Water-based UV (ultraviolet) woodware adhesion colorant mother solution and preparation method thereof

A technology of colorant and water-based defoamer, applied in the field of water-based UV wood adhesion colorant mother liquor and its preparation field, can solve the problems of high odor, unsatisfactory effect of coloring coating adhesion, unclear wood coloring effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

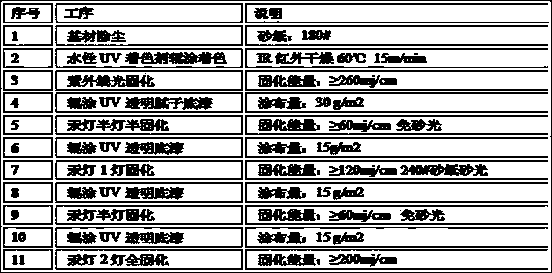

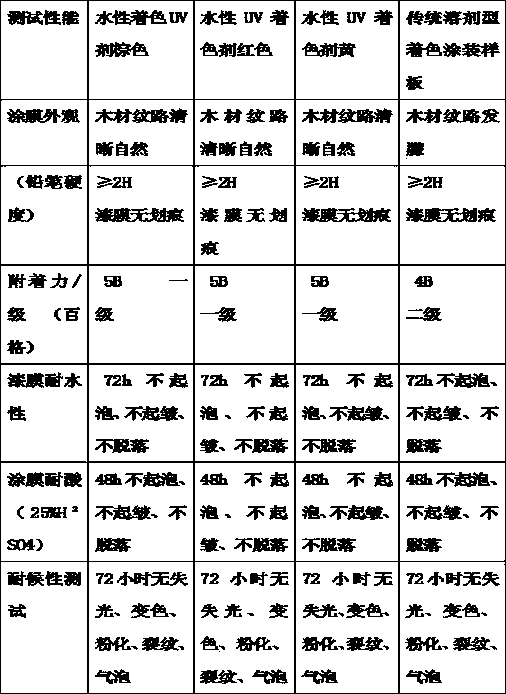

[0019] The present invention will be described in detail below in conjunction with three specific wood plain board coloring embodiments.

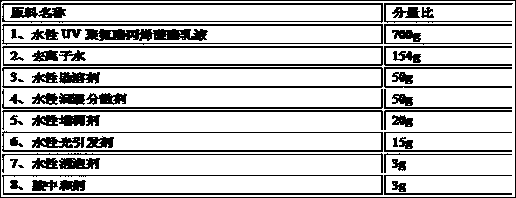

[0020] A water-based UV wood adhesion colorant mother liquor, the product has the following formula composition.

[0021]

[0022] A kind of preparation method of water-based UV woodware adhesion colorant mother liquor:

[0023] (1) First add 50g of co-solvent propylene glycol methyl ether acetate into the cup, then slowly add 15g of 819DW photoinitiator, add 50 of water-based 760W dispersant, add 3g of water-based defoamer Foamex3062, drop into MA-95g and add it, then pre-dilute and stir evenly . Slowly drop 700g of water-based urethane acrylate into the cup and control the stirring speed at 500r / min, dilute and stir 154g of deionized water and 20g of thickener, and then slowly drop into the water-based urethane acrylate emulsion, then add and stir for 30 A new type of water-based UV wood adhesion colorant mother liquor is obtained...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com