Machine tool with floating shaft

A technology of floating shafts and machine tools, which is applied to machine tools suitable for grinding the edge of workpieces, parts of grinding machine tools, grinding machines, etc. It can solve problems such as the absence of floating shafts, achieve simple structure, improve surface quality, and facilitate disassembly and assembly Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

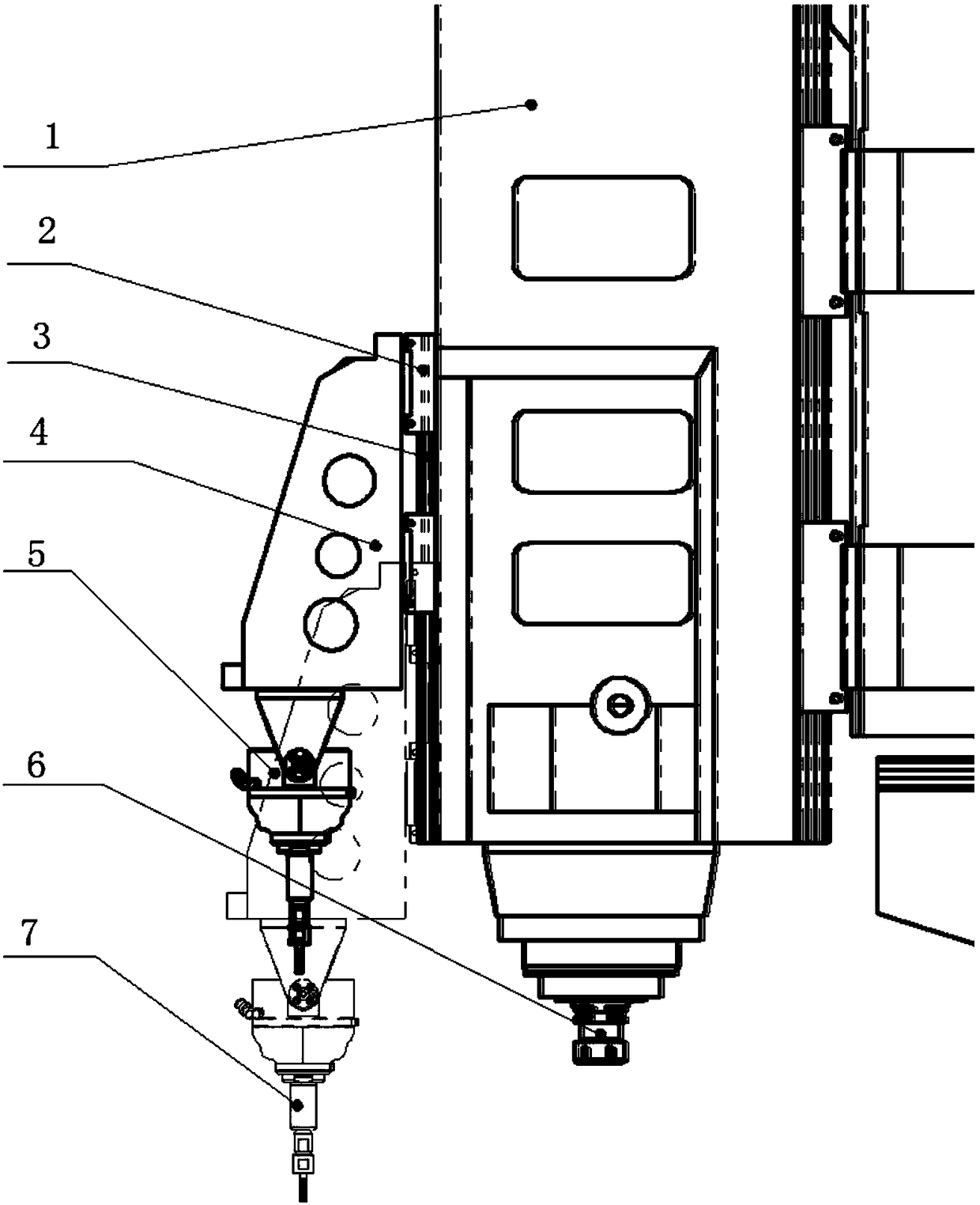

[0024] like figure 1 As shown, a machine tool with a floating axis includes a Z-axis body 1 of the machine tool. A rigid output shaft 6 is provided at the lower end of the Z-axis body 1 of the machine tool. The Z-axis body 1 of the machine tool is installed on the Z-axis guide rail of the machine tool. The Z-axis body 1 is provided with a floating shaft 5 and a power device (not shown in the figure), and the power device is used to push the floating shaft 5 to move up and down to realize output switching between the rigid output shaft 6 and the floating shaft 5 .

[0025] At present, the existing machine tools on the market all include machine tool Z-axis body 1, the lower end of Z-axis body 1 is provided with a rigid output shaft 6, the lower end of rigid output shaft 6 is equipped with a tool, and the machine tool Z-axis body 1 is installed on the Z-axis guide rail of the machine tool , when working, the Z-axis body 1 of the machine tool moves up and down along the Z-axis gu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com