Piling machine

A technology of pile driver and winch, which is applied in the direction of sheet pile wall, drilling equipment, earthwork drilling and mining, etc. It can solve the problems of slow hole drilling speed, severe drill bit jumping, and inability to guarantee hole quality, etc., and achieves easy jacking of punched steel The effect of the search

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The preferred embodiments of the present invention are described below with reference to the accompanying drawings, which are used as a part of this specification to illustrate the principle of the present invention through the embodiments, and other aspects, features and advantages of the present invention will become clear at a glance through the detailed description.

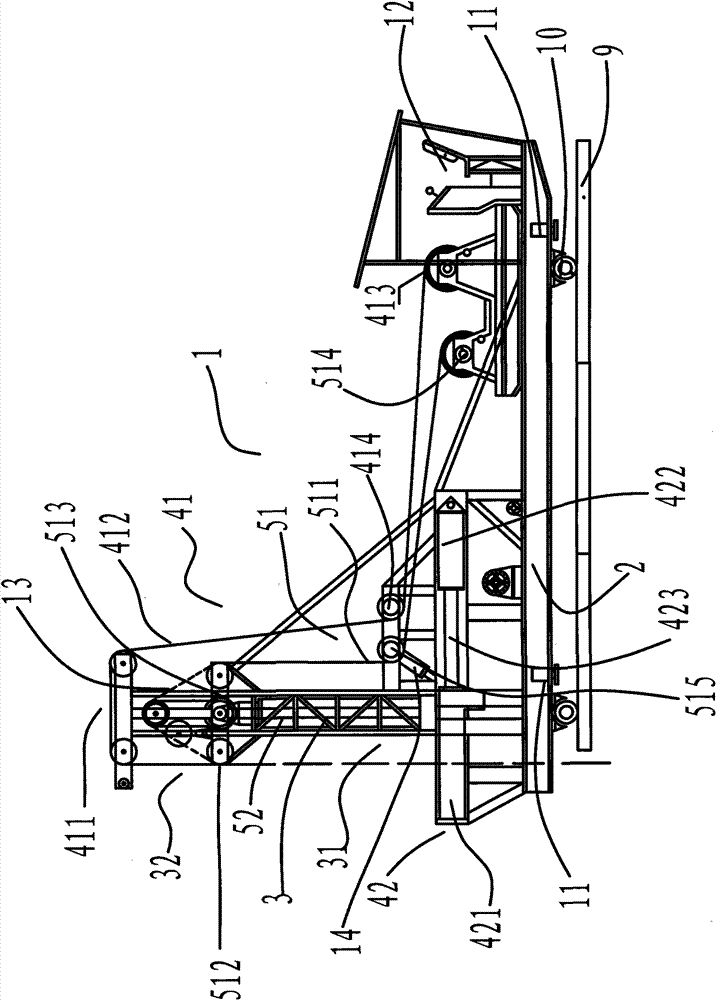

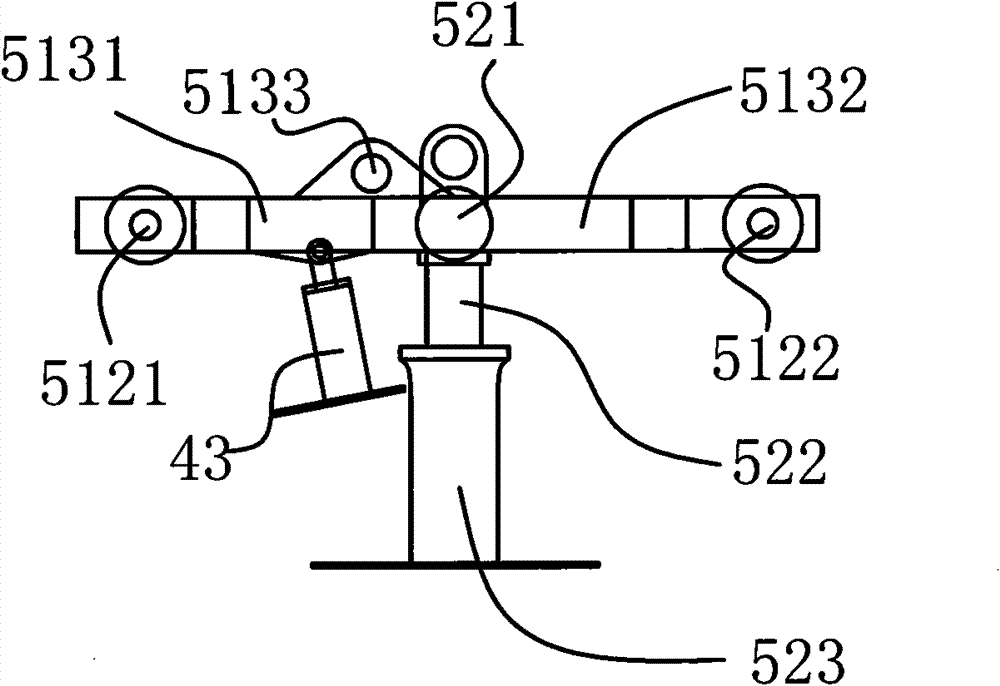

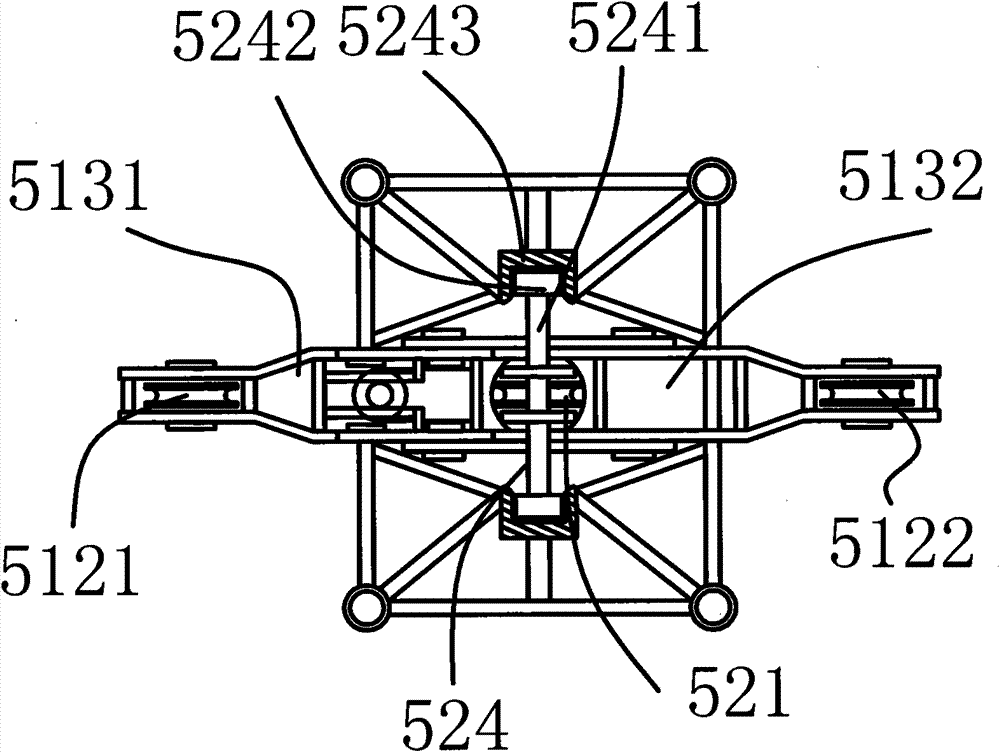

[0044] figure 1 The structural representation of a kind of pile driver provided by the present invention, as figure 1 As shown, a pile driver 1 provided by the present invention includes a chassis 2 and a tower 3 vertically arranged on the chassis 2 , wherein the tower includes a tower base 31 and a tower top 32 . The bottom of the chassis 2 is evenly provided with pipes 10 (seamless steel pipes) front and back, and the chassis 2 is connected to the sleepers 9 at the bottom through the pipes 10; When adjusting the position of the pile driver or adjusting the level of the pile driver, the piston rod of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com