Blade-free rubbing peeling integrated machine for peeling and cleaning thin shell green peel walnuts

A green walnut and integrated machine technology is applied in the field of bladeless thin-shell green walnut peeling and cleaning integrated machine, which can solve the problems of high rate of mechanical damage, cracking, and rotten fruit, insufficient cleaning, and low peeling rate, etc. The effect of reducing cracking and rotten fruit rate, improving processing quality and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

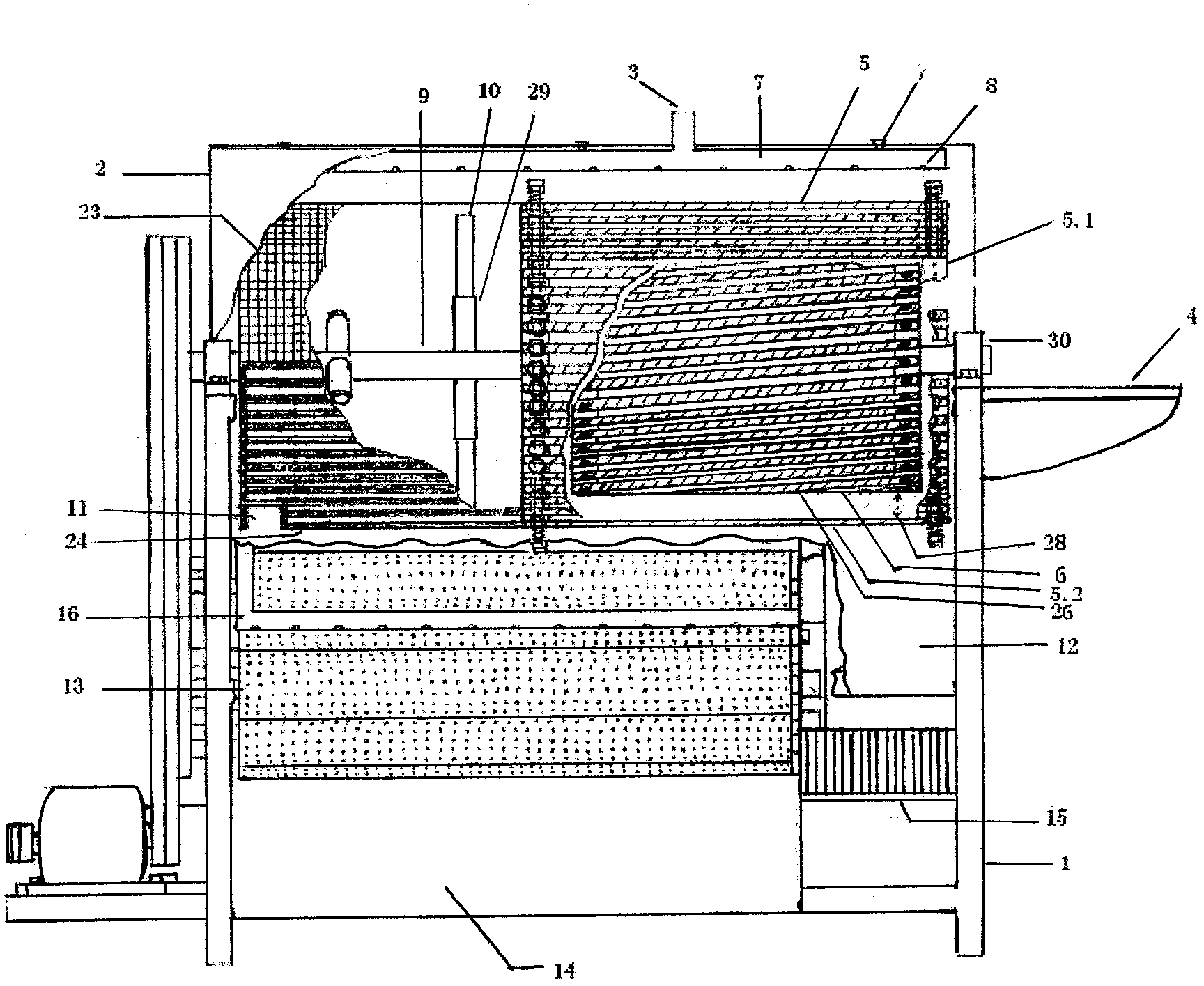

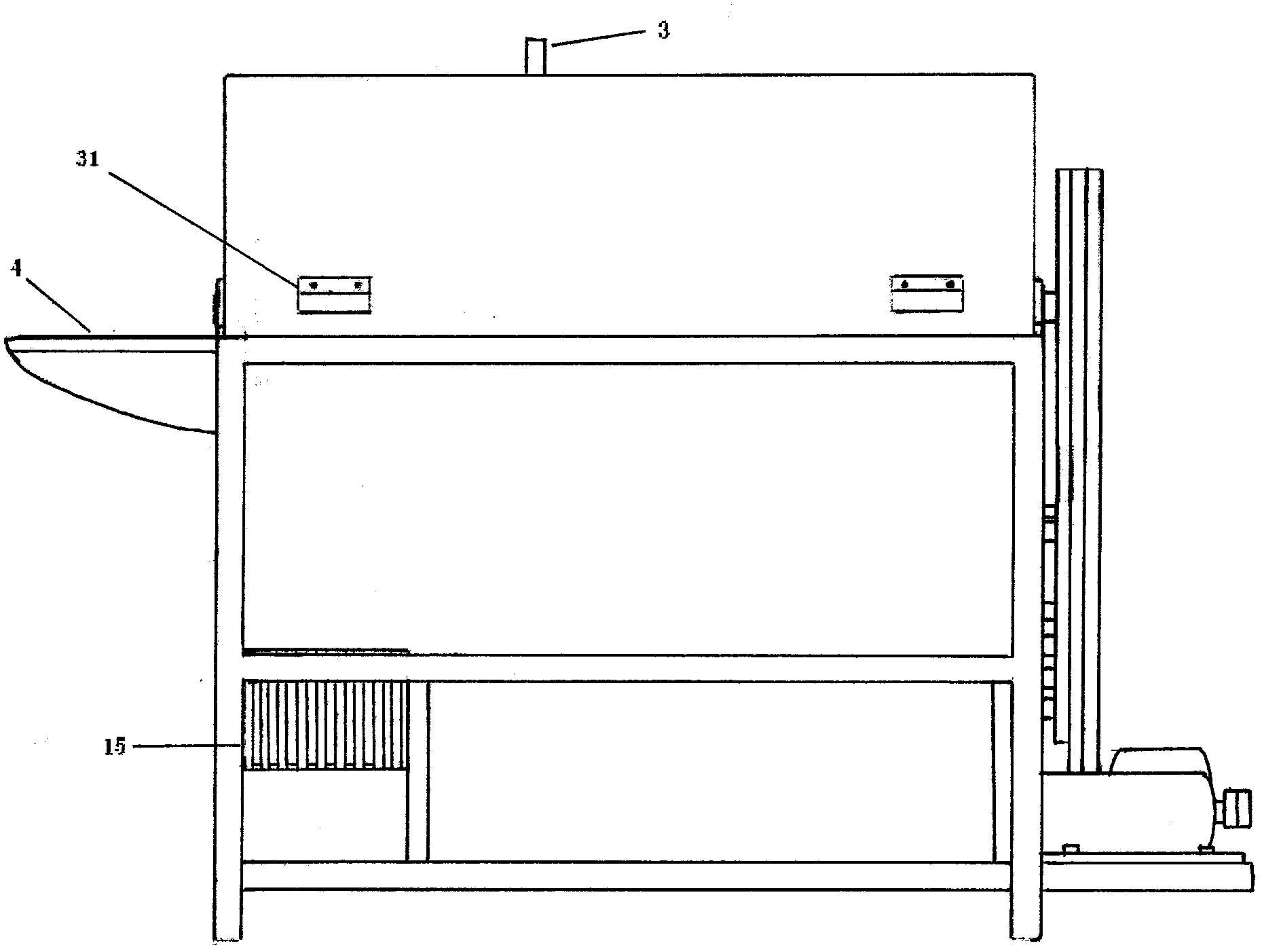

[0024] The all-in-one peeling and cleaning machine for thin-shell green walnuts without blade rubbing and peeling includes a frame 1, a cover 2, a peeling mechanism installed on the frame and located in the cover, a cleaning mechanism, and a transmission connected to the peeling mechanism and the cleaning mechanism Mechanism, the top of the hood is provided with a water inlet 3, the hood is a detachable structure, the green walnut inlet 4 is fixed on one side of the frame, and the back and side of the frame are provided with a slag water shield 27;

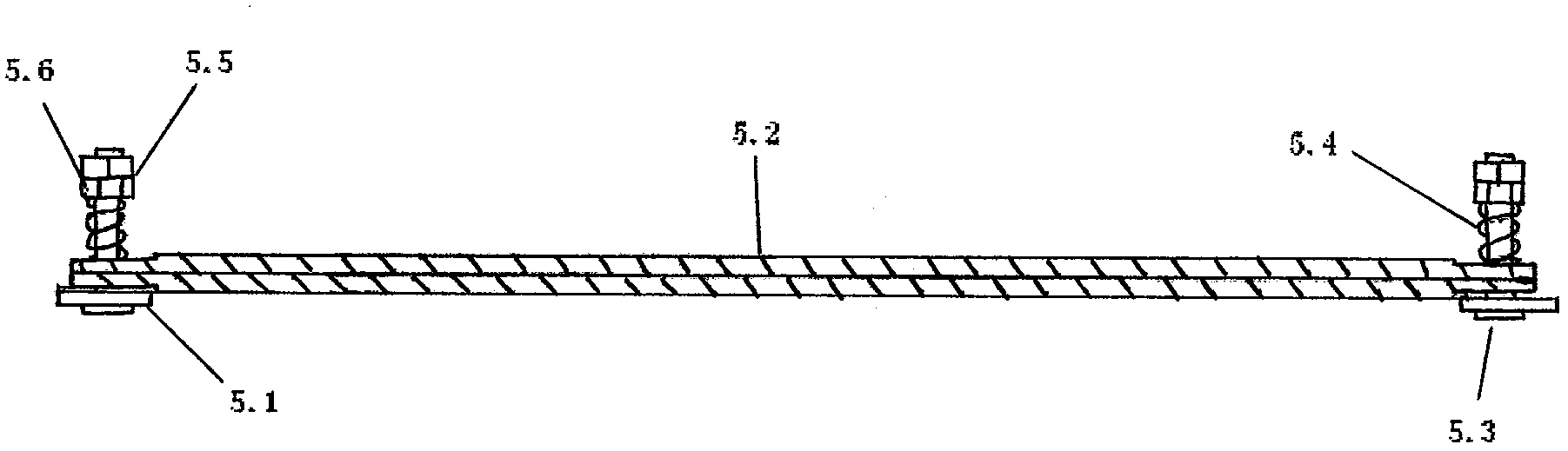

[0025] Such as figure 1 , 2 As shown, the peeling mechanism includes being fixed on the frame and near the elastic peeling stator 5 of the green walnut inlet side, the screening stator fixed on the other side of the frame and the peeling rotor 6 arranged on the inner circumference of the elastic peeling stator, and the screening stator It is composed of an upper curved steel wire screen 23 at 180 degrees and with several 1.5 cm s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com