A method and device for distributing load cutting amount

A technology of load shedding and distribution method, applied in the field of load shedding distribution methods and devices, can solve problems such as large distribution errors, system instability, and failure to achieve expected control effects, avoid over-cutting or under-cutting, improve The effect of assigning precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052]The present invention provides a load shedding distribution method. In order to better understand the technical content of the present invention, specific embodiments are given and described as follows with accompanying drawings.

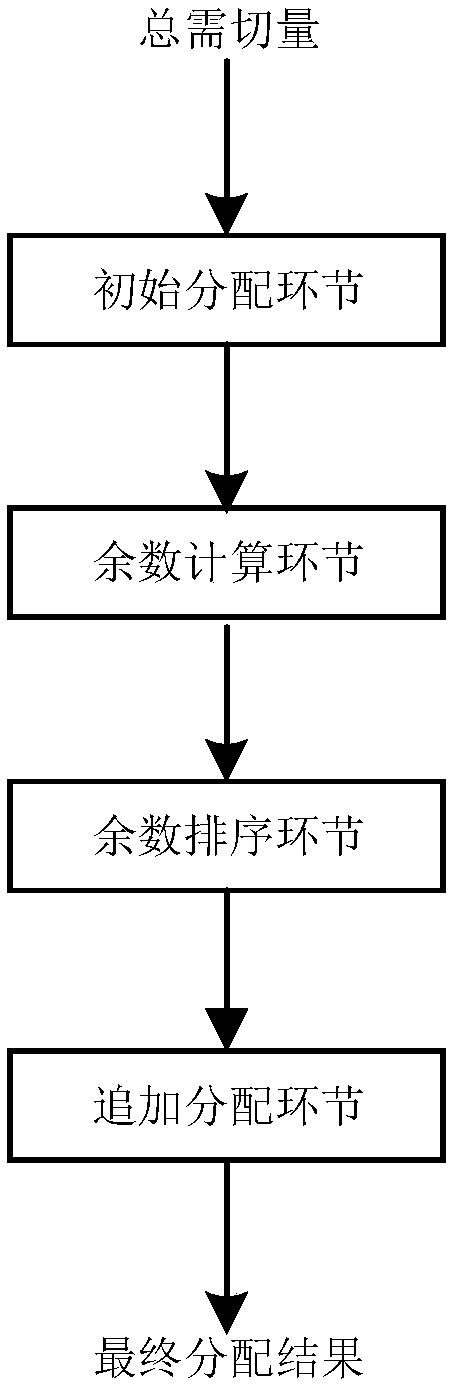

[0053] Such as figure 1 As shown, the solution of the present invention includes the following steps: (1) initial allocation link, (2) remainder calculation link, (3) remainder sorting link, (4) additional allocation link.

[0054] (1) In the initial distribution link, the total demand cut is distributed in proportion to the load shed load of each load shedding substation. Assume that a stability control system has 6 load shedding execution stations, and the total demand cut Pxq=243MW for a certain fault, each The load shedding capacity of the load shedding sub-station is respectively:

[0055] Pkq1=56MW

[0056] Pkq2=67MW

[0057] Pkq3=43MW

[0058] Pkq4=61MW

[0059] Pkq5=80MW

[0060] Pkq6=85MW

[0061] The total shedable load is:

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com