Through-flow air screen cleaning and screening device for screening corns

A cleaning device and corn technology, which is applied in the direction of separating solids from solids with airflow, sieving, solid separation, etc., can solve the problems of insufficient screening, waste, and discharge of entrained corn kernels, etc., to achieve thorough screening and avoid The effect of waste and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

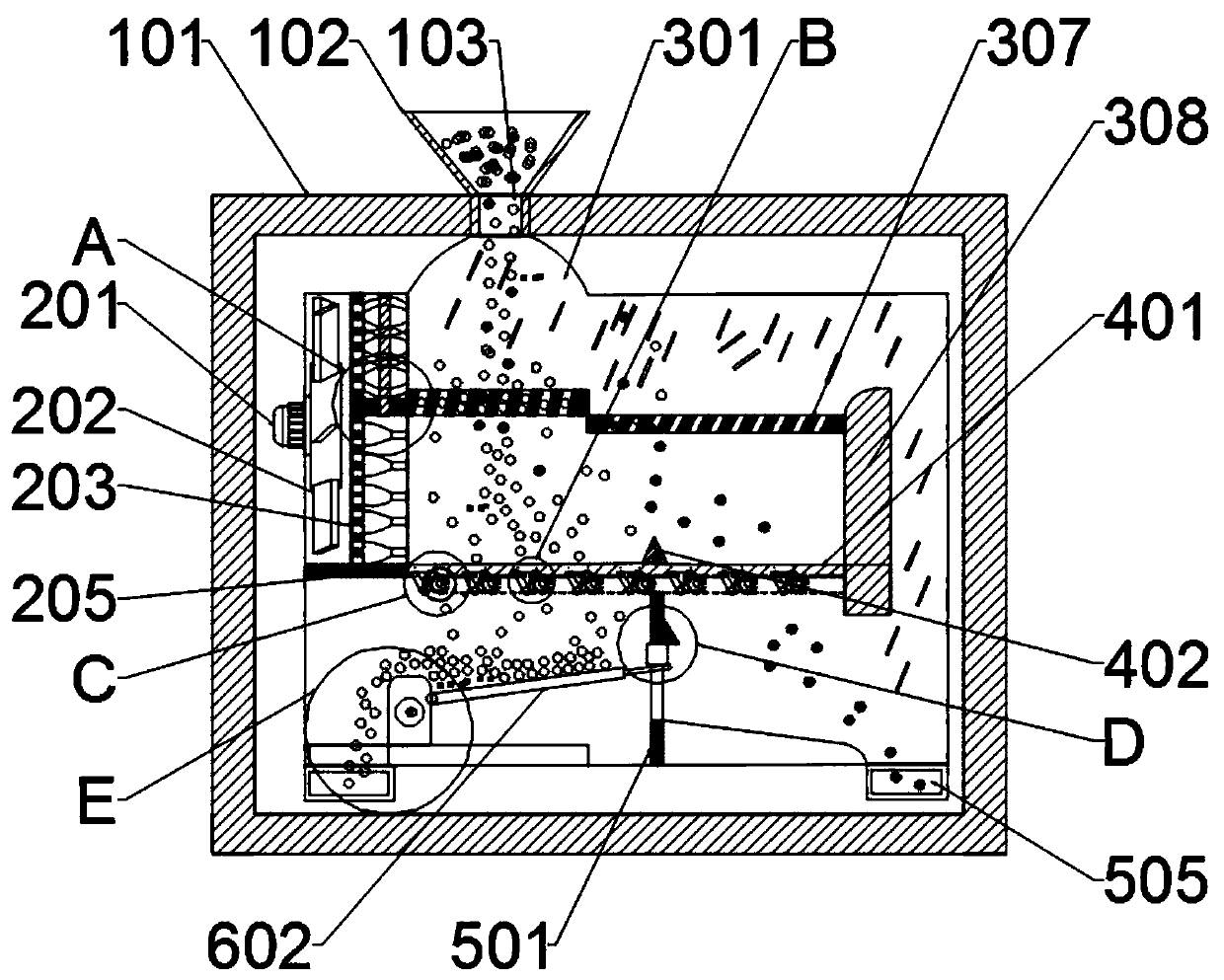

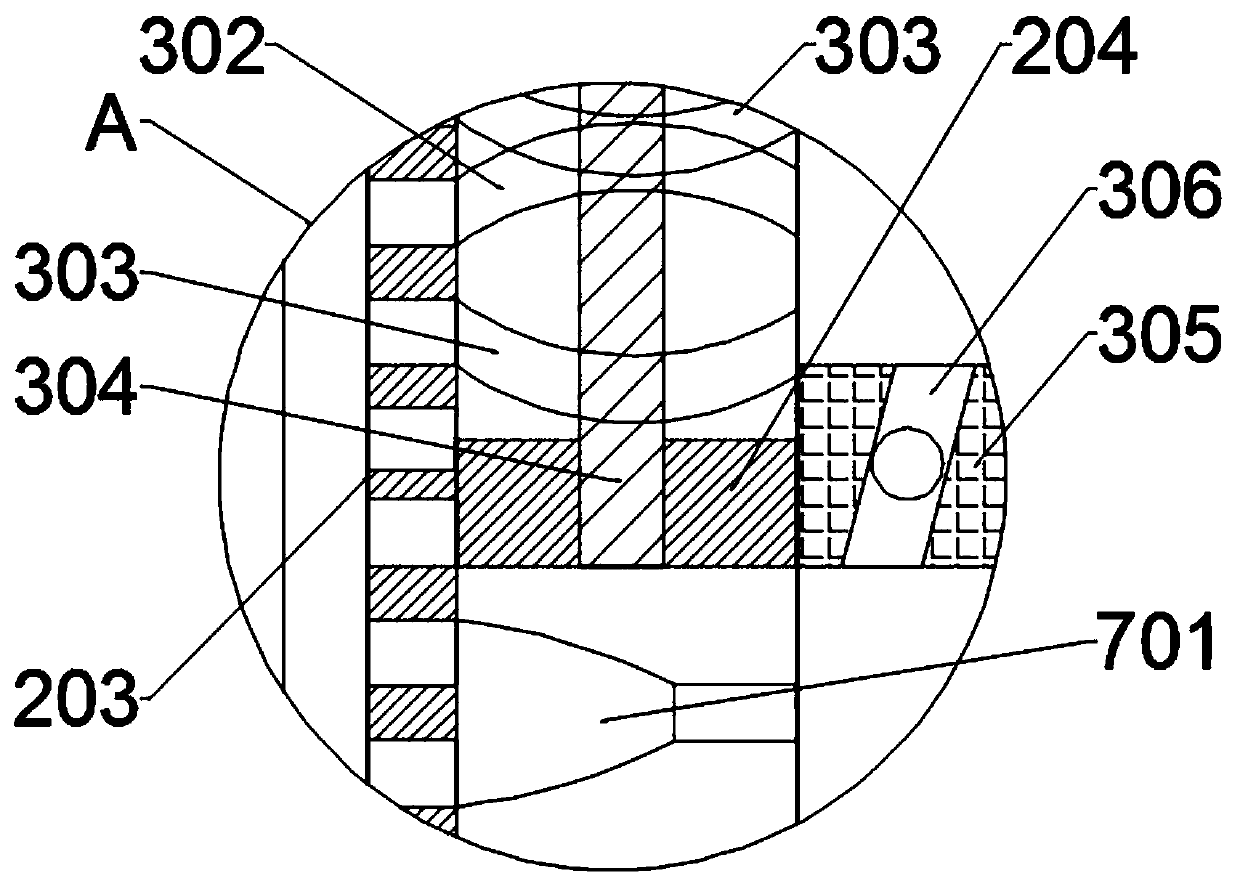

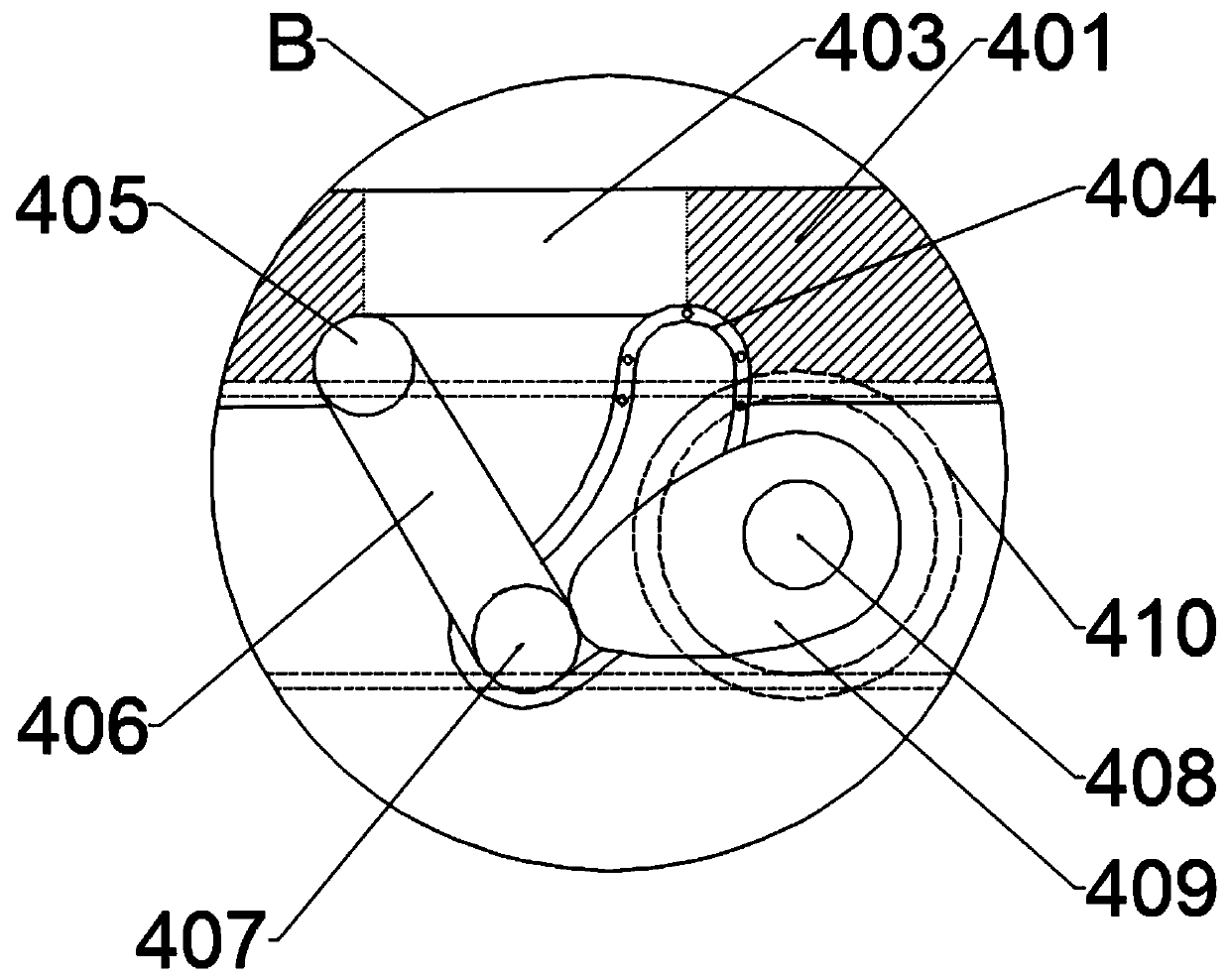

[0019] Example: such as Figure 1-6 As shown, a cross-flow air sieve cleaning device for screening corn includes a feed assembly, a power assembly, a lightweight screening assembly, a refined corn screening assembly, a waste discharge assembly, and a corn discharge assembly. The feed assembly is located in the device The outermost side of the feed assembly plays the role of feeding. The power assembly is installed on one side of the feed assembly. The power assembly plays the role of providing wind kinetic energy for the interior of the device. The exclusion and screening component plays the role of discharging the light forage mixed in the corn. There is a fine corn screening component under the light exclusion and screening component. The fine corn screening component plays the role of eliminating hollow bad corn. There is a waste material discharge assembly, which plays the role of discharging waste materials. One end of the waste material discharge assembly is provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com