Concrete aggregate separation device and separation method thereof

A technology of concrete aggregate and separation device, which is applied in the fields of aggregate separation device, concrete aggregate separation, and concrete aggregate separation device, can solve the problems of insufficient aggregate separation and air pollution, and achieves improved aggregate separation effect, The effect of uniform dispersion and improved separation quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

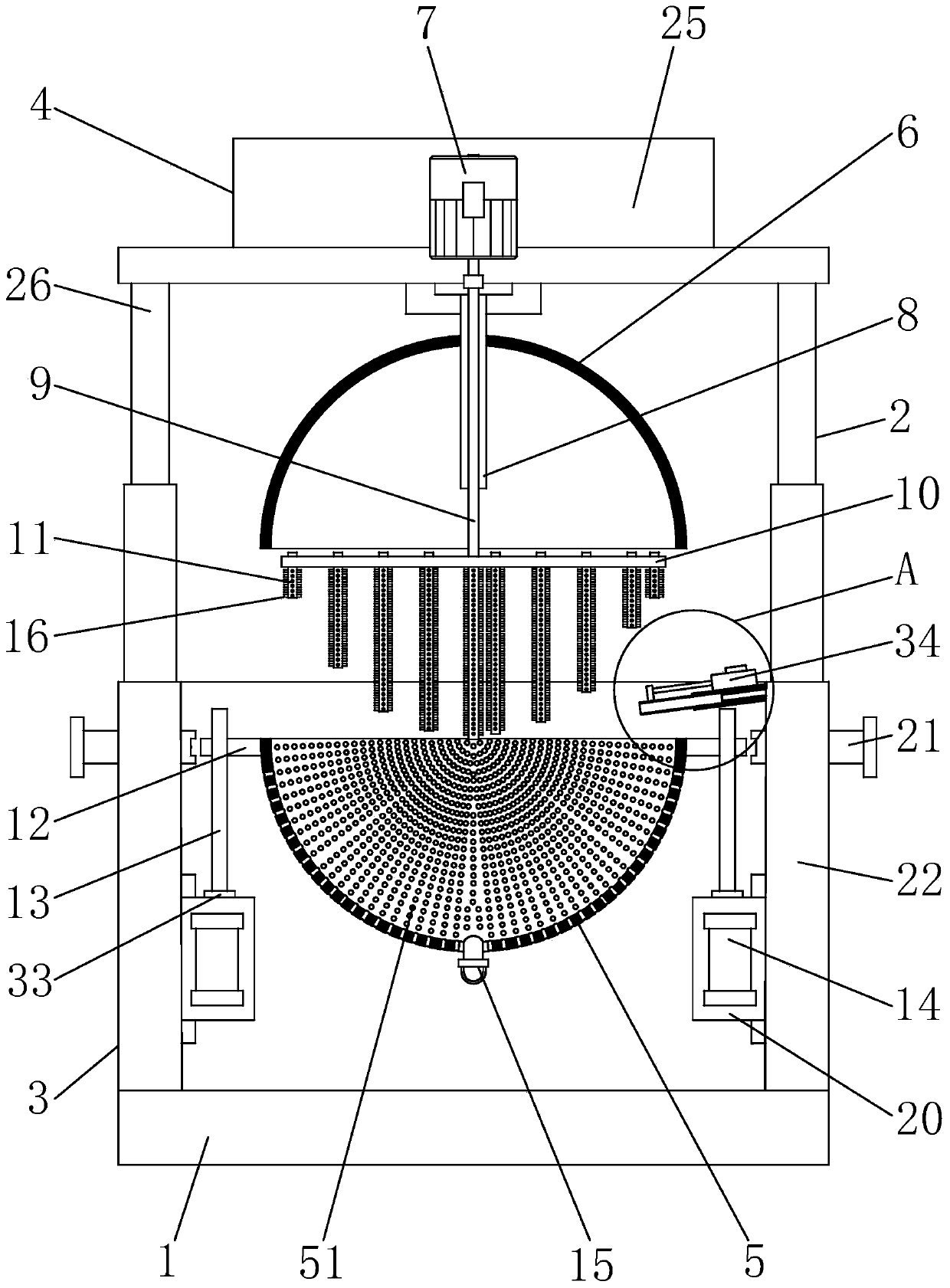

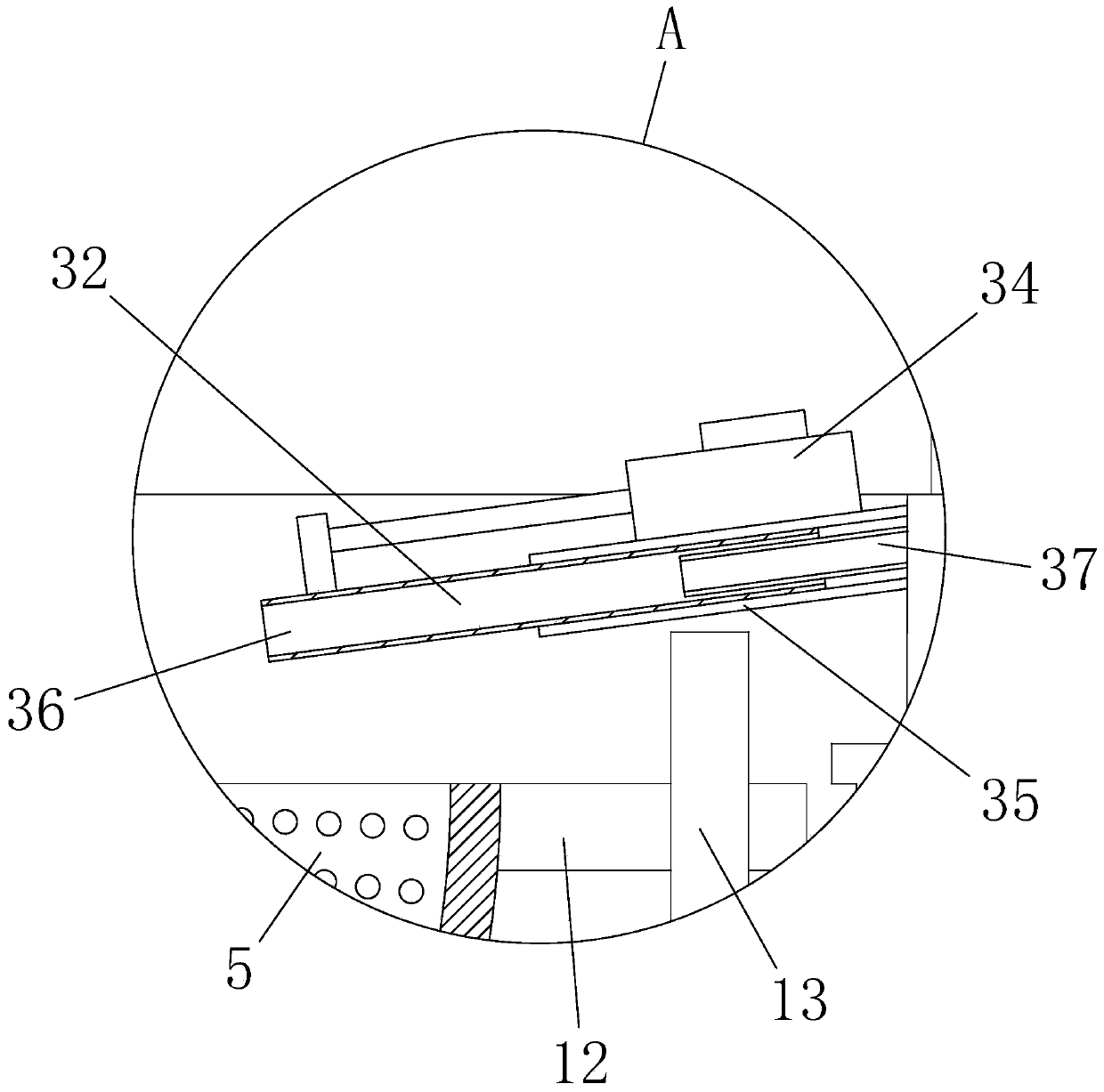

[0077] see figure 1 as well as figure 2 , this embodiment provides a concrete aggregate separation device, which includes a base 1, a separation platform 2, a separation pot 5, a protective cover 6, a weighing mechanism, a feeding mechanism, a stirring assembly and a controller, and may also include a vibration assembly and piston 15. The concrete aggregate separation device of this embodiment can separate concrete aggregates into coarse aggregates and fine aggregates with different particle sizes, and corresponding separation parameters can be set according to the actual size of concrete aggregates.

[0078] The base 1 can be placed on the ground, or on other equipment or devices. The material of the base 1 can be set according to actual needs, such as stainless steel and cement. The shape of the base 1 needs to be set apart from the shape of the bottom of the platform 2 and the placement area of the base 1, such as a rectangular parallelepiped and a circle. A buffer s...

Embodiment 2

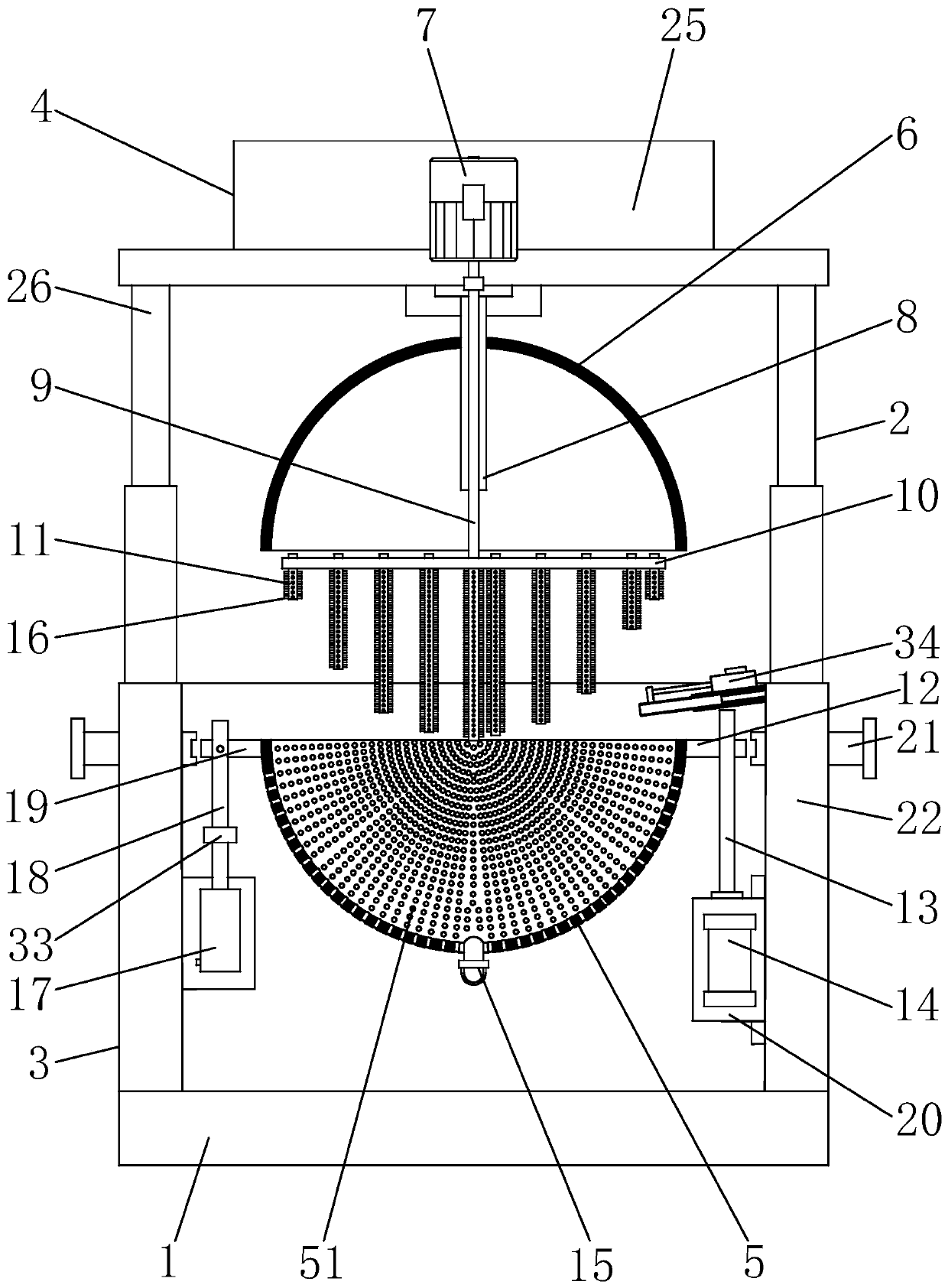

[0096] see image 3 , this embodiment provides a concrete aggregate separation device, which is similar to the aggregate separation device in Embodiment 1, the difference is that the number of vibrating components in this embodiment is one set, and the first fixed column 12 and the second fixed column 13 Rotate the connection, and increase the shaking material component.

[0097] The shaker assembly includes hydraulic cylinder one 17, fixed column three 18 and fixed column four 19. Hydraulic cylinder one 17 is installed on the fixed frame 3. One end of the fixed column three 18 is connected with the movable end of the hydraulic cylinder one 17, and the other end is rotatably connected with one end of the fixed column four 19. The other end of fixed column 4 19 is fixed on the outer wall of separation pot 5. Wherein, the vibrating assembly and the shaking assembly are respectively located on opposite sides of the separation pot 5 . The two draw-in slots are respectively tow...

Embodiment 3

[0100] Please refer to 3, this embodiment provides a concrete aggregate separation device, the device adds a lifting component on the basis of embodiment 2, and the number of lifting components is at least one set. In this embodiment, each group of lifting components includes a wire rope 23 and a lifting motor 24 . Wire rope 23 is wound on hoist motor 24, and free end is fixed on protective cover 6. The lifting motor 24 is fixed on the lifting frame 4 . In this way, when using the shaker assembly, the lifting motor 24 can be rotated, and then the steel wire rope 23 can be pulled to pull up the protective cover 6, so as to shake the aggregate in the separation pot 5, so that the aggregate can be fully mixed and separate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com