the mixer to 50°C, and stir for 15 minutes to completely melt the soap base. Add natural fatty alcohol derivatives, cocamidopropyl betaine and cocoal monoethanolamine, stir well, then add natural fatty alcohol high-efficiency cleaners, essential oils and preservatives, stir well, put in non-woven fabric, above The components are mixed to form a binder, and then the above binder is put into a mold to form a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com