Automated production line used for mechanical part screening

A technology for automated production lines and mechanical parts, applied in the field of mechanical parts processing, can solve problems such as the inability to replace screening holes, and achieve a wide range of applications and the effect of meeting screening needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

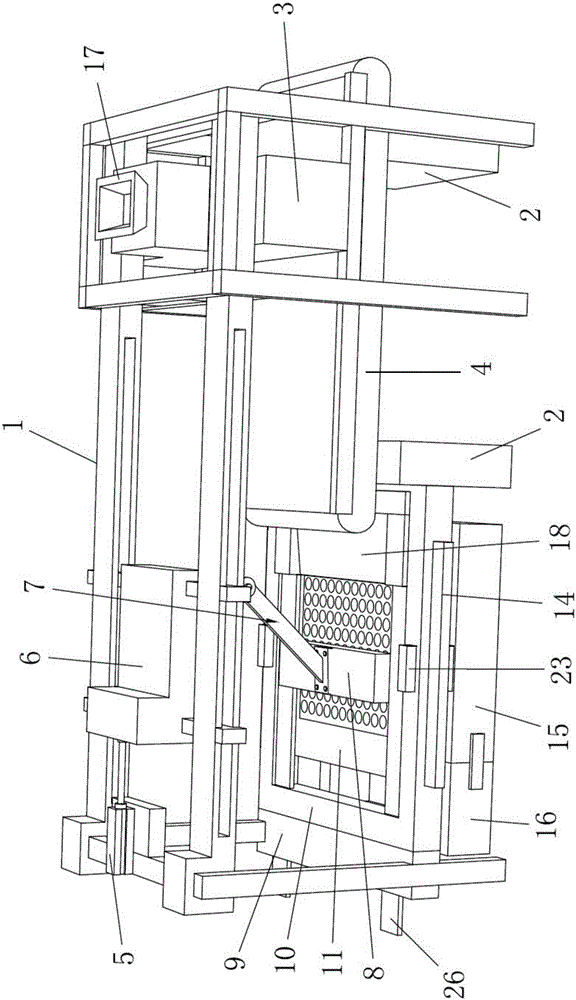

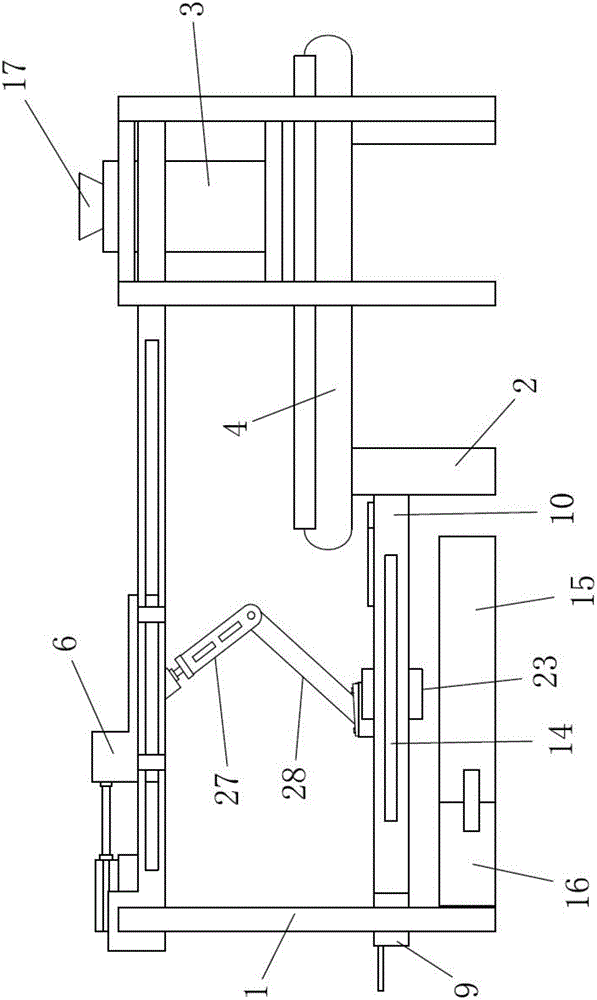

[0027] Such as Figure 1 to Figure 6 As shown, a kind of automatic production line that is used for mechanical part screening of the present invention comprises support frame 1 and support platform 2, and support frame 1 is provided with feeding device 3, and the top of feeding device 3 is provided with collecting port 17, collects The cross-sectional area of the port 17 decreases gradually from top to bottom, which increases the amount of mechanical parts entering the feeding device 3 and improves the screening efficiency. A conveyor belt 4 is arranged on the support platform 2 , and the conveyor belt 4 is arranged below the feeding device 3 . The support frame 1 is provided with a hydraulic driver 5 and a mobile base 6 , and the hydraulic driver 5 drives the mobile base 6 . The bottom of the mobile base 6 is provided with an adjustment mechanism 7 , and the end of the adjustment mechanism 7 is provided with a discharge block 8 . The adjustment mechanism 7 includes a firs...

Embodiment 2

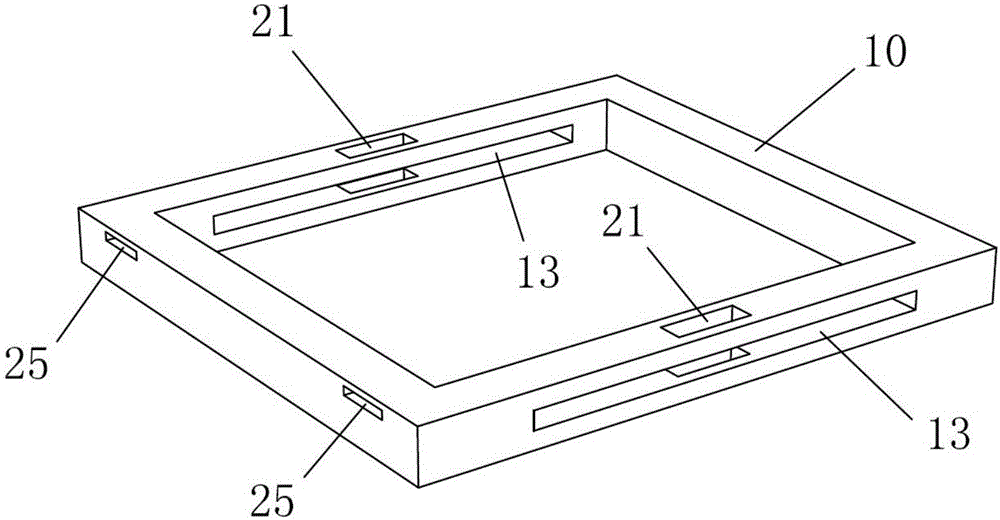

[0034] Such as Figure 7 As shown, the second embodiment of the present invention selects screening plates 11 of different specifications on the basis of the first embodiment. The screening plate 11 of this specification is provided with the second screening hole 29, and the second screening hole 29 is located between the first screening hole 12, and the aperture of the second screening hole 29 is smaller than the aperture of the first screening hole 12, increases a kind of screening hole , thus increasing the screening time of mechanical parts on the screening plate 11 and improving the screening accuracy.

[0035] According to the size of the mechanical parts, the present invention can remove the insert plate 14 from the through hole 13. At this time, the insert plate 14 does not exert force on the screening plate 11, and the operator can take out the screening plate 11 from the screening frame 10. The size of the parts, select the appropriate screening plate 11, the size o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com