Circular building sand screening device

A circular and architectural technology, applied in the direction of screening, solid separation, grille, etc., can solve the problems of poor sand screening effect and insufficient sand screening process, so as to achieve full and thorough screening, improve screening effect, and improve The effect of sieving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

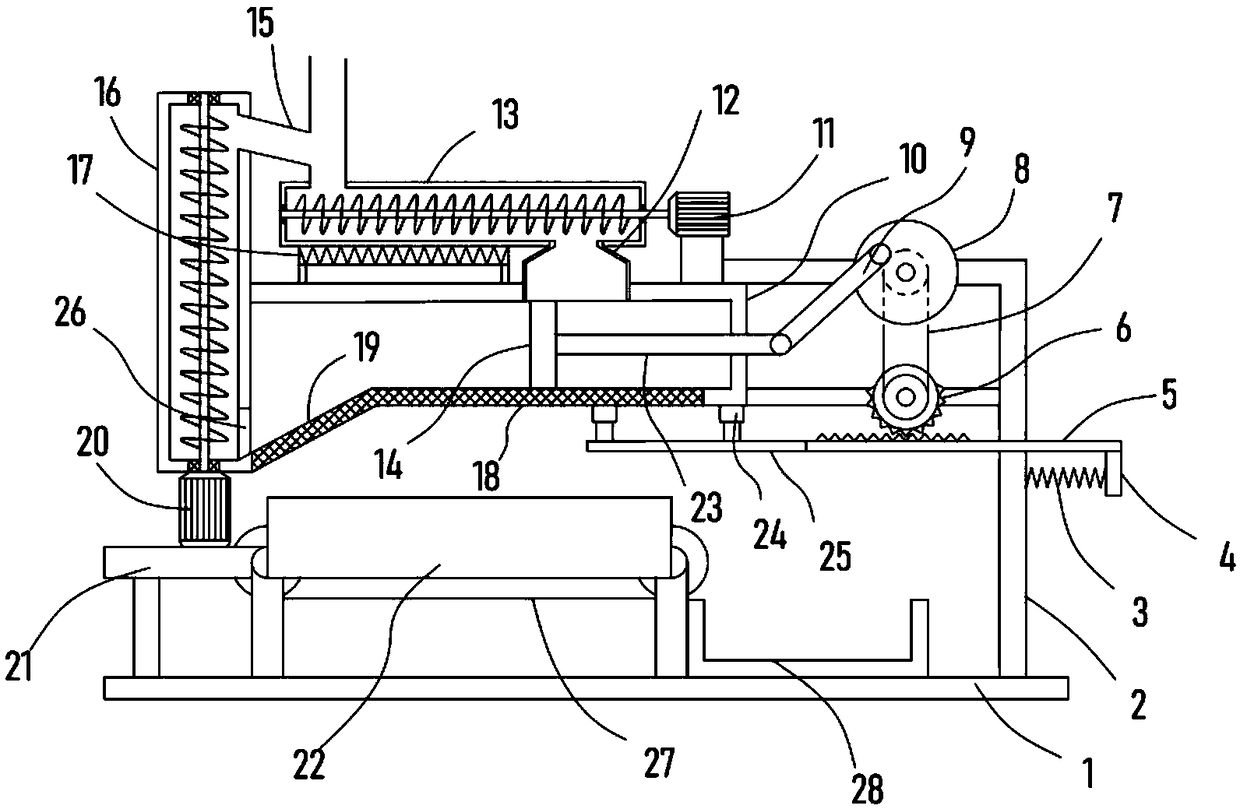

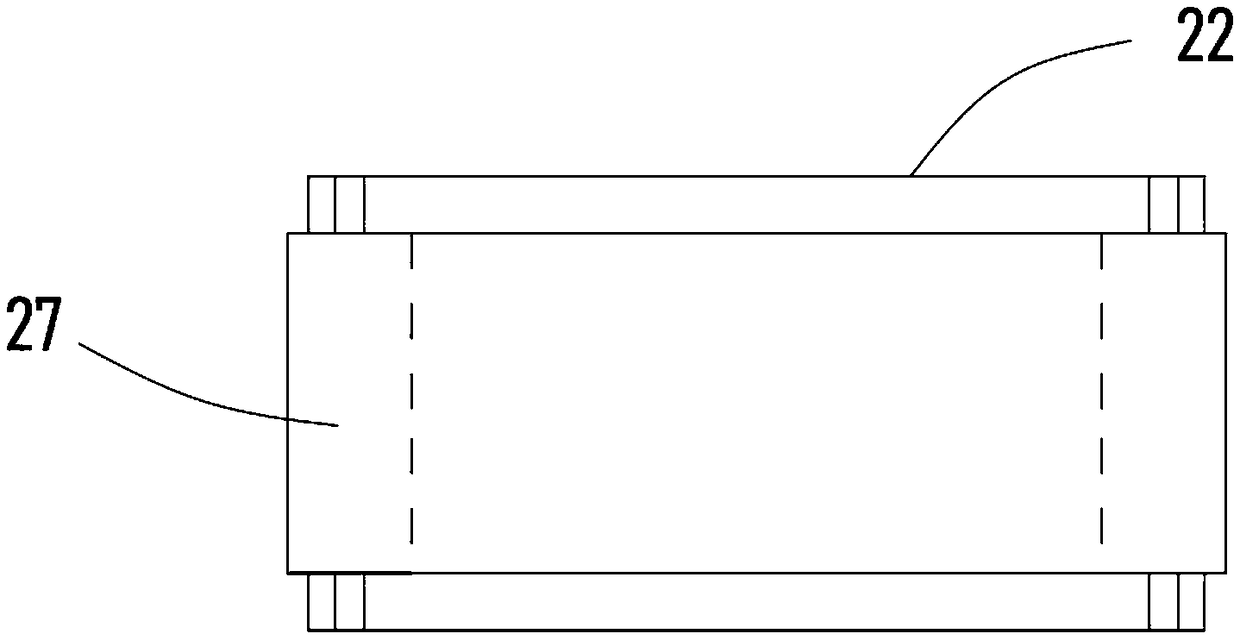

[0021] see Figure 1-3 , a circulating building sand screening device, comprising a support base plate 1, a support frame 2 and a support platform 21 are fixedly installed on the support base plate 1, and a horizontal auger 13 driven by a motor I11 is fixedly installed on the support frame 2 horizontally. The dragon 13 is driven by the motor I11, and the sand in the horizontal auger 13 carries out horizontal rotation and conveying.

[0022] Below the horizontal auger 13, there is a dispersion cylinder 10 connected with it through the discharge pipe 12. The discharge pipe 12 is installed on the lower right bottom of the horizontal auger 13, and the bottom of the dispersion cylinder 10 is embedded with a horizontal screen 18. The dispersion cylinder The lower left part of 10 is embedded and fixed with an inclined screen 19 arranged obliquely. When the sand is transported to the discharge pipe 12 in the horizontal auger 13, it falls to the inside of the dispersion cylinder 10. Th...

Embodiment 2

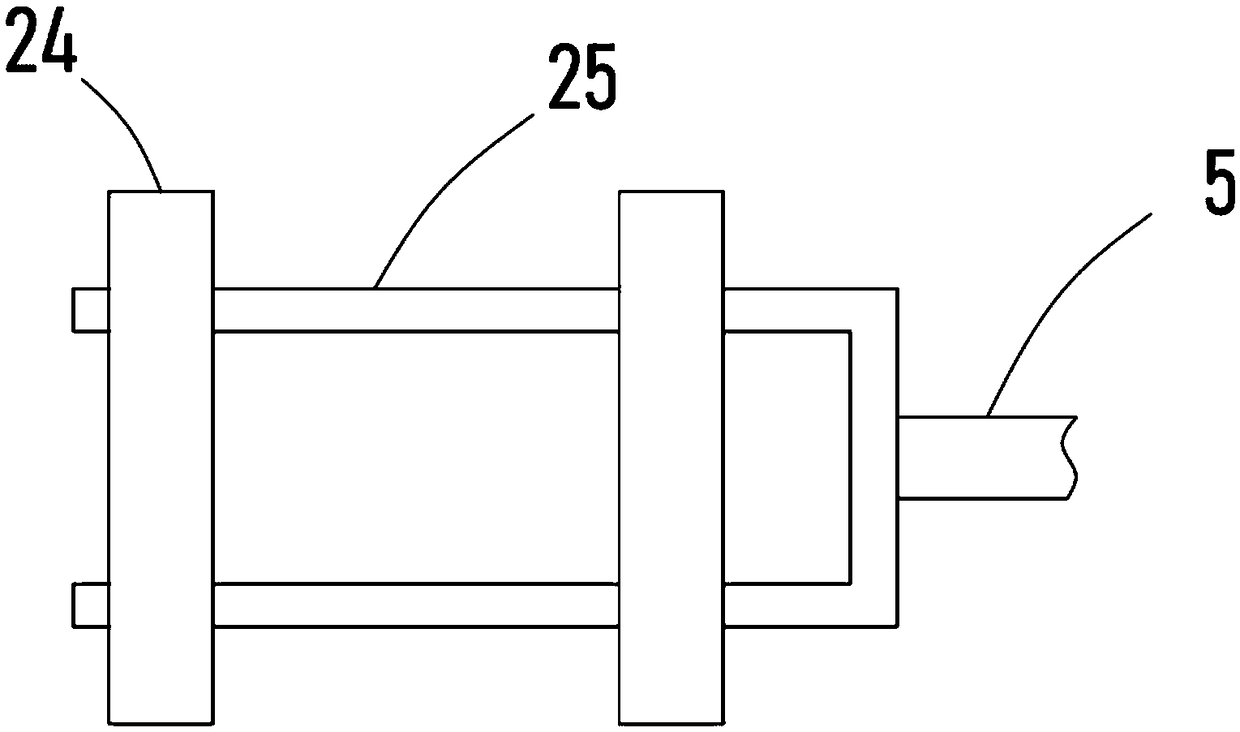

[0029] On the basis of Embodiment 1, in addition, the support frame 2 is provided with an incomplete gear 6 that is driven and connected to the runner 8 through the pulley mechanism 7, and a spur rack that is meshed and connected with the incomplete gear 6 is installed horizontally below the incomplete gear 6. 5. A transmission frame 25 is fixed on the left end of the spur rack 5, and a scraper 24 abutting against the bottom surface of the horizontal screen 18 is fixed on the transmission frame 25.

[0030] Further, a fixed plate 4 is vertically fixed on the right end of the spur rack 5 , and a return spring 3 is fixed horizontally between the fixed plate 4 and the support frame 2 .

[0031] The rotation of the runner 8 drives the incomplete gear 6 to rotate through the pulley mechanism 7, and the incomplete gear 6 drives the spur rack 5 meshed with it to reciprocate and slide left and right under the elastic restoring force of the return spring 3, thereby realizing that the tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com