Deformation control device

A deformation control and mounting column technology, applied in auxiliary devices, manufacturing tools, auxiliary welding equipment, etc., can solve the problems of easy deformation of the car body and high scrapping ratio, and achieve the effects of low cost, increased strength, and avoiding car body deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

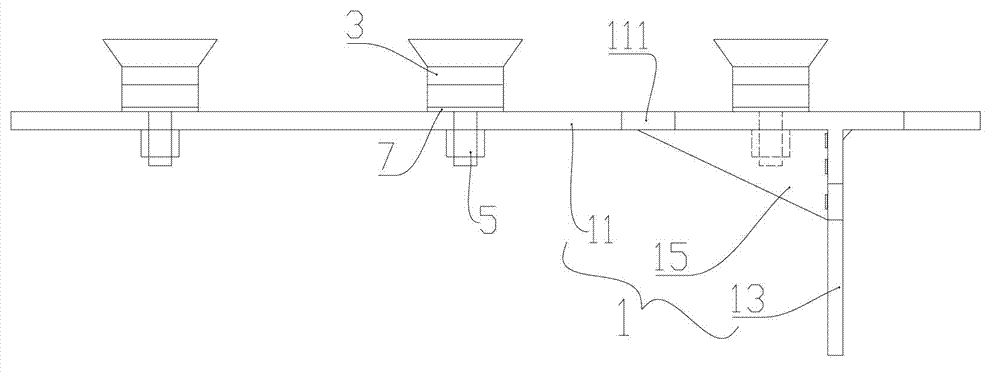

[0016] see figure 1 , an embodiment of the present invention provides a deformation control device installed on a fixture (not shown in the figure). The fixture includes at least one clamping unit (not shown in the figure) and an air circuit (not shown in the figure). The deformation control device includes a support frame 1 and at least one suction cup 3 installed on the support frame 1 . Among them, the support frame 1 is fixed on the fixture; the suction cup 3 is connected to the air path of the fixture through the air pipe (not shown in the figure), and the air is supplied or released to the suction cup 3 through the air path of the fixture, so that the suction cup 3 is adsorbed and positioned or released. body panels.

[0017] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com