Patents

Literature

65results about How to "Prevent overcut" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

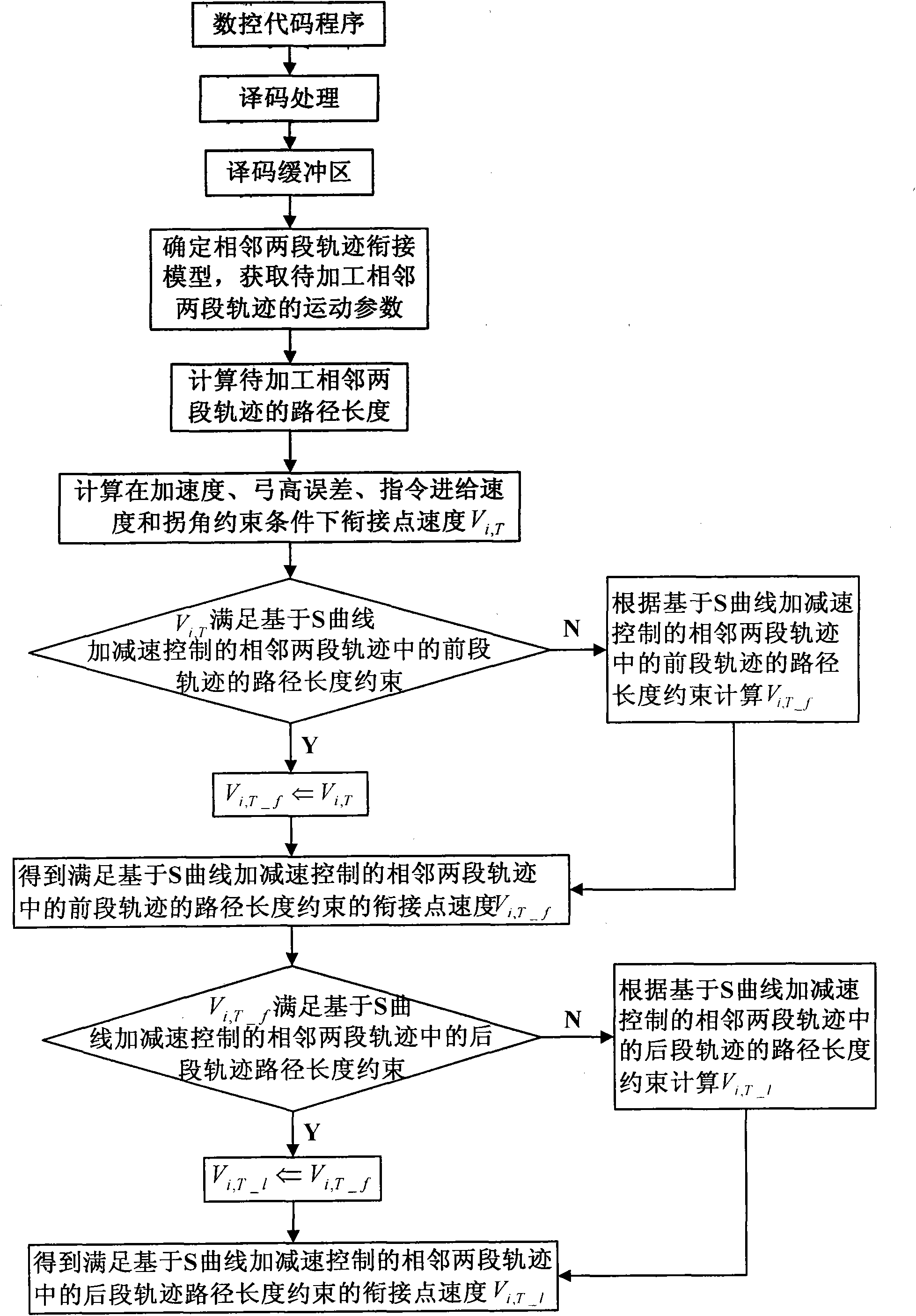

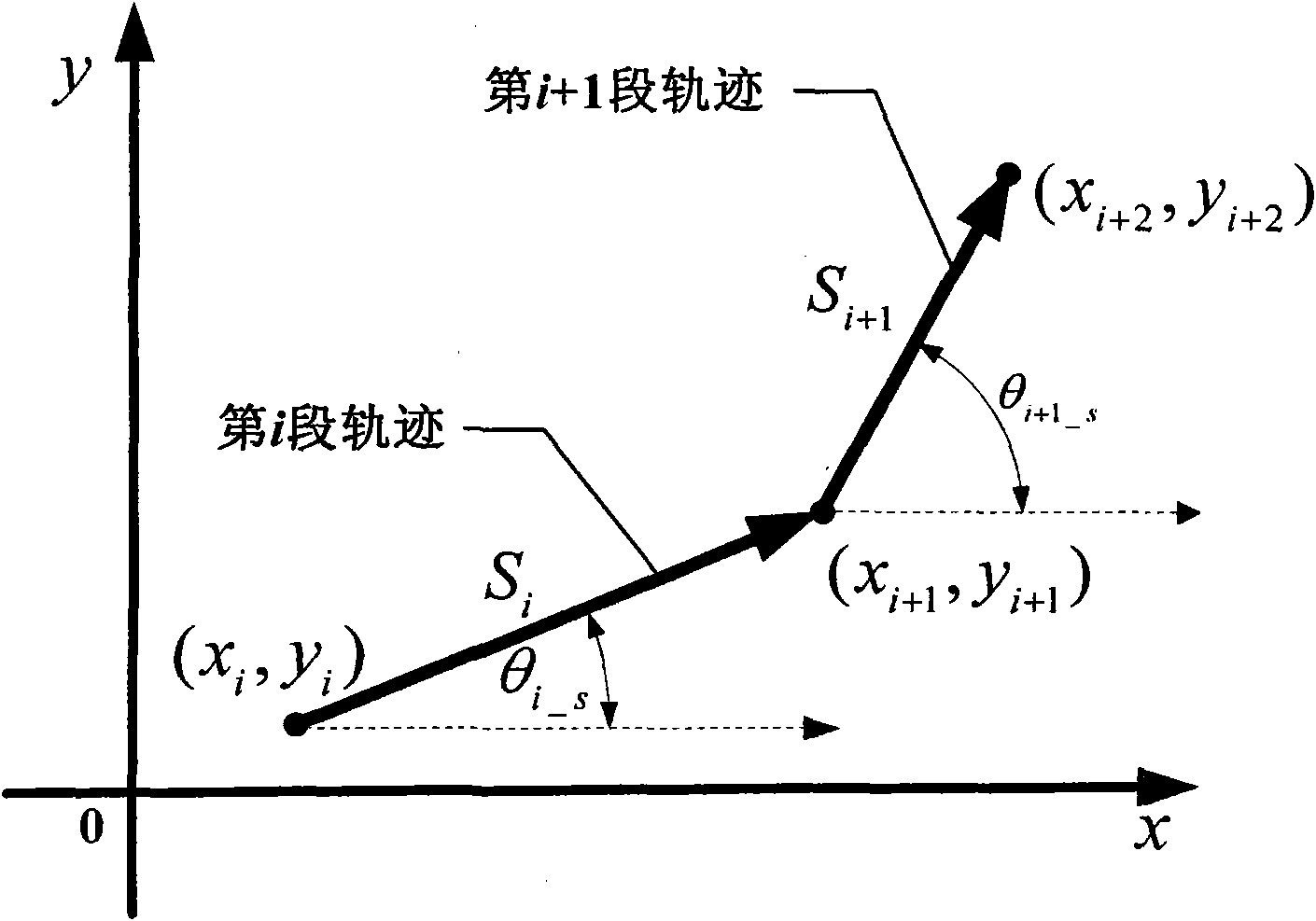

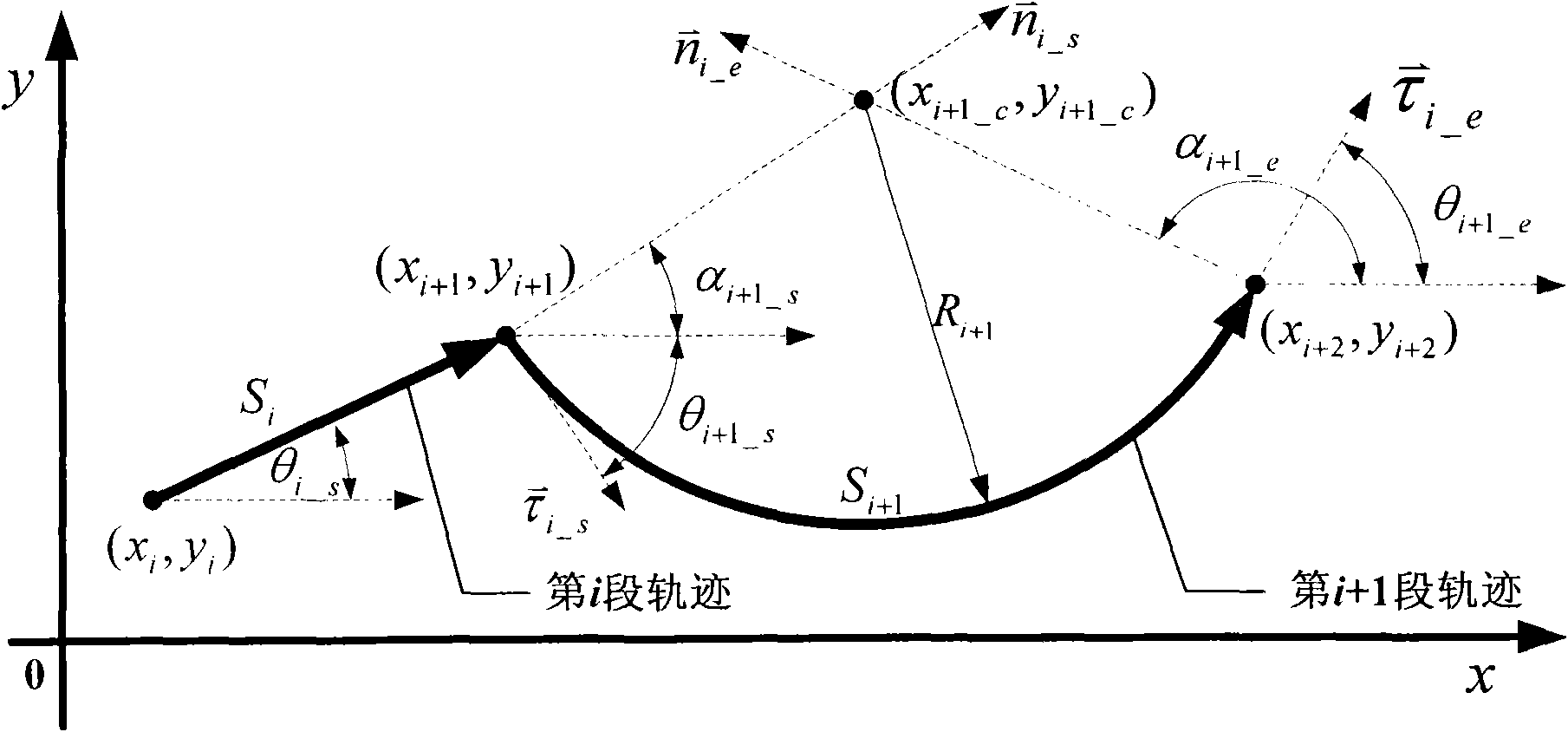

Continuous locus intersegment connecting speed processing method for numerical control system

InactiveCN102141794AContinuous processing pathPrevent overcutNumerical controlPath lengthMotion parameter

The invention discloses a continuous locus intersegment connecting speed processing method for a numerical control system, which comprises the following steps of: determining an adjacent two-segment locus connecting model, and acquiring the movement parameter of the adjacent two-segment locus to be processed; calculating the path length of the adjacent two-segment locus to be processed; calculating the speed of a connecting point of the adjacent two-segment locus under the conditions of acceleration, arch height error, instruction feeding speed and corner constraint; calculating the speed of the connecting point of the adjacent two-segment locus satisfying the condition S curve acceleration and deceleration control-based path length constraint of the front segment locus in the adjacent two-segment locus; and calculating the speed of the connecting point of the adjacent two-segment locus satisfying the condition S curve acceleration and deceleration control-based path length constraint of the rear segment locus in the adjacent two-segment locus, wherein the calculated speed is used as a final value of the adjacent two-segment locus connecting speed. The invention provides the continuous locus intersegment connecting speed processing method for numerical control equipment, so that the processing locus of the numerical control equipment is continuous and the speed is smooth.

Owner:GUANGXI UNIV

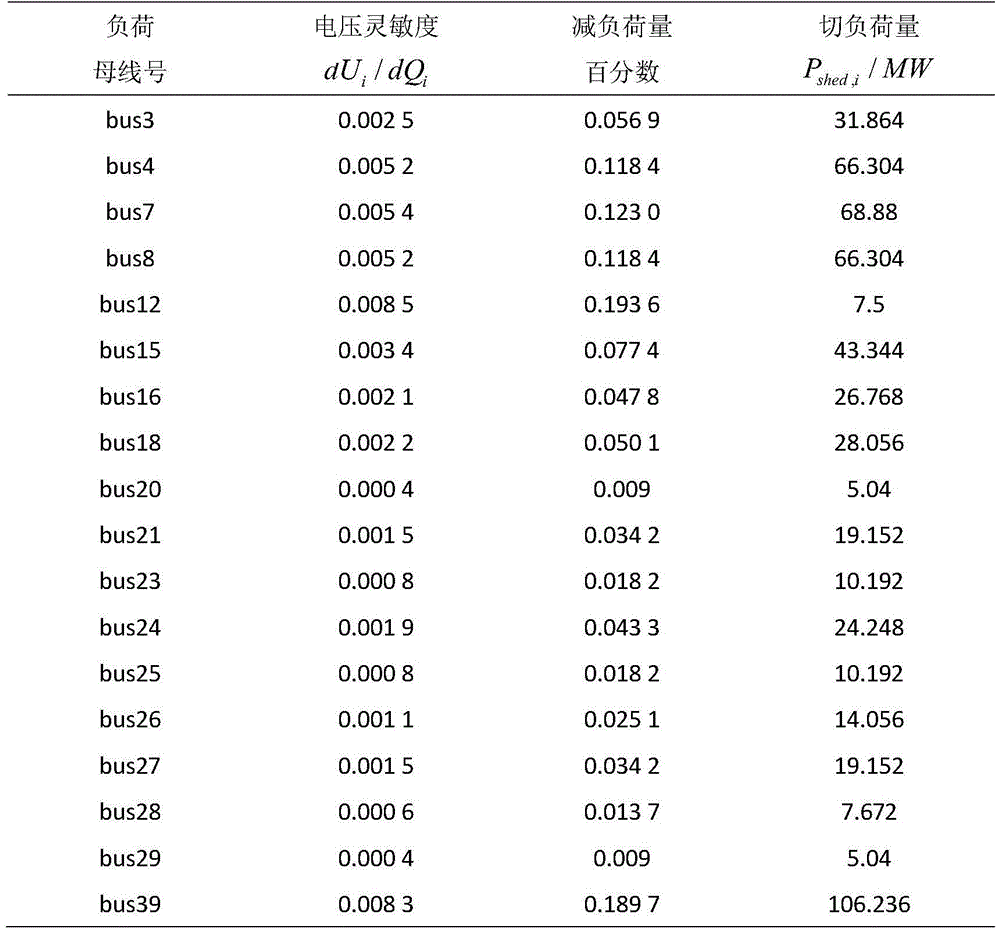

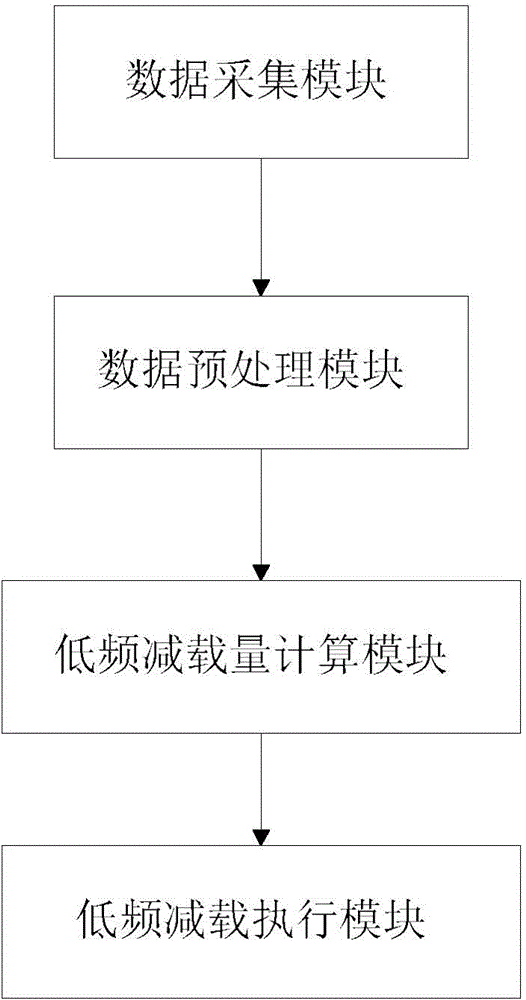

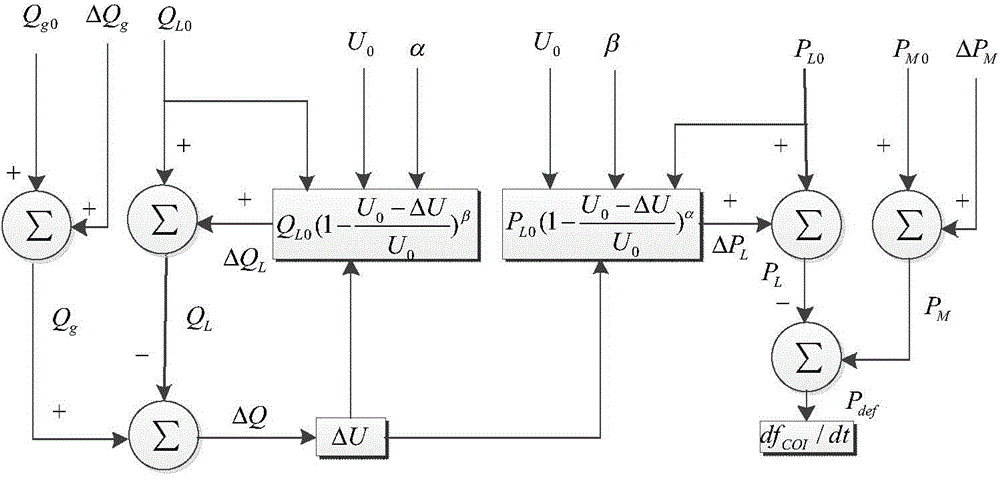

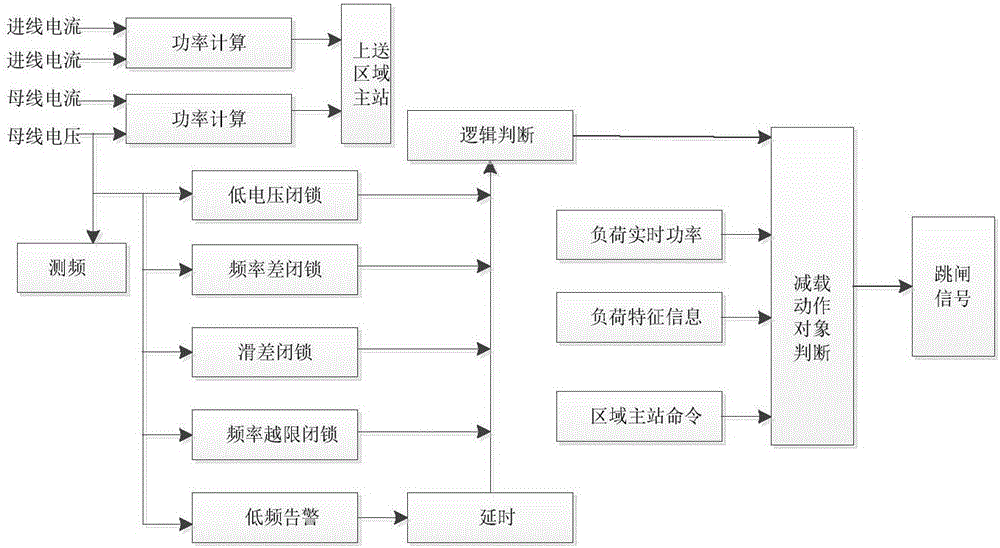

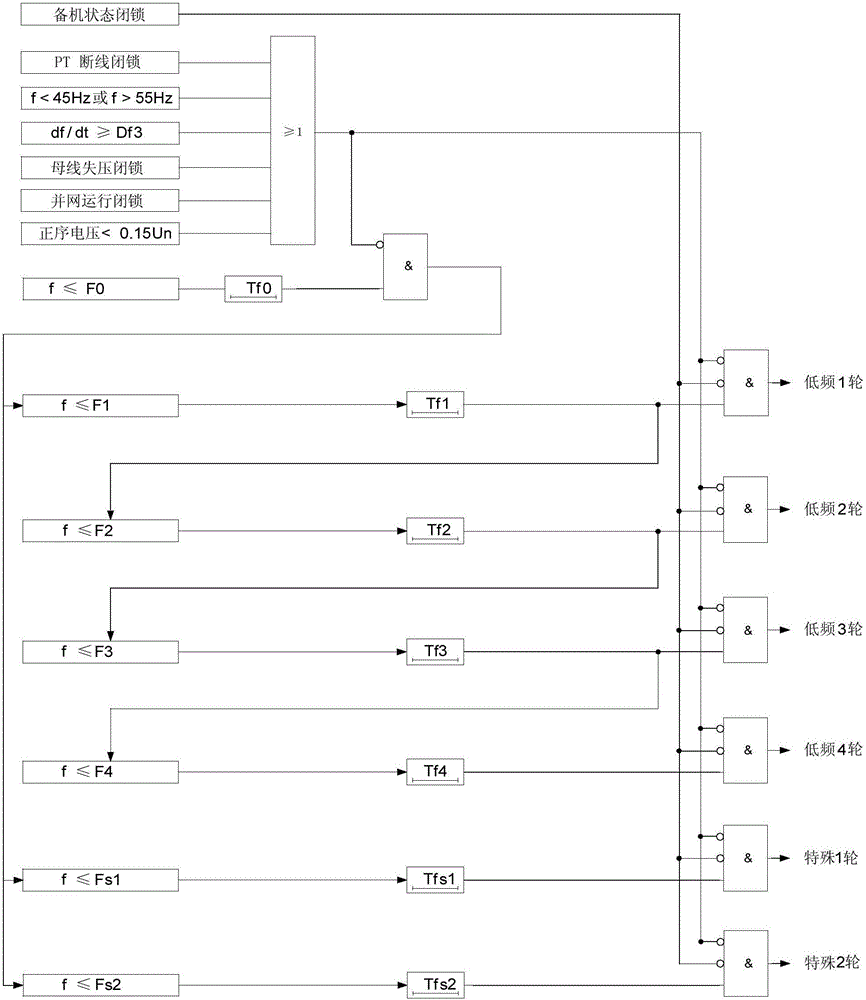

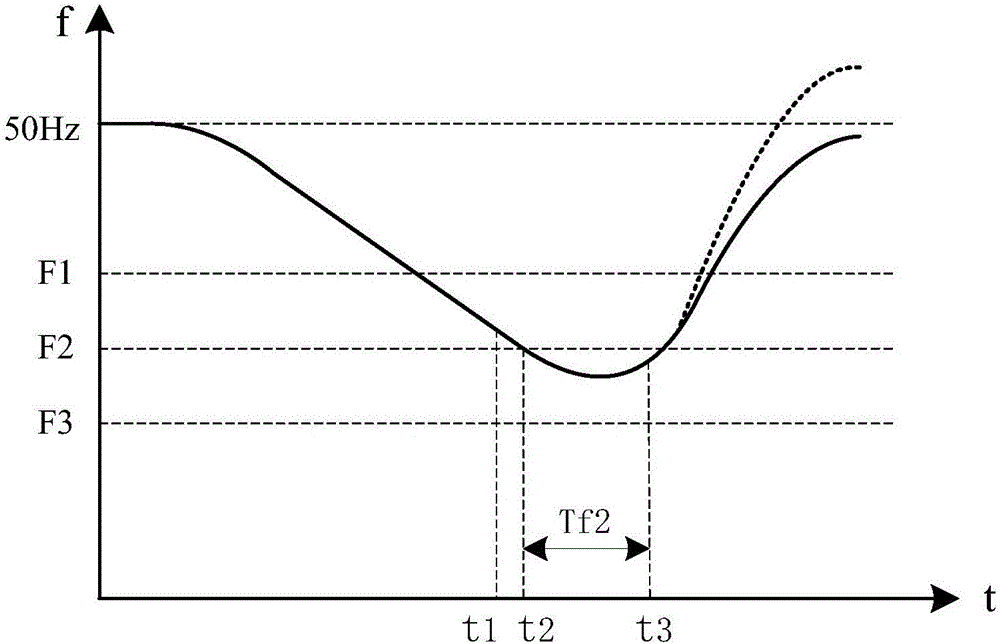

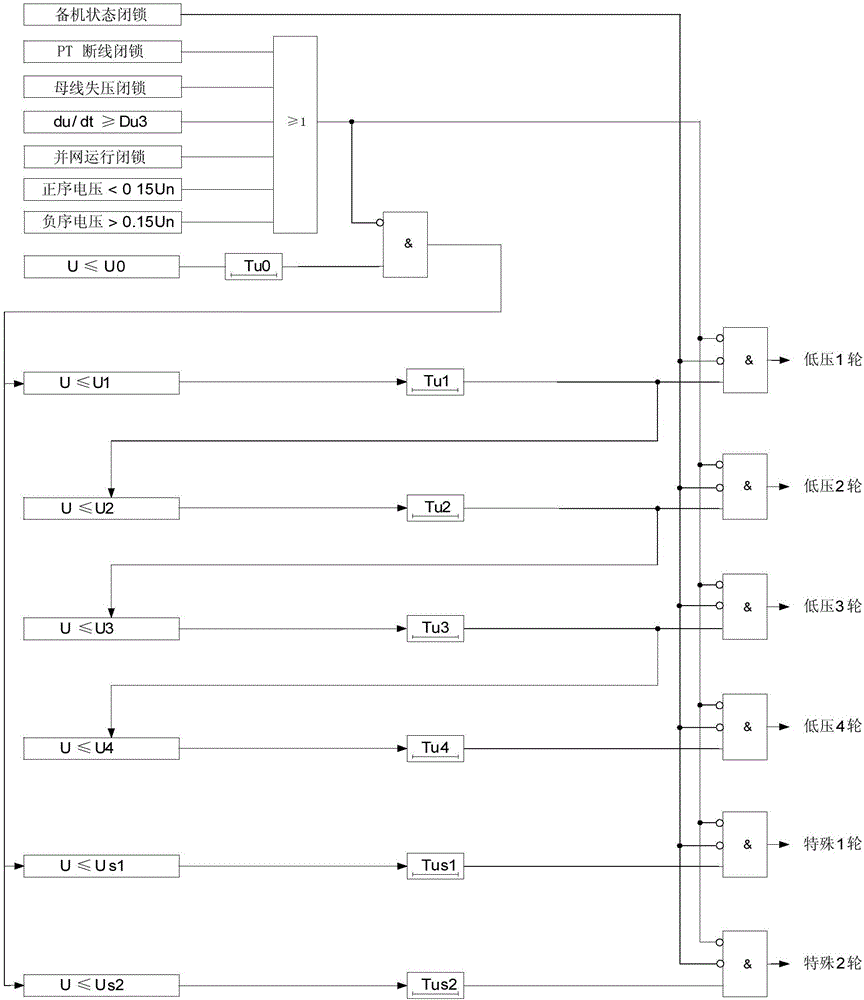

Low-frequency load reduction system and method

InactiveCN104701852APrevent overcutAchieve local balancePower network operation systems integrationAc network voltage adjustmentComputer moduleParallel computing

The invention provides a low-frequency load reduction system and method. The system comprises a data acquiring module, a data preprocessing module, a low-frequency load reduction quantity calculating module and a low-frequency load reduction performing module which are sequentially connected, wherein the data acquiring module is used for acquiring the system data; the data preprocessing module is used for preprocessing the data acquired by the data acquiring module; the low-frequency load reduction quantity calculation module is used for calculating the total load reduction quantity of the system and the load reduction quantity of each load bus of the system; the low-frequency load reduction performing module is used for determining the tangential load bus and the corresponding tangential load quantity. With the adoption of the system and the method, the system frequency can be quickly returned to be stable, and meanwhile, the system voltage stability can be greatly improved.

Owner:BEIJING SIFANG JIBAO AUTOMATION +1

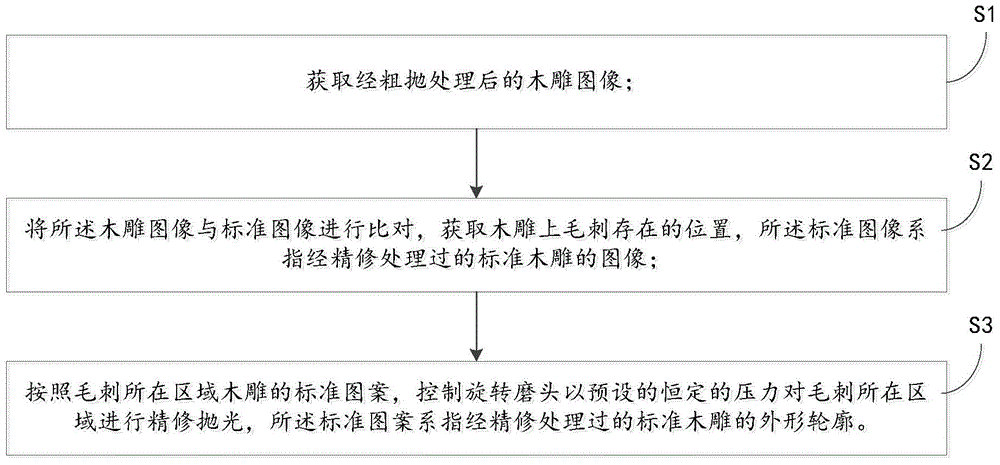

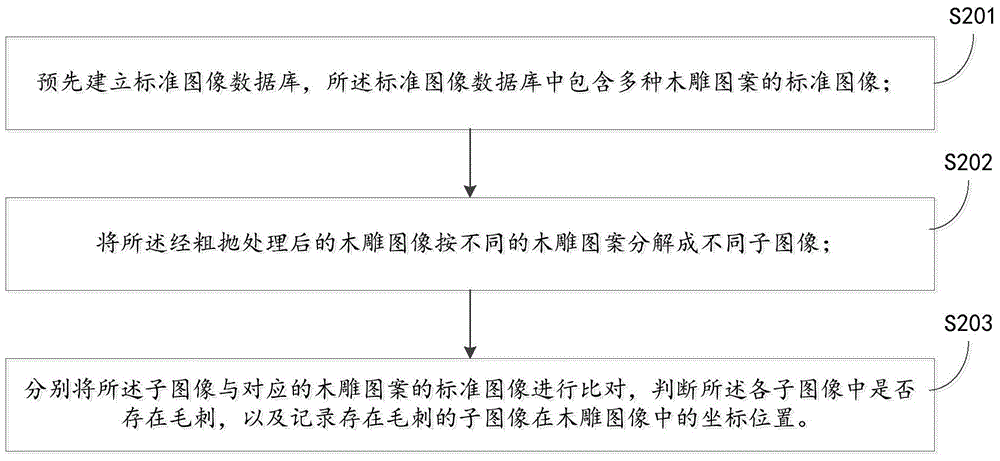

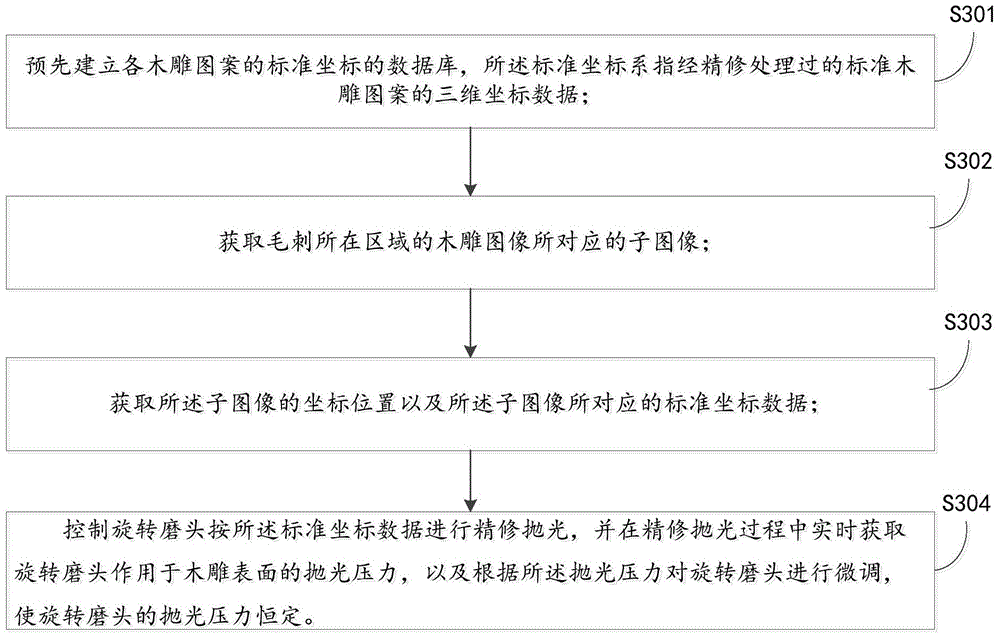

Woodcarving refine method and device based on image processing and force feedback

InactiveCN104959891AImprove search efficiencyQuality improvementEdge grinding machinesImaging processingDigital image processing

The invention discloses a woodcarving refine method based on image processing and force feedback; the method comprises the following steps: obtaining a woodcarving image after rough polishing; comparing the woodcarving image with a standard image so as to obtain burr positions on the woodcarving, and the standard image refers to a standard woodcarving image after refine process; controlling a rotary grinding head to carry out refine polishing on the burr positions with a preset constant pressure according to the woodcarving standard image of the burr positions, wherein the standard image refers to a layout of the standard woodcarving after refine treatment. The invention also discloses a woodcarving refine device based on image processing and force feedback, thus realizing high precision and high efficiency woodcarving refine by a machine.

Owner:福建省天大精诺信息有限公司

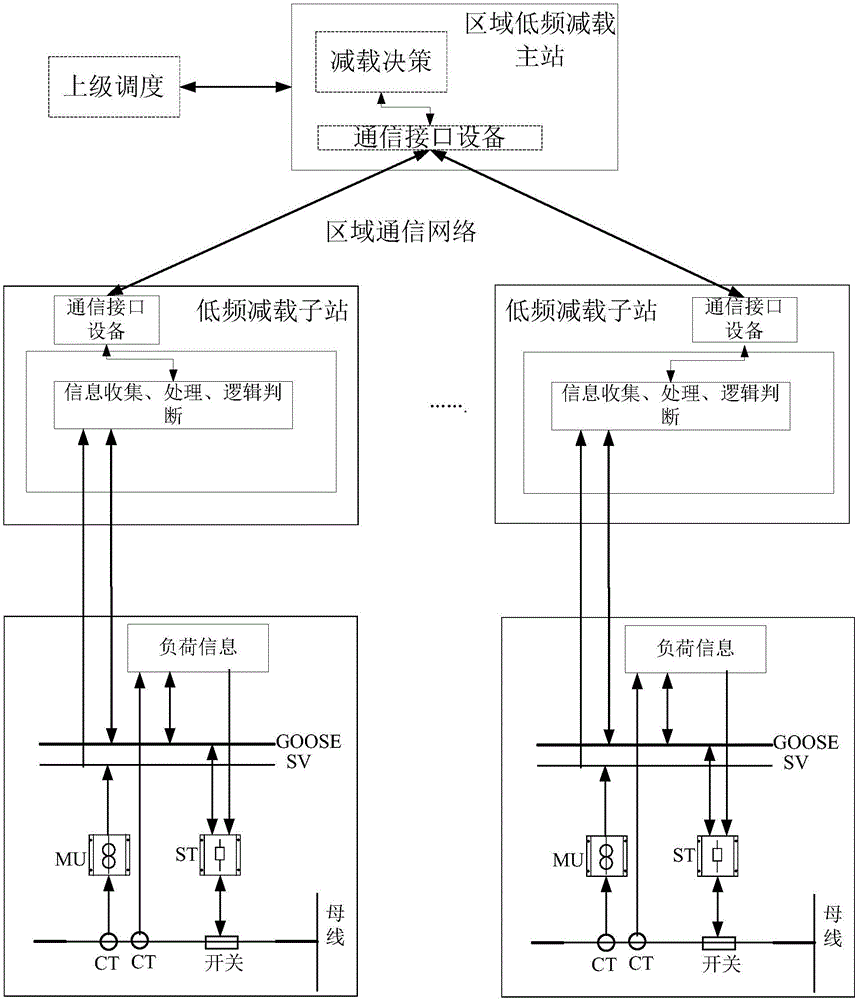

Under-frequency load shedding system and under-frequency load shedding method on basis of panoramic information of regional power grids

InactiveCN106356863AImprove efficiencyImprove accuracyPower network operation systems integrationAc network voltage adjustmentLoad SheddingTransformer

The invention provides an under-frequency load shedding system and an under-frequency load shedding method on the basis of panoramic information of regional power grids. The under-frequency load shedding system comprises combining units and at least two under-frequency load shedding substations. The combining units are connected with transformer substations so as to acquire working parameters of the transformer substations; each under-frequency load shedding substation is connected with the corresponding combining unit so as to acquire the working parameters of the transformer substations; each under-frequency load shedding substation is connected with a regional under-frequency load shedding master station so as to transmit the working parameters of the transformer substations to the regional under-frequency load shedding master station and receive load shedding control instructions transmitted by the regional under-frequency load shedding maser station; each under-frequency load shedding substation is connected with intelligent interfaces of load so as to control disconnection / connection of the load according to the load shedding control instructions; power grid operation information in regions can be acquired by the under-frequency load shedding substations in the connection regions of the regional under-frequency load shedding master station, so that power grid load and load flow in the regions can be controlled in a unified and coordinated manner; the load can be correspondingly shed by the under-frequency load shedding substations in the regions when faults occur.

Owner:XUCHANG XJ SOFTWARE TECH +3

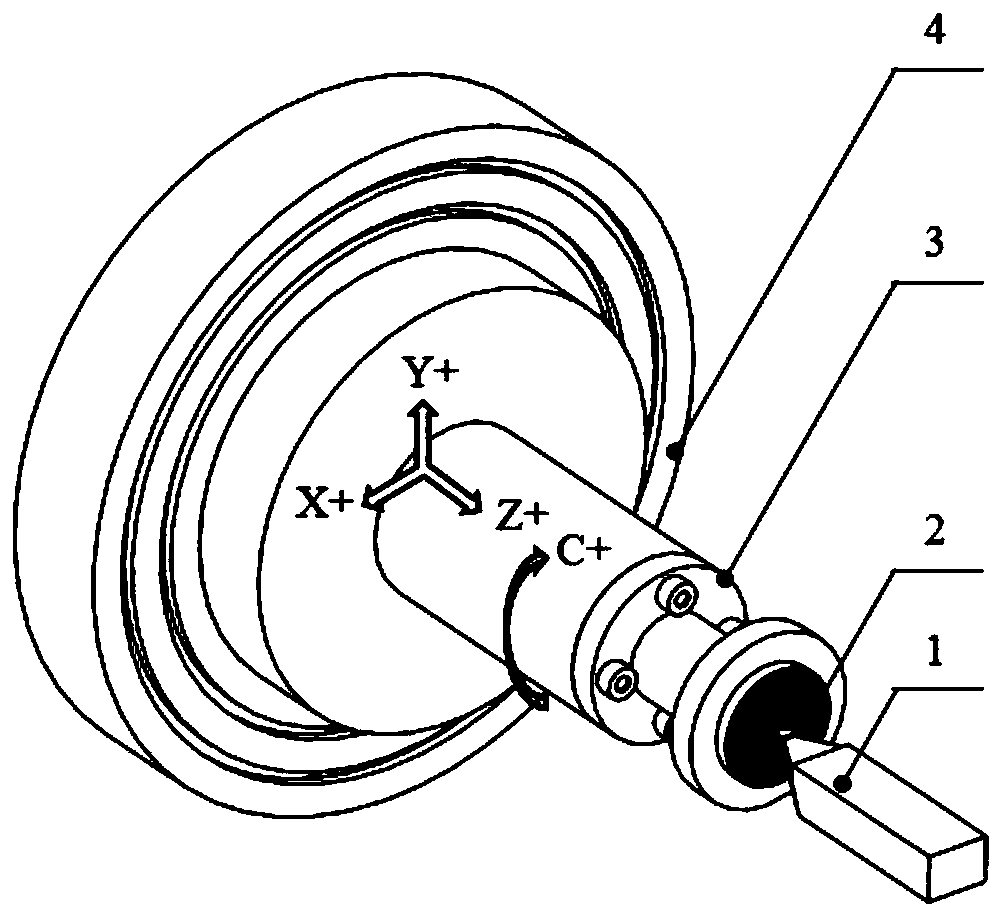

Fixed-point rotary cutting method for off-axis microlens machining

The invention discloses a fixed-point rotary cutting method for off-axis microlens machining, and relates to a fixed-point rotary cutting method. The problem that the machining precision of a microlens is reduced due to the high-frequency motion which adversely affects the motion stability of a machine tool when the corner radius is compensated in the prior art, and the problem that planning of acutting track is difficult are solved. The method comprises the first step of adjusting the distance between the rotation center axis of a workpiece and the spindle axis of an ultra-precision machinetool to be controlled within 0.5 micrometer, the second step of controlling the radial distance between a tool tip of a tool and the rotation center axis of the workpiece to be within 0.5 micrometer by adopting a trial cutting method, the third step of moving the tool tip to the central axis position of a certain microlens unit of a microlens part to be machined through machine tool linkage, the fourth step of planning an actual cutting track, the fifth step of achieving cutting machining of one single microlens unit through machine tool linkage and the sixth step of repeatedly performing thethird, fourth and fifth steps till all the microlesn units on the surface are machined. The fixed-point rotary cutting method is used for off-axis microlens machining.

Owner:HARBIN INST OF TECH

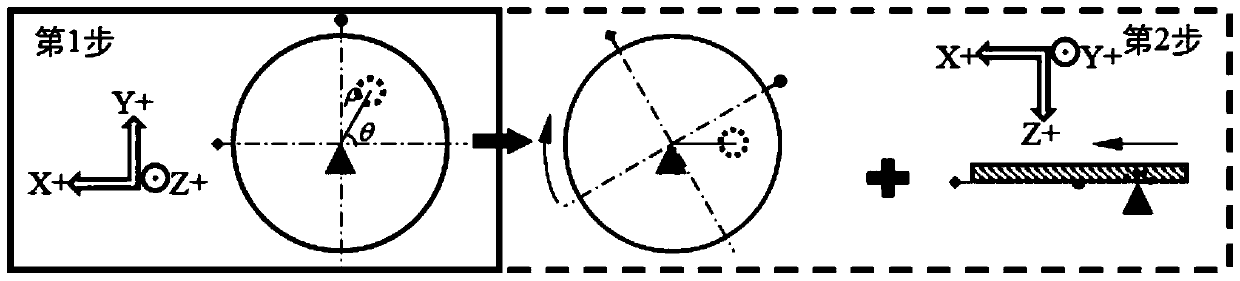

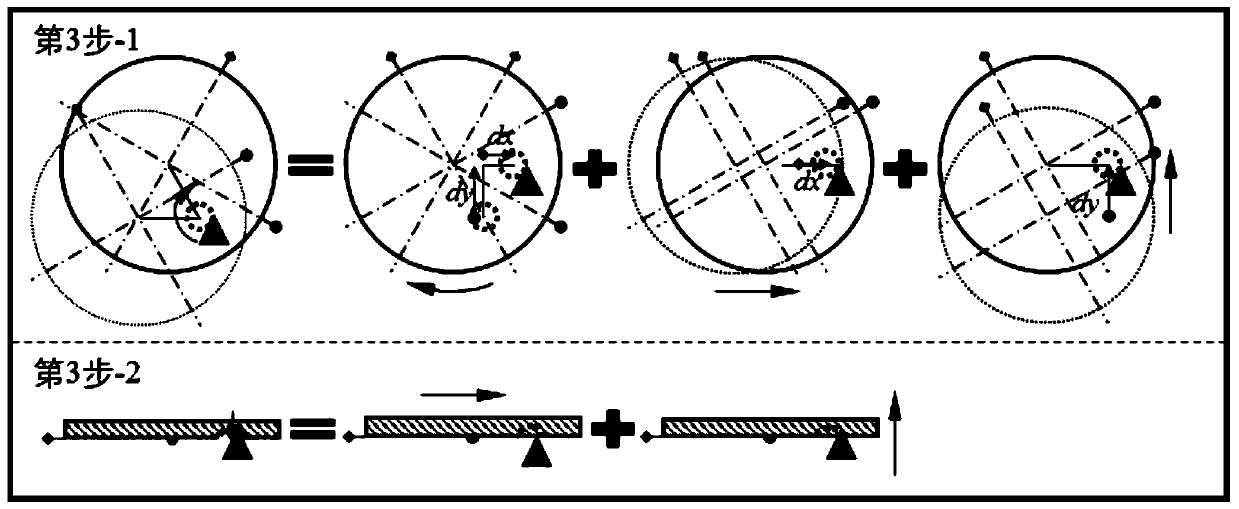

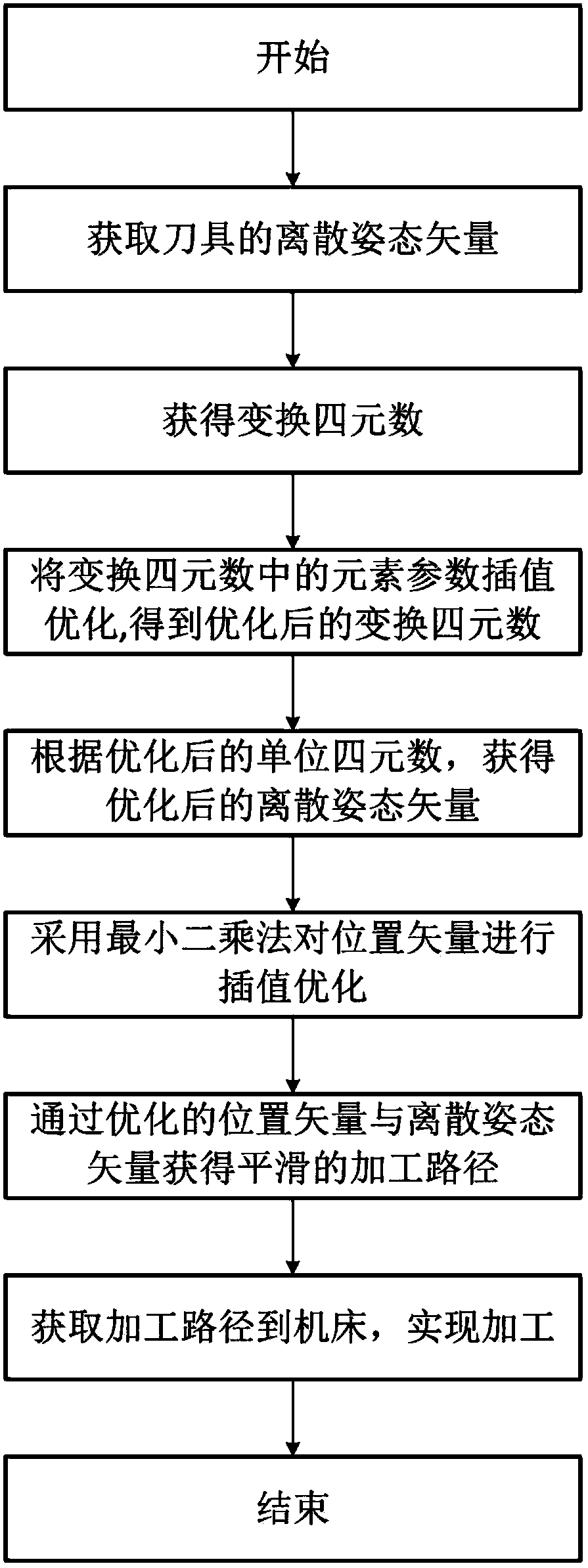

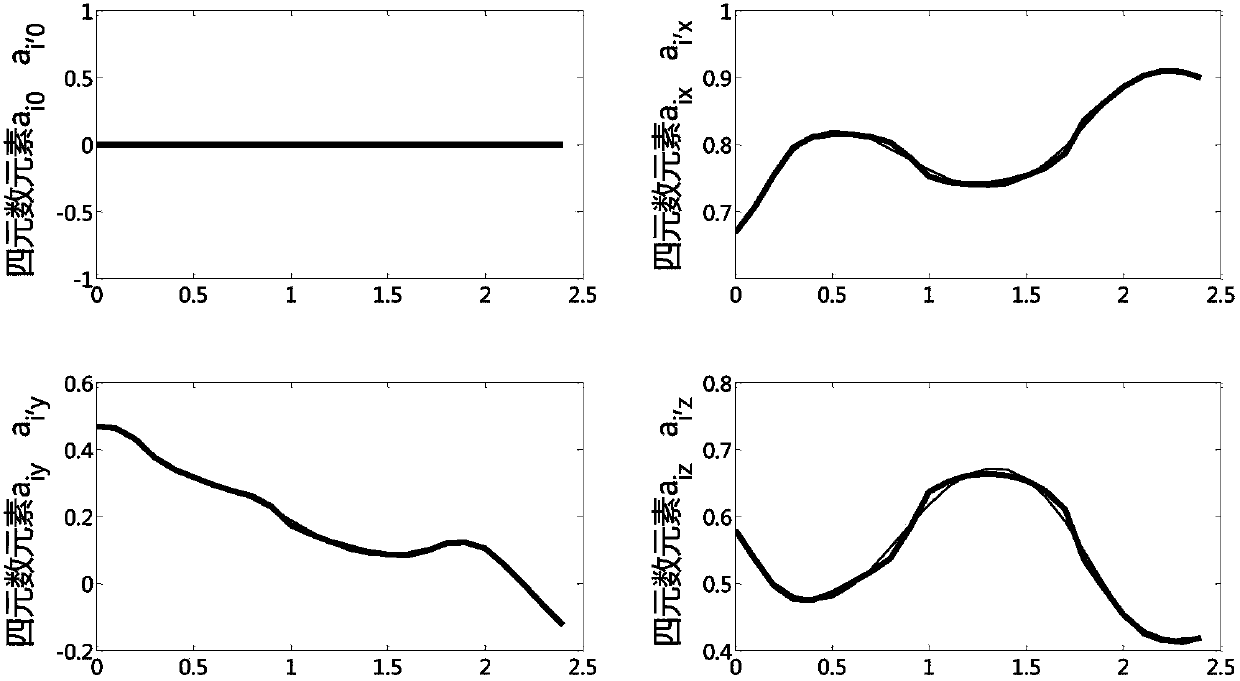

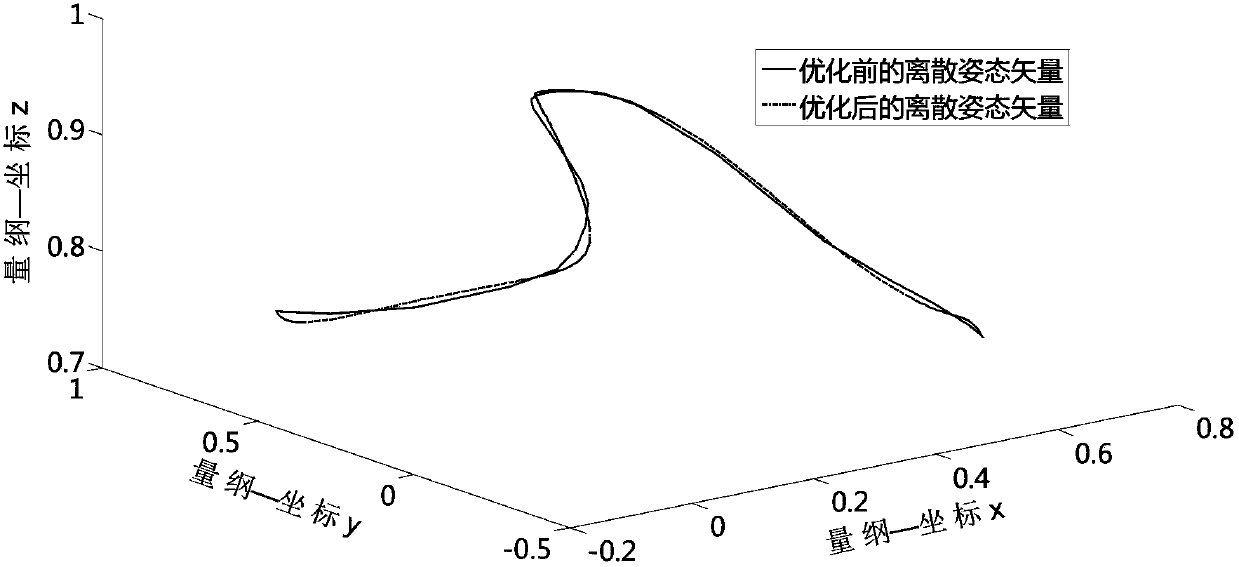

Method for smoothing machining route of five-axle machining cutter

The invention discloses a method for smoothing a machining route of a five-axle machining cutter. The method comprises the steps of obtaining a discrete attitude vector and a position vector of a five-axle machining cutter on a unit spherical surface; obtaining a transformation quaternion according to the discrete attitude vector; carrying out parameter interpolation optimization of the transformation quaternion in the quaternion space by the least square method so as to obtain optimized unit quaternion; obtaining the optimized discrete attitude vector that is located on the unit spherical surface according to the optimized unit quaternion; carrying out the interpolation optimization of the position vector by adopting the least square method; obtaining the smooth machining route by the interpolation-optimized position vector and the optimized discrete attitude vector; and inputting the smooth machining route into a five-axle numerically-controlled machine tool so as to realize the machining of workpieces. According to The method disclosed by the invention, the interpolation of the discrete attitude points on the unit spherical surface can be conducted to form a continuous smooth trace, and the cutting is conducted practically by the smooth trace to enhance machining precision.

Owner:HUST WUXI RES INST

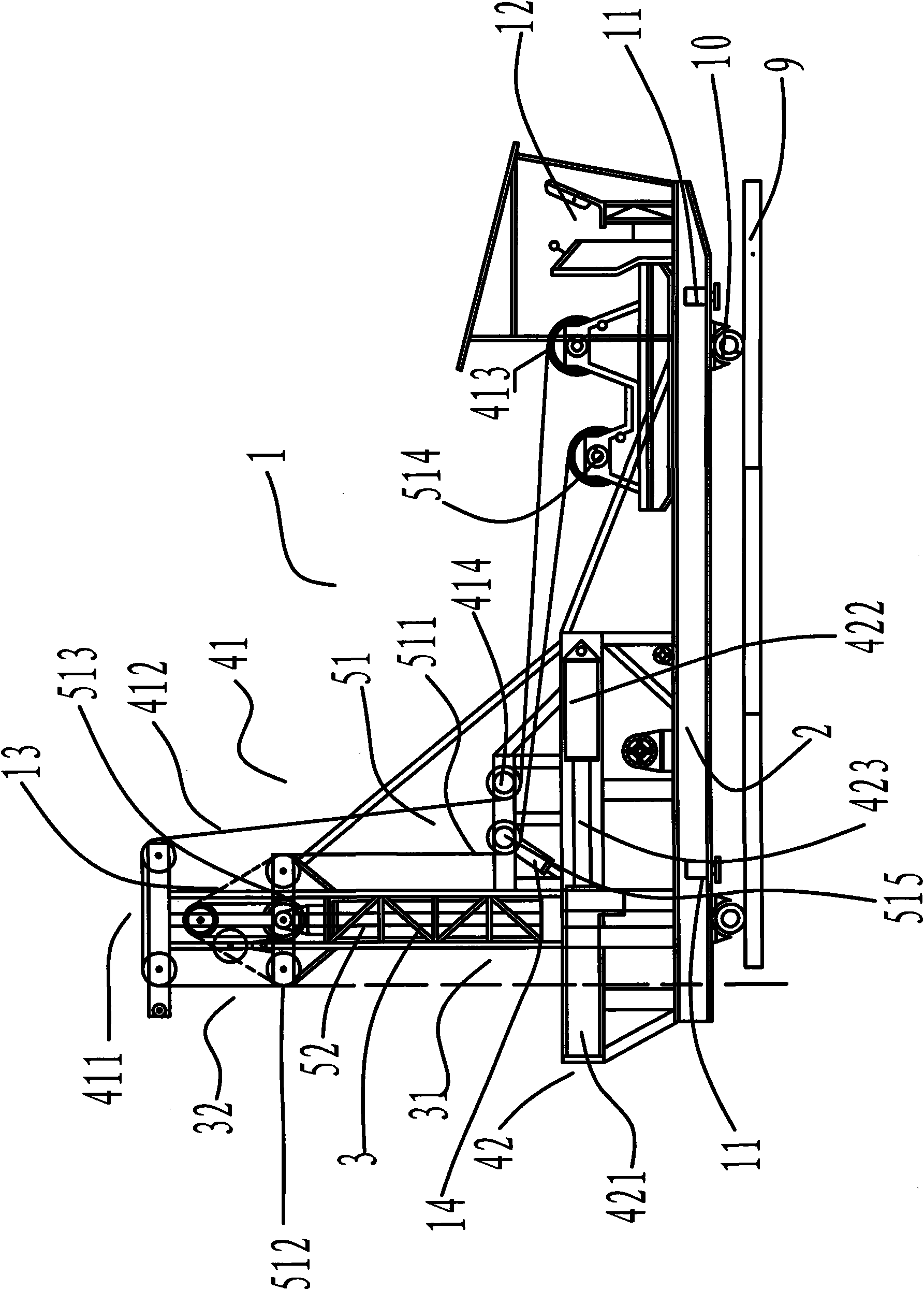

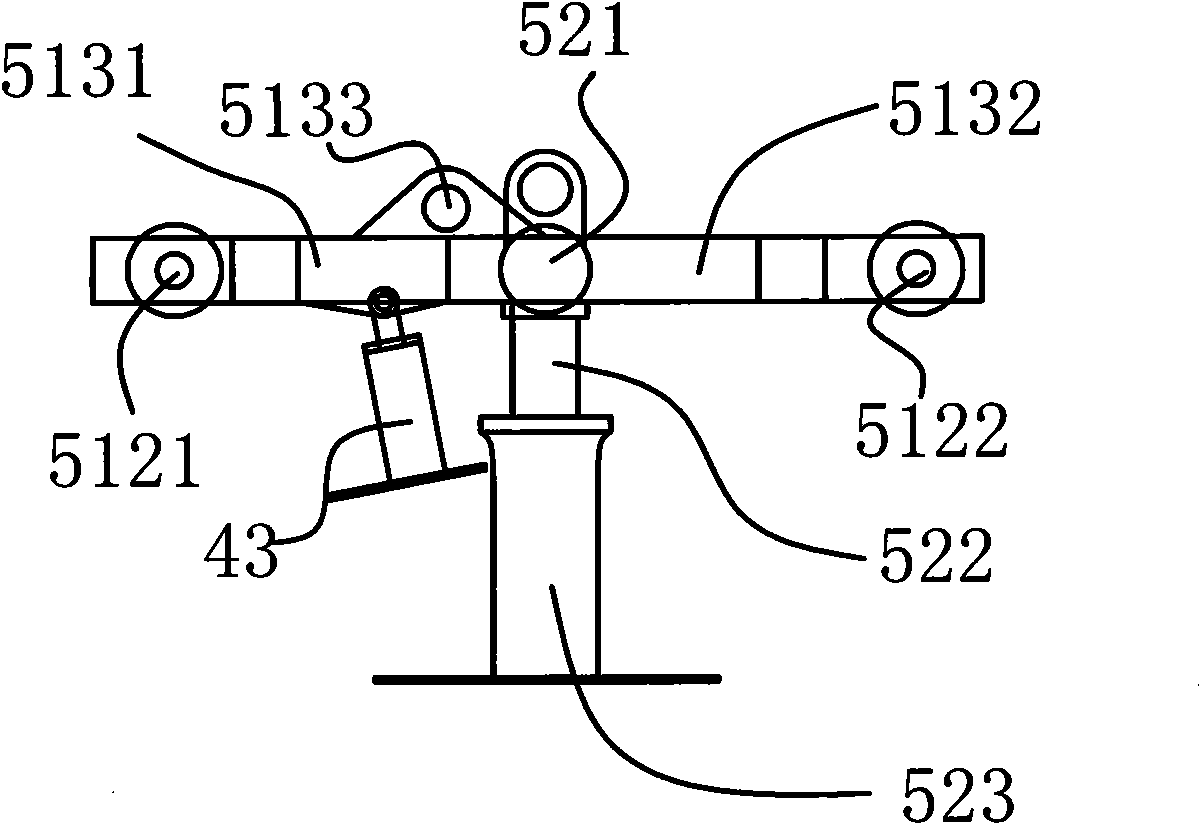

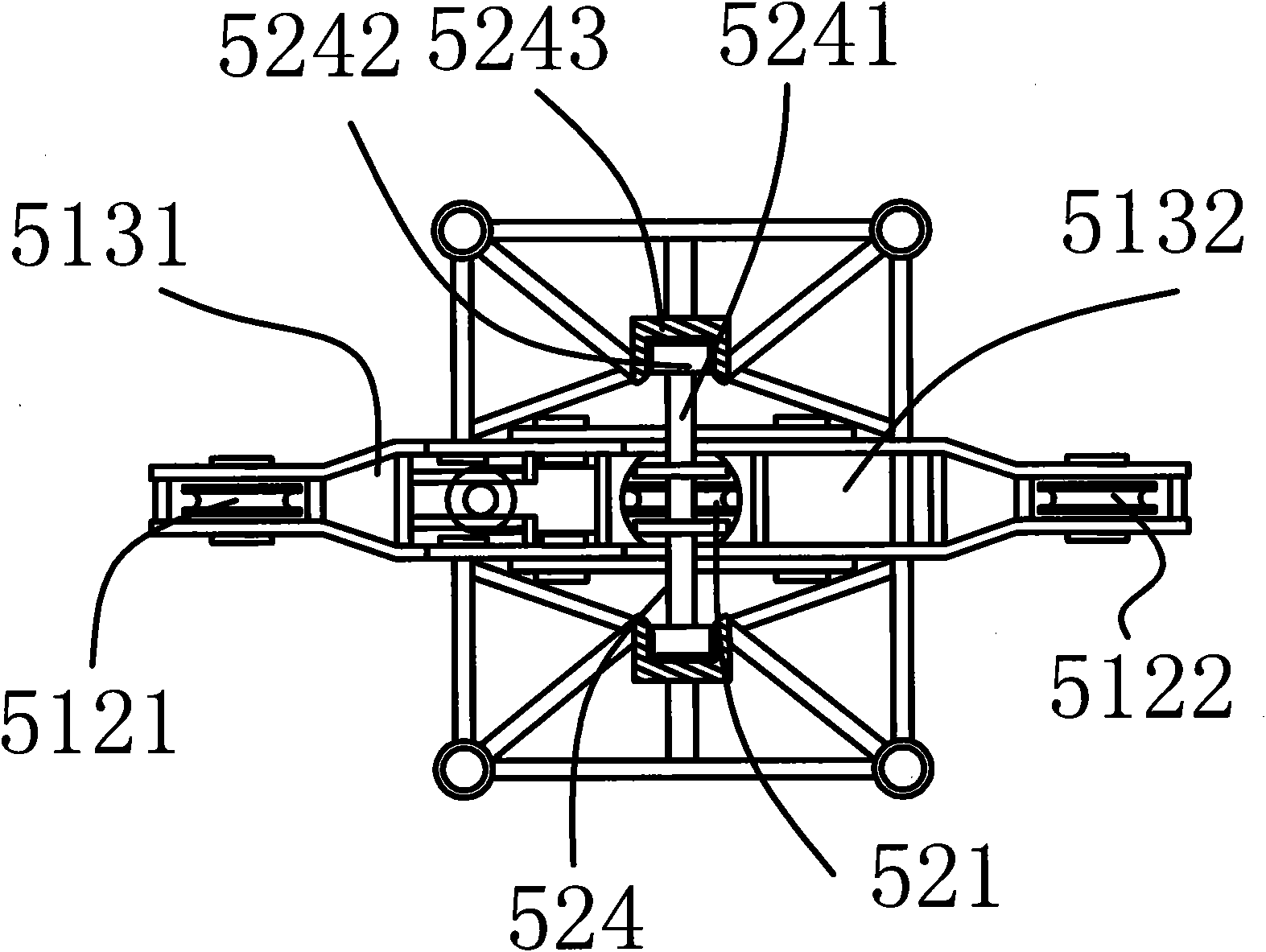

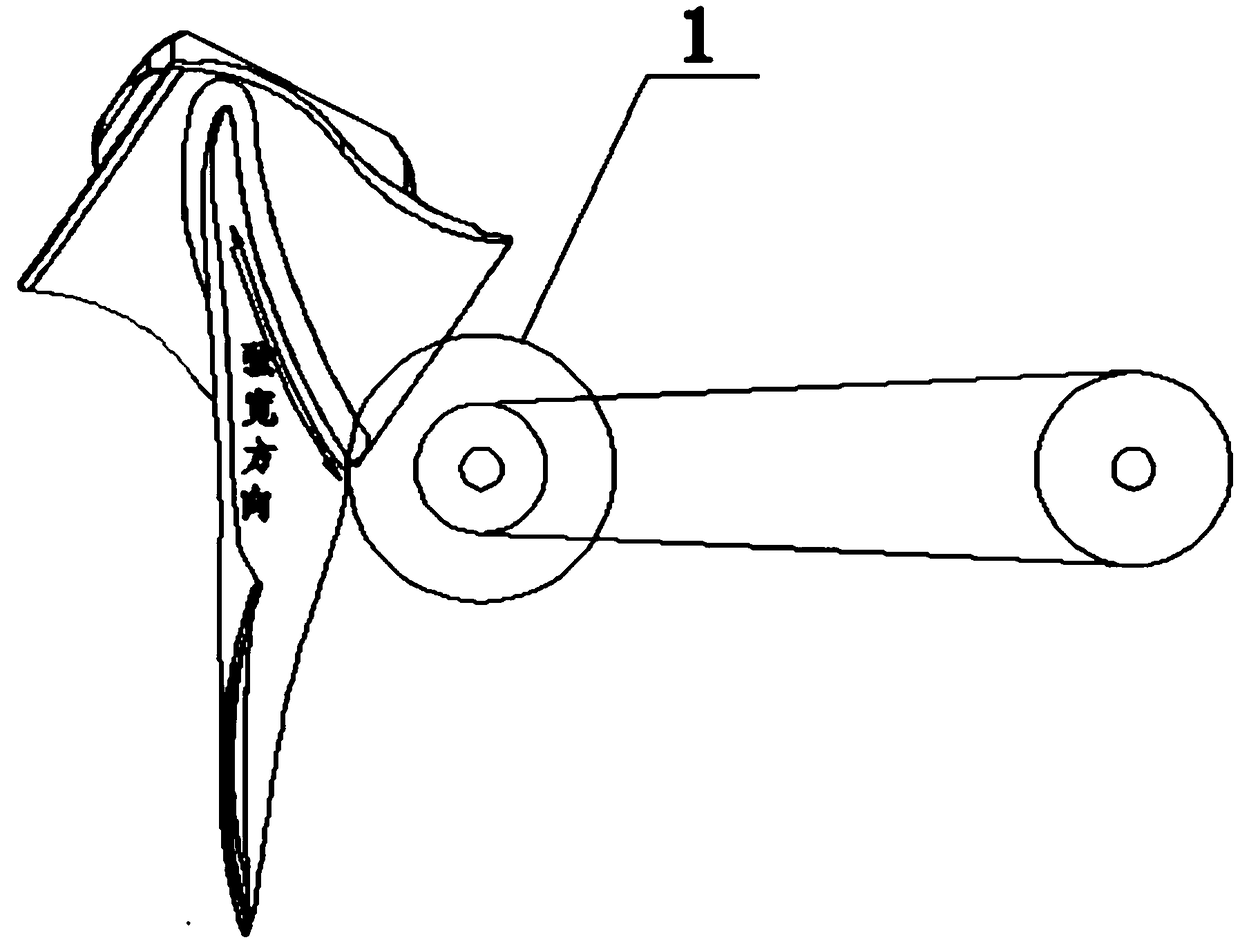

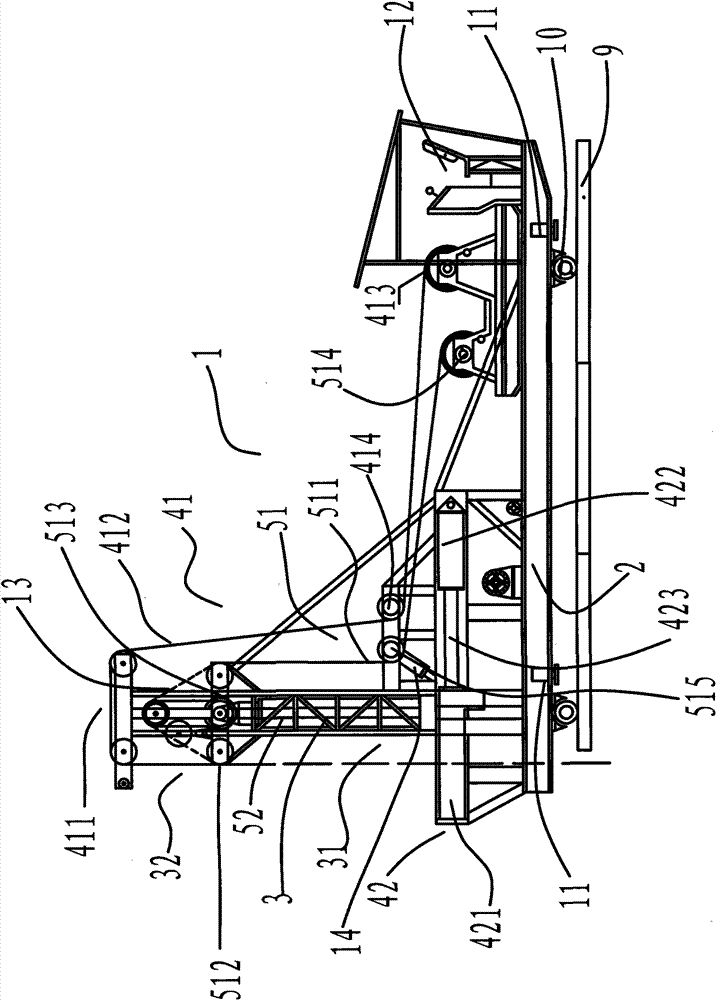

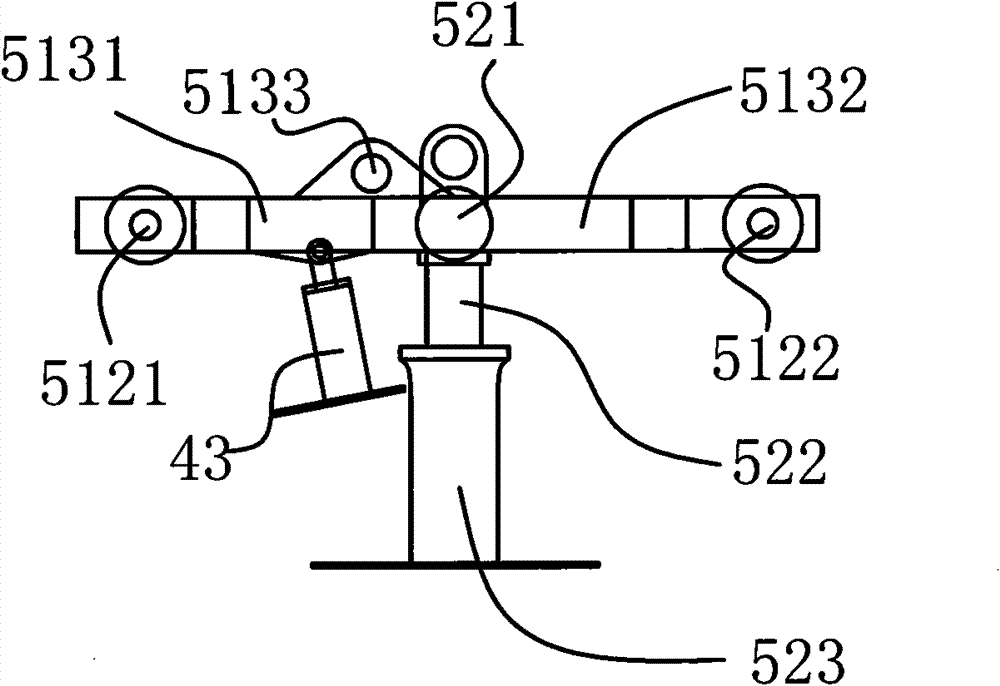

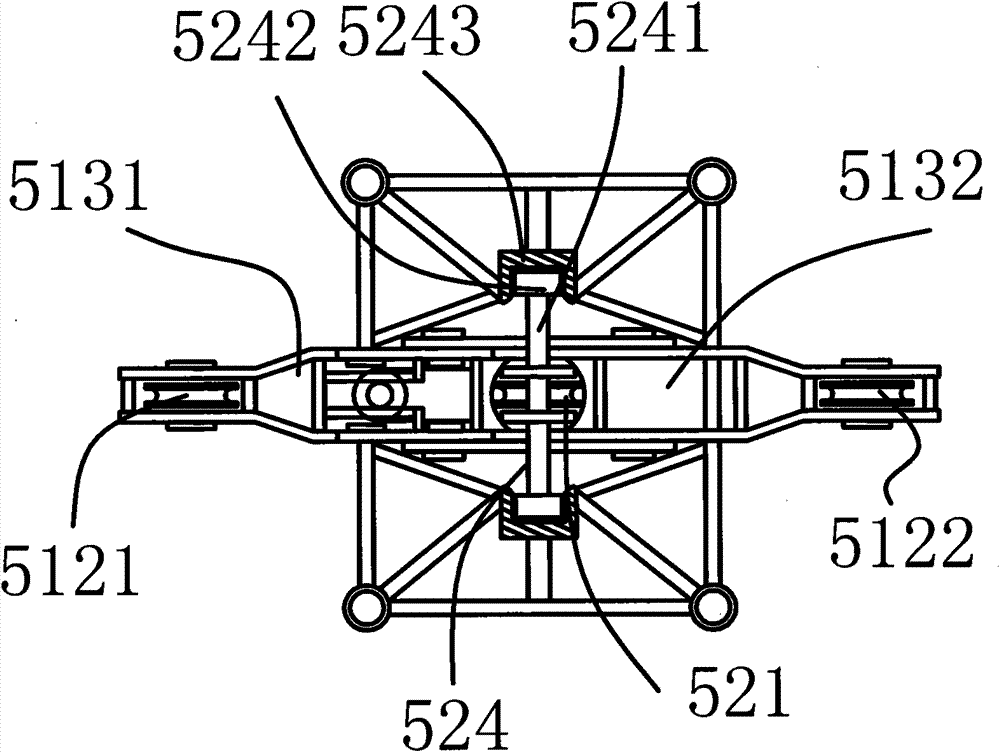

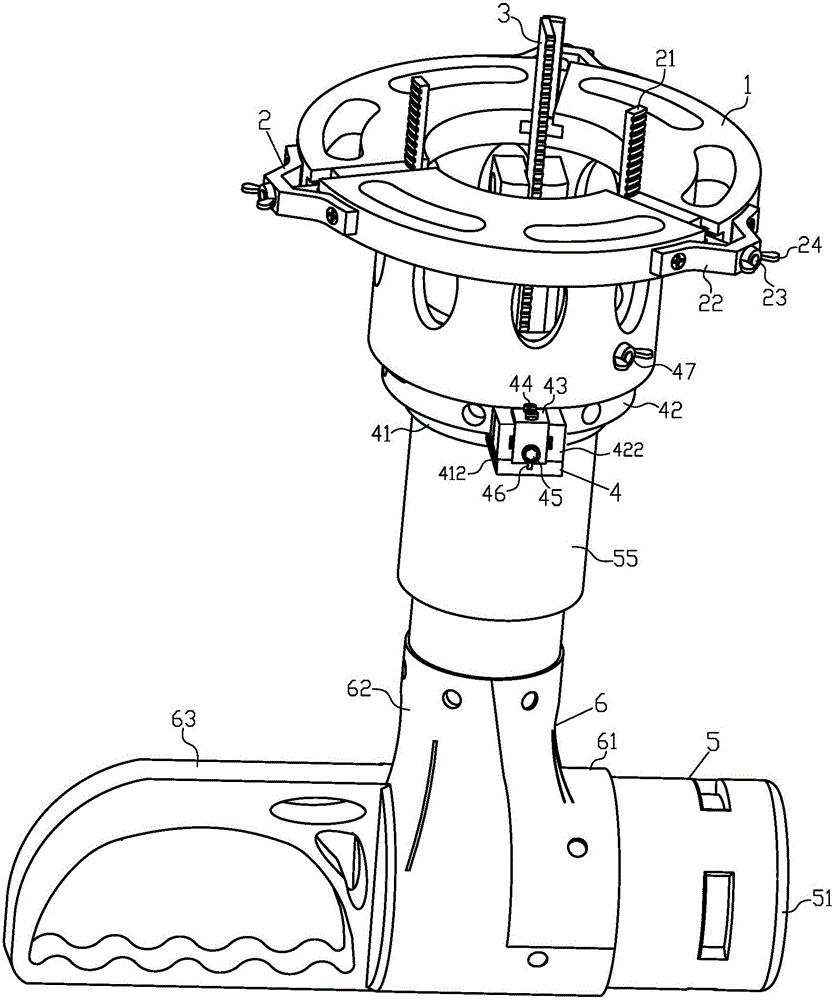

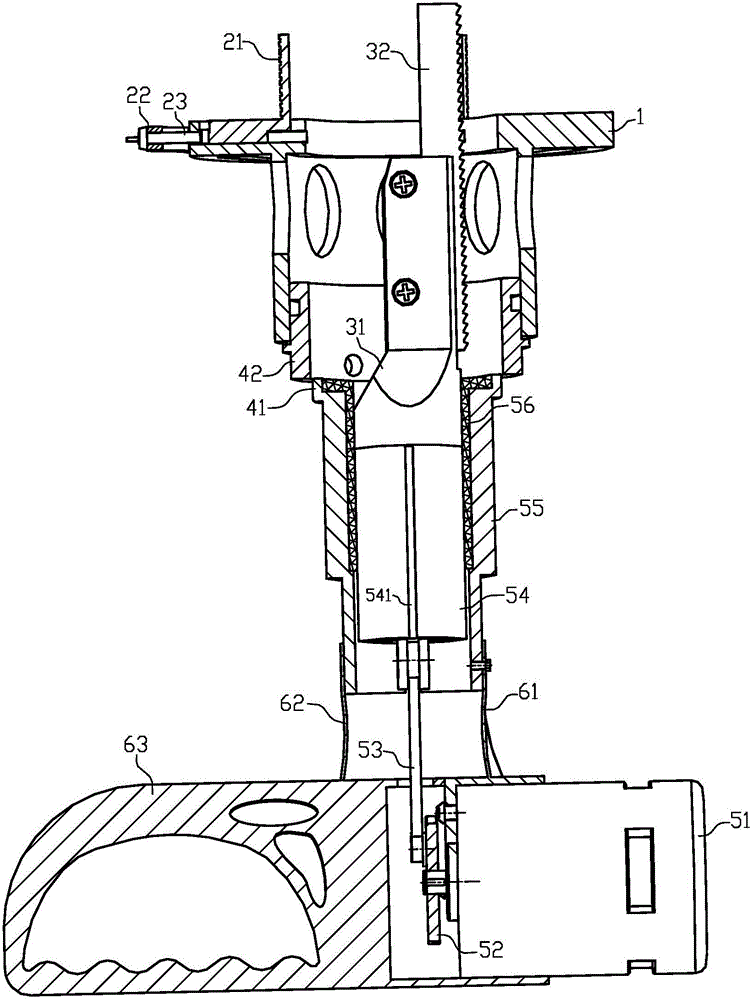

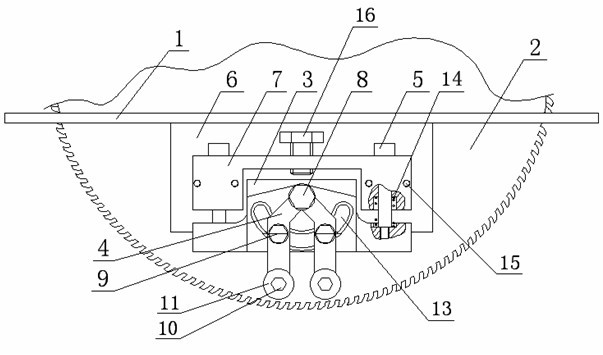

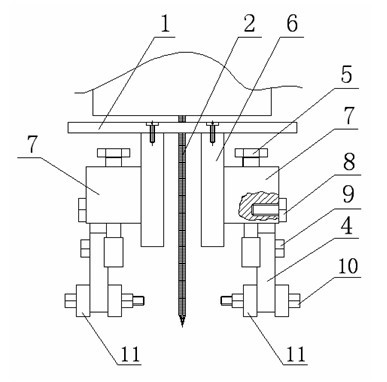

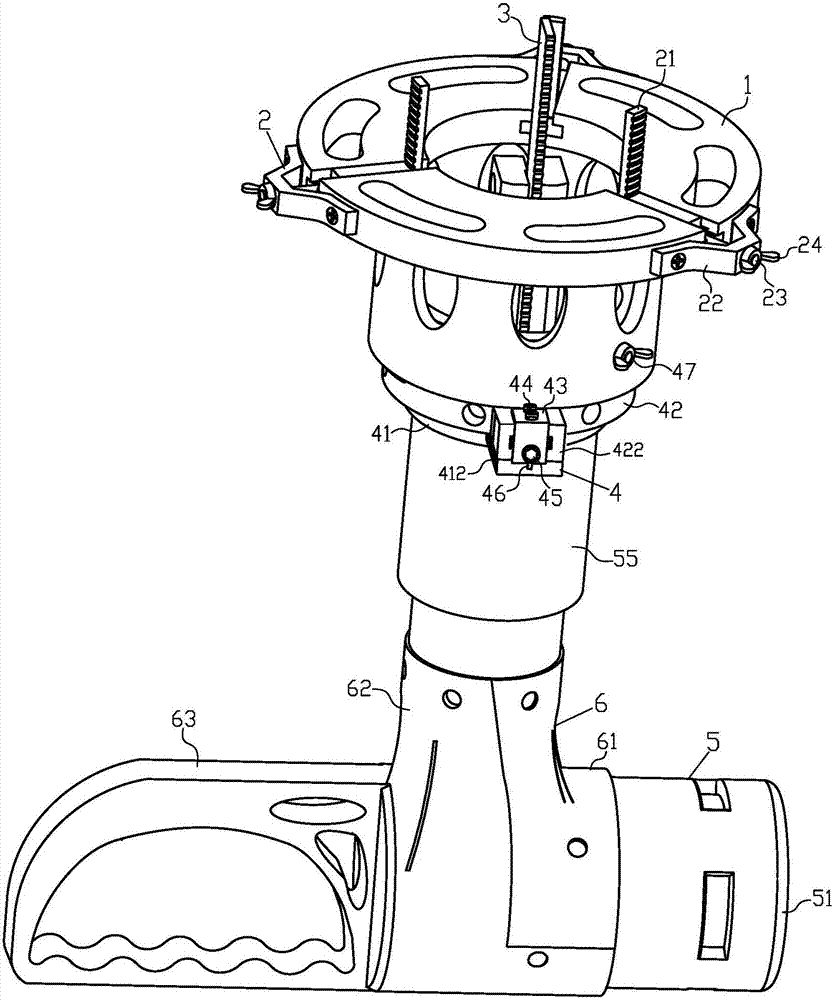

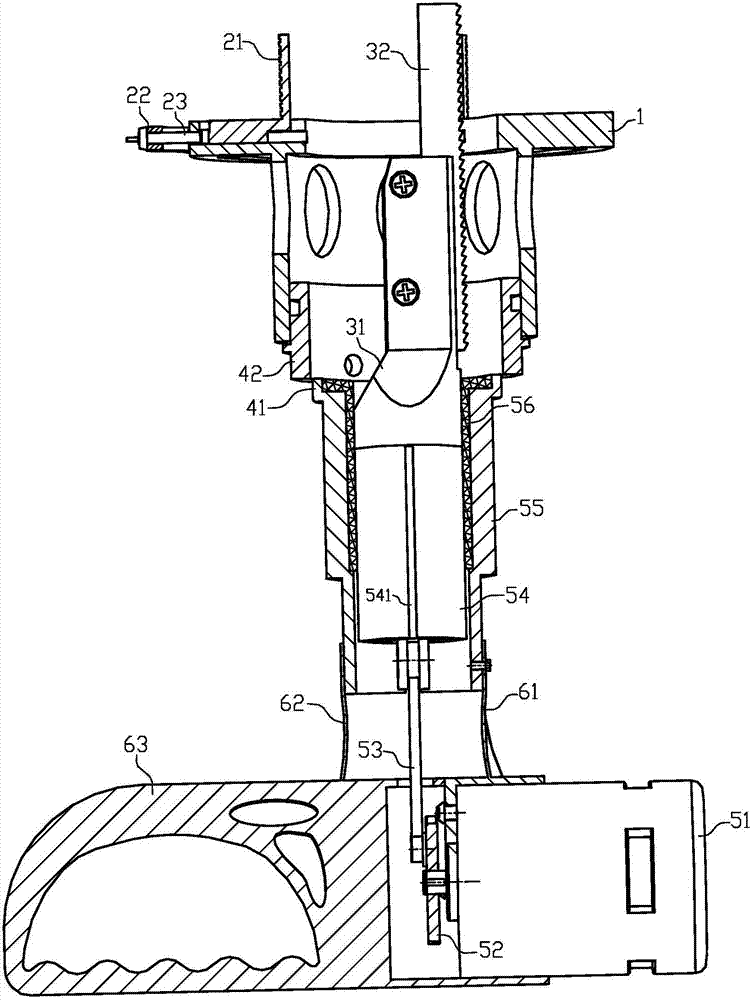

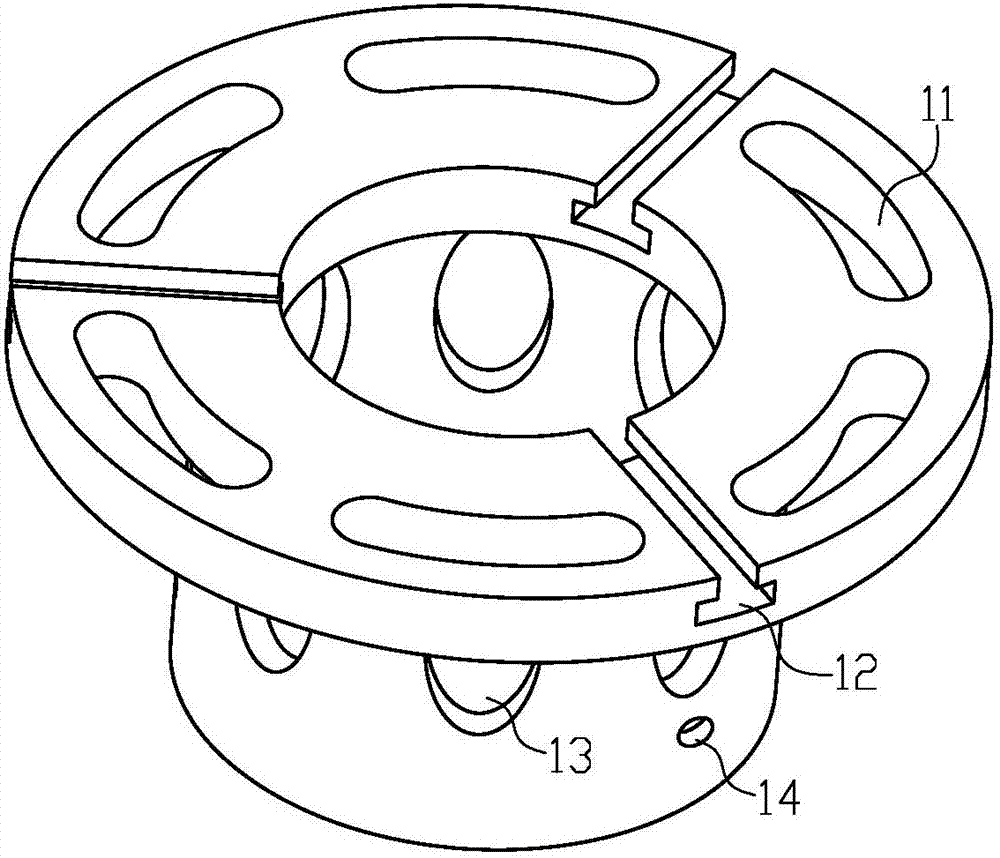

Piling machine

ActiveCN101871316AEasy to moveRealize stepless speed changeDrilling drivesBulkheads/pilesPunchingBlock and tackle

The invention provides a piling machine, which comprises drilling equipment for drilling, punching equipment for punching and a drilling turnplate device arranged on a chassis, wherein the drilling turnplate device comprises a drilling turnplate which is driven by hydraulic pressure and is expandable; a punching transmission device comprises a cross beam arranged on a tower and a pulley block arranged on the cross beam; the cross beam is divided into a front movable cross beam and a rear fixed cross beam; the front movable cross beam is hinged with the rear fixed cross beam and can rotate around the point of intersection between the front movable cross beam and the rear fixed cross beam; the pulley block comprises a front guide pulley arranged on the front movable cross beam and a rear guide pulley arranged on the rear fixed cross beam; and the punching equipment comprises a hydraulic jacking device for jacking a punching steel rope in the punching transmission device. The piling machine realizes drilling and punching functions, improves working efficiency and shortens construction period.

Owner:李恩怡

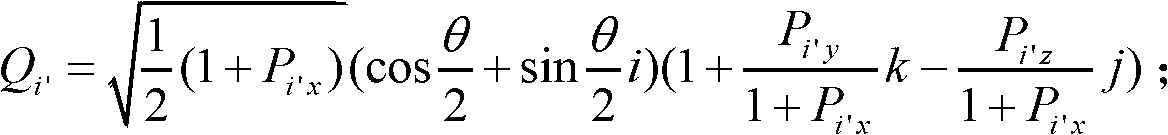

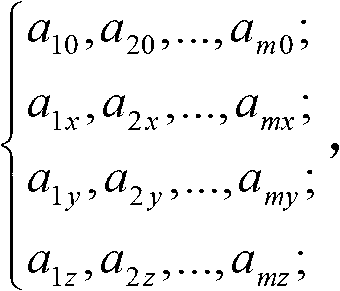

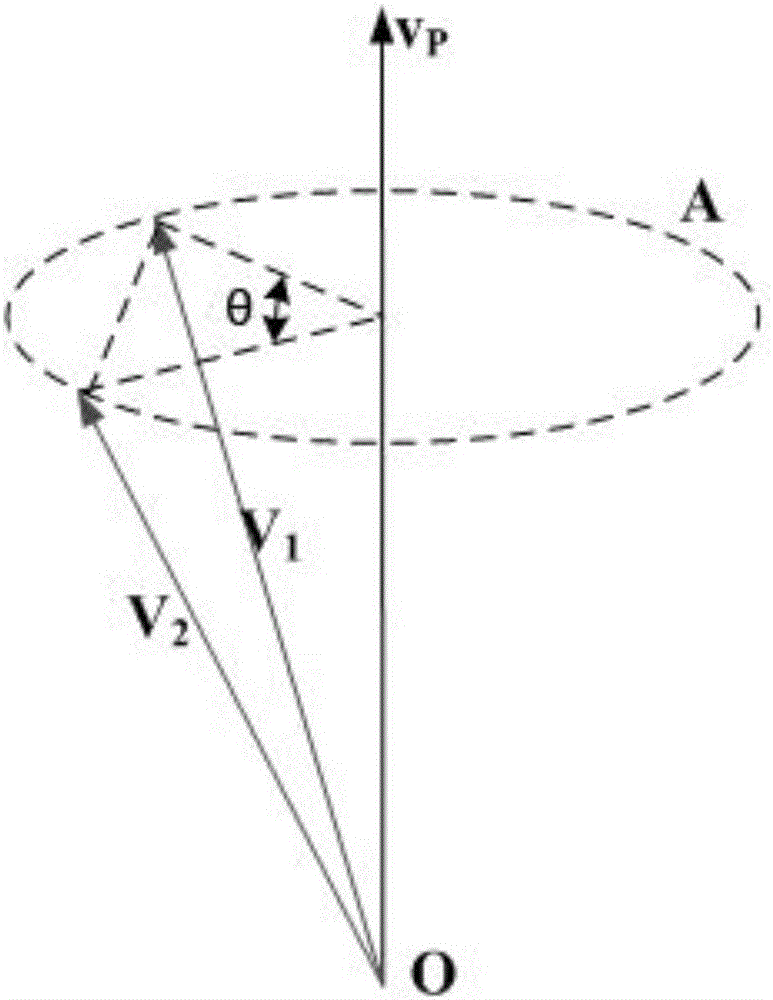

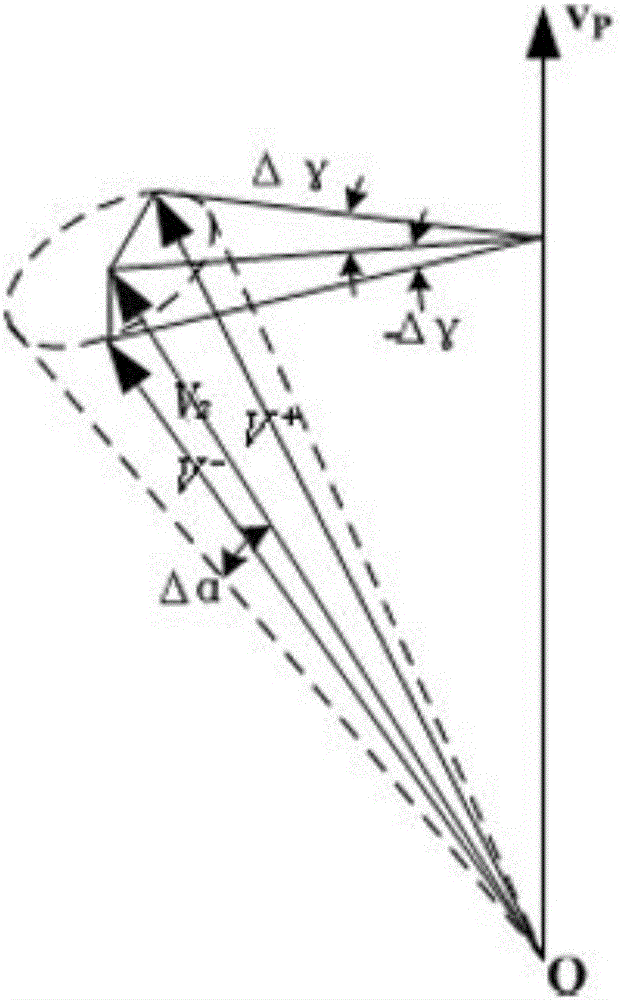

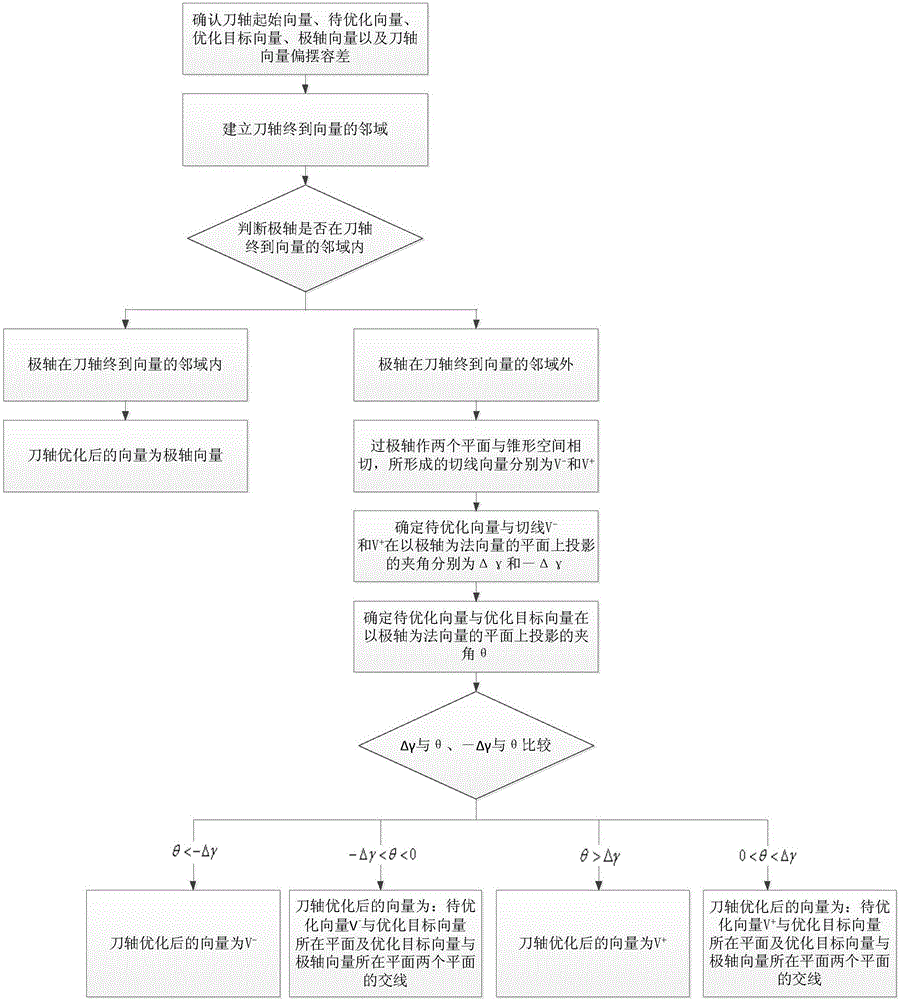

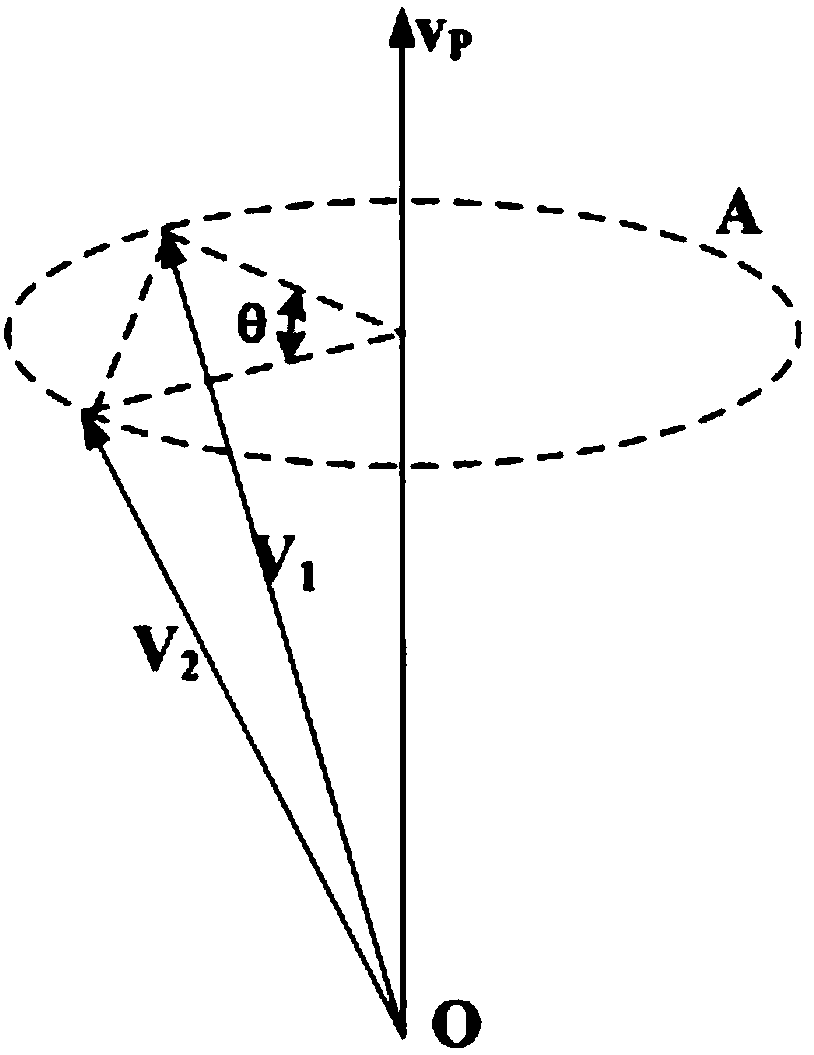

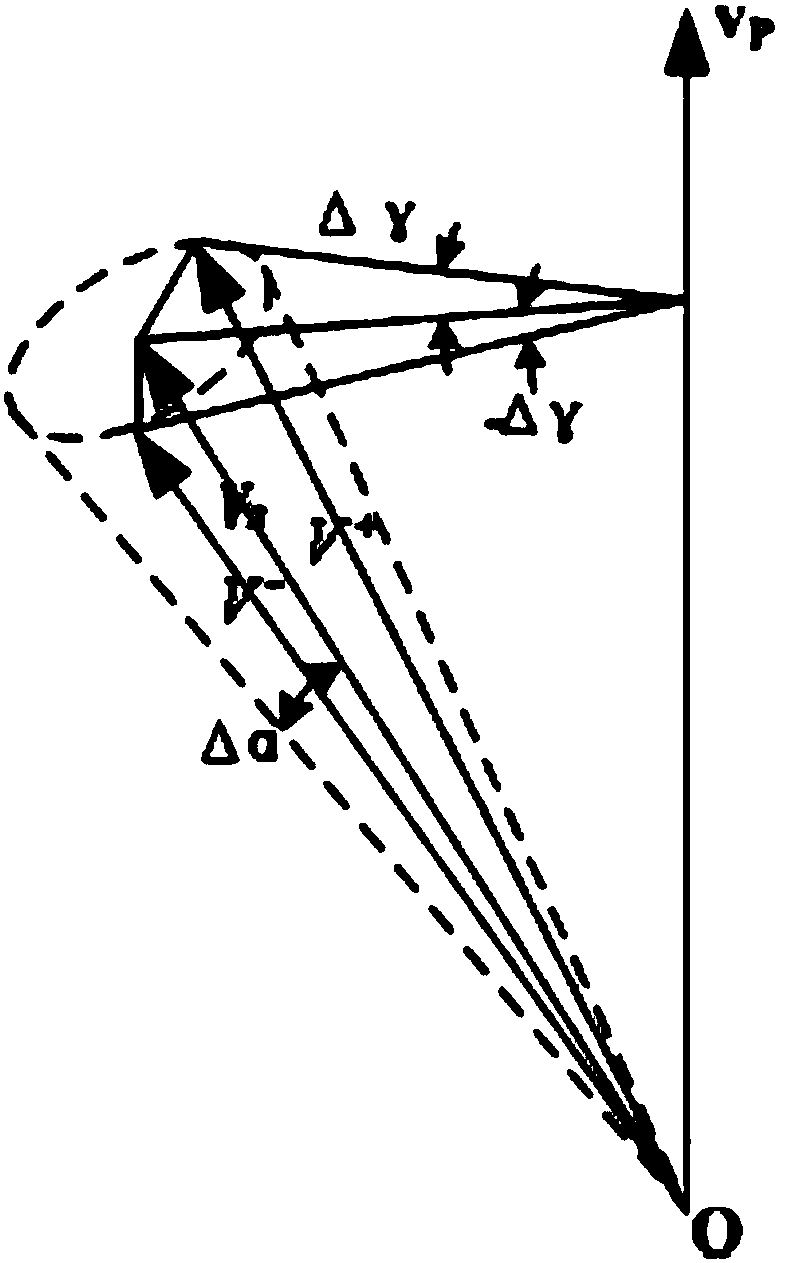

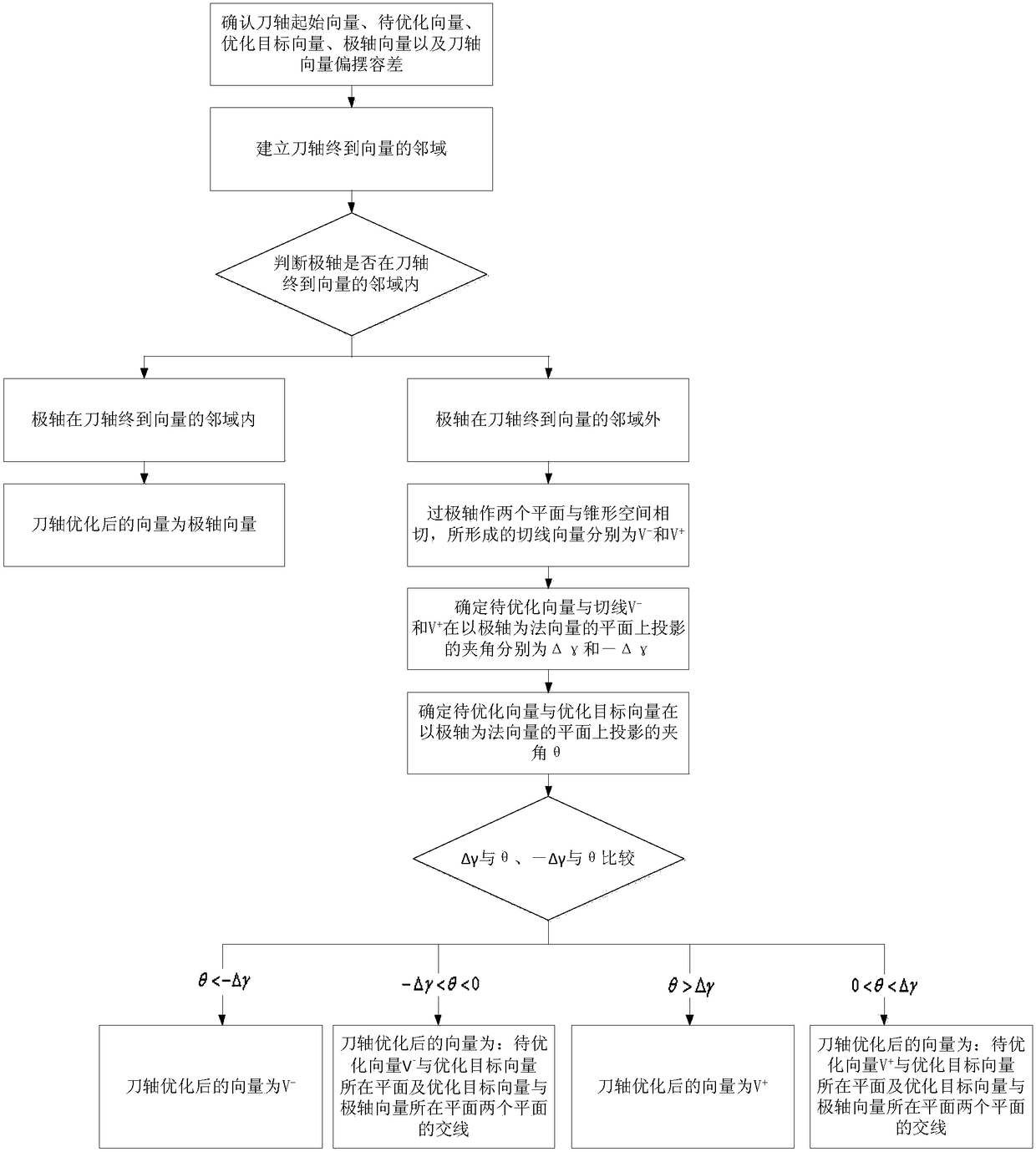

Optimizing method for five-axis numerical control machining singular region cutter location point

ActiveCN105717874ALittle change in angle of rotationPrevent overcutNumerical controlRotational axisCutter location

The invention discloses an optimizing method for a five-axis numerical control machining singular region cutter location point.A cutter shaft destination vector in a neighbourhood of the cutter shaft destination vector is optimized to obtain the optimized cutter shaft vector, so that the included angle theta between the projects, on a plane with the polar axis as a normal vector, of a cutter shaft start vector and the cutter shaft destination vector is the smallest to reduce the motion quantity of a first rotating shaft of a machine tool, and the cutter track in a singular region is optimized.By the adoption of the optimizing method, reliability of machining accuracy can be improved, program calculation is simple, the machining time is greatly shortened, and machining efficiency is improved.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

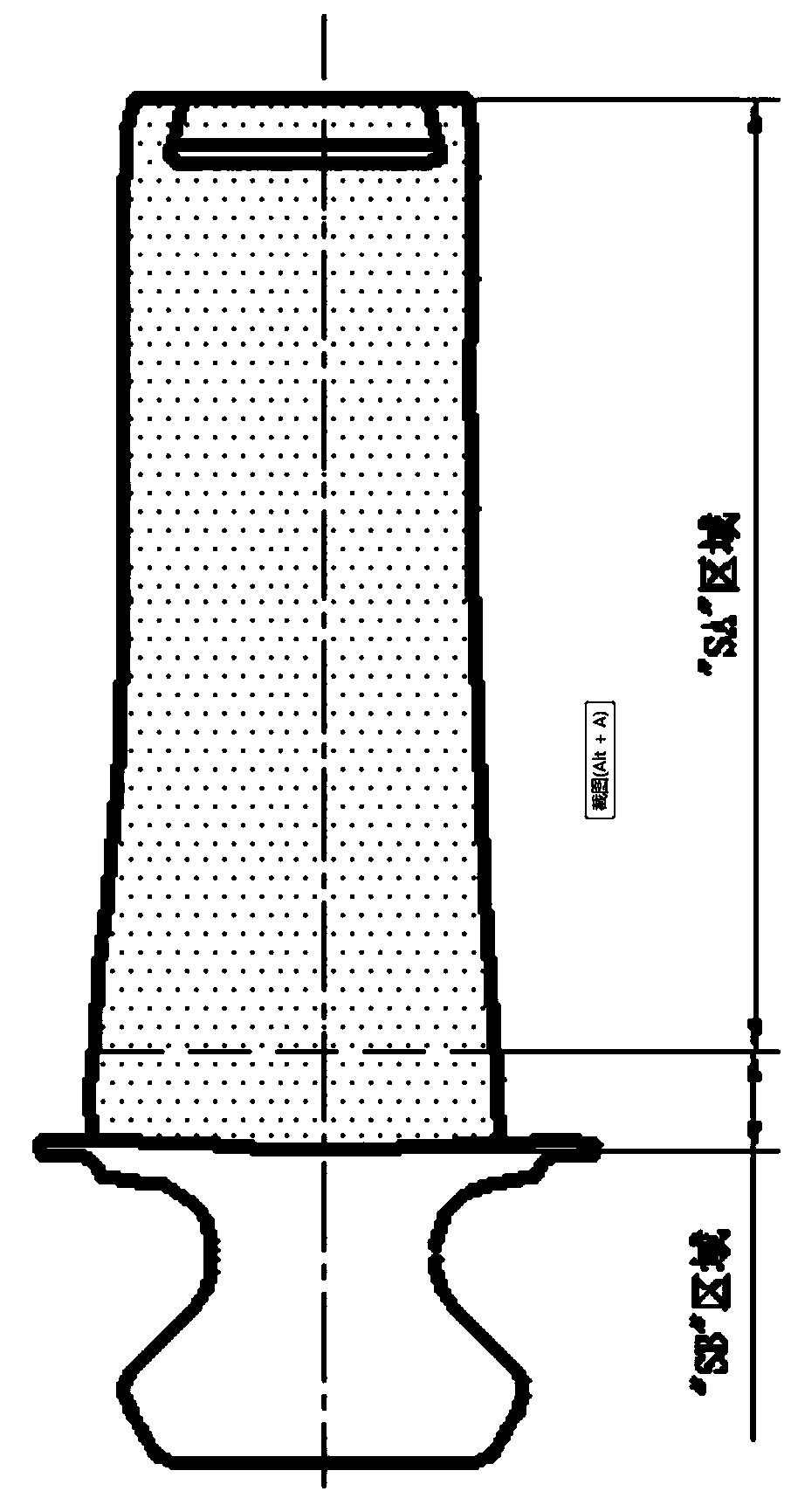

Numerical control grinding and finishing method for blade shot peening surface

ActiveCN108972354AAvoid overall overheatingImprove grinding efficiencyAbrasive machine appurtenancesNumerical controlMaterial removal

The invention relates to a numerical control grinding and finishing method for a blade shot peening surface. The numerical control grinding and finishing method for the blade shot peening surface comprises the following steps: finishing a blade root round corner transition zone, coarsely grinding a blade body profile surface, and finely grinding the blade body profile surface. At the same time, aiming at the situation that the blade profile surface is a free-form surface, the curvature changes greatly, and the difference of the sizes and shapes of different blades is large, the numerical control abrasive belt grinding produces the problem of local grinding unevenness. The numerical control grinding and finishing method for the blade shot peening surface provided by the invention optimizesa contact wheel. And for the problem of local less polishing or over polishing, the local treatment is performed through a program. The numerical control grinding and finishing method for the blade shot peening surface provided by the invention has the advantages of uniformly covering a crater on the blade shot peening surface and having small amount of material removal under the premise of ensuring that the roughness meets the quality requirement, and ensuring that the stress and influence depth of a shot peening residual compressive stress layer meet the design requirement.

Owner:AECC AERO SCI & TECH CO LTD

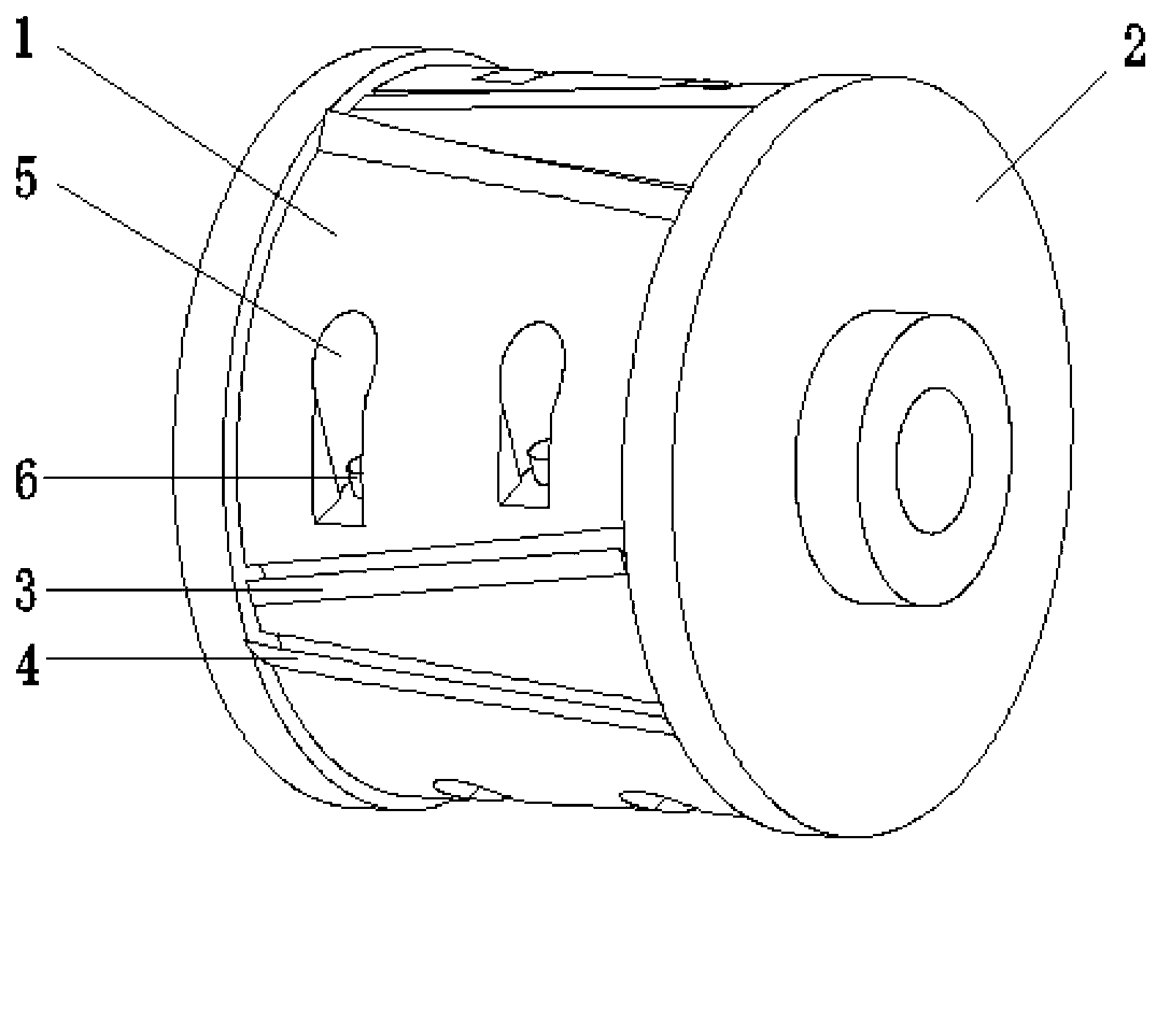

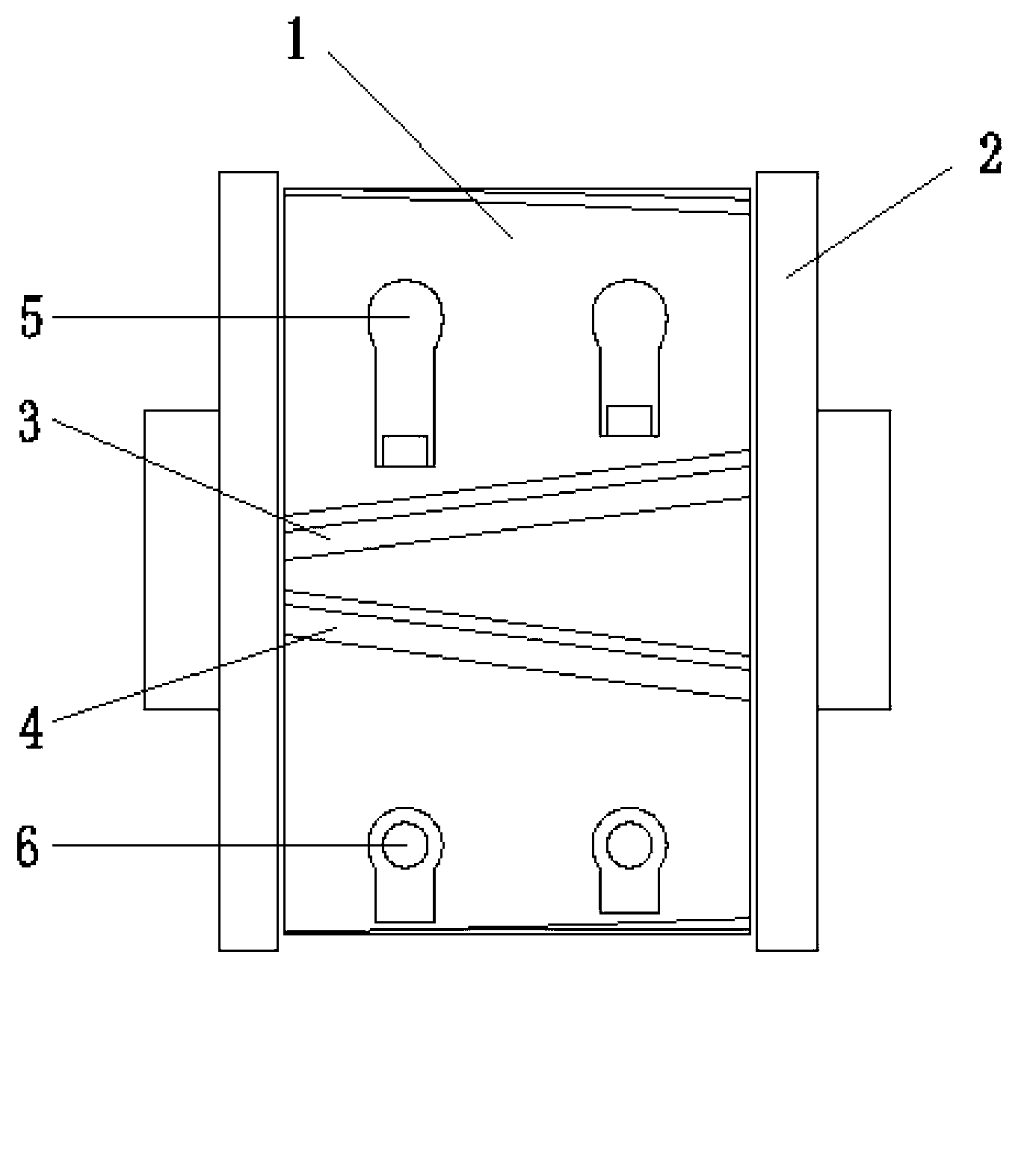

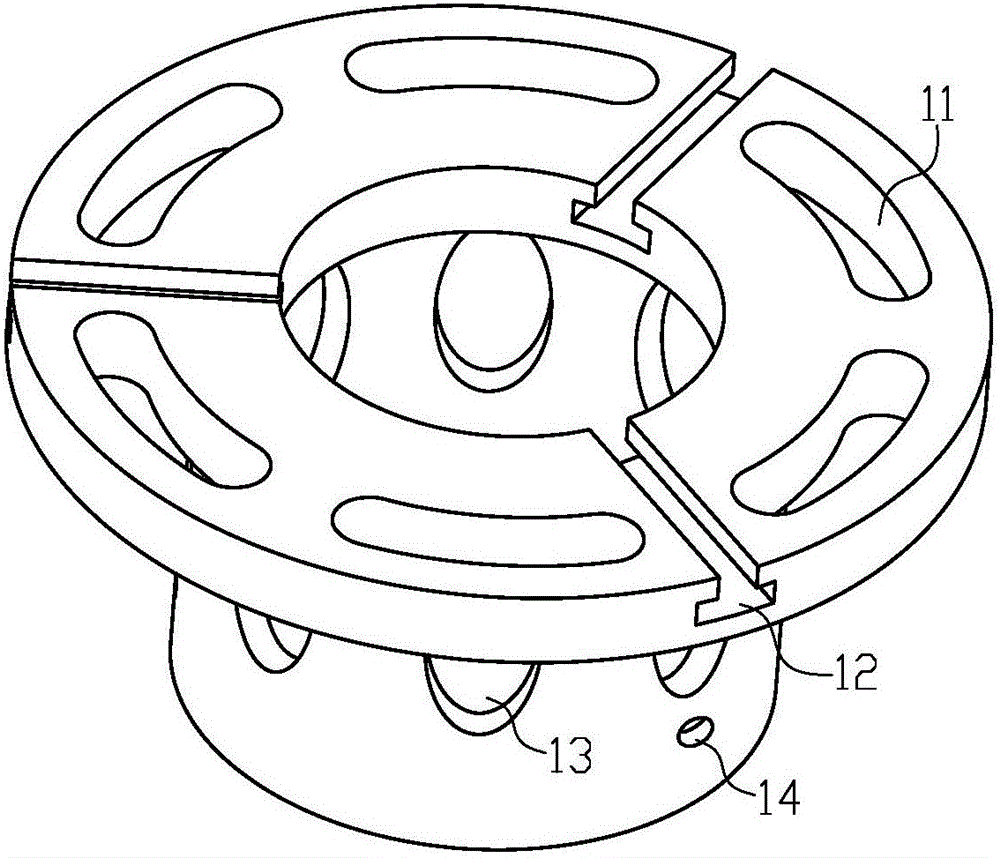

Cutting tool assembly of debarker

The invention discloses a cutting tool assembly of debarkers. The cutting tool assembly comprises a cutting wheel and two limit discs, wherein the cutting wheel is in the shape of a cylinder, a limit disc is respectively arranged on the left and right side of the cutting wheel and the diameter of the limit disc is larger than that of the cutting wheel. A plurality of cutter blade mountings are arranged on the outer periphery of the cutting wheel, each cutter blade mounting is provided with an upper cutter blade in the shape of a strip and a lower cutter blade, the upper cutter blade and the lower cutter blade are arranged obliquely, the biggest distances of the blades of upper cutter blade and the lower cutter blade to the axis of the limit discs are both lager than the radius of the limit disc, and the upper cutter blade and the lower cutter blade are staggered. The cutting tool assembly can control the cutting depth through limit discs and therefore, over-cutting can be avoided. The oblique arrangement of the blades of the upper cutter blade and the lower cutter blade enables the cutting tools to receive a rational counter-cutting force, thereby prolonging the service life of the cutting tools and the interlaced arrangement of the upper cutter blade and the lower cutter blade improves the cutting efficiency and shortens the processing time.

Owner:SUZHOU WUZHONG DISTRICT GUANGFU XIANGXUE NURSERY GARDEN

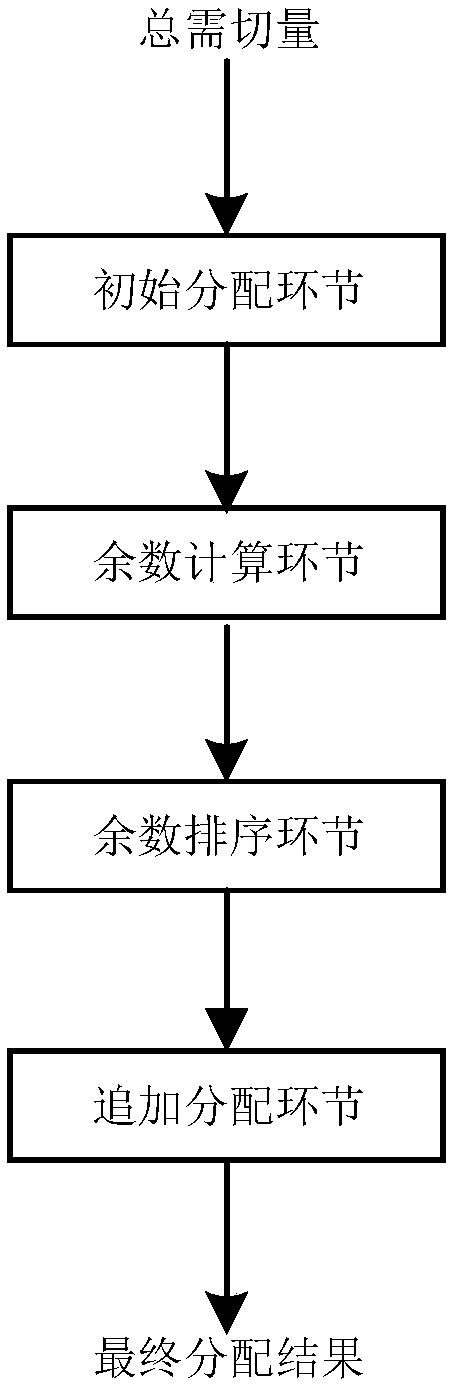

A method and device for distributing load cutting amount

ActiveCN109359840AImprove load shedding distribution accuracyPrevent overcutPower network operation systems integrationResourcesLoad SheddingInitial volume of distribution

A method for distributing load cutting amount includes such steps as (1) proportionally distributing total required cutting amount according to cut load of each load-cutting sub-station, obtaining initial distribution amount of each load-cutting sub-station without rounding during distribution, counting total initial distribution amount of each load-cutting sub-station, calculating difference between total required cutting amount and initial distribution amount to obtain the residual required cutting amount. (2) calculating the distribution remainder of each load shedding sub-station after theinitial distribution module is distributed; (3) allocating residues in descending order; (4) adding and distributing load cutting amount to the remaining required cutting amount at each load sheddingsub-station in the order of the distribution remainder from large to small until the total required cutting amount is equal to the total distribution amount. The invention also discloses a corresponding load-cutting distribution device. The scheme of the invention improves the distribution precision of the load-cutting amount, and can effectively avoid over-cutting or under-cutting caused by rounding.

Owner:NR ELECTRIC CO LTD +1

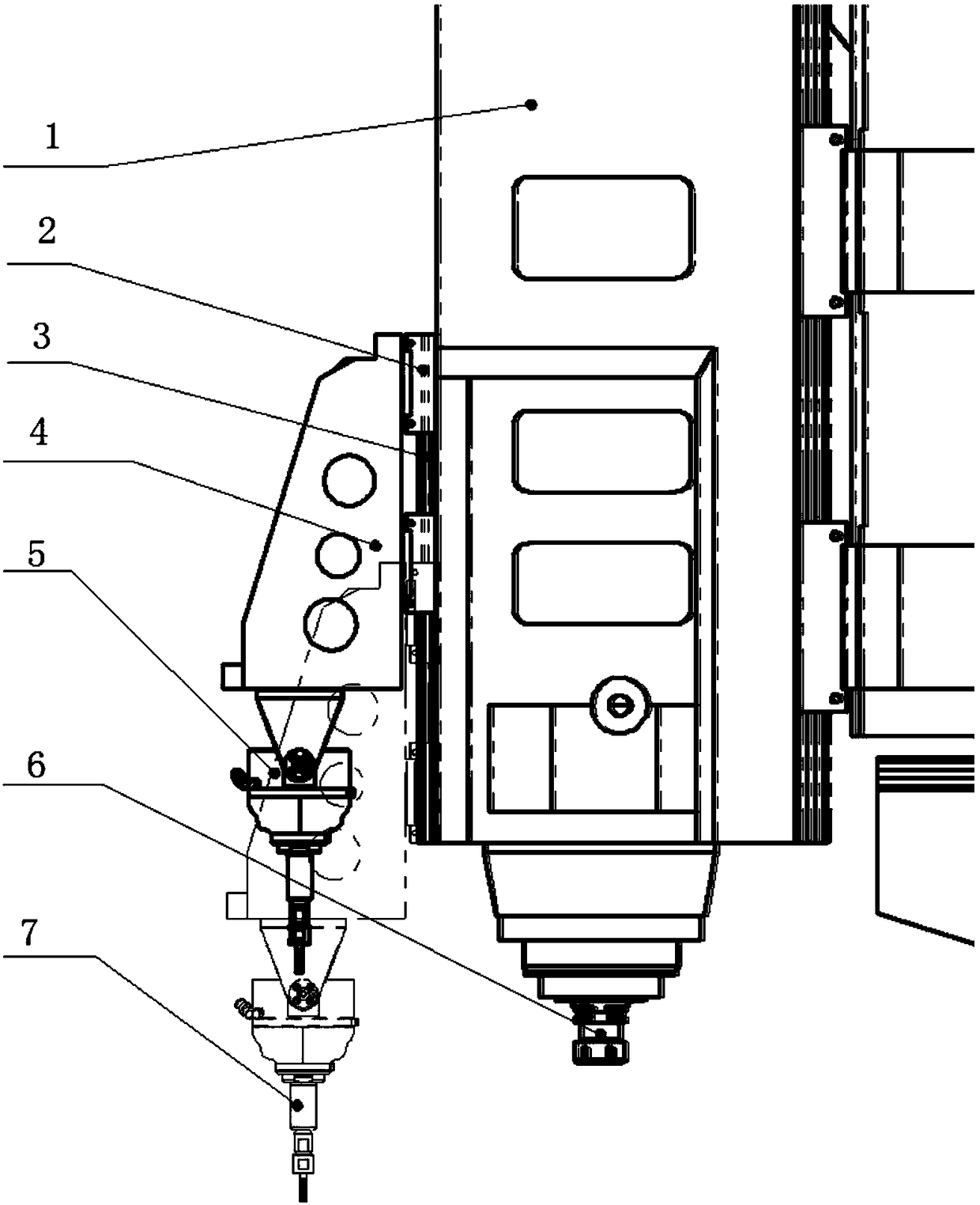

Machine tool with floating shaft

PendingCN108581695APrevent overcutImprove surface qualityEdge grinding machinesGrinding machine componentsEngineeringMachine tool

The invention discloses a machine tool with a floating shaft. The machine tool with the floating shaft comprises a machine tool Z-axis body, wherein the machine tool Z-axis body is arranged on a machine tool Z-axis guide rail; a rigid output shaft is arranged at the lower end of the machine tool Z-axis body; the floating shaft and a power device are arranged on the machine tool Z-axis body; and the floating shaft is arranged on the machine tool Z-axis body through an installing mechanism and can move under the action of the power device, so that the switching of the output shaft and the floating shaft is realized during processing. The machine tool with the floating shaft combines the technologies of a traditional floating shaft; the rigid output shaft and the floating shaft can be freelyswitched; when the common processing is carried out (for example, the surfaces of part of regular castings are polished), the quality of products can be ensured very well by adopting the rigid output;when the special processing is carried out (for example, the surfaces of part of irregular castings are burred, ground or polished), the undercutting problem of workpieces can be effectively avoidedby adopting the floating shaft output; and the surface quality and product yield of workpieces are improved.

Owner:CHONGQING ROBEST INTELLIGENT EQUIP CO LTD

CNC (Computer Numerical Control) high-speed drilling and tapping system

InactiveCN108296876APrevent overcutAvoid tool breakageAutomatic control devicesFeeding apparatusNumerical controlMachining process

The invention discloses a CNC (Computer Numerical Control) high-speed drilling and tapping system. The CNC high-speed drilling and tapping system comprises the steps of rough machining and finish machining. The CNC high-speed drilling and tapping system is characterized in that displacement induction is performed on the machining during the rough machining, and real-time position feedback is performed on a cutter during finish machining. According to the CNC high-speed drilling and tapping system, the displacement is fed back in real time, and the rough machining is tracked in real time, so that the problem of more machining residues is avoided; additionally, the position of the cutter is monitored in real time, the track of the cutter used for the finish machining is monitored, sharp point control is performed on a complex 3D molding surface, the machining step pitch of the path of the CNC finish machining cutter is respectively calculated according to the sharp point height, and whenthe position of the machining cutter is far, the displacement of the cutter is compensated; and automatic overcut preventing treatment is set, so that the phenomena of overcut and damage to the cutter due to sudden increase of cutting load of the cutter are avoided, the cutting process of the cutter can be protected, and the safe operation of high-speed machining is realized.

Owner:KUNSHAN BOGUTE ELECTROMECHANICAL EQUIP

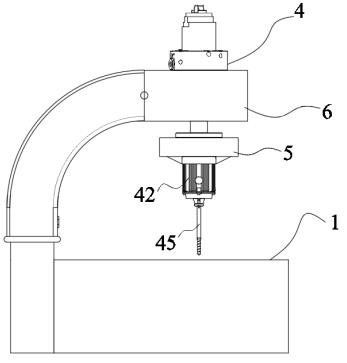

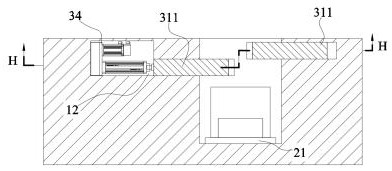

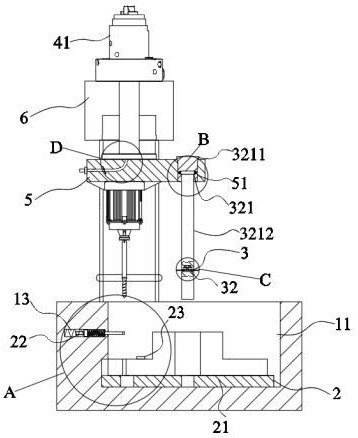

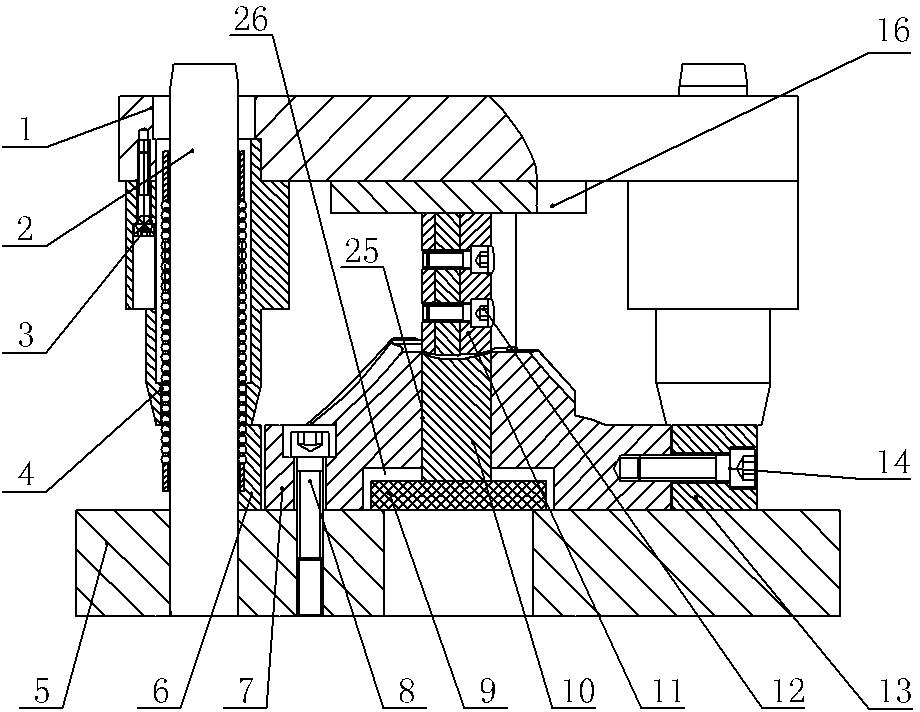

Bearing seat super-precision drilling machining device with correcting and deviation preventing functions

InactiveCN114833378APrevent scratching or even jammingImprove correction smoothnessPositioning apparatusBoring/drilling componentsMachine partsStructural engineering

The invention discloses a bearing seat superfinishing drilling device with correcting and deviation preventing functions, which comprises a base, a clamping device, a deviation correcting device, an adjusting device and a mounting seat, the base is connected with the clamping device, the clamping device is in transmission connection with the deviation correcting device, the deviation correcting device is in transmission contact with the adjusting device, the deviation correcting device is connected with the base, and the mounting seat is connected with the base. A support is arranged between the base and the mounting seat, the mounting seat is located on the upper side of the base, the adjusting device is connected with the mounting seat, a forming cavity is formed in the base, the clamping device comprises a floating plate, the floating plate is movably connected with the forming cavity, two clamping seats are arranged on the upper side of the floating plate and located on the two sides of a bearing seat, and the clamping seats are connected with the bearing seat in a clamped mode. The drilling deviation direction is reset through the deviation correcting device, the drilling precision is improved, power adjustment is conducted through the adjusting device, the drilling quality is improved, ear pieces of the to-be-machined parts on the two sides of the bearing seat are sequentially clamped through the clamping seat, and therefore the bearing seat is limited.

Owner:江苏振赋林智能科技有限公司

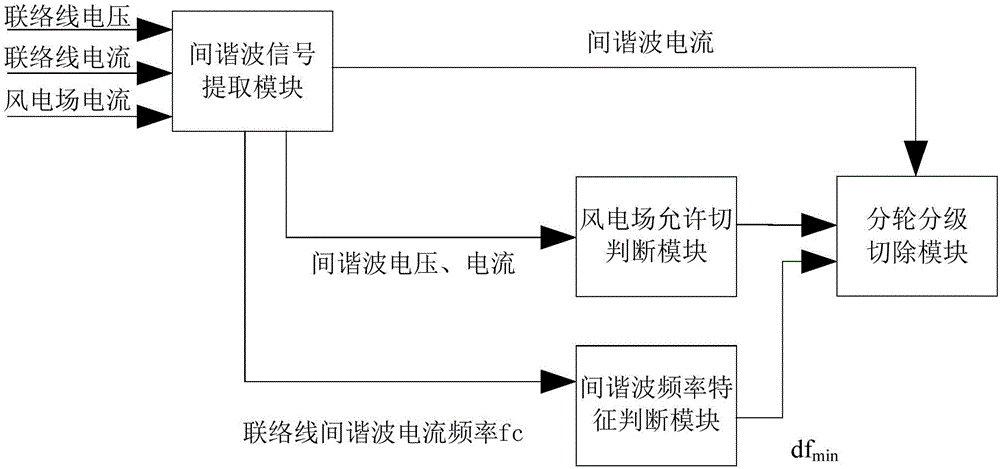

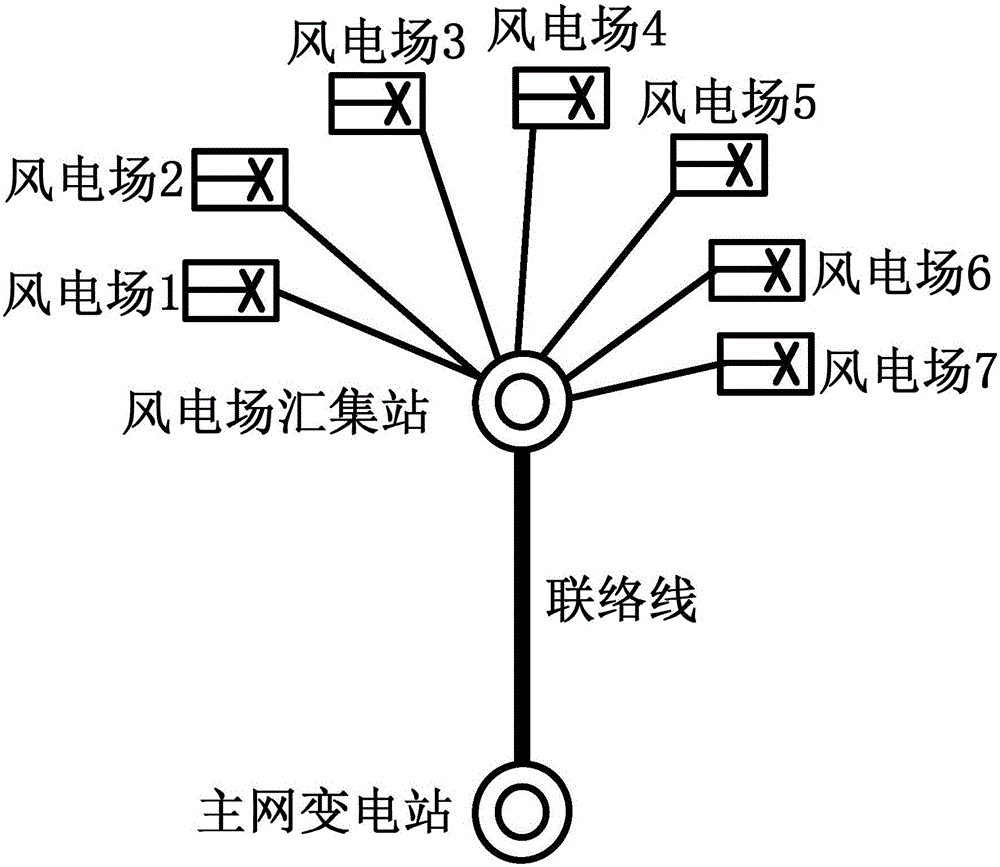

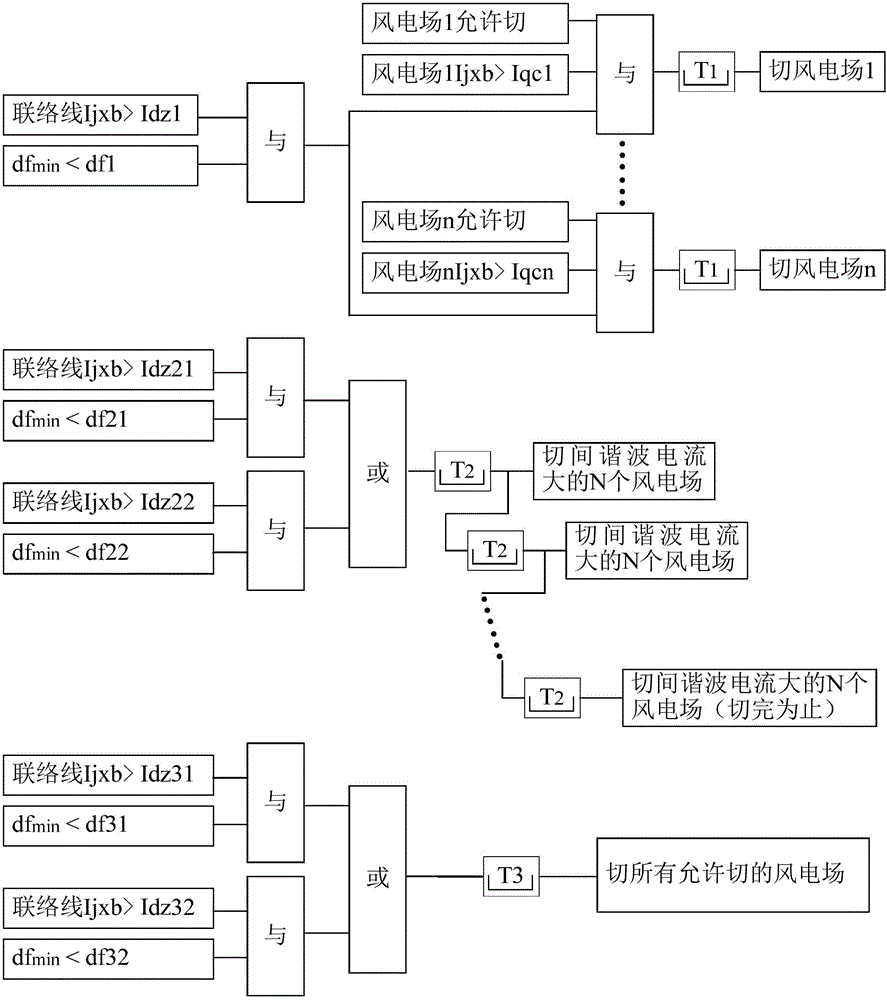

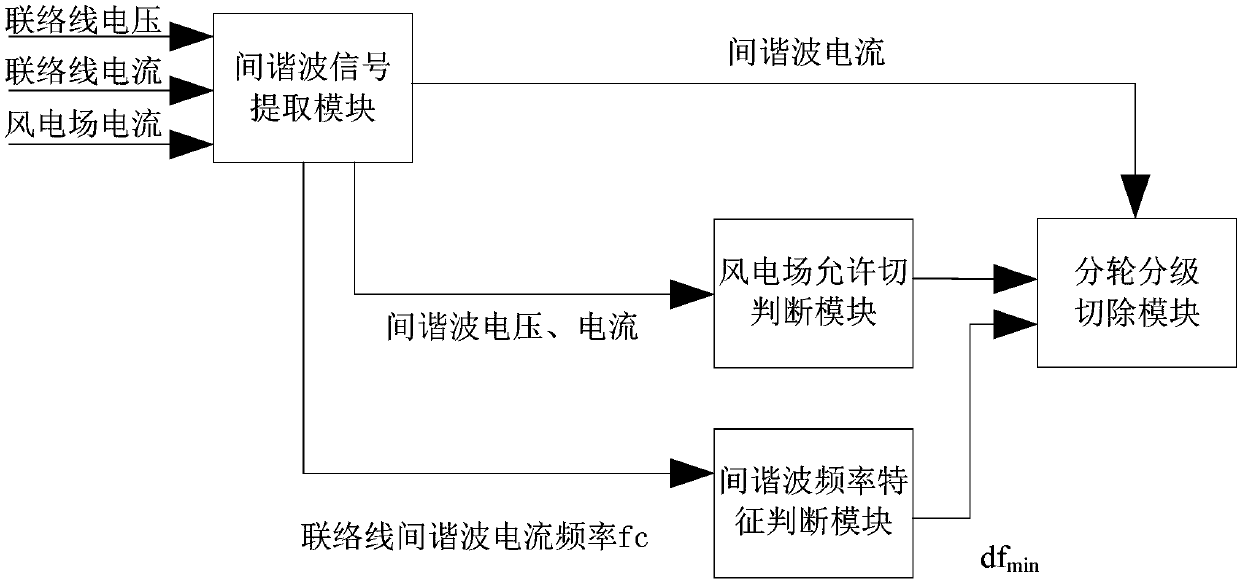

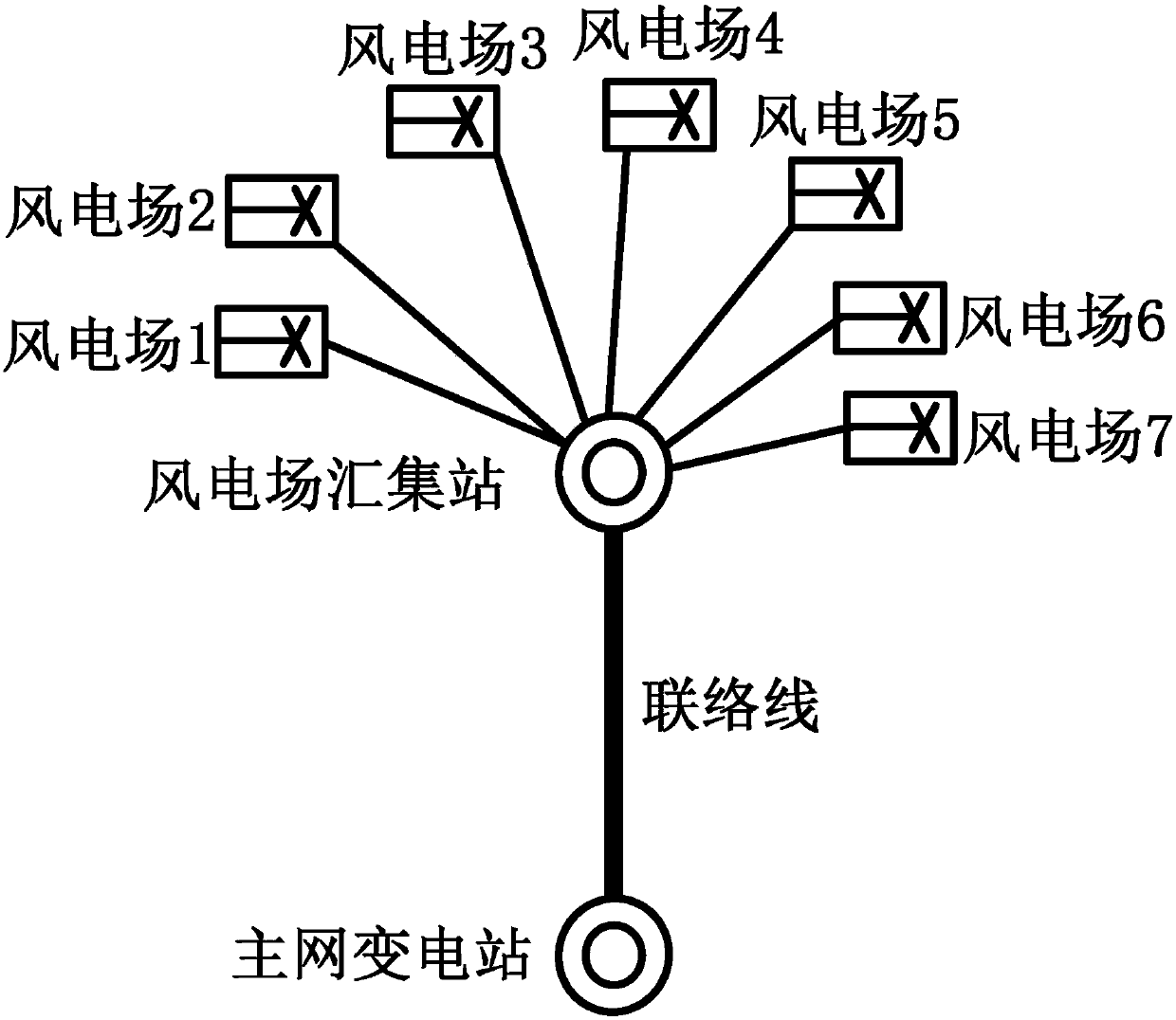

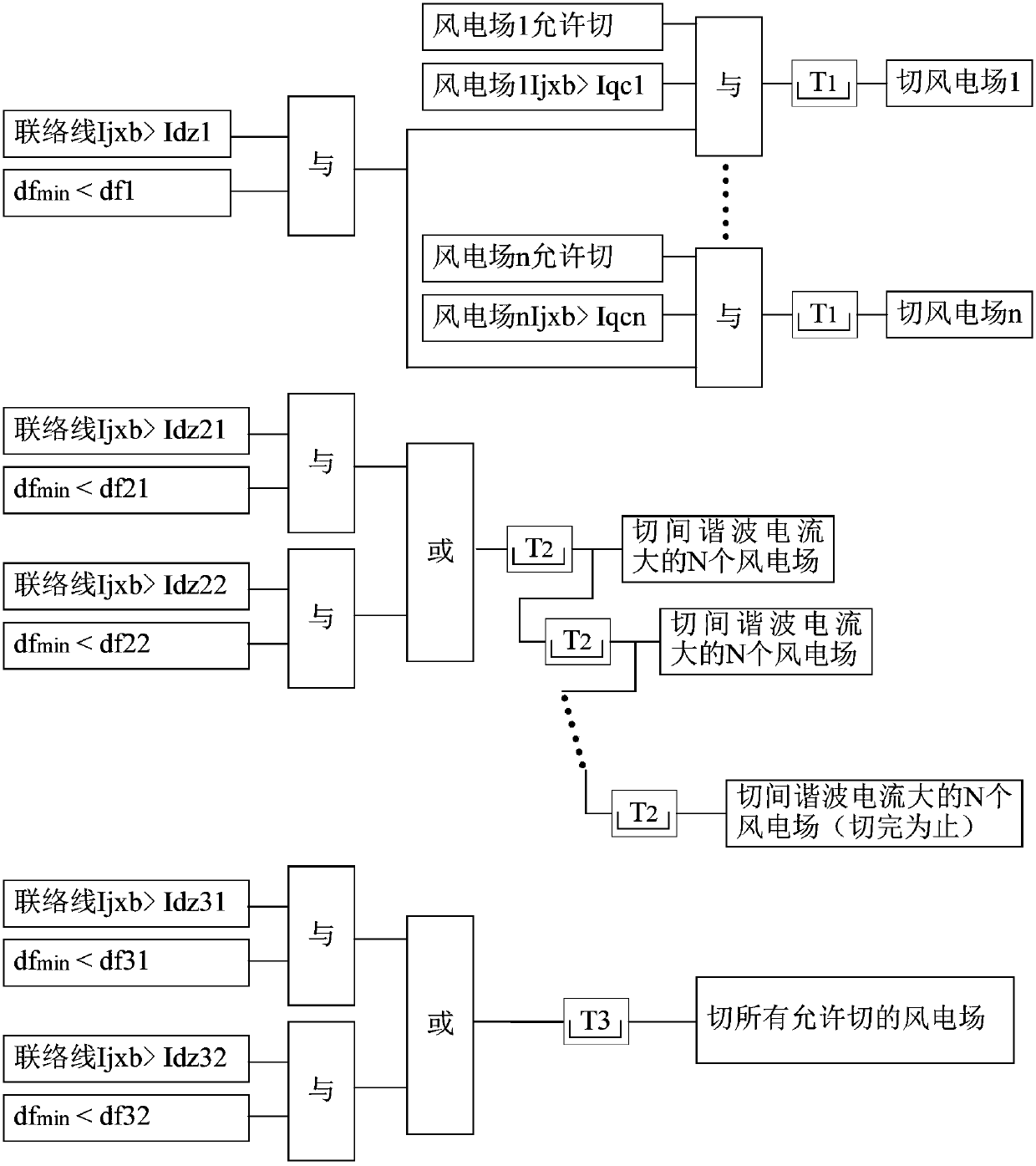

Inter-harmonics control method in wind power collection station

ActiveCN105896541AEnsure safetyPrevent overcutHarmonic reduction arrangementAc network to reduce harmonics/ripplesFrequency spectrumHarmonic control

The present invention discloses an inter-harmonics control method in a wind power collection station. The method comprises that an inter-harmonic signal extraction module carries out spectral analysis on a tie line current from the wind power collection station to a main network, calculates frequency fc of a harmonic component with the maximum amplitude, and extracts inter-harmonic signals in a tie line voltage and each wind power farm current; a wind power farm that is allowed to be cut in the collection station is determined according to the tie line inter-harmonic current, the inter-harmonic voltage, and the wind power farm inter-harmonic current; absolute values of difference values between the fc and a set of characteristic frequencies are calculated, and a minimum value dfmin among the absolute values is solved; and a sub-round and level-to-level cutting module cuts each wind power farm that is allowed to be cut in a series of rounds and level by level according to the tie line inter-harmonic current, the dfmin, and the wind power farm inter-harmonic current. According to the method disclosed by the present invention, the tie line between the wind power collection station and the main network, and each wind power farm can be monitored simultaneously, the relatively large inter-harmonic current existing in the power grid can be online monitored in real time, and whether there is an inter-harmonic generation source in the wind power collection station can be online determined in real time.

Owner:STATE GRID XINJIANG ELECTRIC POWER CORP +2

Piling machine

ActiveCN101871316BEasy to moveRealize stepless speed changeDrilling drivesBulkheads/pilesPunchingEngineering

The invention provides a piling machine, which comprises drilling equipment for drilling, punching equipment for punching and a drilling turnplate device arranged on a chassis, wherein the drilling turnplate device comprises a drilling turnplate which is driven by hydraulic pressure and is expandable; a punching transmission device comprises a cross beam arranged on a tower and a pulley block arranged on the cross beam; the cross beam is divided into a front movable cross beam and a rear fixed cross beam; the front movable cross beam is hinged with the rear fixed cross beam and can rotate around the point of intersection between the front movable cross beam and the rear fixed cross beam; the pulley block comprises a front guide pulley arranged on the front movable cross beam and a rear guide pulley arranged on the rear fixed cross beam; and the punching equipment comprises a hydraulic jacking device for jacking a punching steel rope in the punching transmission device. The piling machine realizes drilling and punching functions, improves working efficiency and shortens construction period.

Owner:李恩怡

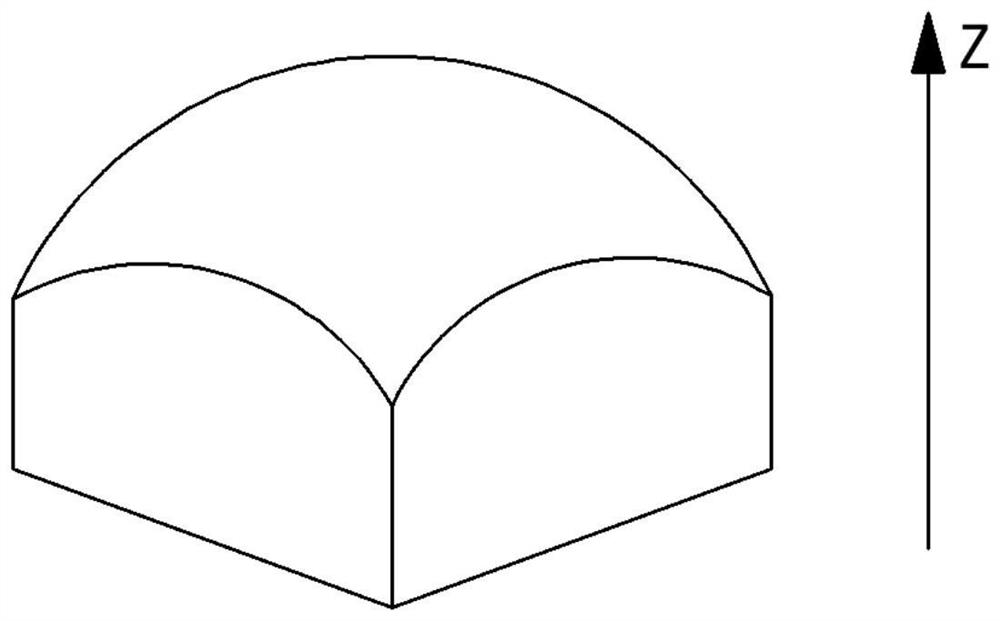

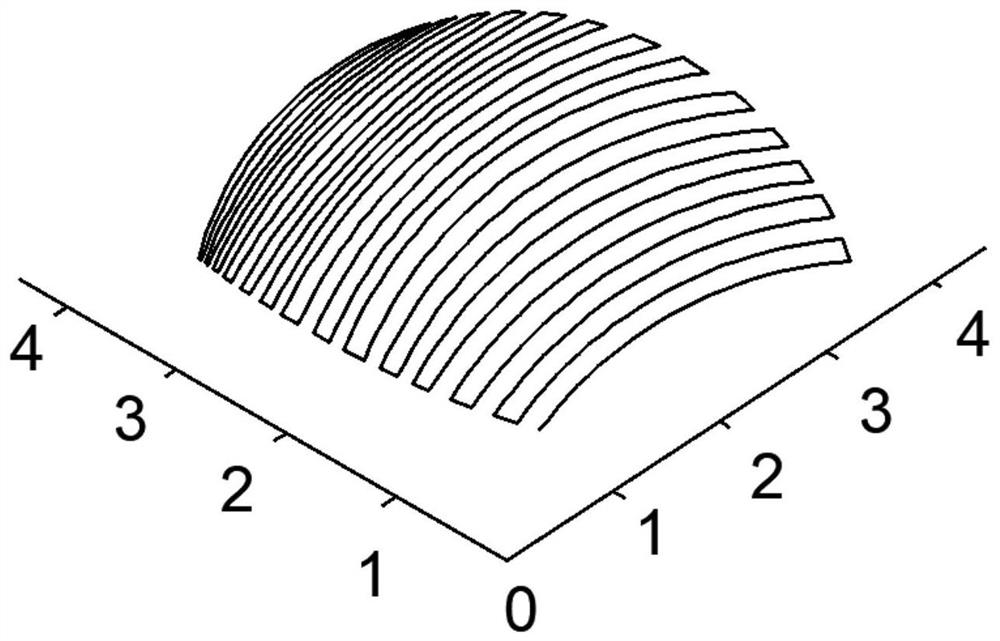

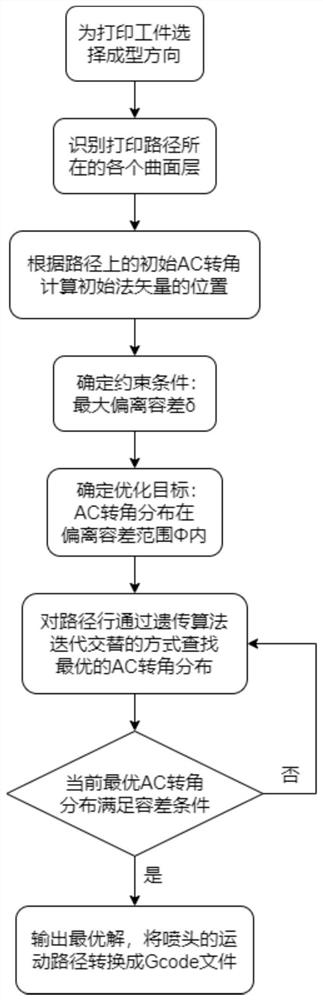

AC corner optimization method for five-axis 3D printing line cutting path planning

ActiveCN113119450AImprove printing efficiencyPrevent overcutAdditive manufacturing apparatus3D object support structuresSurface layerEngineering

The invention provides an AC corner optimization method for five-axis 3D printing line cutting path planning. The AC corner optimization method comprises the following steps that 1, the forming direction is selected according to the characteristics of a printing model; 2, all curved surface layers where the printing paths are located are recognized, the printing path on one curved surface layer is located on one curved surface, and each curved surface layer refers to an optimization unit of the AC corner; and 3, an AC corner optimization objective function and constraint conditions are constructed, all path lines of all optimization units are sequentially optimized according to the printing sequence, and the optimal AC corner distribution on 3D printing line cutting paths of all the curved surface layers is obtained. According to the method, the normal vector of the nozzle axis and the machining surface is within the maximum deviation tolerance range delta; the AC corner of the adjacent point is within the deviation tolerance range phi; the nozzle does not need to be lifted in the printing process, continuous printing can be conducted till workpiece printing is finished, and the printing efficiency is improved; and overcutting of the workpiece is avoided, the workpiece can be protected against damage, and the printing quality of finished workpiece products is improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Electric remover for fractured pipe joints

InactiveCN105690325AAvoid damageEasy to removeMetal-working hand toolsReciprocating motionEngineering

The invention discloses an electric remover for fractured pipe joints, which comprises a supporting seat, tension devices, a cutting device, a feed regulation device, a driving device and a tail stand, wherein the tree groups of tension devices fix the supporting seat on a pipe connector in an inner-bracing tensioning manner; radial feed regulation and circumferential rotation regulation of saw blades in the cutting device are realized through the feed regulation device; the driving device drives the saw blades to perform reciprocating motion so as to cut a fractured pipe joint. According to the electric remover for the fractured pipe joints, the manner of cutting before removing is adopted, so that the damage to the inner thread of an original pipe joint is extremely low, and damage caused by repair is avoided; moreover, the motor is adopted for driving the saw blades to perform reciprocating cutting, which saves both time and labor and realizes rapid removing and repairing of the fractured pipe joint; besides, the feed regulation device can realize feed control and regulation of the saw blades, to further determine the cutting position and depth and avoid over cutting, therefore the electric remover for the fractured pipe joints has the characteristics of being compact in structure, simple and rapid in operation and control, and capable of easily removing the fracture pipe connector and the like.

Owner:ANHUI UNIV OF SCI & TECH

A Harmonic Control Method Between Wind Power Gathering Stations

ActiveCN105896541BEnsure safetyPrevent overcutHarmonic reduction arrangementAc network to reduce harmonics/ripplesFrequency spectrumHarmonic control

The present invention discloses an inter-harmonics control method in a wind power collection station. The method comprises that an inter-harmonic signal extraction module carries out spectral analysis on a tie line current from the wind power collection station to a main network, calculates frequency fc of a harmonic component with the maximum amplitude, and extracts inter-harmonic signals in a tie line voltage and each wind power farm current; a wind power farm that is allowed to be cut in the collection station is determined according to the tie line inter-harmonic current, the inter-harmonic voltage, and the wind power farm inter-harmonic current; absolute values of difference values between the fc and a set of characteristic frequencies are calculated, and a minimum value dfmin among the absolute values is solved; and a sub-round and level-to-level cutting module cuts each wind power farm that is allowed to be cut in a series of rounds and level by level according to the tie line inter-harmonic current, the dfmin, and the wind power farm inter-harmonic current. According to the method disclosed by the present invention, the tie line between the wind power collection station and the main network, and each wind power farm can be monitored simultaneously, the relatively large inter-harmonic current existing in the power grid can be online monitored in real time, and whether there is an inter-harmonic generation source in the wind power collection station can be online determined in real time.

Owner:STATE GRID XINJIANG ELECTRIC POWER CORP +2

Method for smoothing machining route of five-axle machining cutter

Owner:HUST WUXI RES INST

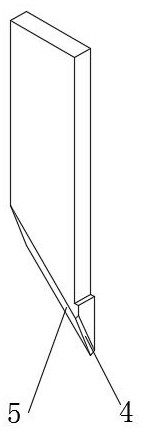

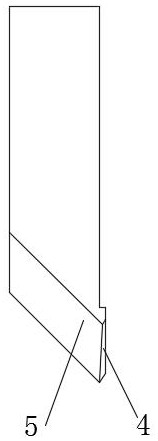

Depth adjustable rescue cutter

InactiveCN102161116ARealize profiling cuttingAvoid the shortcoming that it is easy to cause cutting injury to the body of the rescued personMetal sawing devicesLandslideEngineering

The invention discloses a depth adjustable rescue cutter, which comprises a cutter bottom plate (1) and a saw blade (2), wherein the saw blade (2) is arranged on the output shaft of a motor; the motor is fixed with the cutter bottom plate (1); a back plate (6) is vertically fixed below the cutter bottom plate (1) and is in parallel with the plane of the cutter blade (2); a group of depth feeding control mechanisms are arranged on the outer sides of the back plate (6) respectively through bolts; and each depth feeding control mechanism comprises a flexible seat (3), a support arm (4), a flexible arm (5), a central shaft (8), an adjustable rod (9), an axle (10) and a bearing (11). The rescue cutter uses two groups of depth feeding control mechanisms to realize depth-control cutting and four groups of rolling wheels to realize profiling cutting, so that the rescue cutter is suitable to be used as a rescue cutting device in the situations of car accident, mudslide, earthquake burying and the like.

Owner:HUAZHONG UNIV OF SCI & TECH WUCHANG BRANCH

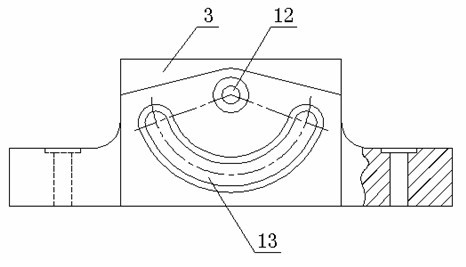

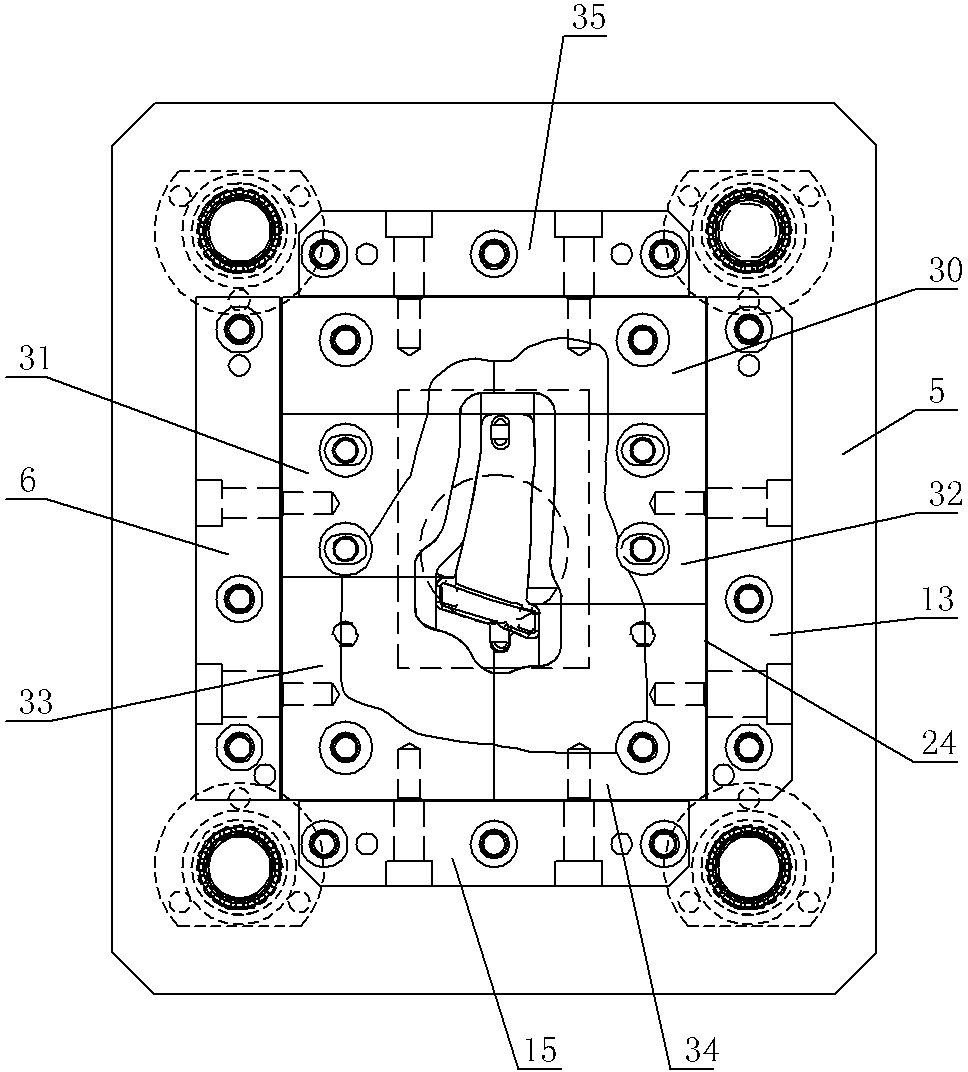

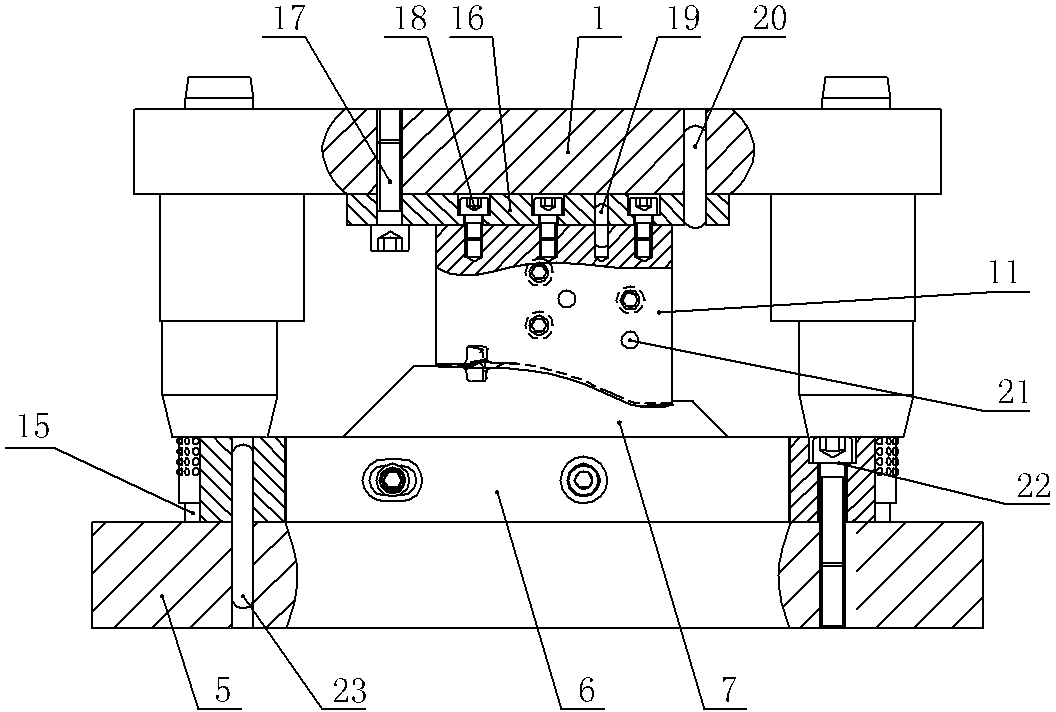

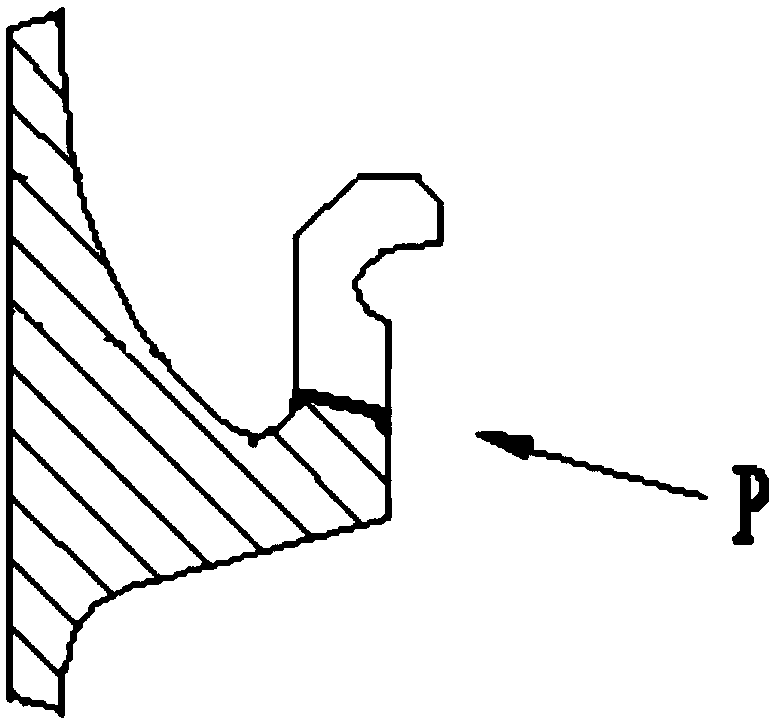

Cold cutting die for titanium alloy precision-forged blade

ActiveCN102989860AEffective deformation controlGuarantee processing qualityTitanium alloyMaterials science

The invention provides a cold cutting die for a titanium alloy precision-forged blade, which can effectively control the deformation for the side cut of the titanium alloy blade, improve the production efficiency and lower the production cost. The cold cutting die comprises an upper die plate and a lower die plate, as well as a punch and a lower die, wherein the upper die plate and the lower die plate are connected by a guide pillar and a ball guide sleeve in a matching manner, the punch is arranged on the lower die plate by a punch base plate, the cold cutting die is characterized in that the lower die comprises a female die and a support die, the female die is fixedly arranged on the lower die plate by a screw, the female die is internally provided with a vertical through slot and a horizontal through slot which are perpendicularly communicated, the support die is arranged in the vertical through slot, the lower end of the support die is supported by a rubber mat, the rubber mat is arranged on the lower die plate and positioned in the horizontal through slot, and the support die is 3-5mm higher than the female die under non-working state.

Owner:WUXI TURBINE BLADE

A method for optimizing tool positions in five-axis NC machining of singular regions

ActiveCN105717874BLittle change in angle of rotationPrevent overcutNumerical controlCutter locationEngineering

The invention discloses an optimizing method for a five-axis numerical control machining singular region cutter location point.A cutter shaft destination vector in a neighbourhood of the cutter shaft destination vector is optimized to obtain the optimized cutter shaft vector, so that the included angle theta between the projects, on a plane with the polar axis as a normal vector, of a cutter shaft start vector and the cutter shaft destination vector is the smallest to reduce the motion quantity of a first rotating shaft of a machine tool, and the cutter track in a singular region is optimized.By the adoption of the optimizing method, reliability of machining accuracy can be improved, program calculation is simple, the machining time is greatly shortened, and machining efficiency is improved.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

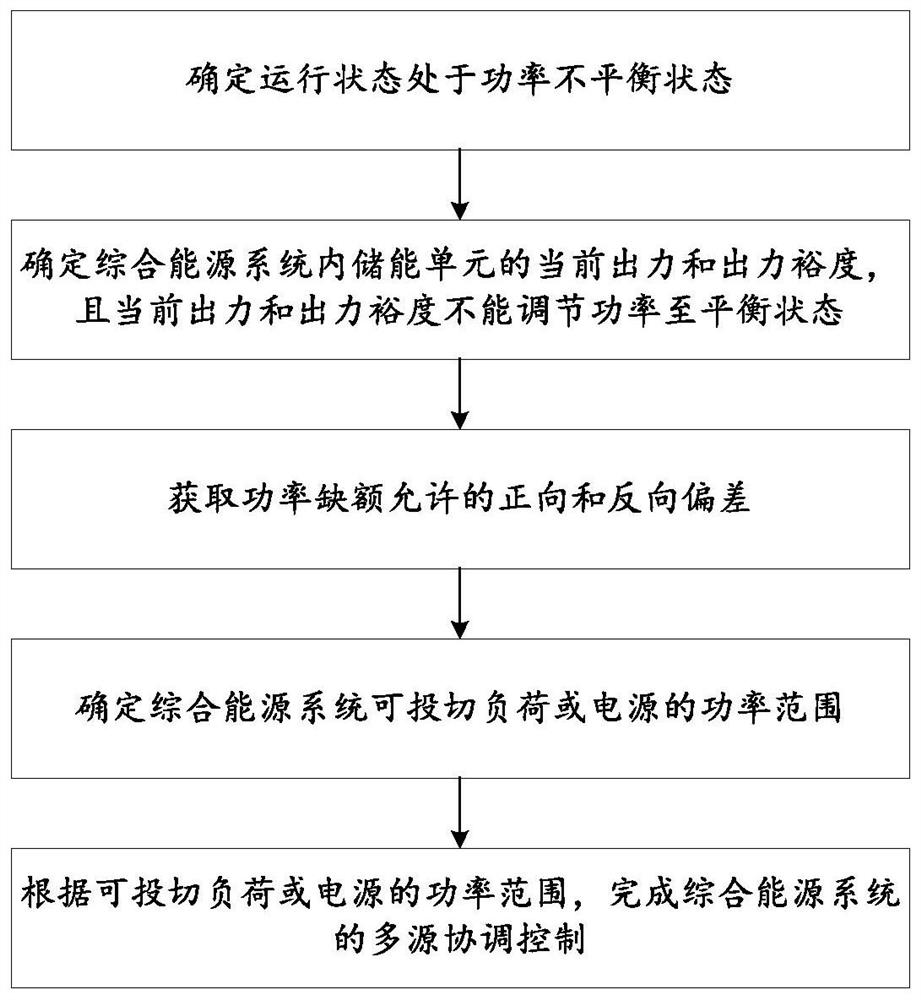

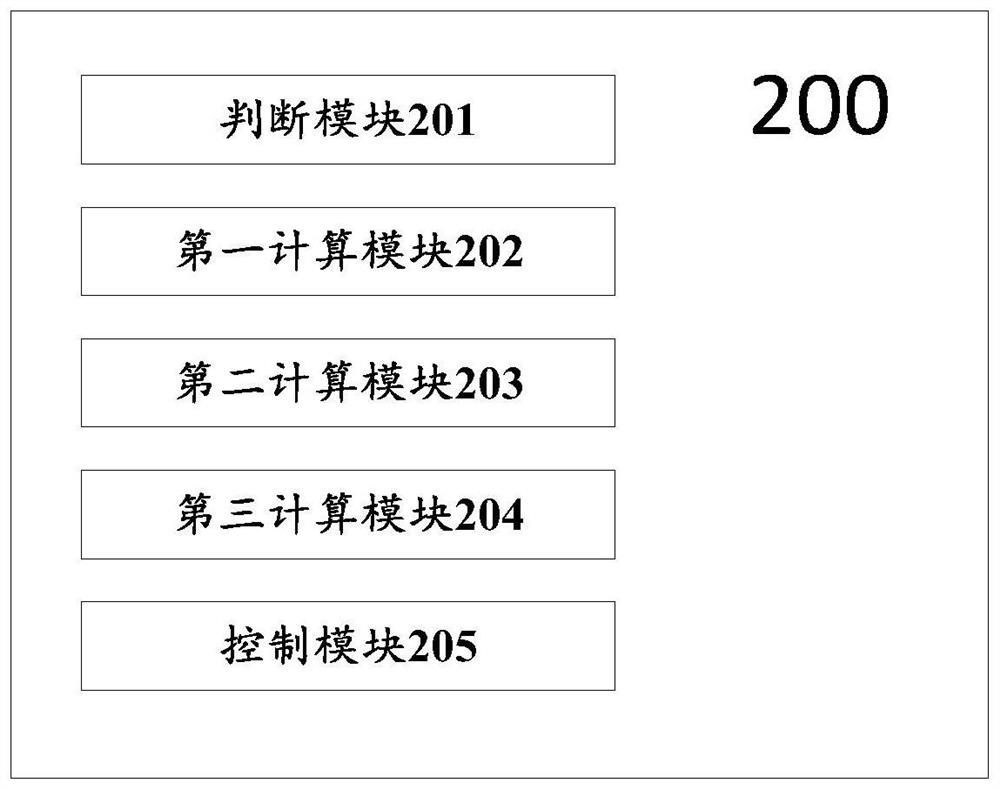

Multi-source coordination control method and system for integrated energy system

PendingCN112688369APrevent overcutAvoid stabilityPower network operation systems integrationSingle network parallel feeding arrangementsLoad SheddingIntegrated energy system

The invention discloses a multi-source coordination control method and system for an integrated energy system, and belongs to the technical field of intelligent power grids. The method comprises the following steps: determining that an operation state is in a power imbalance state; determining the current output and the output margin of an energy storage unit in the integrated energy system, wherein the current output and the output margin cannot adjust the power to a balance state; obtaining forward and reverse deviations allowed by the power vacancy; determining a switchable load of the integrated energy system or a power range of a power supply; and completing multi-source coordination control of the integrated energy system according to the power range of the switchable load or the power supply. According to the invention, the problems of certain over-switching, insufficient flexibility and the like of the existing load shedding method are solved, the over-switching amount of the system can be effectively reduced, the economy of load control is improved, and the influence of frequent switching of the load or the power supply on the stability of the system is avoided.

Owner:STATE GRID SHANGHAI ENERGY INTERCONNECTION RES INST CO LTD +2

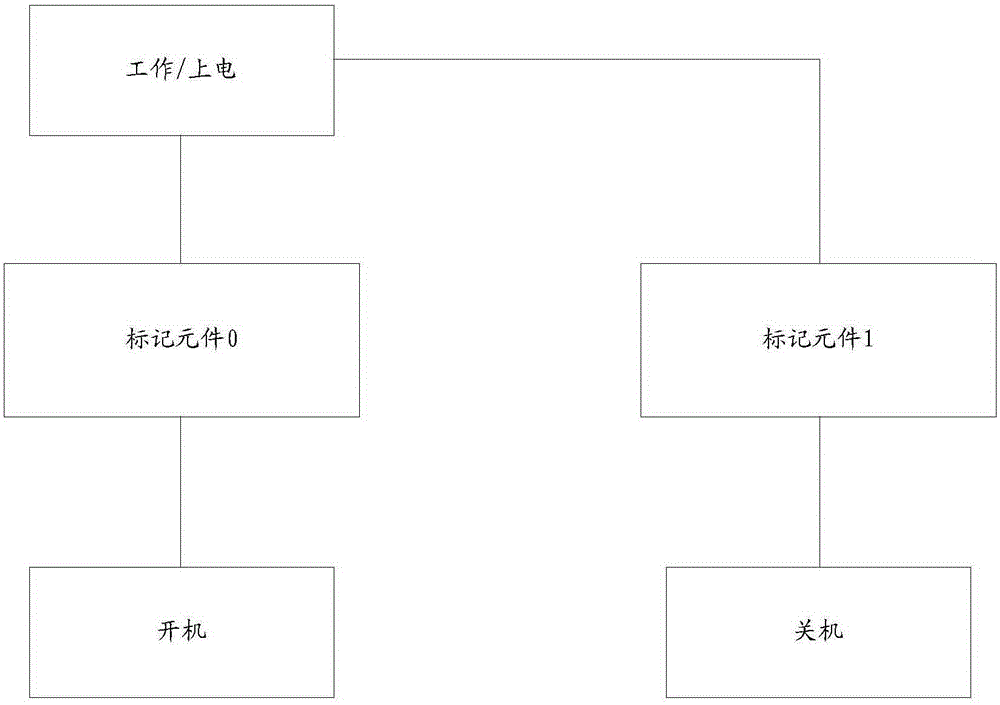

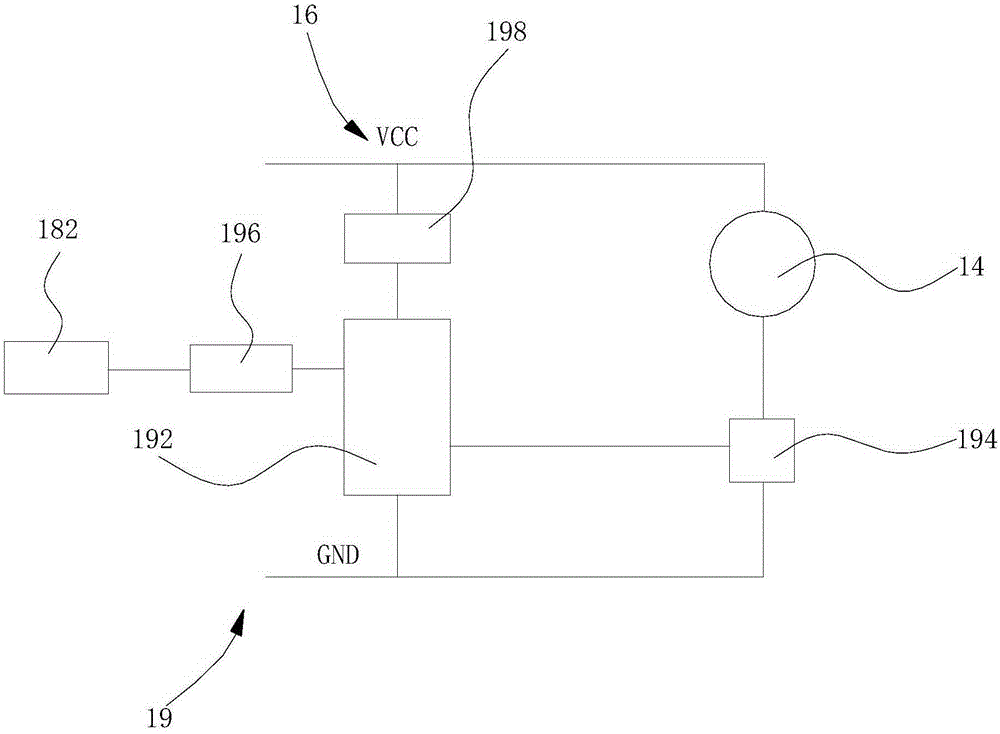

Power tool and control method for same

ActiveCN106444433AReduce the difficulty of operationPrevent overcutProgramme control in sequence/logic controllersEngineeringPower tool

The invention relates to a power tool which comprises a power tool body. The power tool body comprises a housing, a motor, an working head, a power supply, a detecting unit and a control unit. The motor is accommodated in the housing. The working head is driven by the motor and a power is output from the motor. The power supply supplies power to the motor. The detecting unit is used for determining whether the power tool body arrives at a preset position of a workpiece. The control unit is connected with the detecting unit and the motor. On the condition that the detecting unit detects a fact that the power tool body reaches the preset position of the workpiece, the motor is stopped so that the working head correspondingly stops power outputting to a position with the anticipated cutting length on the workpiece. Therefore, an operator does not require paying attention to the accurate position of a saw blade, thereby preventing excessive cutting. Furthermore automatic stopping is realized, thereby reducing operation difficulty of the user and realizing high convenience in use. Furthermore, compared with a mechanical backstop mode, the power tool has advantages of no requirement for individual arrangement of a blocking fitting, simple structure and low manufacture cost. The invention further provides a control method for the power tool.

Owner:POSITEC POWER TOOLS (SUZHOU) CO LTD

A flat blade cutting method for hard plates

ActiveCN111673804BAvoid it happening againWon't squeezeMetal working apparatusStructural engineeringStraight segment

The invention relates to the technical field of plate cutting, in particular to a method for cutting a hard plate with a flat edge, which uses a flat edge knife to cut an edge at a corner, wherein the flat edge of the flat edge knife is aligned with a required cut piece, The convex edge is aligned with the unnecessary pieces, and the vertical rake face is aligned with the cutting corner to start cutting; use the flat edge to cut the other side at the corner, wherein the flat edge is aligned with the required pieces , the convex edge is aligned with the unnecessary pieces, and the vertical rake face is aligned with the cutting corner to start cutting; repeat the above steps until all the corners are cut, and use the flat blade cutter to cut the middle straight section Until all the straight sections are cut, wherein, the flat edge of the flat edge cutter is aligned with the required pieces, and the convex edge is aligned with the unnecessary pieces. This cutting method will not squeeze the required pieces, avoid changes in the internal structure and properties of the material, and avoid white edges. The straight edge knife and the flat edge reverse knife realize the cutting at the corners and avoid overcutting.

Owner:CHANGZHOU SINAJET SCI & TECH

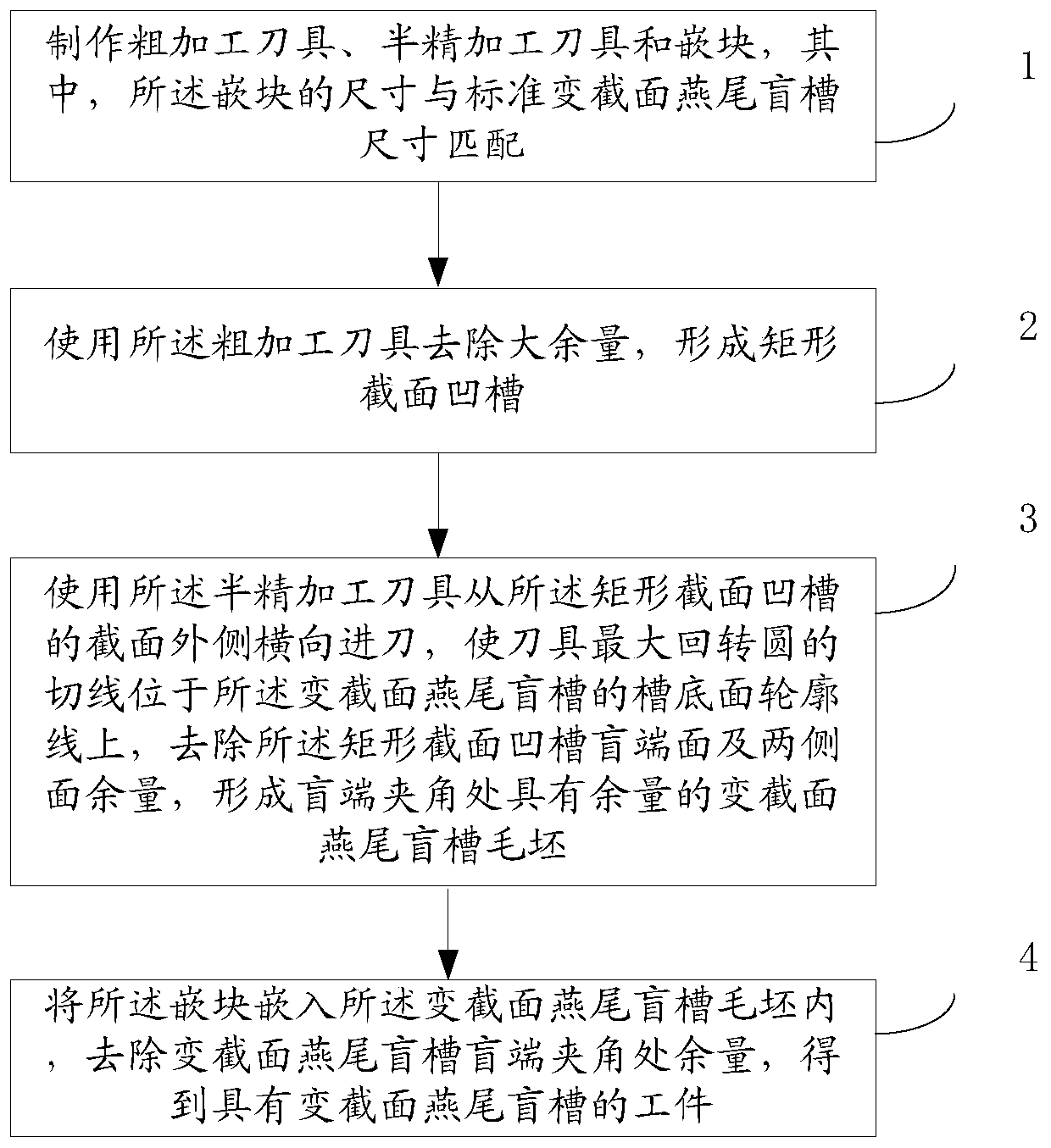

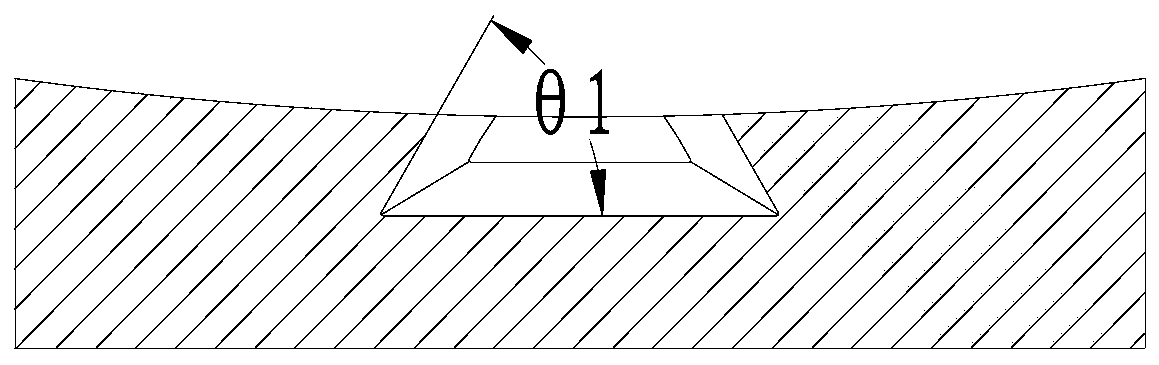

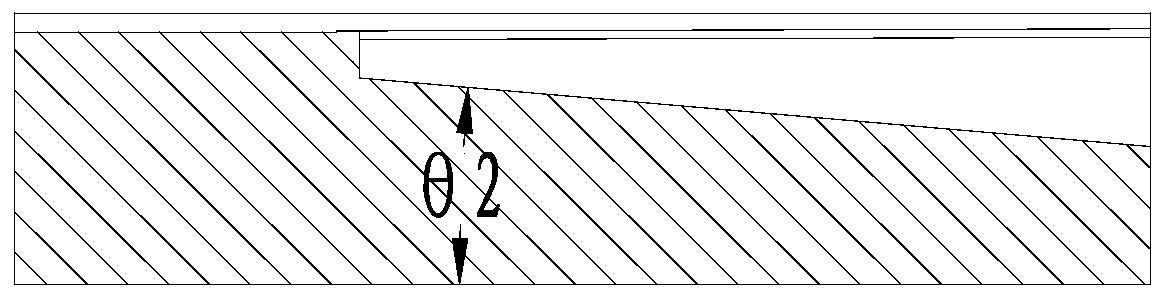

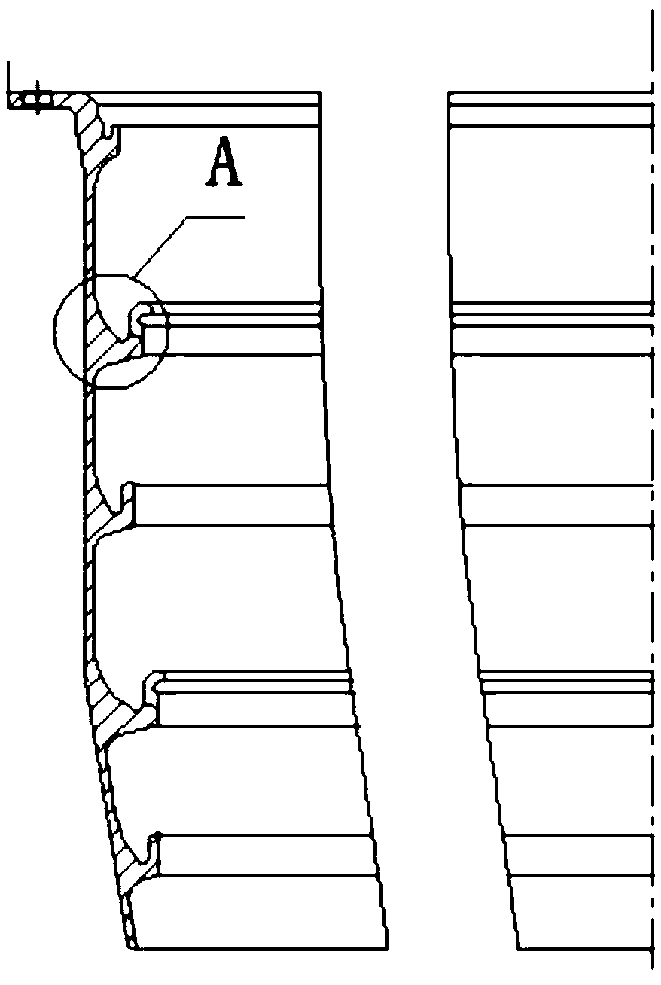

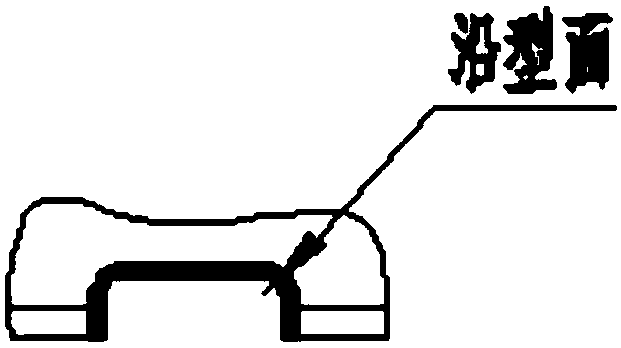

A kind of composite material variable-section dovetail blind groove machining method

The invention provides a method for machining a variable cross-section dovetail blind groove of a composite material, and belongs to the technical field of machining. The method includes the steps that a rough machining tool, a semi-finishing tool and an insert block are manufactured; the rough machining tool is used for removing the large allowance to form a rectangular cross-section groove; the semi-finishing tool is used for conducting transverse cutting feed from the outer side of the cross section of the rectangular cross-section groove, the tangent line of the maximal turning circle of the tool is located on the groove bottom face contour line of the variable cross-section dovetail blind groove, the allowances of the blind end face and the two side faces of the rectangular cross-section groove are removed, and accordingly a variable cross-section dovetail blind groove workblank with the allowance being reserved at the blind end included angle position is formed; and the insert block is embedded into the variable cross-section dovetail blind groove workblank, the allowance at the blind end included angle position of the variable cross-section dovetail blind groove is removed and a workpiece with the variable cross-section dovetail blind groove can be obtained. By the adoption of the machining method provided by the invention, overcut of the blind end is avoided; the tool durability is effectively improved, and production cost is reduced; and corner chipping happening in the machining process of the workpiece dovetail groove is prevented.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

A Machining Method to Avoid Tool Interference

ActiveCN107971540BImprove processing efficiencyGuarantee processing qualityMilling equipment detailsEngineeringTurbine

The invention discloses a processing method for avoiding cutter interference. The processing method is used for developing and processing a low-pressure turbine case weld assembly and comprises the following steps: at first, calculating a proper transformation angle of the taper slot of a part and measuring the deformation of the part to ensure that the allowance is to be processed; then, adoptingan end mill to carry out layered rough mill processing, and according to the processing parameters of the part, reserving 0.2mm allowance for the single side of finish machining; and finally, according to the specific requirements of the taper slot, selecting a proper end mill to carry out finish-milling processing by adopting a correct angle to ensure related size requirements. The processing method effectively ensures the processing quality of the part and effectively solves the problems about cutter interference, low processing efficiency and not-in-place processing caused by part deformation to ensure the processing quality of the part.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Multi-level wheel-stage interlocking island protection method applicable to large-scale new energy power station

ActiveCN105896491APrevent overcutIncrease the level of automationEmergency protective circuit arrangementsDevice typePower station

The invention discloses a multi-level wheel-stage interlocking island protection method applicable to a large-scale new energy power station. The multi-level wheel-stage interlocking island protection method comprises the following steps: (1) determining the constant value of island protection characteristic quantity according to the stability domain degree of the large-scale new energy power station system, and stably dividing the system into a plurality of levels; (2) generating corresponding logic expression according to the type of each interval equipment of the large-scale new energy power station and exit matrix configuration; (3) generating wheel-stage interlocking logic; and (4) identifying stable levels of the system after an island phenomenon occurs by calculating a characteristic variable value in real time, and acting on an exit matrix according to a wheel-stage interlocking logic distinguishing result so as to guarantee the rapidity and reliability of exit tripping. The method is applied to a wheel-stage interlocking logic method, the problem of overcutting appearing in the island protection process of the large-scale new energy power station is prevented, the method has higher automation level, the operation process can be simplified, the operation and maintenance costs are reduced, the reliability of operation is improved, and the method has extensive applicability at the same time.

Owner:NARI TECH CO LTD +3

Broken pipe joint electric remover

InactiveCN105690325BAvoid damageEasy to removeMetal-working hand toolsReciprocating motionEngineering

The invention discloses an electric remover for fractured pipe joints, which comprises a supporting seat, tension devices, a cutting device, a feed regulation device, a driving device and a tail stand, wherein the tree groups of tension devices fix the supporting seat on a pipe connector in an inner-bracing tensioning manner; radial feed regulation and circumferential rotation regulation of saw blades in the cutting device are realized through the feed regulation device; the driving device drives the saw blades to perform reciprocating motion so as to cut a fractured pipe joint. According to the electric remover for the fractured pipe joints, the manner of cutting before removing is adopted, so that the damage to the inner thread of an original pipe joint is extremely low, and damage caused by repair is avoided; moreover, the motor is adopted for driving the saw blades to perform reciprocating cutting, which saves both time and labor and realizes rapid removing and repairing of the fractured pipe joint; besides, the feed regulation device can realize feed control and regulation of the saw blades, to further determine the cutting position and depth and avoid over cutting, therefore the electric remover for the fractured pipe joints has the characteristics of being compact in structure, simple and rapid in operation and control, and capable of easily removing the fracture pipe connector and the like.

Owner:ANHUI UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com