Grain screening and drying device

A drying device and grain technology, applied in the directions of drying, drying machine, drying gas arrangement, etc., can solve the problems of poor sealing, polluting the working environment, general screening and drying degree, etc., to prevent clogging and sealing Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

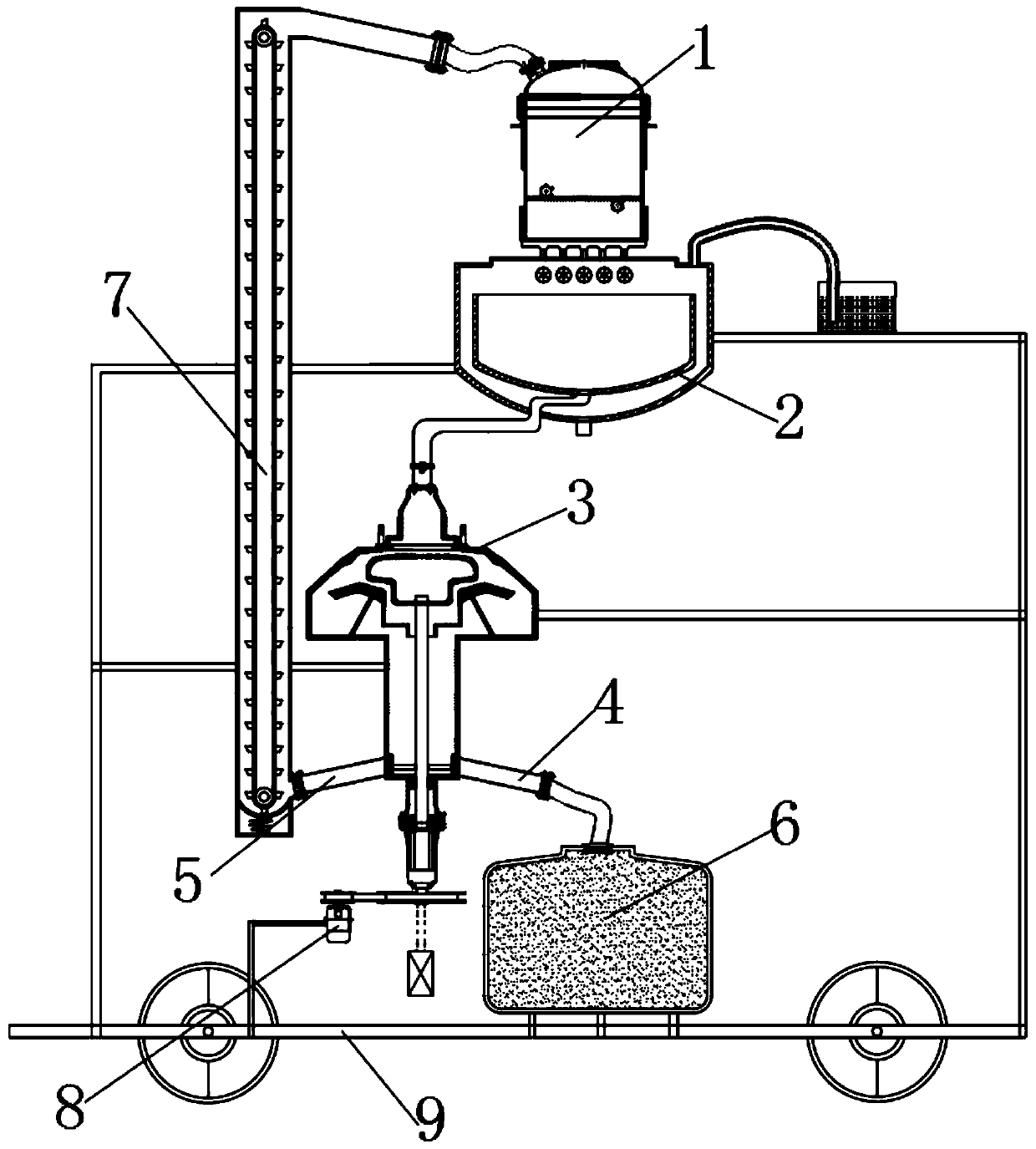

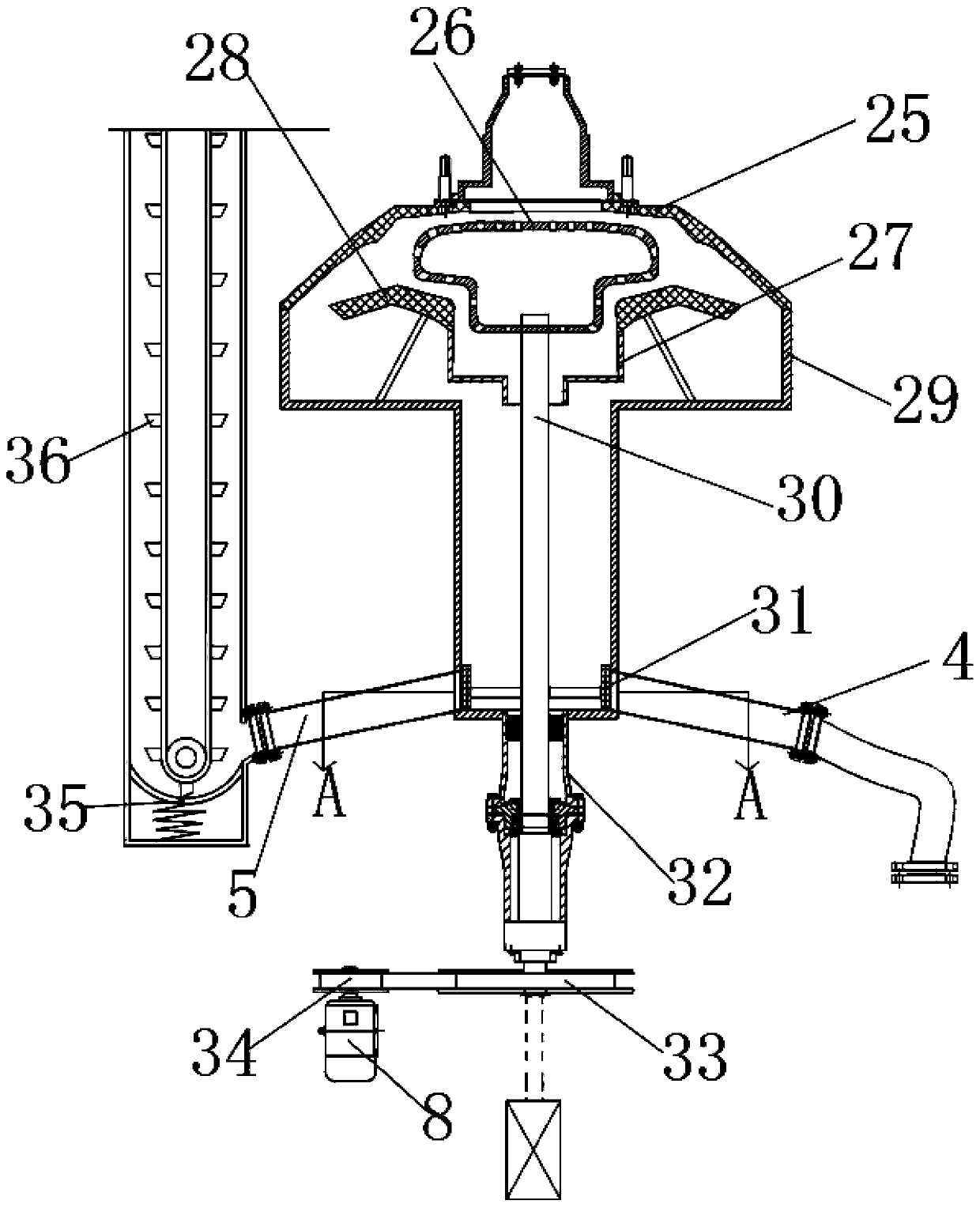

[0029] Example: see Figure 1-8, the present invention provides a technical solution: a grain screening and drying device, which includes a drying assembly, a screening assembly and a lifting device, the screening assembly is used to screen the grains and place them separately and temporarily store them, the drying The assembly is used to dry the screened grain, and the dried grain enters the storage bin 6 or is lifted by the lifting device to the screening assembly for secondary processing. The drying assembly, screening assembly and Lifting devices are all arranged on the support 9.

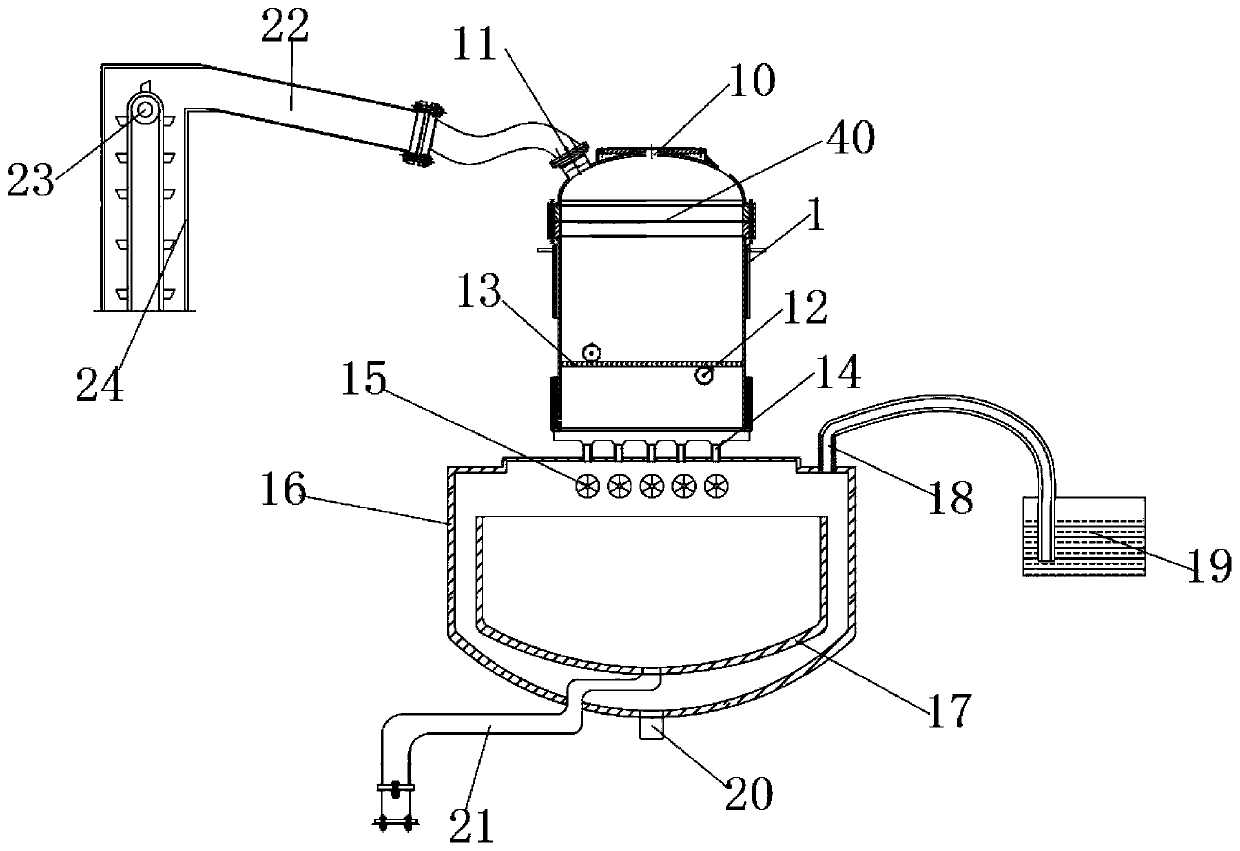

[0030] Wherein, the screening assembly includes a feeding bin 1 and a screening bin 2, the top of the feeding bin 1 is provided with a feeding port 10, through the feeding port 10, grains such as rice are dropped into the feeding bin 1, and the feeding bin 1 The bottom of the screen is connected with the screening bin 2, and the screening bin 2 includes a screening auxiliary bin 16 and a scree...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com