Cleaning method and device for evaporator of cooling-only air conditioner

A cleaning device and evaporator technology, applied in the field of air conditioners, can solve the problems of related accessories loss, labor and cost, and the evaporator is easy to accumulate dust, and achieves the effect of reducing energy consumption and reducing the loss of accessories

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

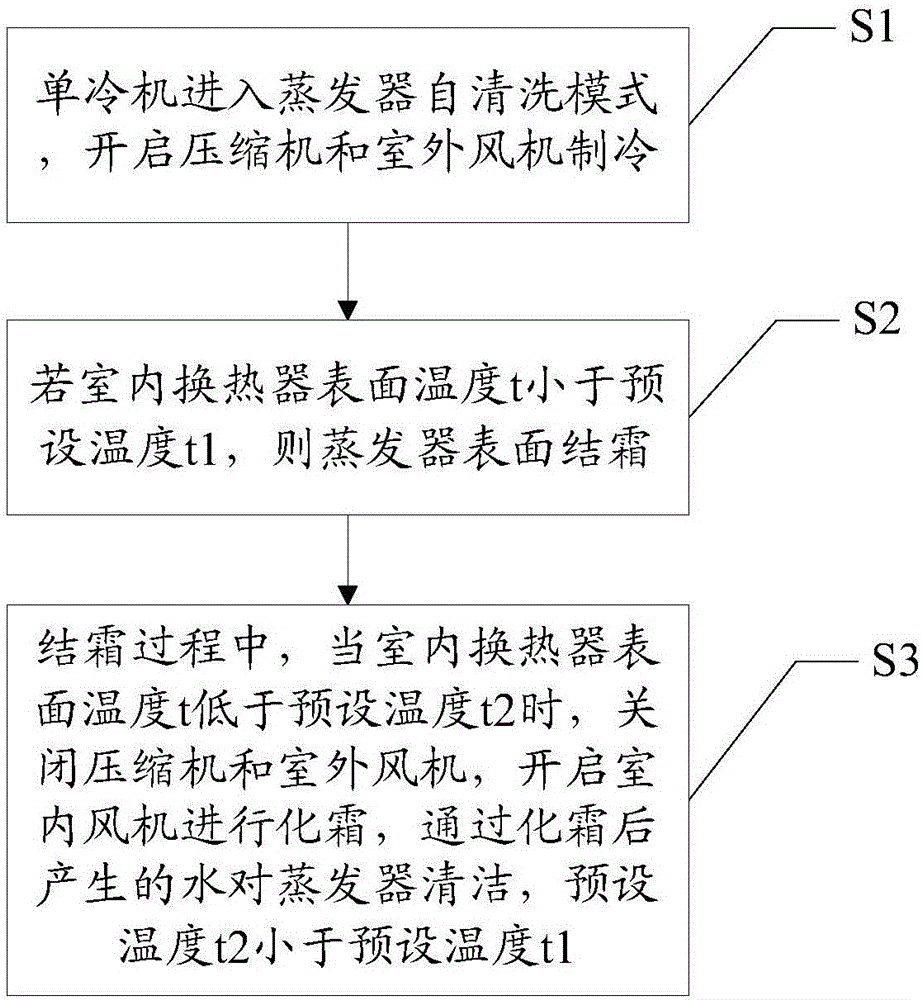

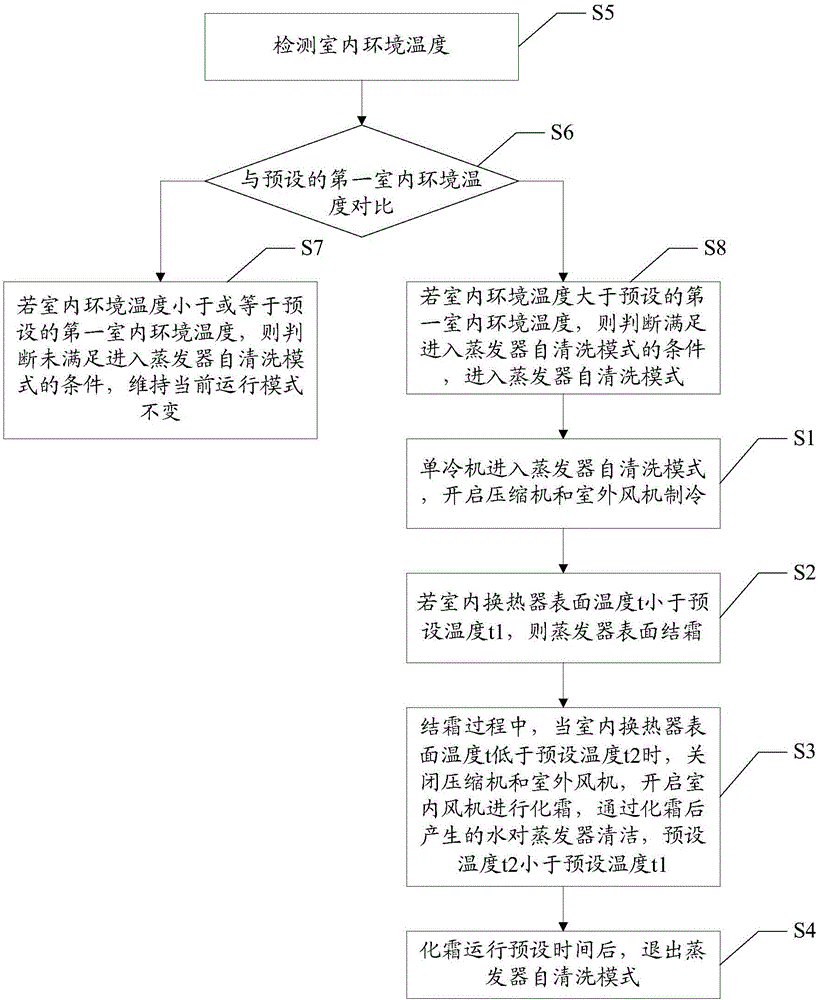

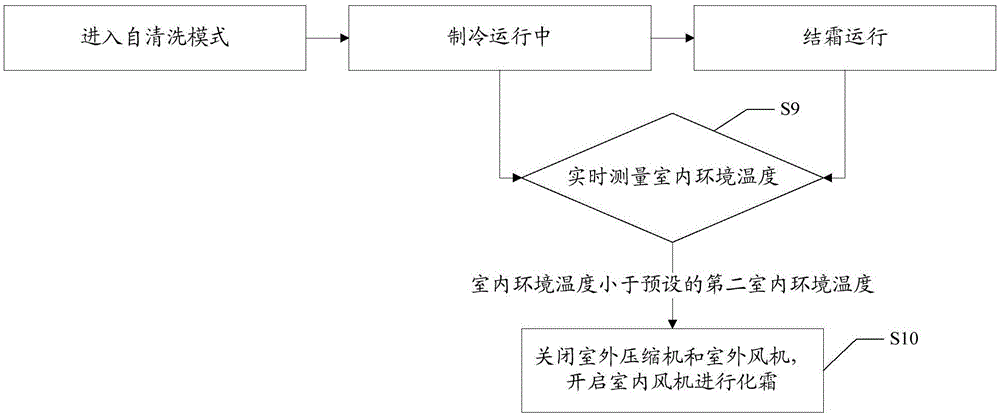

[0040] The main solution of the embodiment of the present invention is: the single cooler enters the self-cleaning mode of the evaporator, and the compressor and the outdoor fan are turned on for cooling; if the surface temperature t of the indoor heat exchanger is lower than the preset temperature t1, frost will form on the surface of the evaporator; In frost mode, when the surface temperature t of the indoor heat exchanger is lower than the preset temperature t2, the compressor and the outdoor fan are turned off, and the indoor fan is turned on to defrost. The water generated after defrosting cleans the evaporator, and the preset temperature is t2. less than the preset temperature t1. . The invention also discloses an evaporator cleaning device of a single cooler. The invention realizes the automatic cleaning of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com