Automatic screening device for sample particles

An automatic and granular technology, which is applied in the fields of filtration, solid separation, chemical instruments and methods, etc., can solve the problems of long time-consuming, difficult to clean, low degree of automation, etc., to ensure airtightness and stability, prevent cross-contamination, The effect of ensuring cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing:

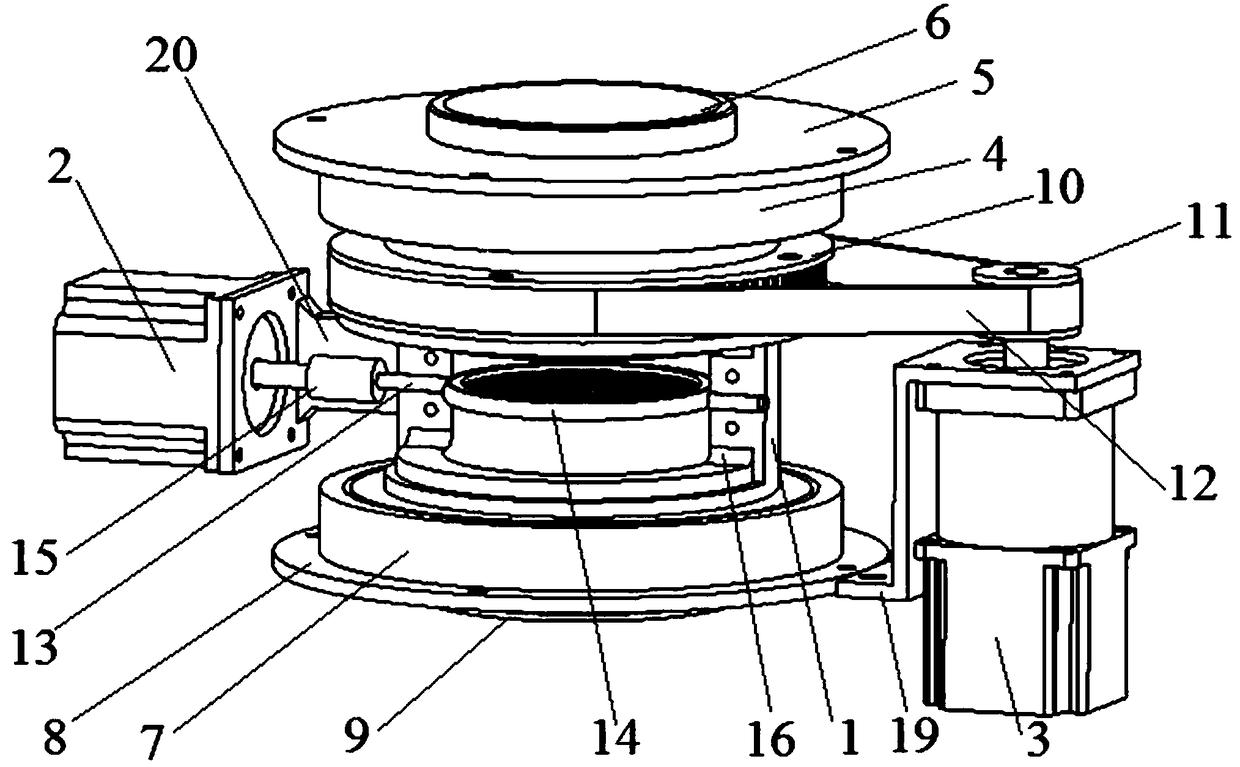

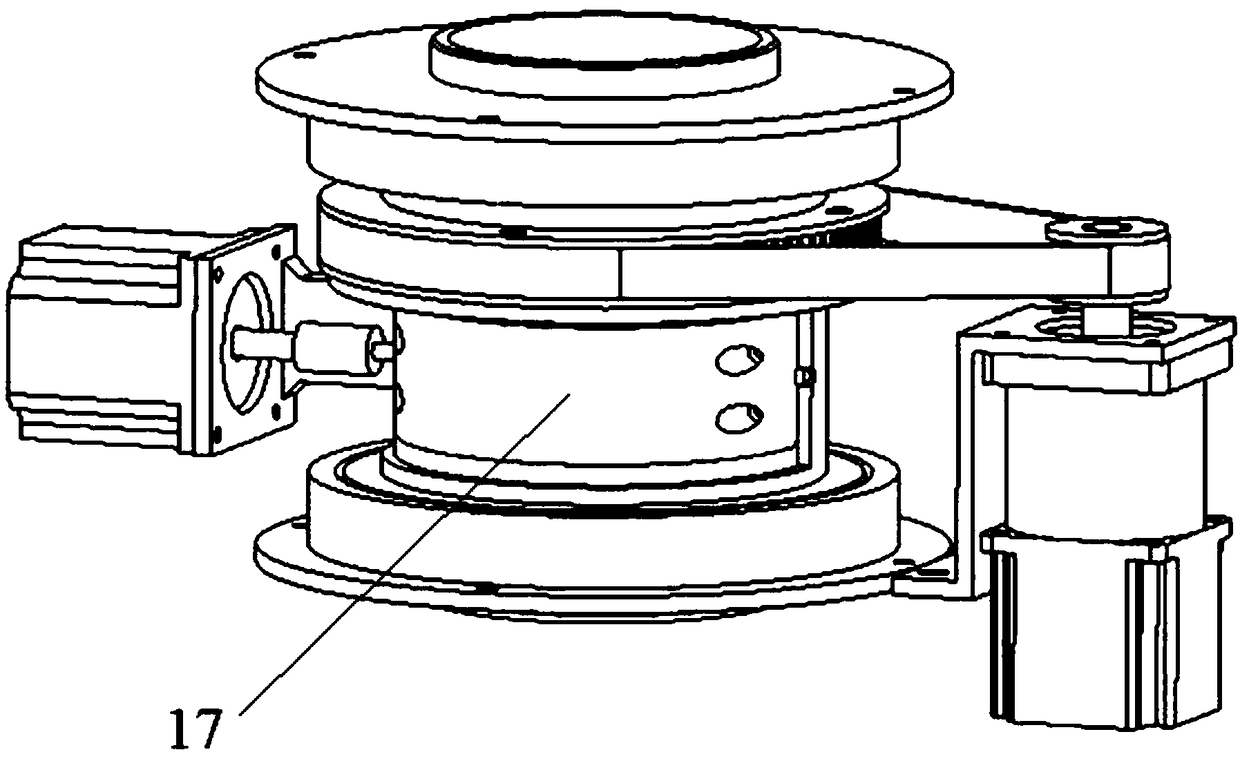

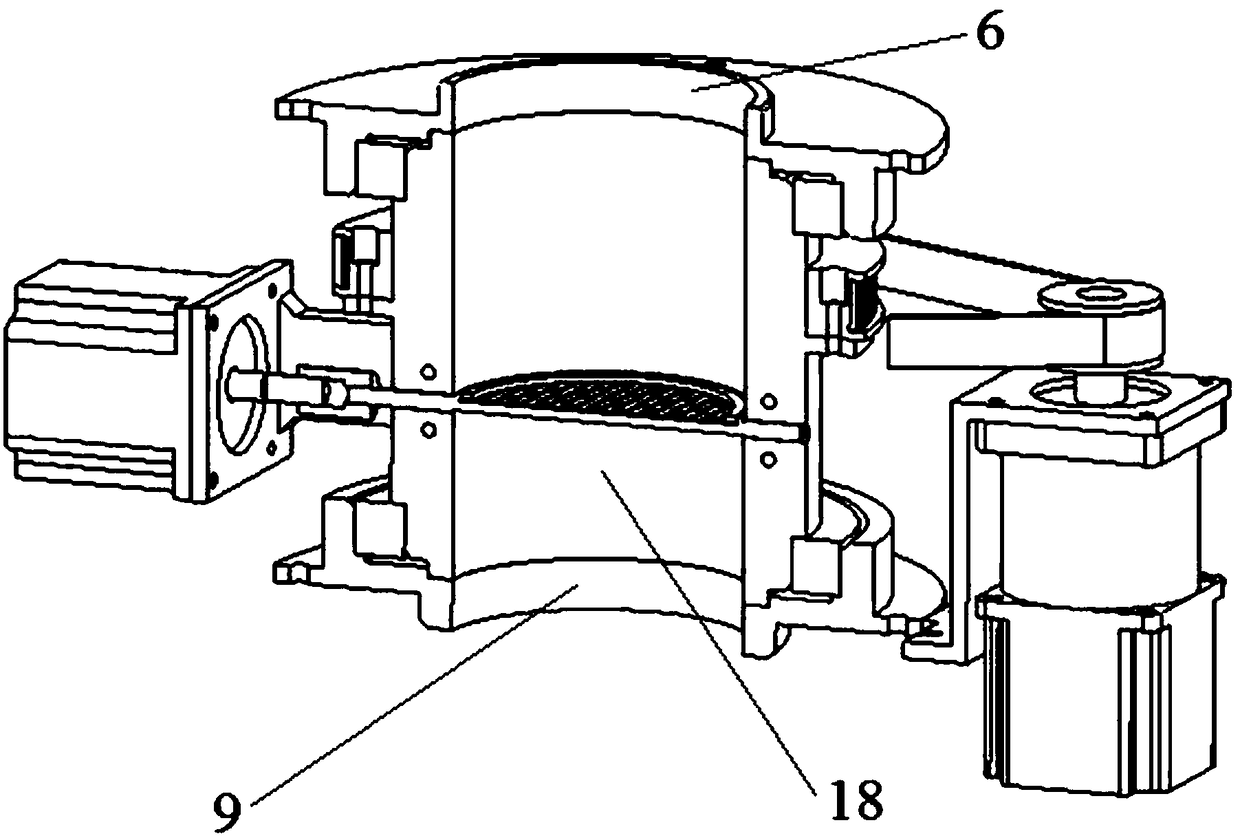

[0023] refer to Figure 1 to Figure 4 The shown automatic sieving device for sample particles includes a movable chamber 1 , an automatic overturning drive motor 2 , and an automatic sieving drive motor 3 .

[0024] The movable cavity 1 is a cylindrical structure, the upper end and the lower end of the movable cavity 1 are respectively movably connected with a sample inlet bearing 4 and a sample outlet bearing 7 , and a synchronous driven gear 11 is fixed on the periphery of the movable cavity 1 .

[0025] A sample inlet flange 5 is fixed on the top of the sample inlet bearing 4, and a cylindrical sample inlet 6 is arranged at the center of the sample inlet flange 5. The inlet flange 5 can be easily connected with other equipment, and the cylindrical structure of the inlet 6 is convenient for installing an injection funnel or connecting with other equipment. The sample ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com