Cold cutting die for titanium alloy precision-forged blade

A titanium alloy and precision forging technology, applied in the field of cold cutting die for titanium alloy precision forging blades, can solve the problems of high processing cost, low efficiency, easy deformation, etc., to ensure processing quality, improve processing efficiency, and control the accuracy of chord width. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

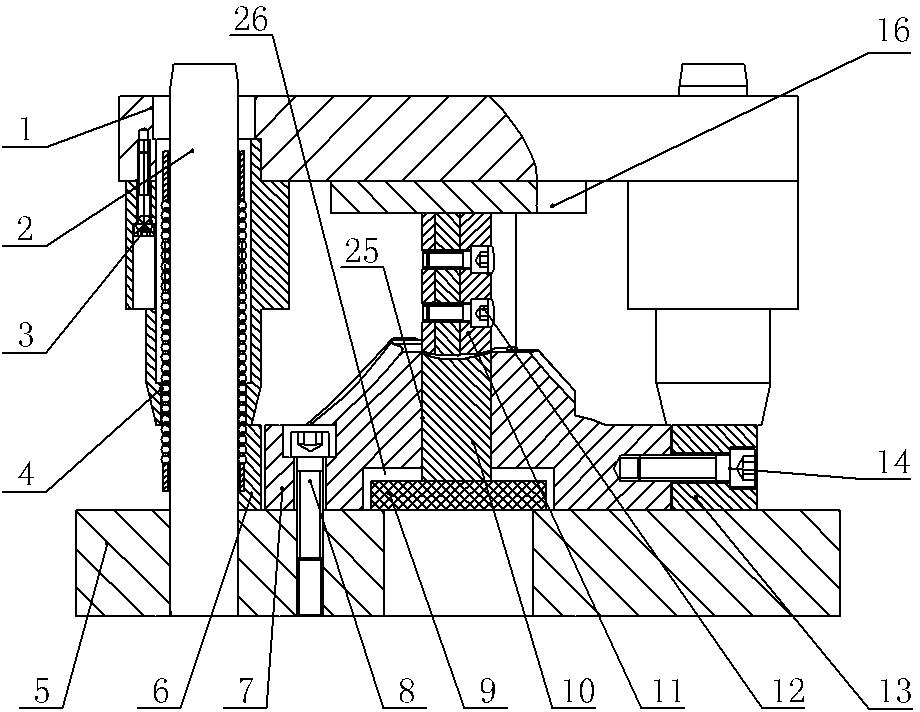

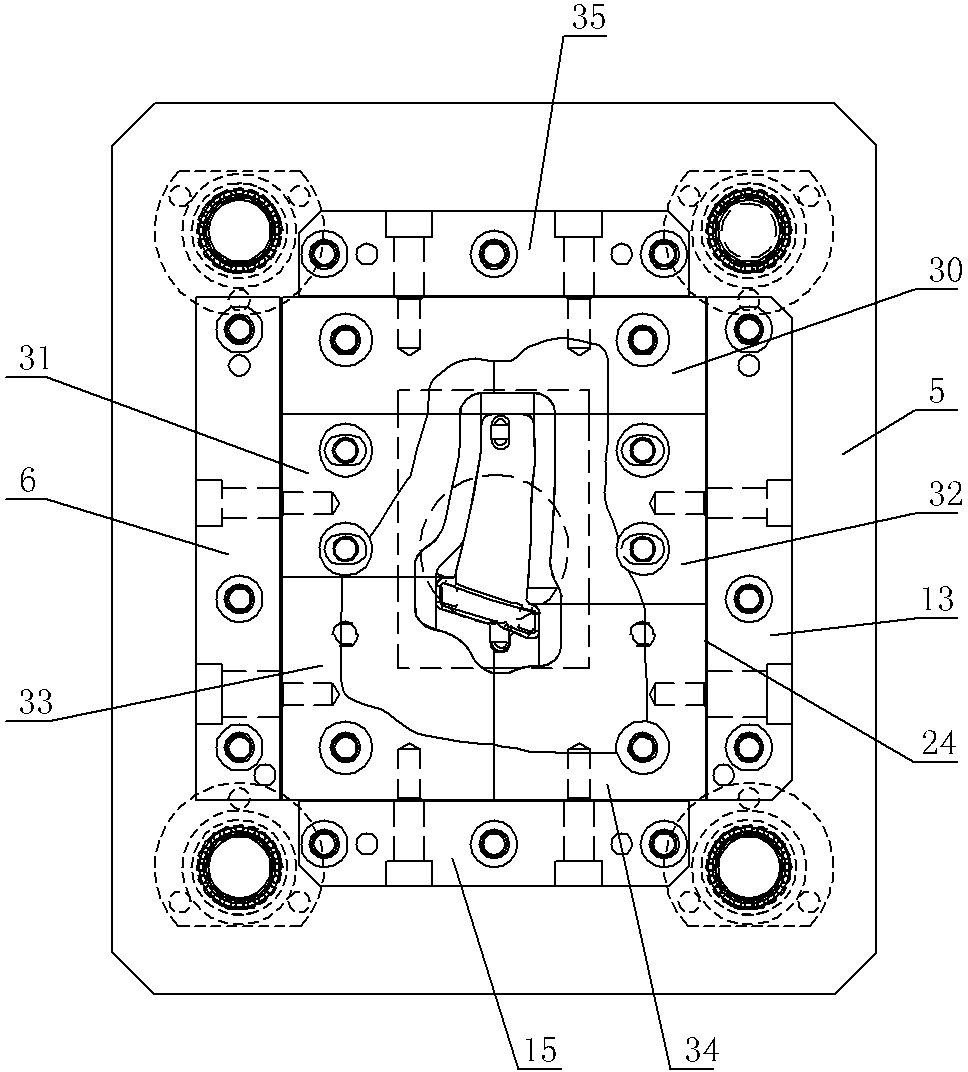

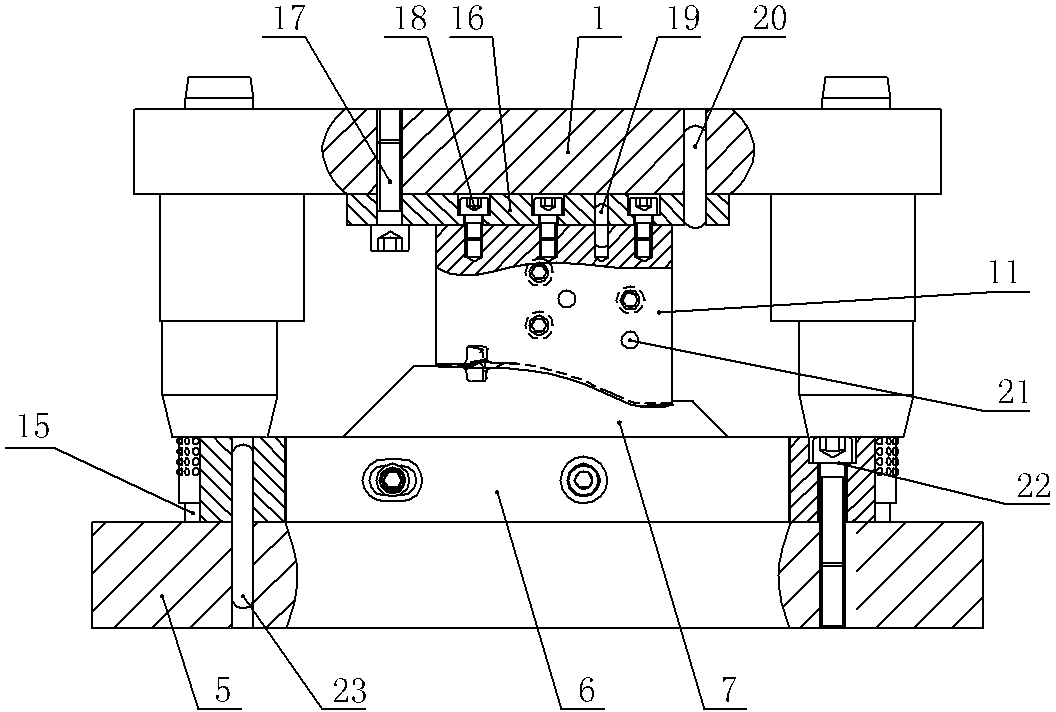

[0020] See figure 1 , figure 2 with image 3 , the cold cutting die of the present invention comprises an upper template 1, a lower template 5, a punch 11 and a lower mold, the upper template 1 and the lower template 5 are connected through a guide column 2 and a ball guide bush 4, and the punch 11 passes through the punch The backing plate 16 is installed under the upper template 1, the lower mold includes a female mold 7 and a supporting mold 10, the female mold 7 is fixed on the lower template 5 by screws 8, and the female mold 7 is provided with vertical through grooves 25 and The horizontal channel 26, the supporting mold 10 is installed in the vertical channel 25, and its lower end is supported by the rubber pad 9, and the rubber pad 9 is installed on the lower template 1 and is located in the horizontal channel 26, and the supporting mold 10 is in the non-working state 3mm-5mm higher than the female mold 7, the gap between the punch 11 and the female mold 7 is 0.05mm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com