Three-machine-driving double-mass-body subresonance self-synchronizing probability constant thickness screen and parameter determining method

A dual-mass, self-synchronizing technology, used in chemical instruments and methods, sieves, solids separation, etc., can solve the problems of large dynamic loads, large-scale equipment, and particularly high requirements on the strength of vibrating screens. Efficiency improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

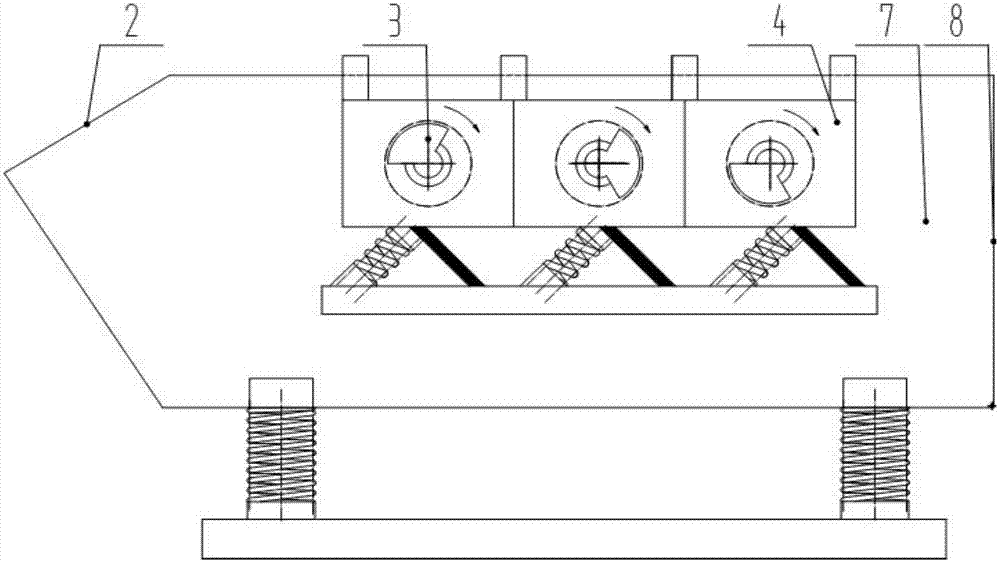

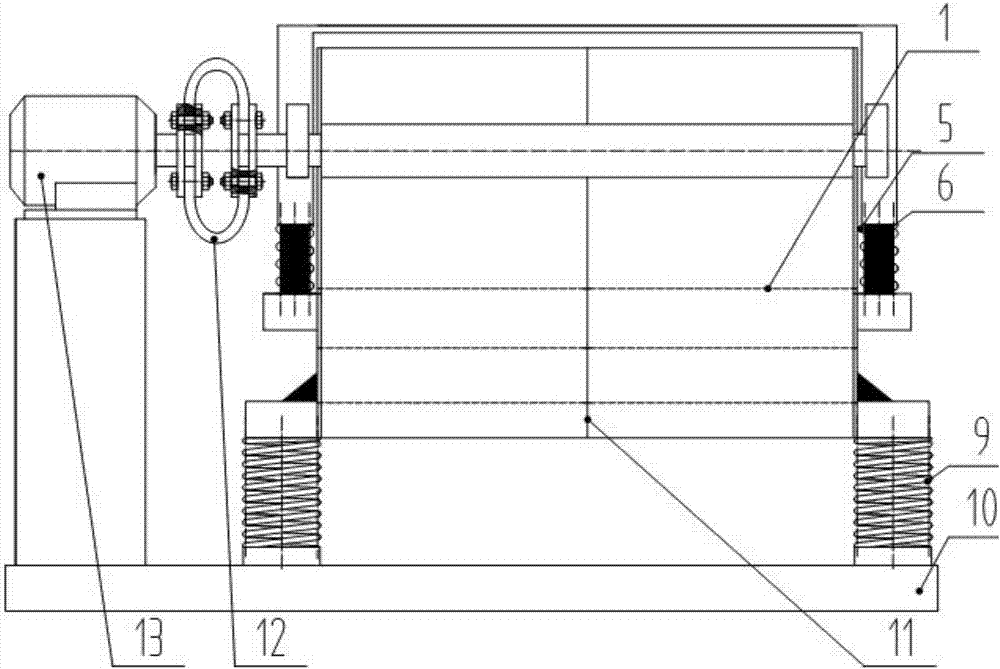

[0157] Such as Figure 4 A dynamic model of a vibrating system in which the main vibrating body consists of two rigid bodies and three eccentric rotors. Rigid body A is connected to base and rigid body B respectively through springs and guide plates, and three eccentric rotors are installed on rigid body B. In addition, the vibrating spring is parallel to the x-axis and perpendicular to the guide plate. The three eccentric rotors revolve around the center of the eccentric rotation axis o 1 , o 2 and o 3 rotate, and the center of rotation o 1 , o 2 , o 3 collinear. An induction motor drives three eccentric rotors to rotate counterclockwise together. In the text, are the rotation angles of the three eccentric rotors, respectively. Due to the limitation of the guide plate, it can be assumed that the whole system has only one degree of freedom along the x direction, denoted by x.

[0158] Some numerical analyzes are given to verify the theoretical results. During the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com