A flat blade cutting method for hard plates

A cutting method and flat blade technology, which can be used in metal processing and other directions, and can solve the problem of scrapping white edge materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

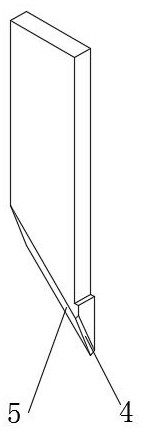

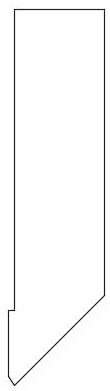

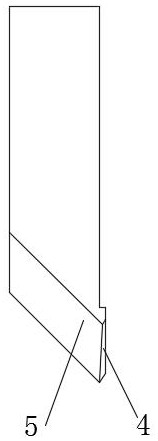

[0037] Such as Figures 1 to 7 It is a schematic diagram of the structure of the present invention, a method for cutting a hard plate with a flat edge, including a cutting knife set, and the cutting knife set includes a flat edge positive knife 1, a flat edge reverse knife 2, and a flat edge cutter 3. The specific cutting method is as follows:

[0038] Step S1: Use the flat edge positive knife 1 to cut an edge at the corner, where the flat edge of the flat edge positive knife 1 is aligned with the required piece, and the convex edge of the flat edge positive knife 1 is aligned with the unnecessary cut piece piece, the vertical rake face of the flat front knife 1 aligns with the cutting corner and starts cutting;

[0039] Step S2: Use the flat-edged counter-knife 2 to cut the other side at the corner, where the flat edge of the flat-edged counter-knife 2 is aligned with the desired piece, and the convex edge of the flat-edged counter-knife 2 is aligned with the unnecessary piec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com