Cutting tool assembly of debarker

A cutting tool and peeling machine technology, which is applied to bark, wood processing equipment, manufacturing tools, etc., can solve the problems of low cutting efficiency, difficulty in controlling the cutting depth of the tool, and poor quality of finished products, so as to shorten the processing time and prolong the service life , to prevent the effect of overcutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

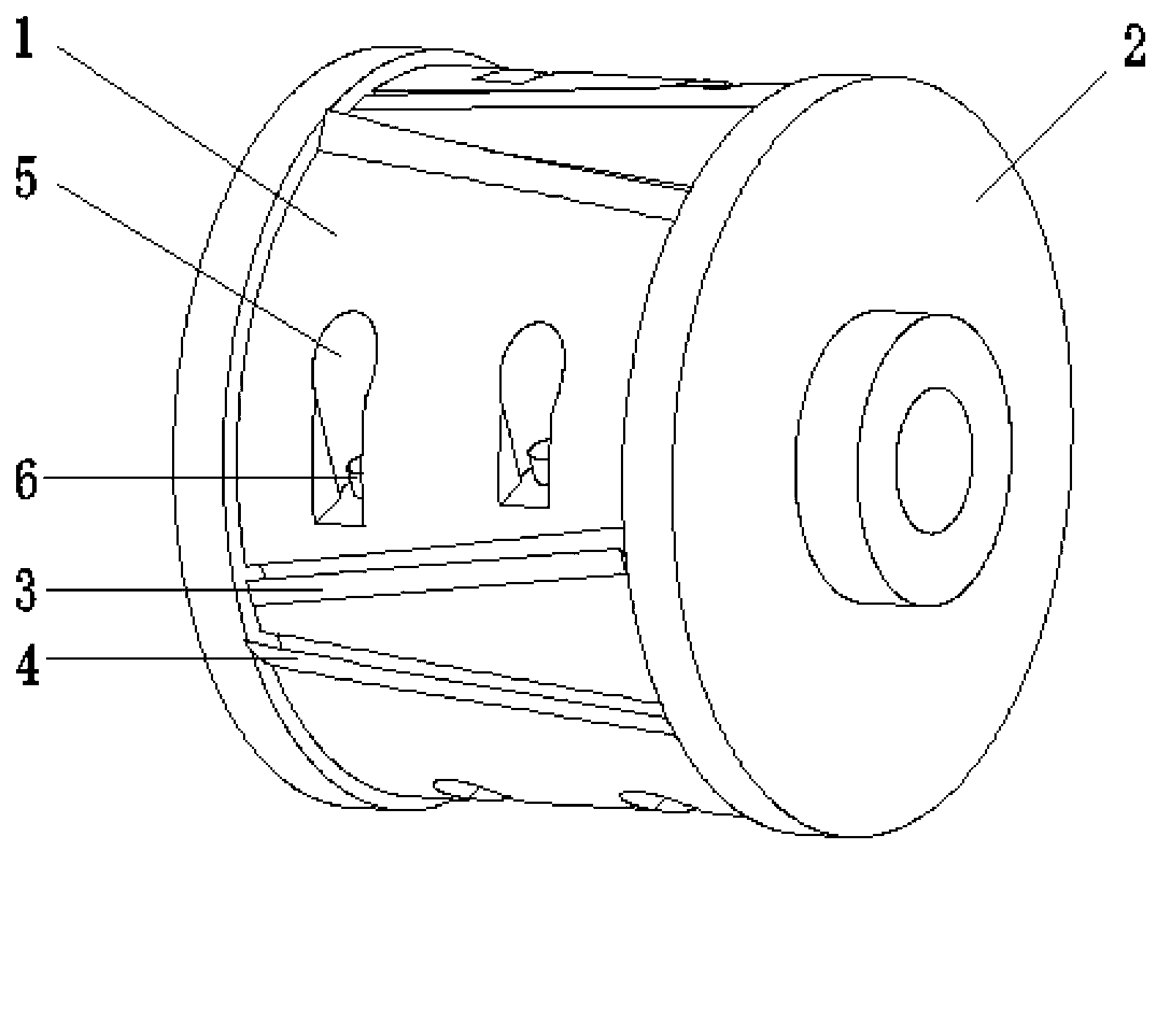

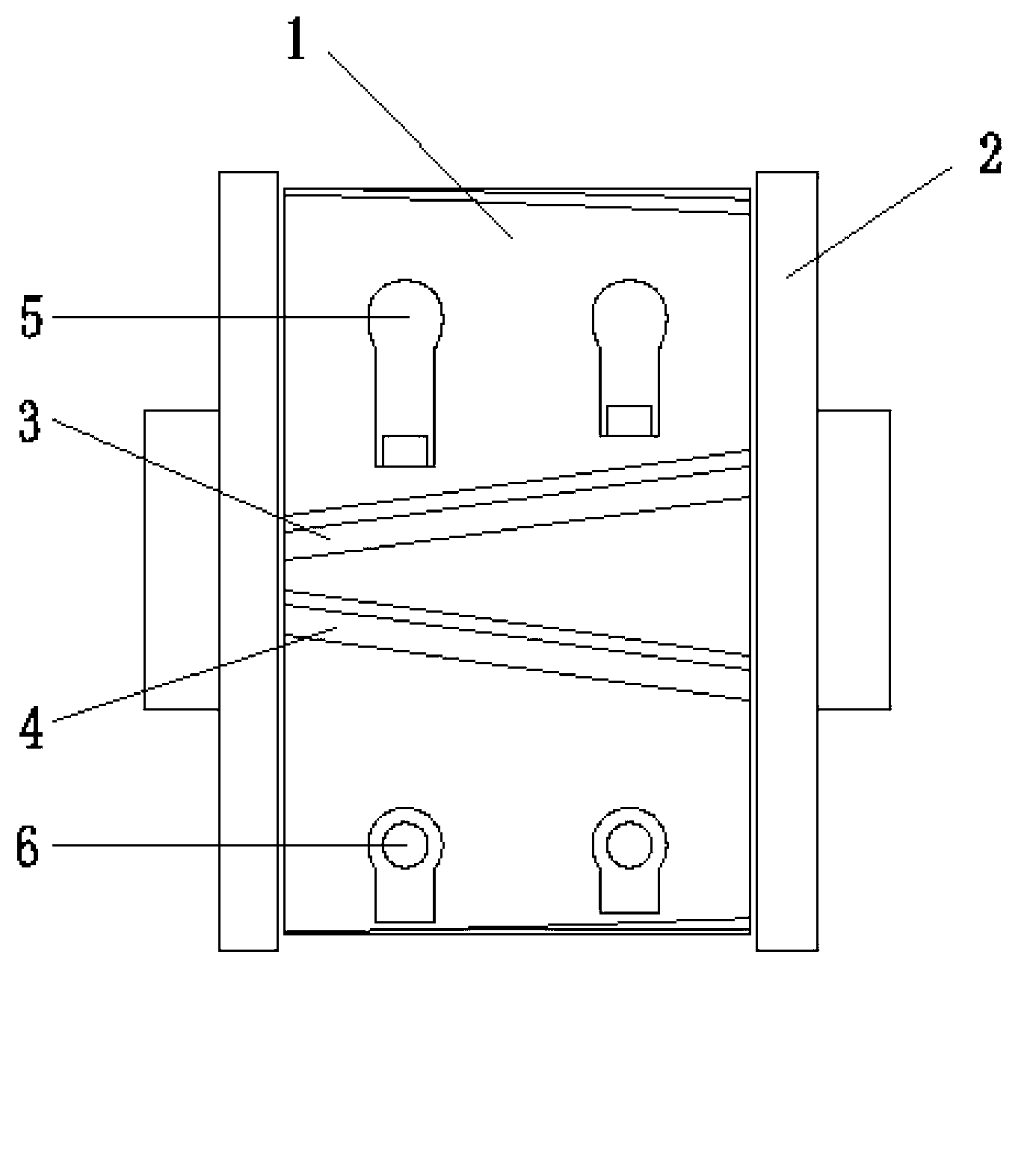

[0013] The present invention is described below in conjunction with accompanying drawing.

[0014] as attached figure 1 , 2 Shown is a cutting tool assembly of a tree peeling machine according to the present invention, including a cutter head 1 and a limiting disc 2; the cutter disc 1 is cylindrical; the limiting disc 2 has two, two Limiting discs 2 are respectively arranged at the left and right ends of the cutter head 1; the diameter of the limiting disc 2 is larger than the diameter of the cutter head 1; the outer circumference of the cutter head 1 is provided with 4 blade mounting parts, 4 blades The mounting parts are evenly distributed on the outer circumference of the cutterhead 1; an upper blade 3 and a lower blade 4 are arranged on each blade mounting part; the upper blade 3 and the lower blade 4 are elongated blades, The upper blade 3 and the lower blade 4 are arranged obliquely, and the maximum distance from the blades of the upper blade 3 and the lower blade 4 to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com