Mushroom screening device

A screening device and mushroom technology, applied in sorting and other directions, can solve the problems of mushroom damage, low sorting efficiency, and failure to meet sorting requirements, and achieve the effects of convenient operation, simple structure, and high screening efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

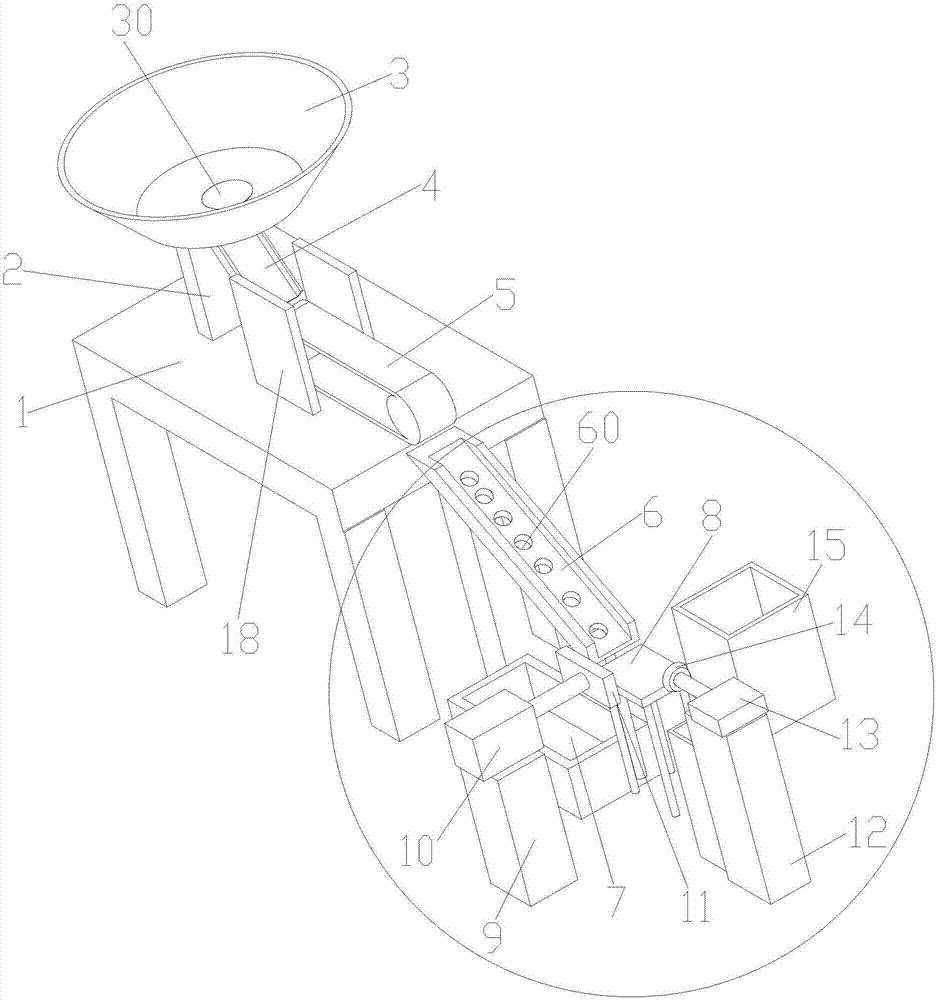

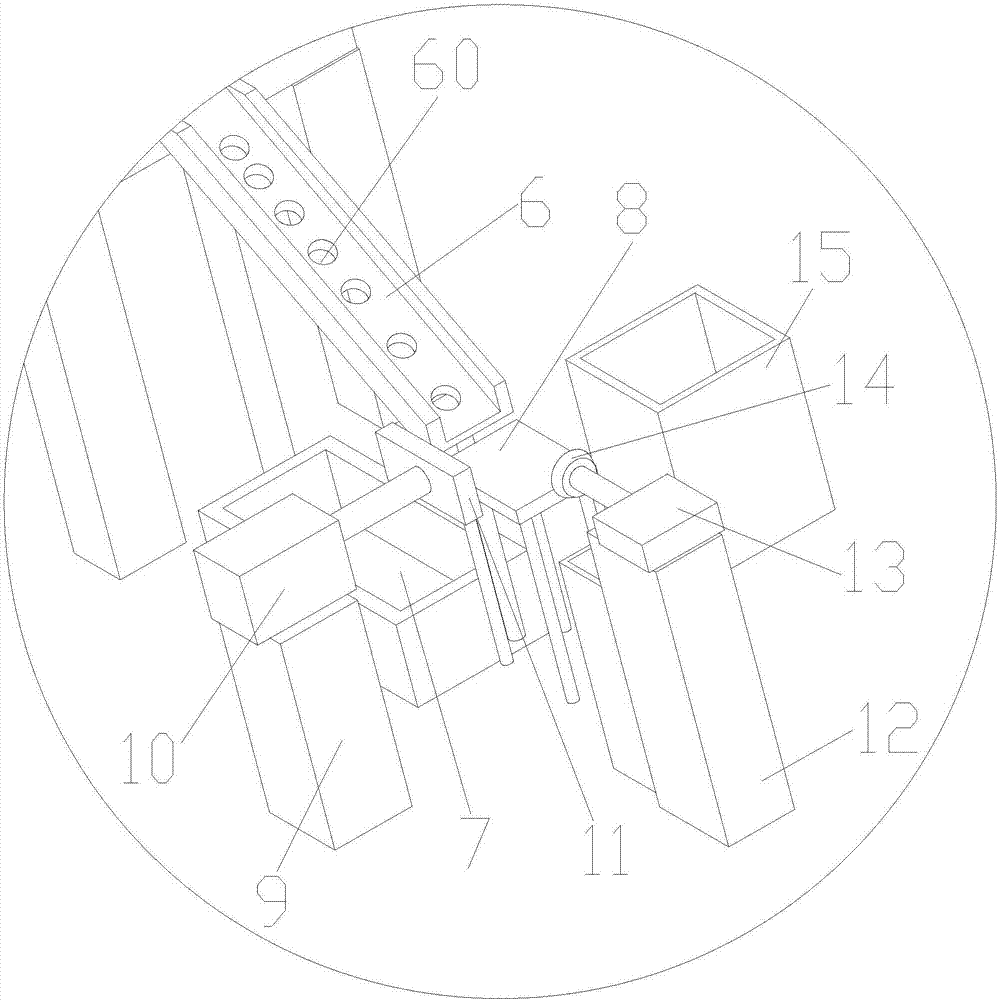

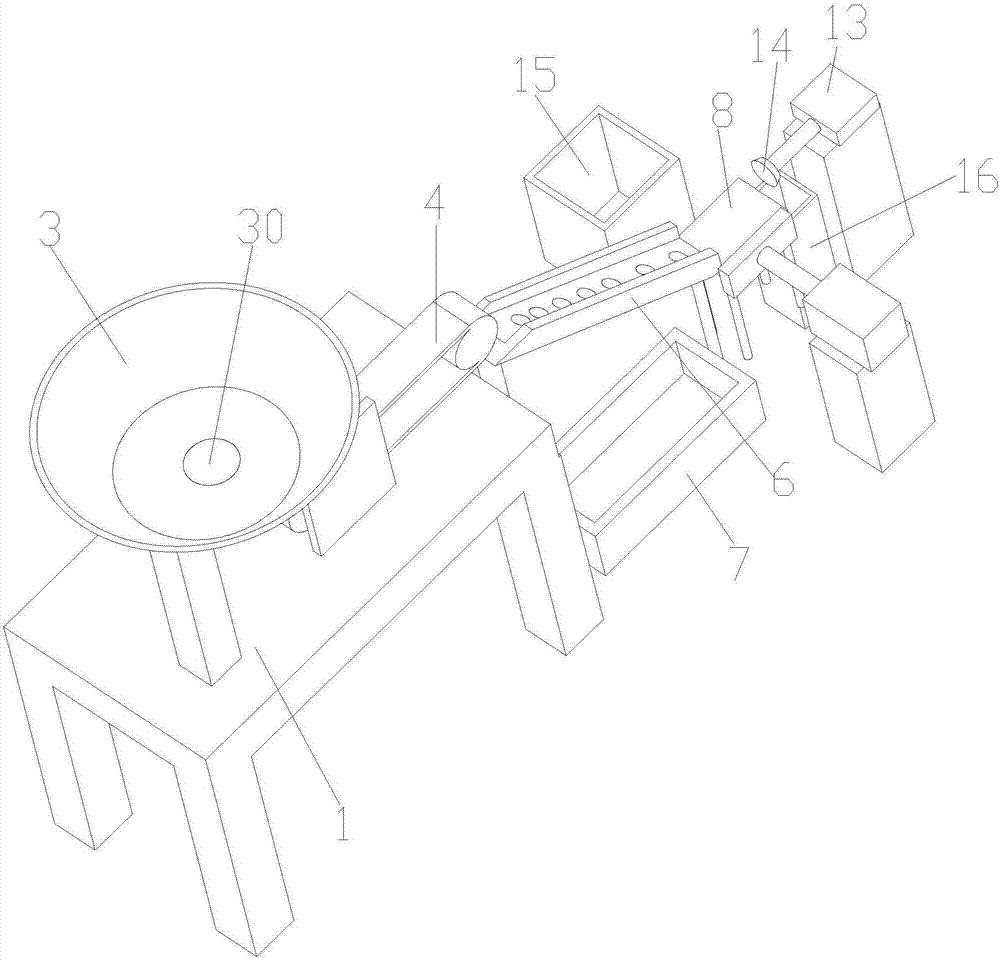

[0013] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0014] as attached Figure 1-3 The shown mushroom screening device of the present invention includes a chassis 1, a support block 2, a discharge tray 3, a first transmission channel 4, a conveyor belt 5, a second transmission channel 6, a first collection frame 7, a support Panel 8, first base 9, pusher cylinder 10, push plate 11, second base 12, suction cylinder 13, electric sucker 14, second collection frame 15, third collection frame 16 and weight sensor 17; The bottom frame 1 is provided with a discharge tray 3 fixed on the support block 2; the center of the discharge tray 3 is provided with a first blanking hole 30; the lower end of the first blanking hole 30 is provided with an inclined setting The first transmission channel 4; the lower end of the first transmission channel 4 is provided with a conveyor belt 5; the lower end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com