AC corner optimization method for five-axis 3D printing line cutting path planning

A 3D printing and path planning technology, applied in 3D object support structure, additive manufacturing, processing data acquisition/processing, etc., can solve the problems of overcutting of workpieces due to rotation angle difference, reduce printing efficiency, etc., and achieve protection from damage, Improve printing efficiency and improve printing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with accompanying drawing and example the present invention is described in further detail.

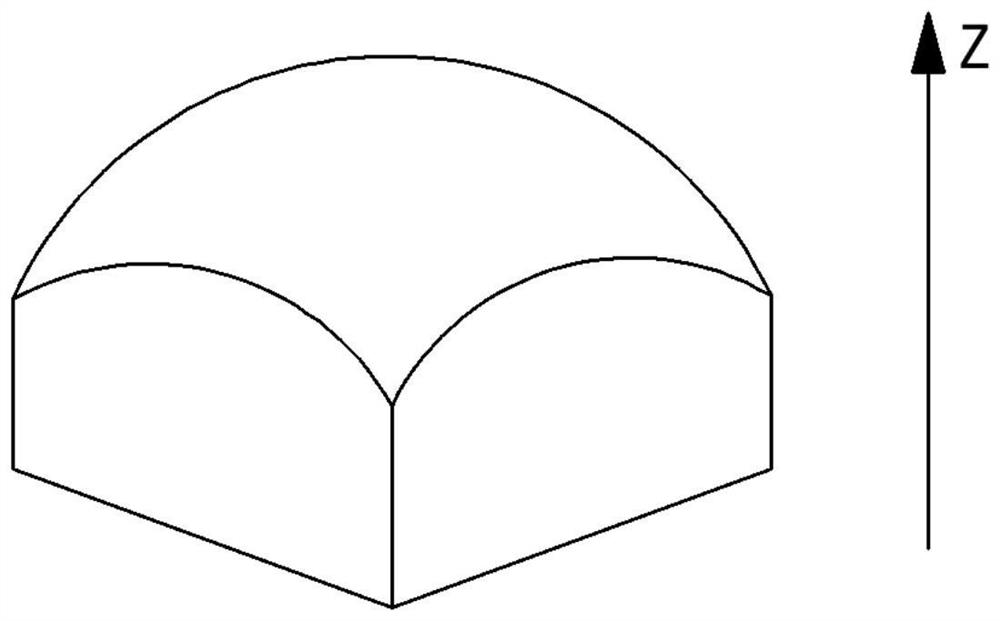

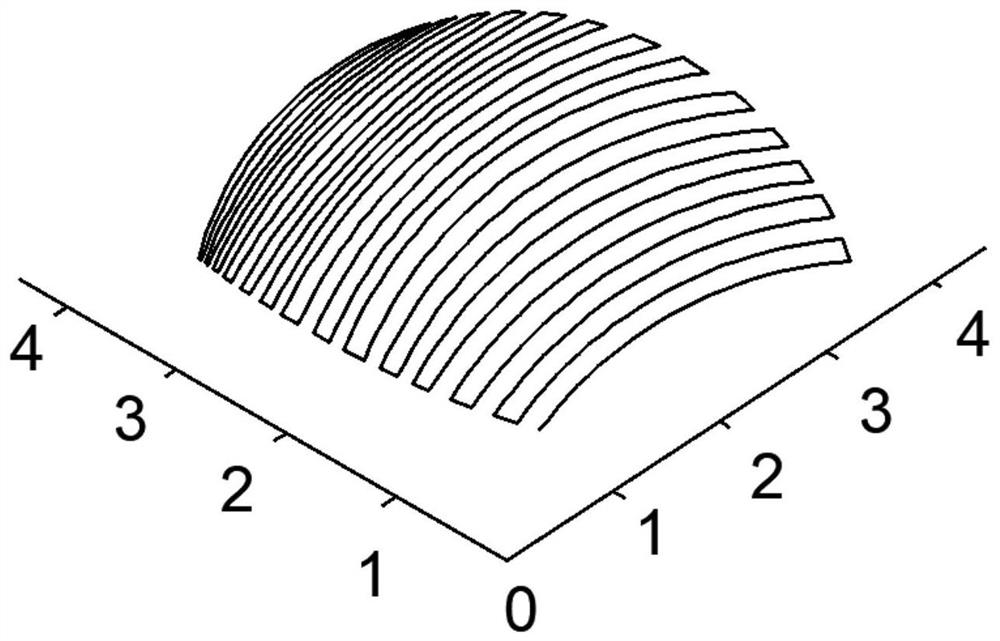

[0028] This embodiment uses FDM technology for five-axis 3D printers to perform model slice layering and path planning. The model M to be printed is as follows figure 1 As shown, the multi-axis 3D printer used is composed of two parts: the upper nozzle is fixed at the end of the XYZ three-degree-of-freedom mechanical arm, and the lower part of the heating bed platform for carrying workpieces is fixed on the AC two-axis turntable, where the A-axis rotates The degree of freedom is the rotational degree of freedom around the X-axis, and the C-axis rotational degree of freedom is the rotational degree of freedom around the Z-axis.

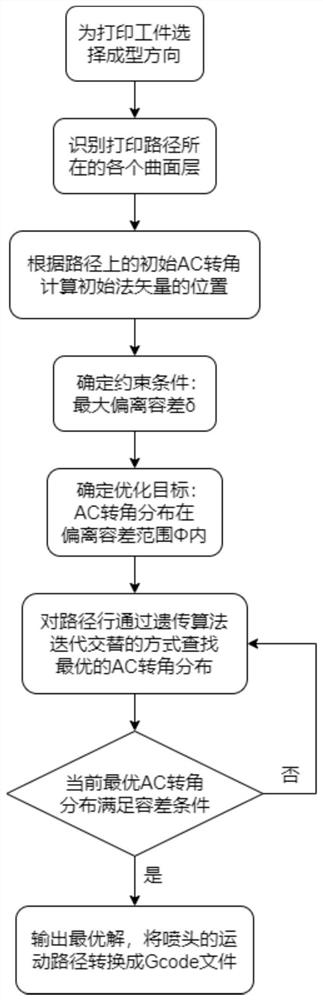

[0029] An AC corner optimization method for five-axis 3D printing line cutting path planning, including the following steps, such as image 3 Shown:

[0030] Step 1: According to the characteristics of the printed model M, select ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com