Assembly type prestress applying device for foundation pit steel supporting structure

A technology of applying device and steel support, applied in the direction of foundation structure engineering, excavation, construction, etc., can solve the problems of high engineering cost, unsuitable for mass use, difficult to meet the deformation requirements of foundation pit, etc., to strengthen the ability to resist the deformation of foundation pit , Good use and promotion value, real-time controllable effect of prestress loading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

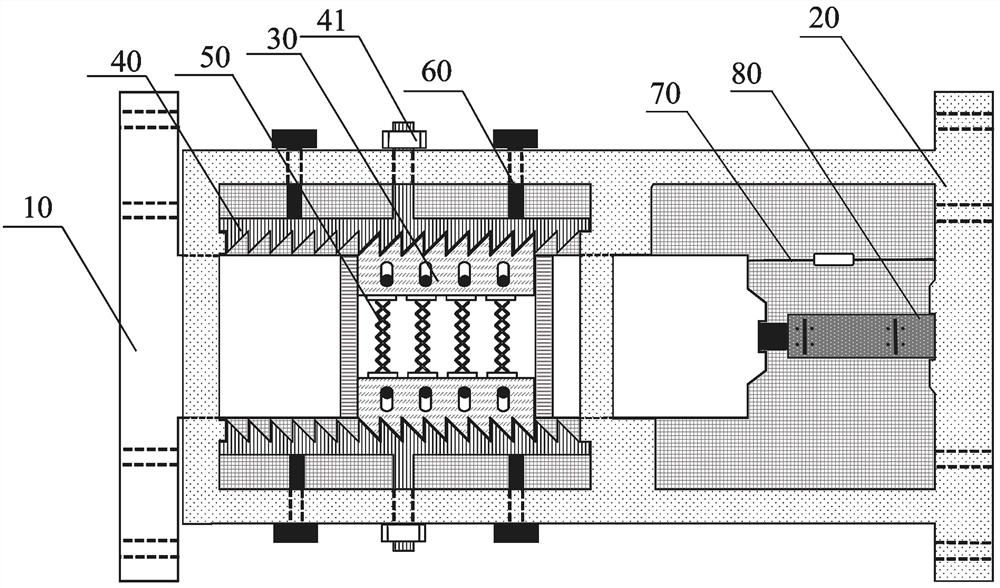

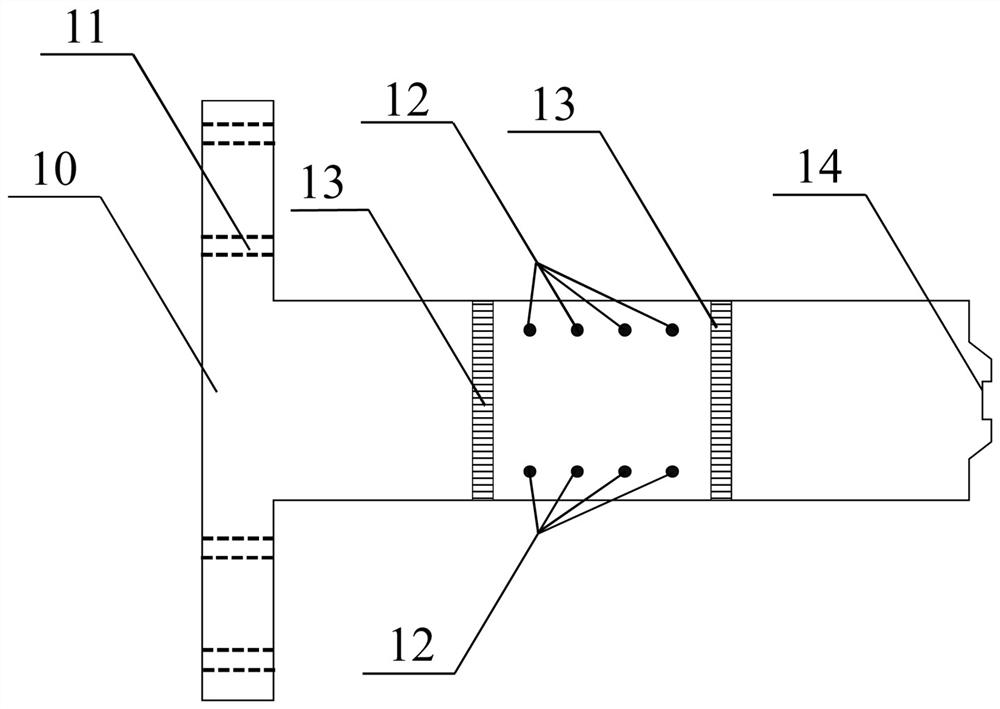

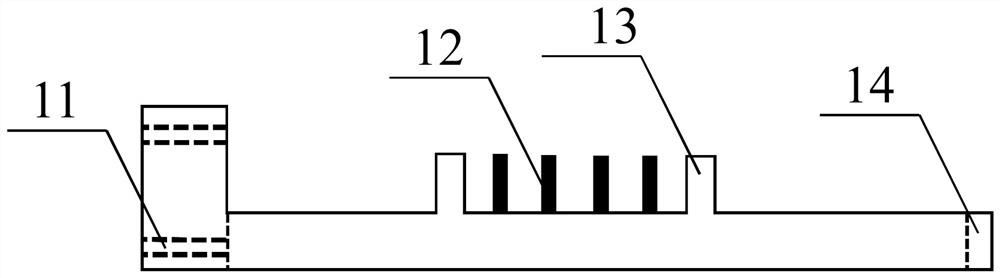

[0023] The present invention will be further described in detail through specific embodiments below in conjunction with the accompanying drawings. The present application can be implemented in many different forms, and is not limited to the implementation described in this embodiment. The purpose of providing the following specific embodiments is to facilitate a clearer and more thorough understanding of the technical content of this solution, where the words indicating orientation such as up, down, left, and right are only for the positions of the structures shown in the corresponding drawings.

[0024] The invention is an assembled prestressing structural device used for the steel support of the foundation pit, which can be flexibly installed on the nodes of the steel support structure through the locking of the tooth plate, and can effectively control the deformation of the foundation pit by adjusting the size of the support prestress.

[0025] According to attached figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com