Patents

Literature

165results about How to "Evenly screened" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

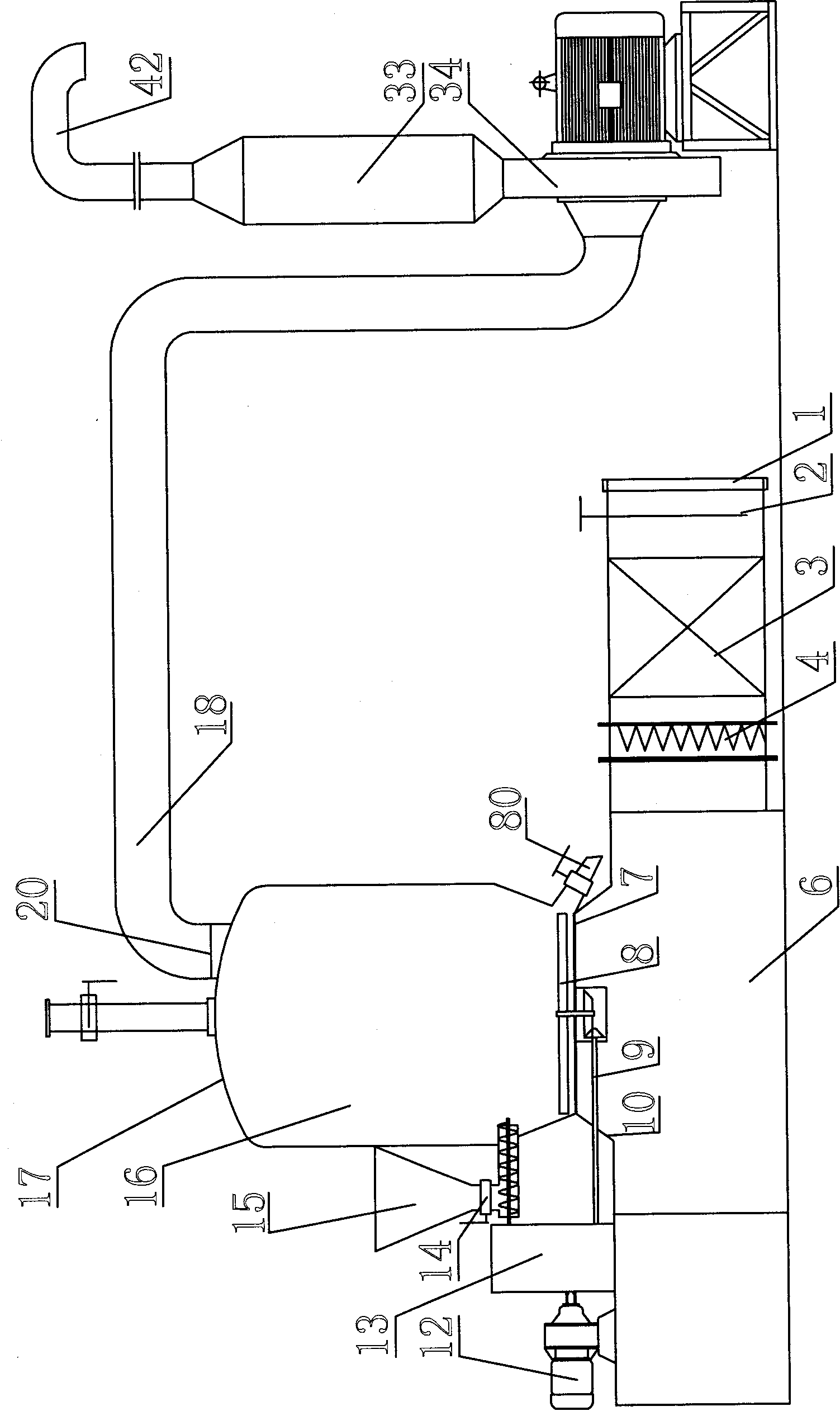

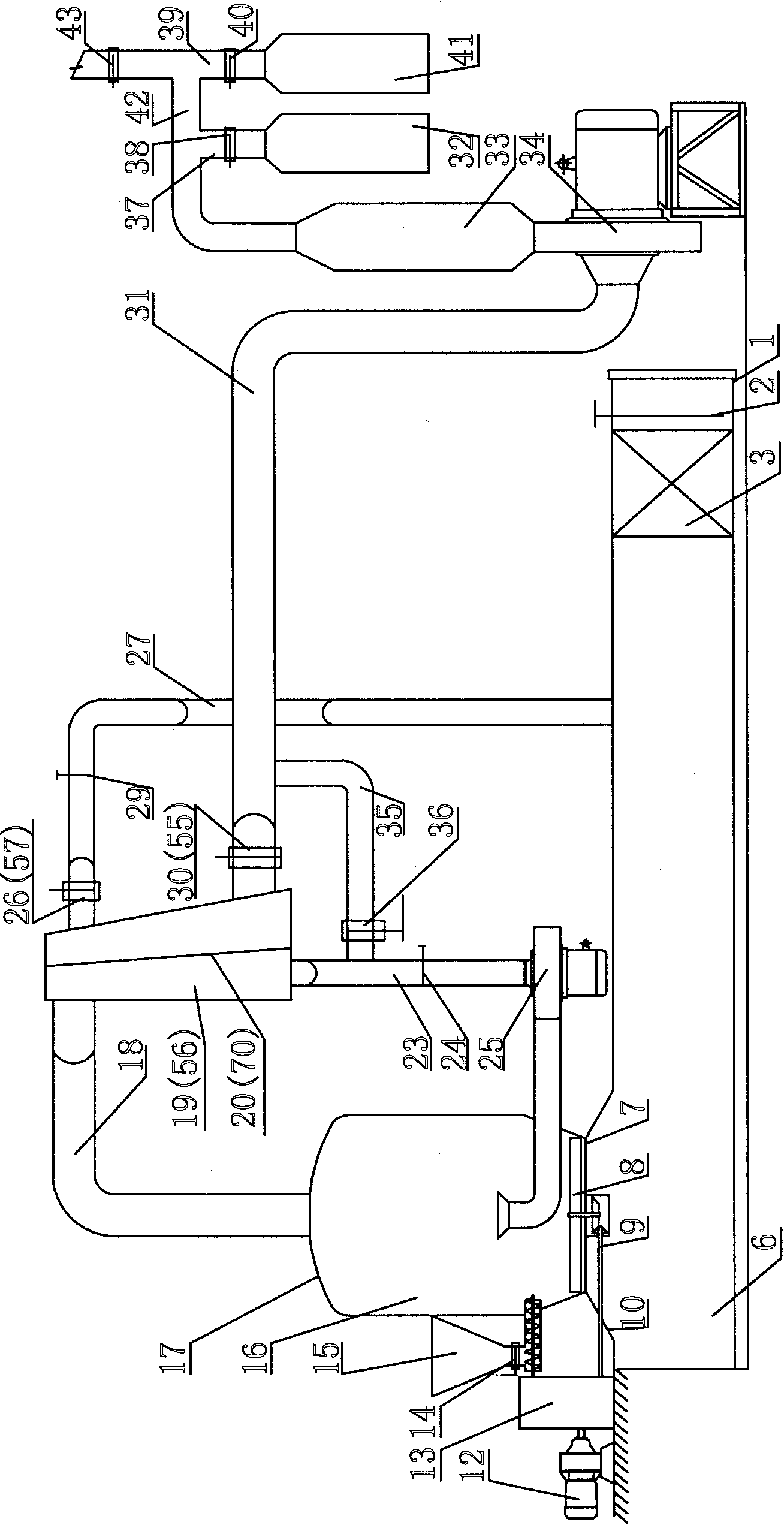

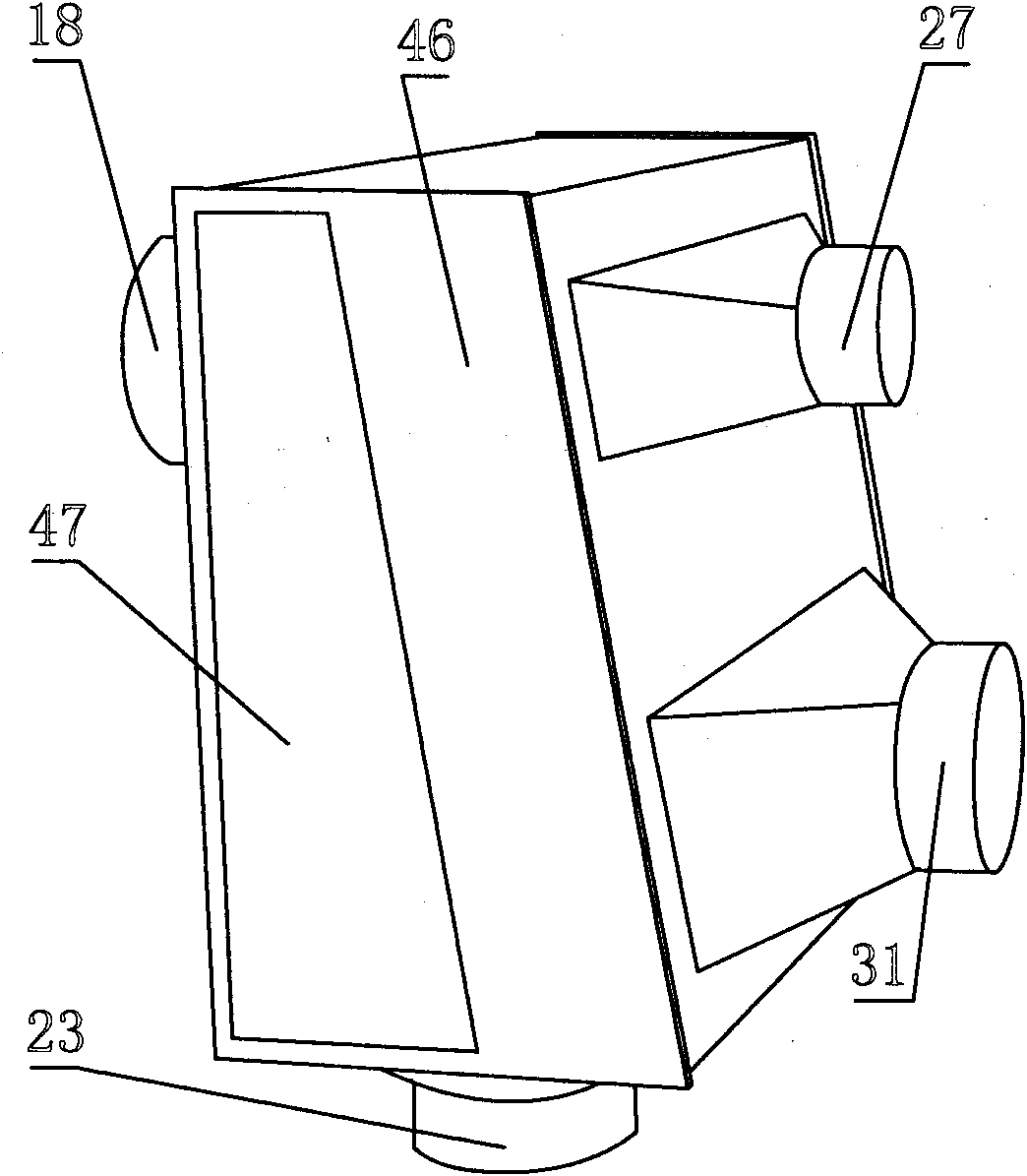

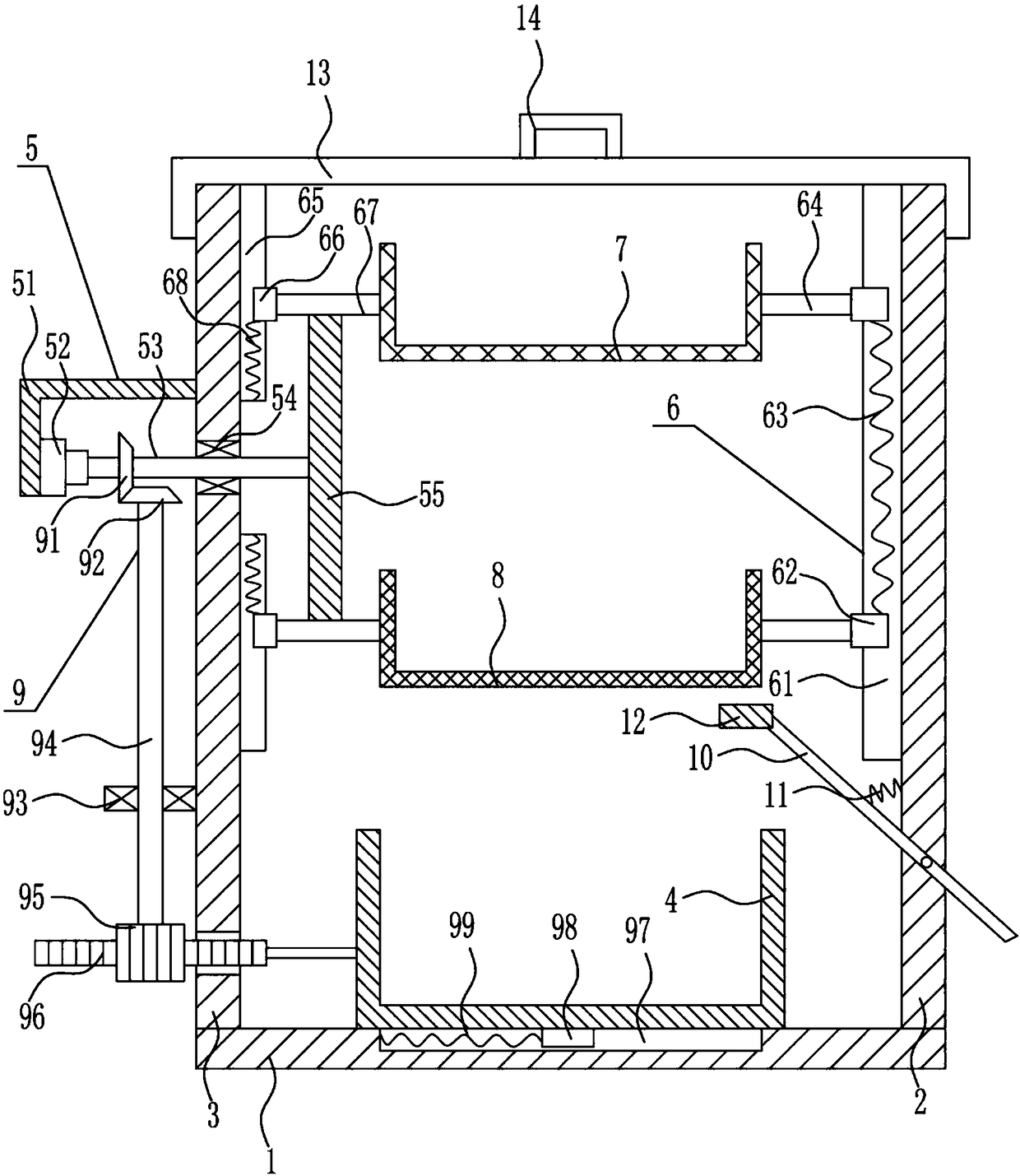

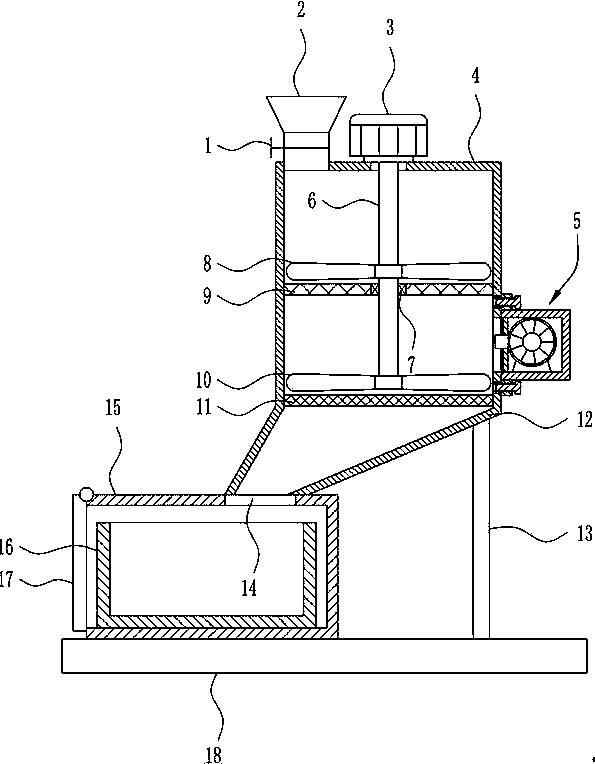

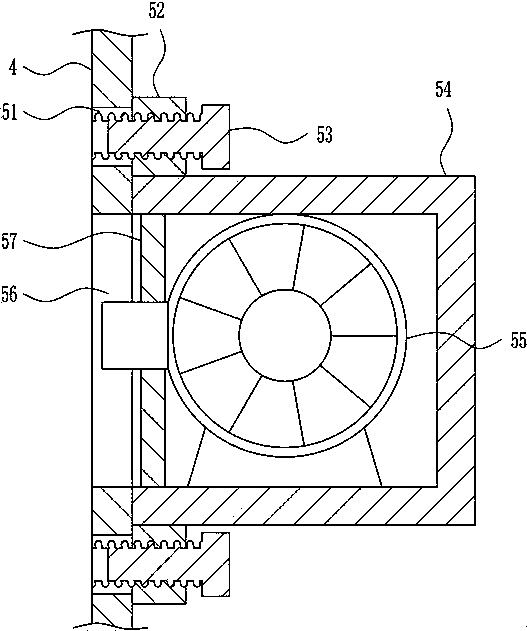

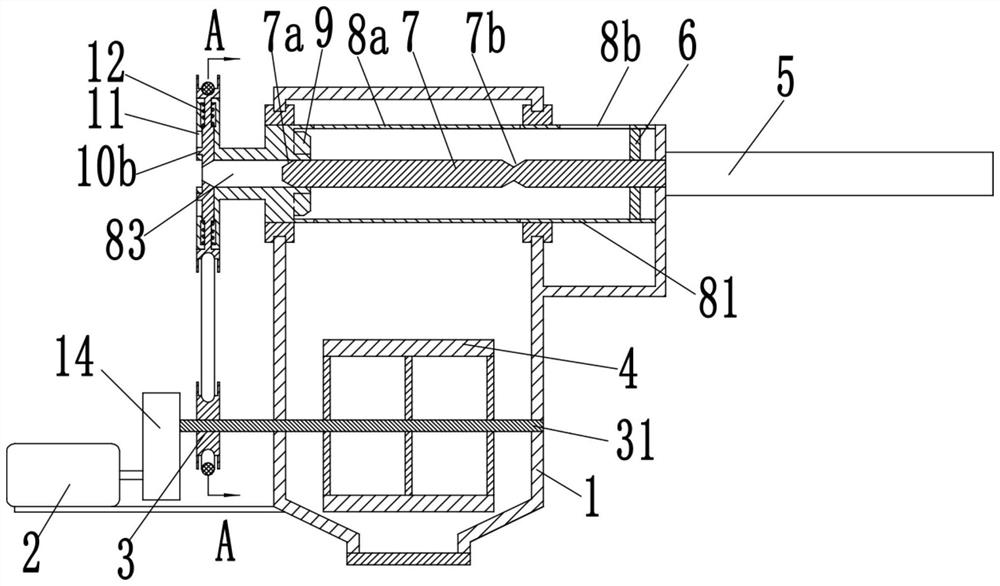

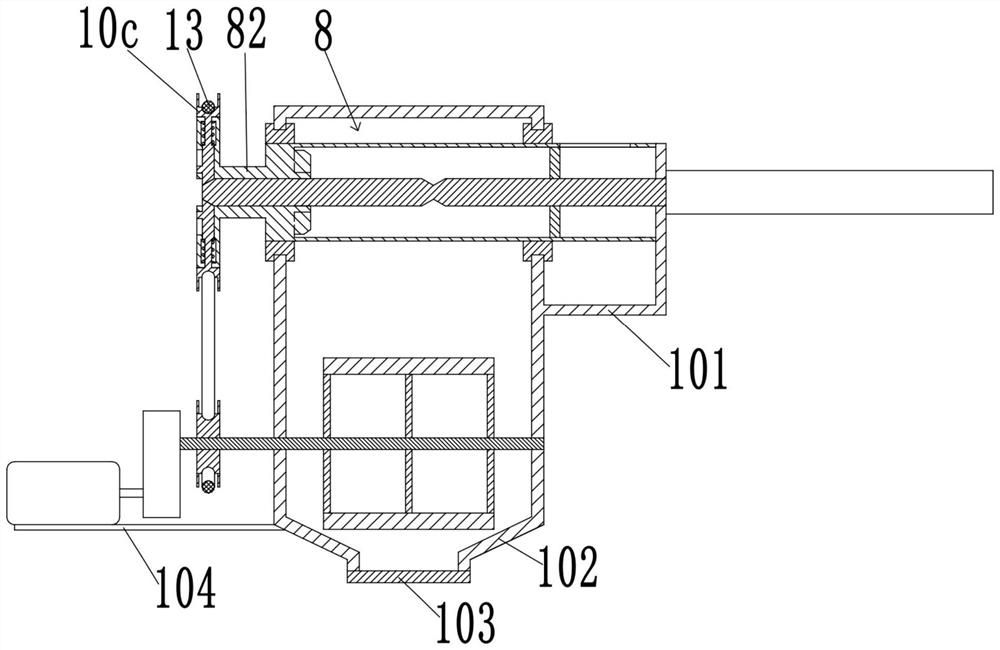

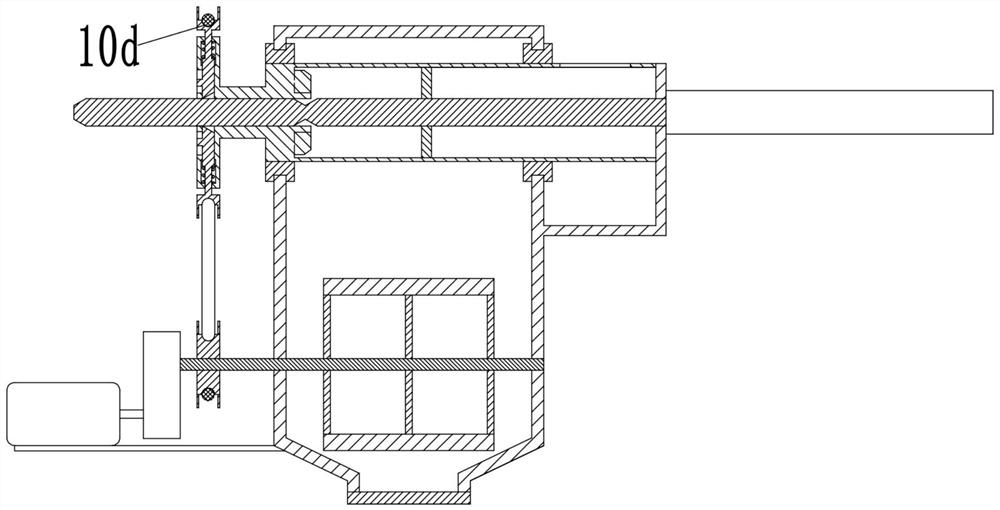

Air flow screening device for micron-sized powder materials

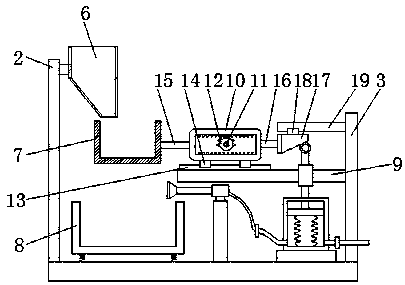

The invention relates to an air flow screening device for micron-sized powder materials, belonging to the screening technical field of powder engineering. The device is formed by improving the existing boiling dryer as follows: a front exhaust main pipe of the existing dryer is divided into a front exhaust main pipe and a back exhaust main pipe, a sieve plate mesh box with a sieve inside is added between the front exhaust main pipe and the back exhaust main pipe to increase the space dimensions of a fluid bed so as to increase the area of the sieve, so that the effective drift diameter of the sieve is increased, and the pore diameter of the sieve can be changed; a blowback device is added to prevent the sieve from being clogged; a circulating device is added to circulate the powder back to the main cavity of the fluid bed; and a pneumatic transmitting and discharging device is added on the basis of the original exhaust system. The device overcomes the defects that the existing boiling dryer can be only used for millimeter-sized particle materials due to the small sieve area and large meshes of the existing boiling dryer and powder materials are piled on the sieve and clog the sieve to block or even disable the air exhaust so as to affect the normal operation of the air jet screening when a small-pore sieve is used in the existing boiling drier. And the invention is applicable to the screening of powder materials.

Owner:YUNNAN GUZHIJI NUTRIMENT CO LTD

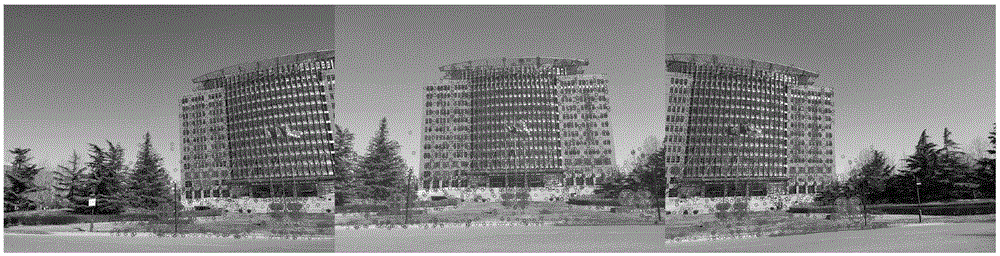

CUDA (Compute Unified Device Architecture)-based panoramic video monitoring system

ActiveCN105245841AImprove efficiencySmooth real-time monitoring videoClosed circuit television systemsPhase correlationFrame rate

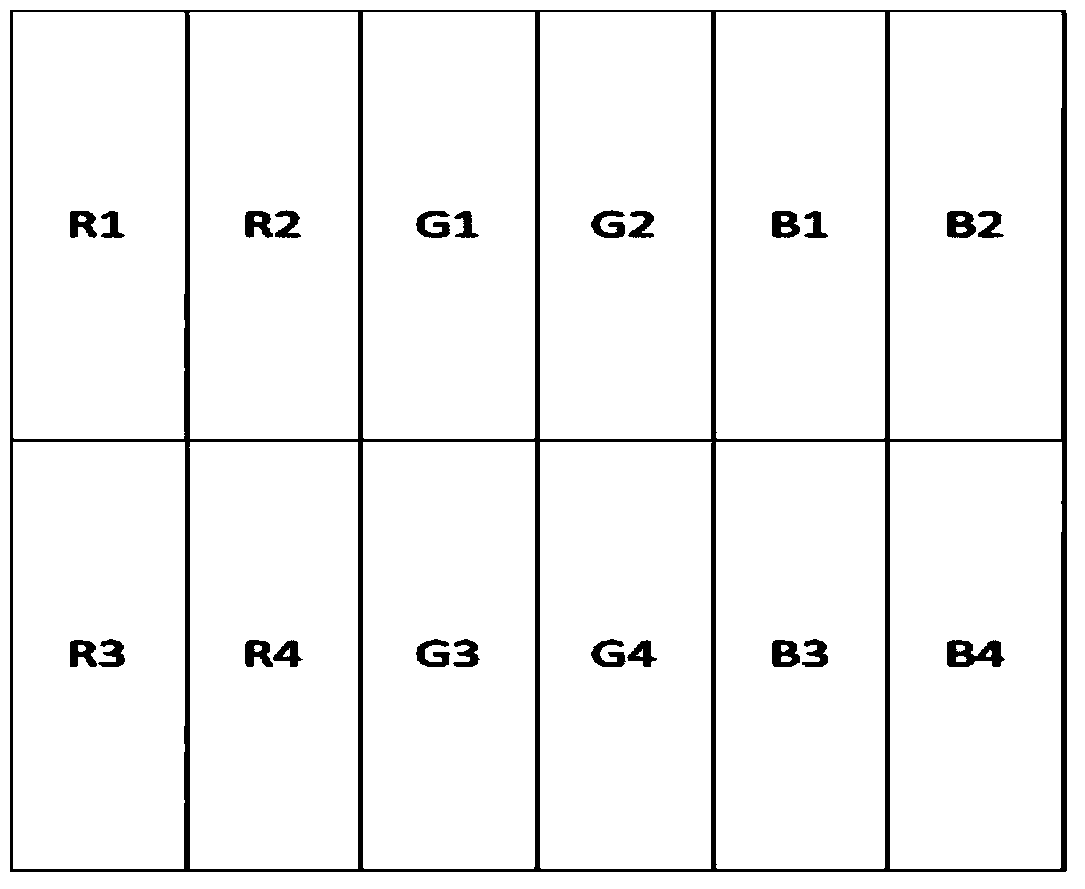

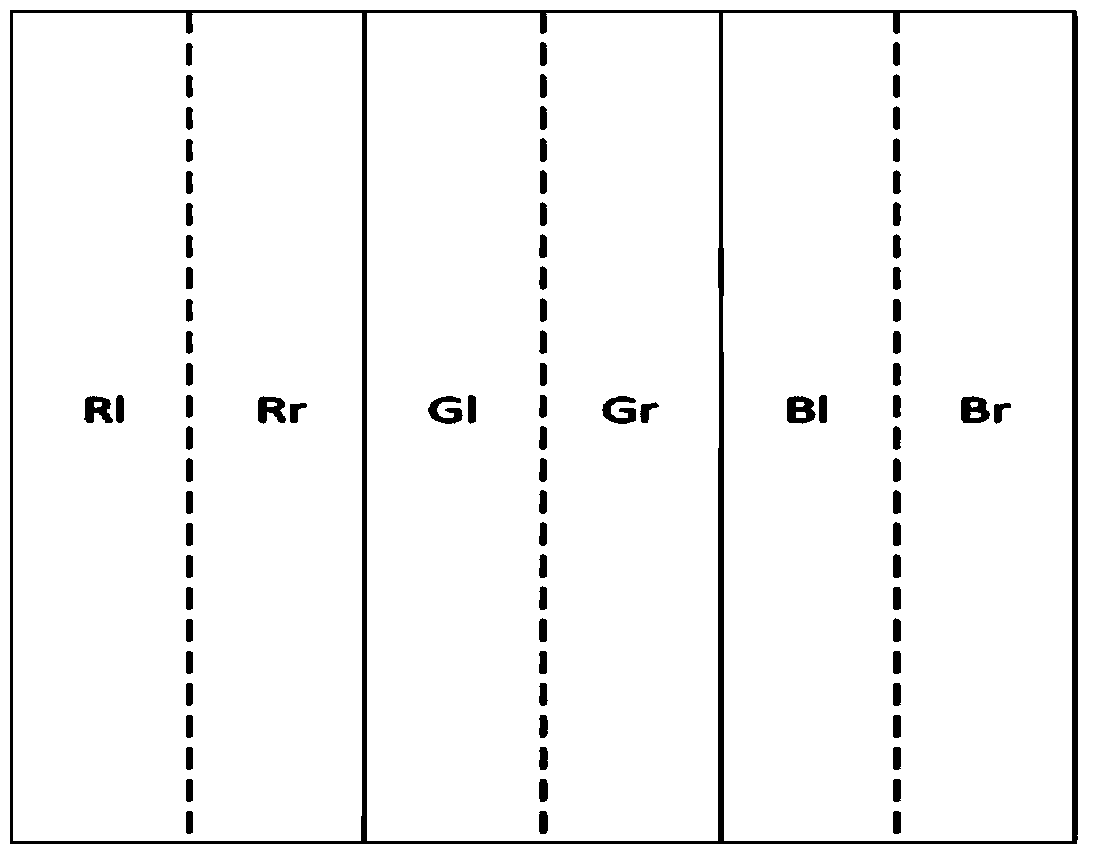

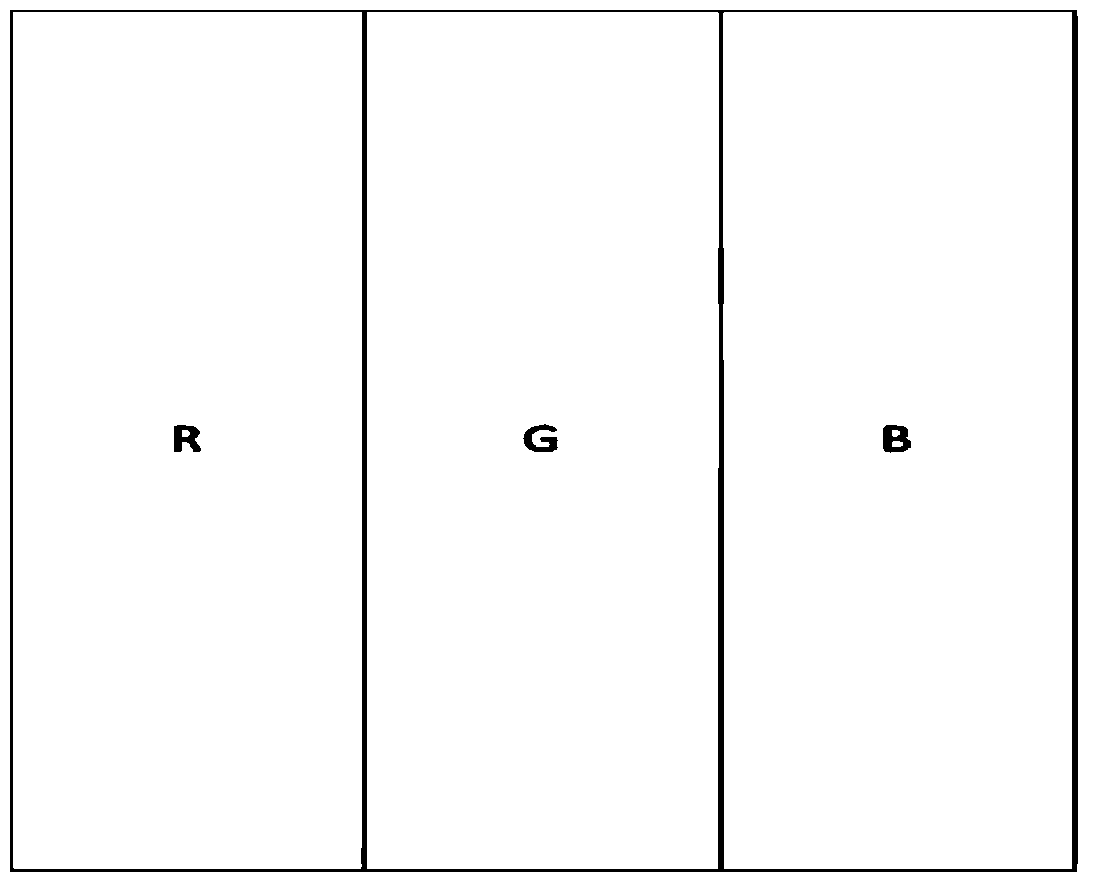

The invention discloses a CUDA (Compute Unified Device Architecture)-based panoramic video monitoring system. Firstly, overlapping regions among a plurality of video images are estimated with a phase correlation method, and SURF (Speeded-Up Robust Transform) feature points are extracted in the overlapping regions and registered, so that algorithm time is shortened, and subsequent mismatching is reduced. Secondly, a fusion algorithm combining an improved optimal fusion line and a multi-resolution algorithm is provided, so that edge jumping and ghost phenomena are eliminated, and the visual effects of videos are improved. Lastly, a GPU (Graphics Processing Unit) is used for accelerating at a fusion stage, so that the splicing speed is further increased. As proved by experimental results, real-time splicing of three paths of monitoring videos can be realized effectively, and a frame rate is up to 20 frames through the system. Compared with a conventional CPU (Central Processing Unit) version, the system has the advantage that the real-time requirement of video splicing can be met.

Owner:BEIJING UNIV OF TECH

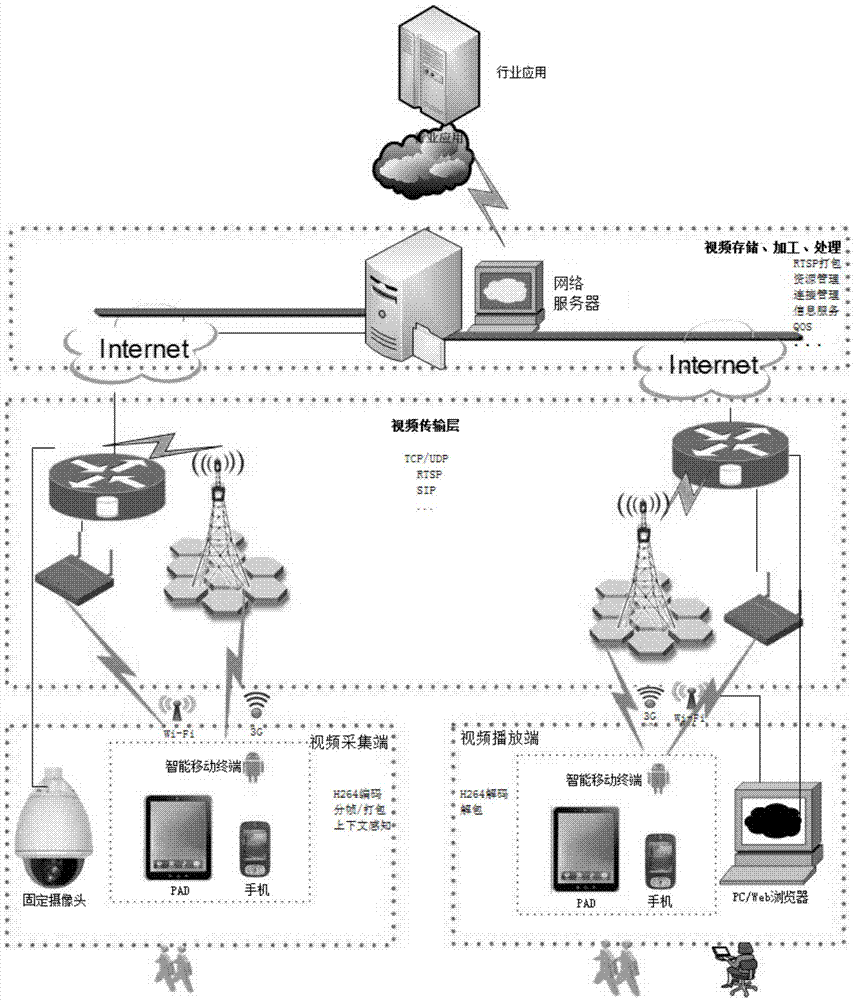

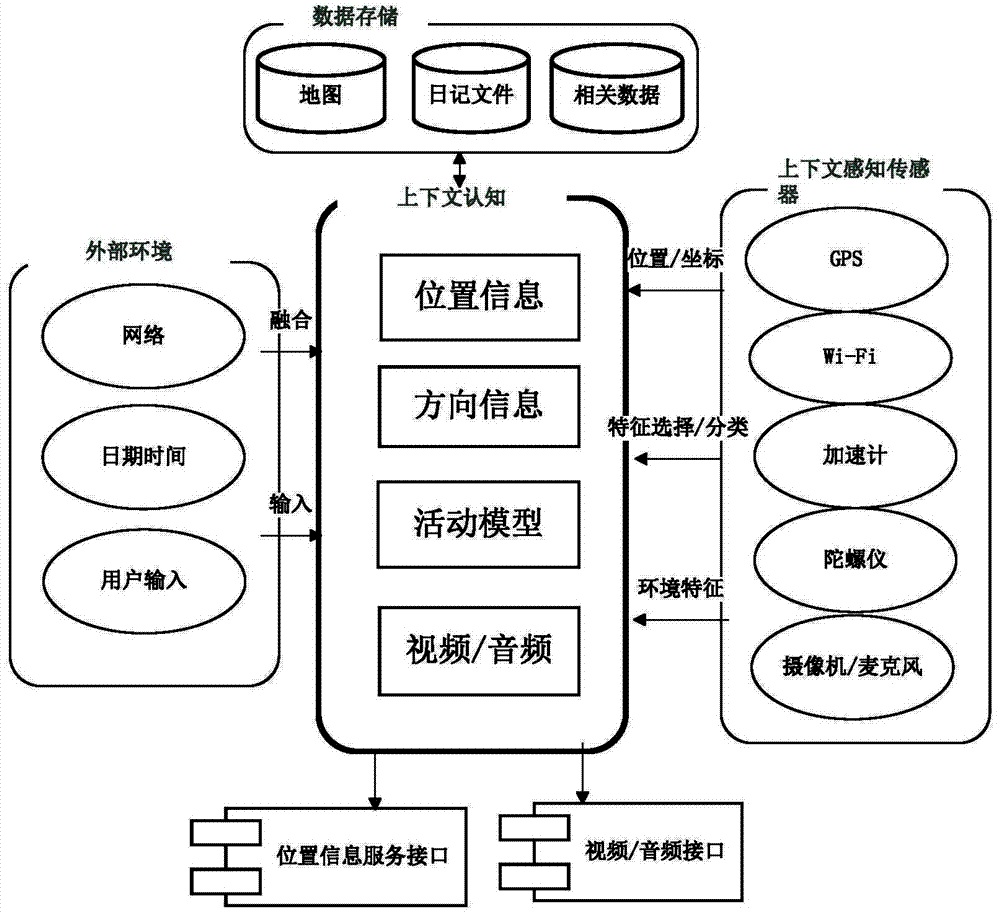

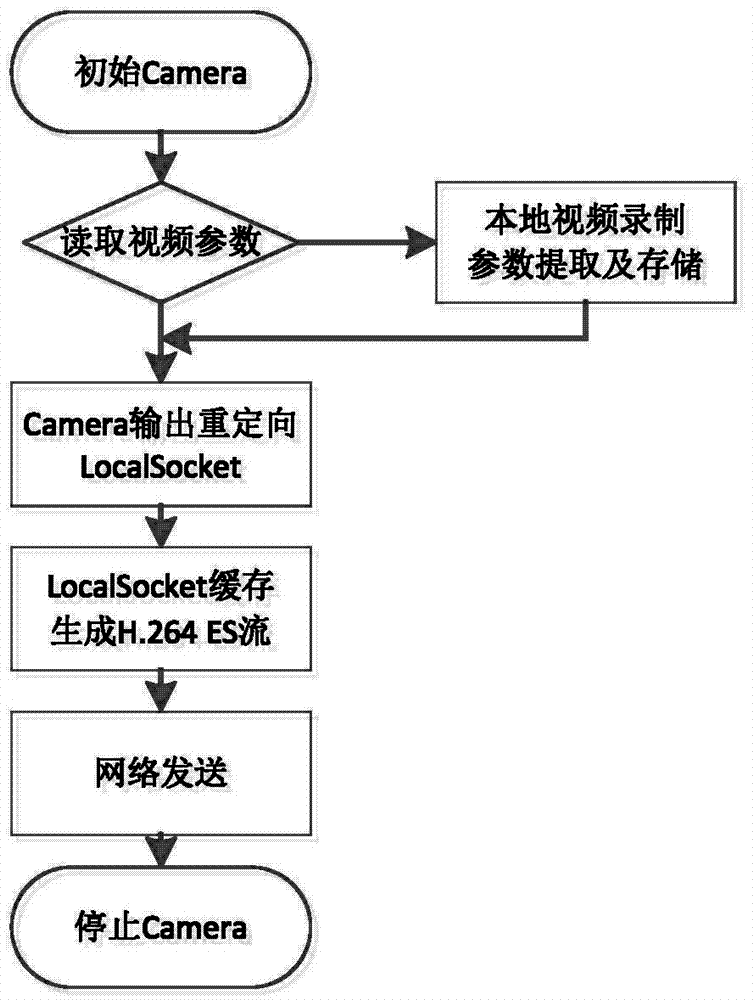

Context sensing-based intelligent mobile terminal field monitoring method

InactiveCN103716584AEasy to search and analyzeReduce concentrationClosed circuit television systemsDigital video signal modificationSearch analyticsVideo transmission

Disclosed is a context sensing-based intelligent mobile terminal field monitoring method. A monitoring system is arranged for monitoring. The monitoring system comprises a video acquiring end, a server end, and a video playing end, which are connected through a network. An intelligent mobile terminal acquires field video data and transmits the video date together with corresponding context data to the server end. The video playing end is connected with the server end through the network for checking videos and realizing the field monitoring. The method can allow real-time video acquisition and transmission at anytime and anywhere flexibly and conveniently and integrate context sensing information, such as filed video position information. Therefore, the interaction bottleneck is reduced; users do not need to classify the videos and add notes to the videos artificially; the searching and analyzing of the videos are facilitated; the system is enabled to have stronger adaptability; and the adoption of a mixed mode 3G mobile phone video transmission QOS strategy, the video quantity is good and the screen is smooth.

Owner:NANJING UNIV

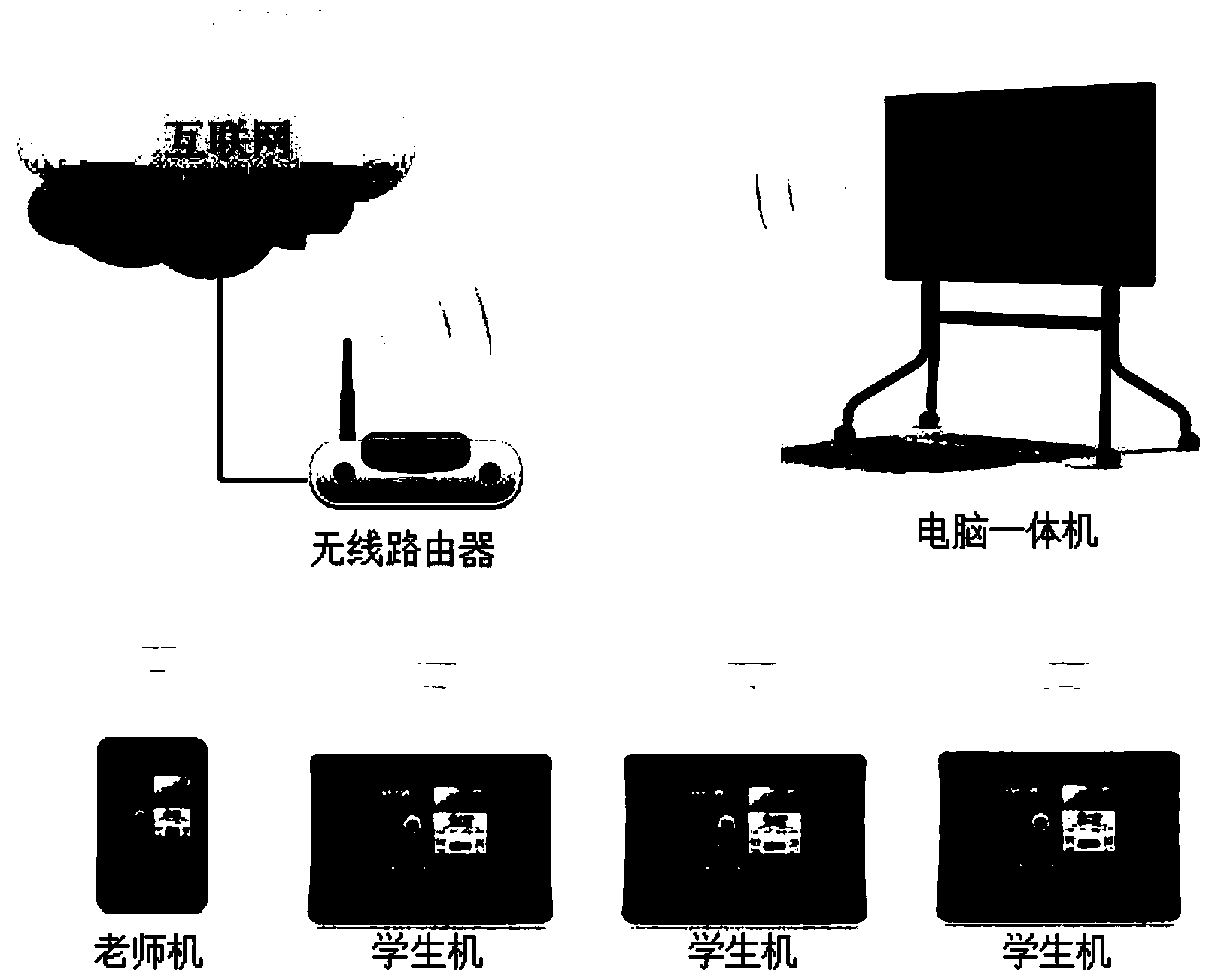

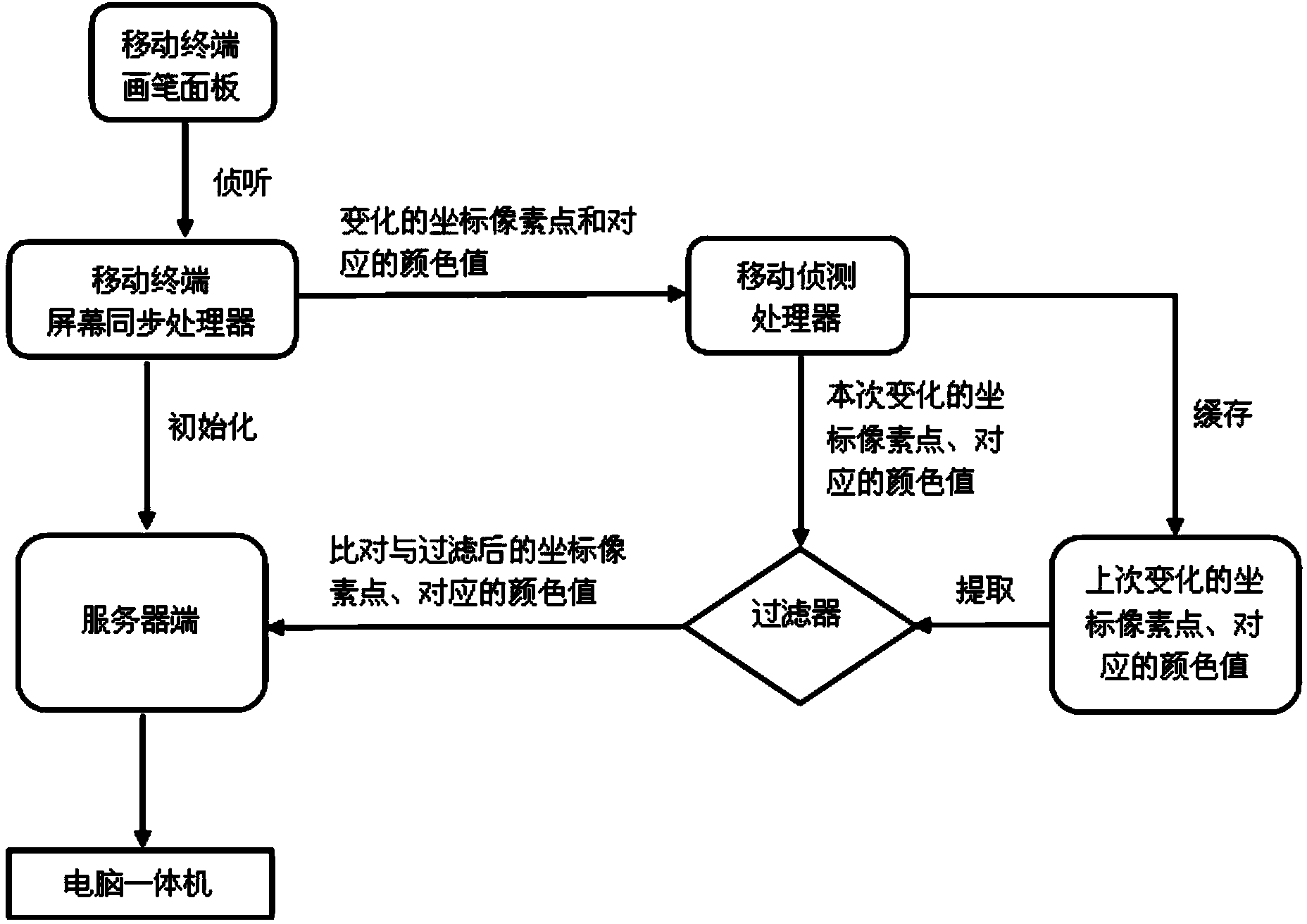

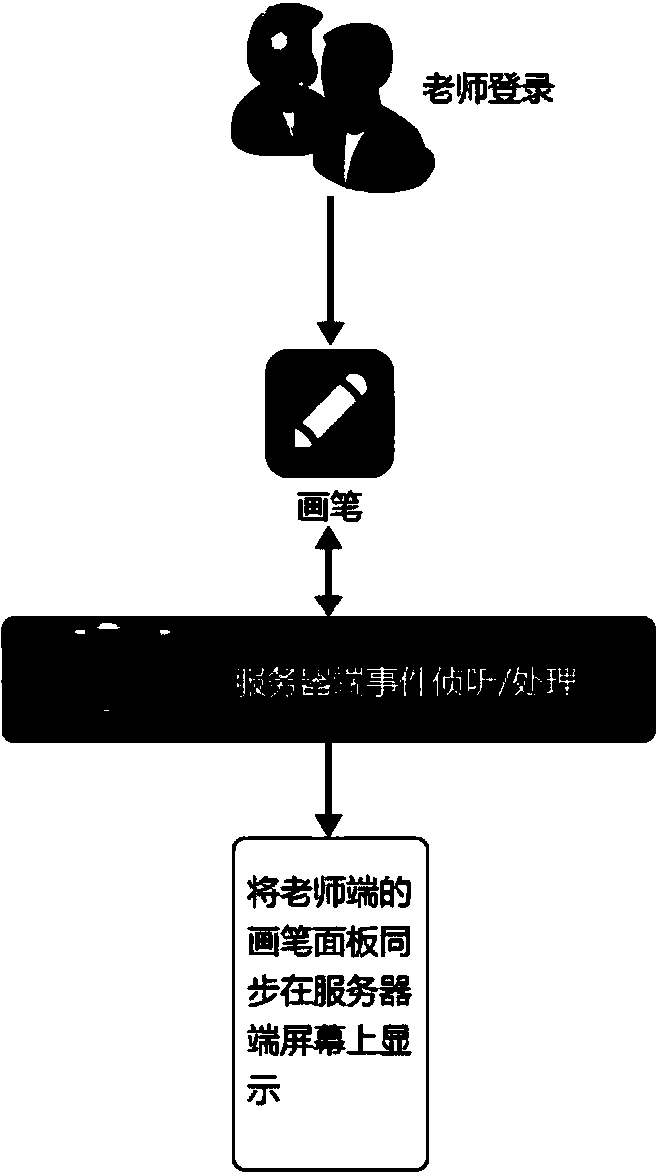

Class synchronization system based on wireless network

InactiveCN104184739AImprove efficiencyReduce data volumeTransmissionElectrical appliancesData synchronizationWireless router

The invention provides a class synchronization system based on the wireless network. The class synchronization system based on the wireless network comprises a wireless router, an all-in-one computer, a mobile terminal and a server side. The method adopted in the class synchronization system comprises the monitoring step, the judging step and the outputting step. In the monitoring step, the picture information of a brush panel of the mobile terminal is monitored in real time, and a picture synchronization order is sent to the server side to request for the synchronous displaying. In the judging step, whether the picture of the brush panel changes or not is judged, wherein if yes, a screen synchronization processor packages the coordinate pixel points and the corresponding color values of the changing parts in real time and transmits the coordinate pixel points and the corresponding color values of the changing parts to the server side to be processed, and synchronization picture information is generated. In the outputting step, the synchronization picture information is output to the all-in-one computer to be displayed. The screen picture of the mobile terminal can be synchronized to the all-in-one computer to be displayed in real time, the consumption on the CPU, the internal storage and the wireless network flow is reduced, the speed and running efficiency are high, and the synchronization picture is fluent.

Owner:陈小鹏

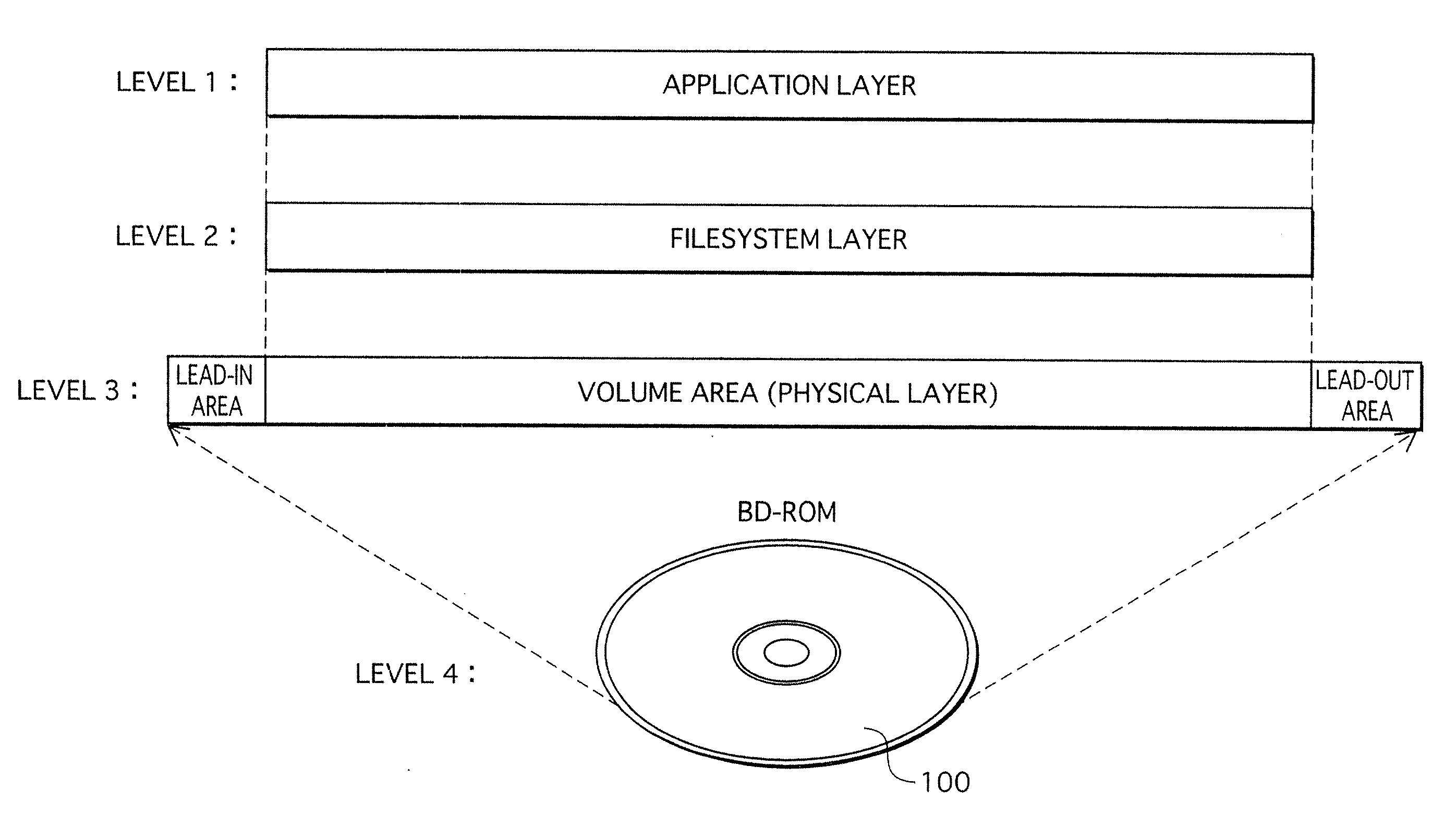

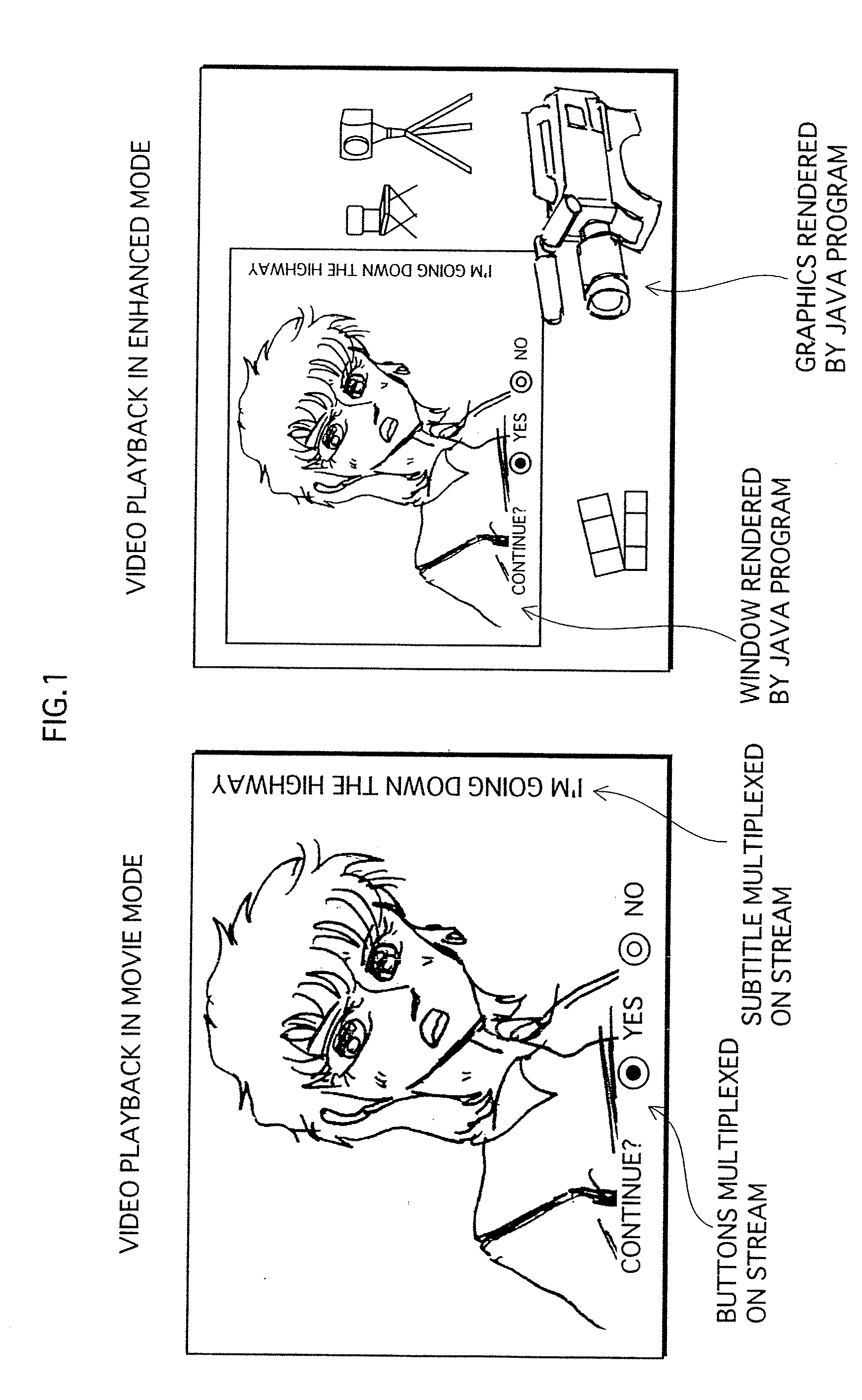

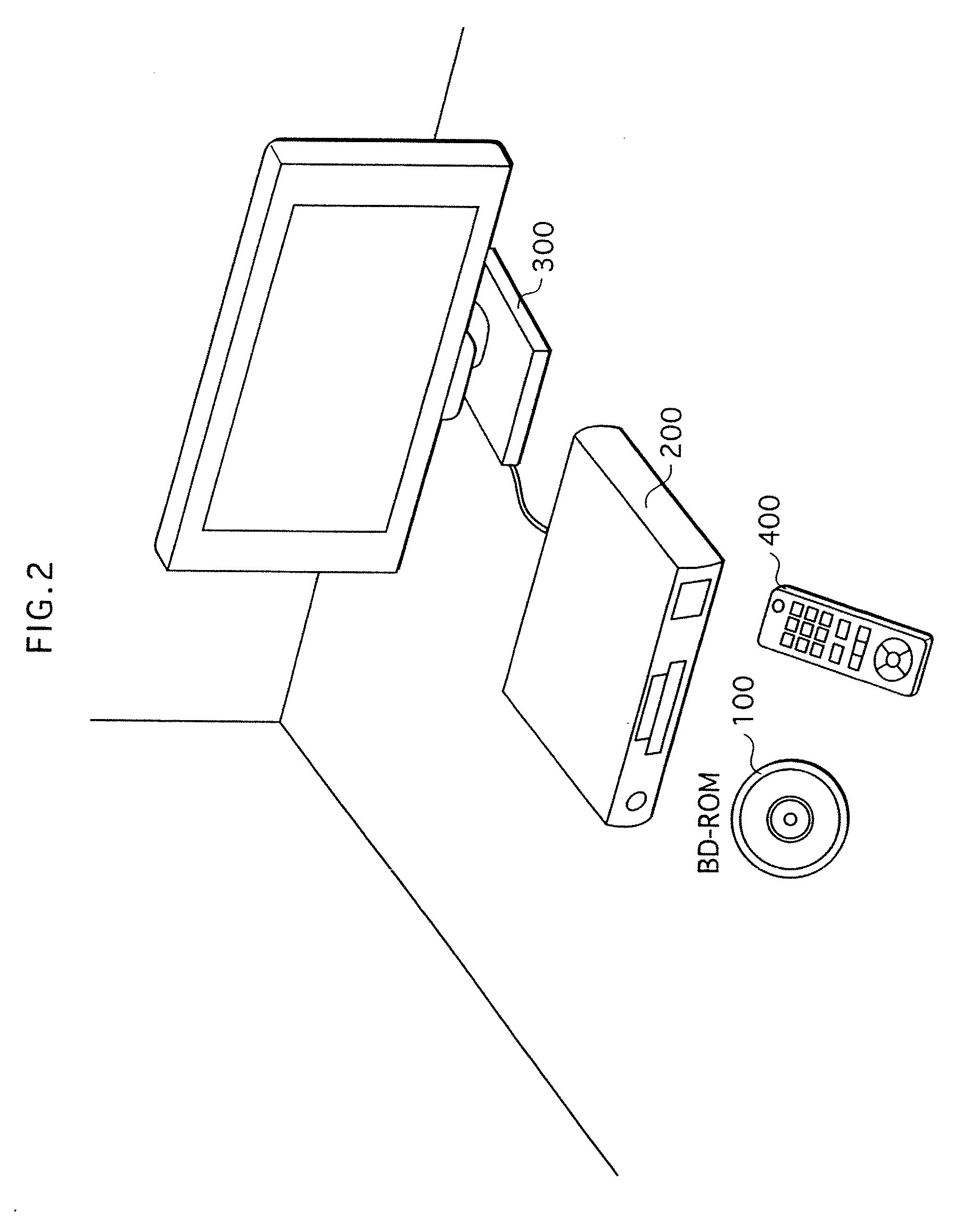

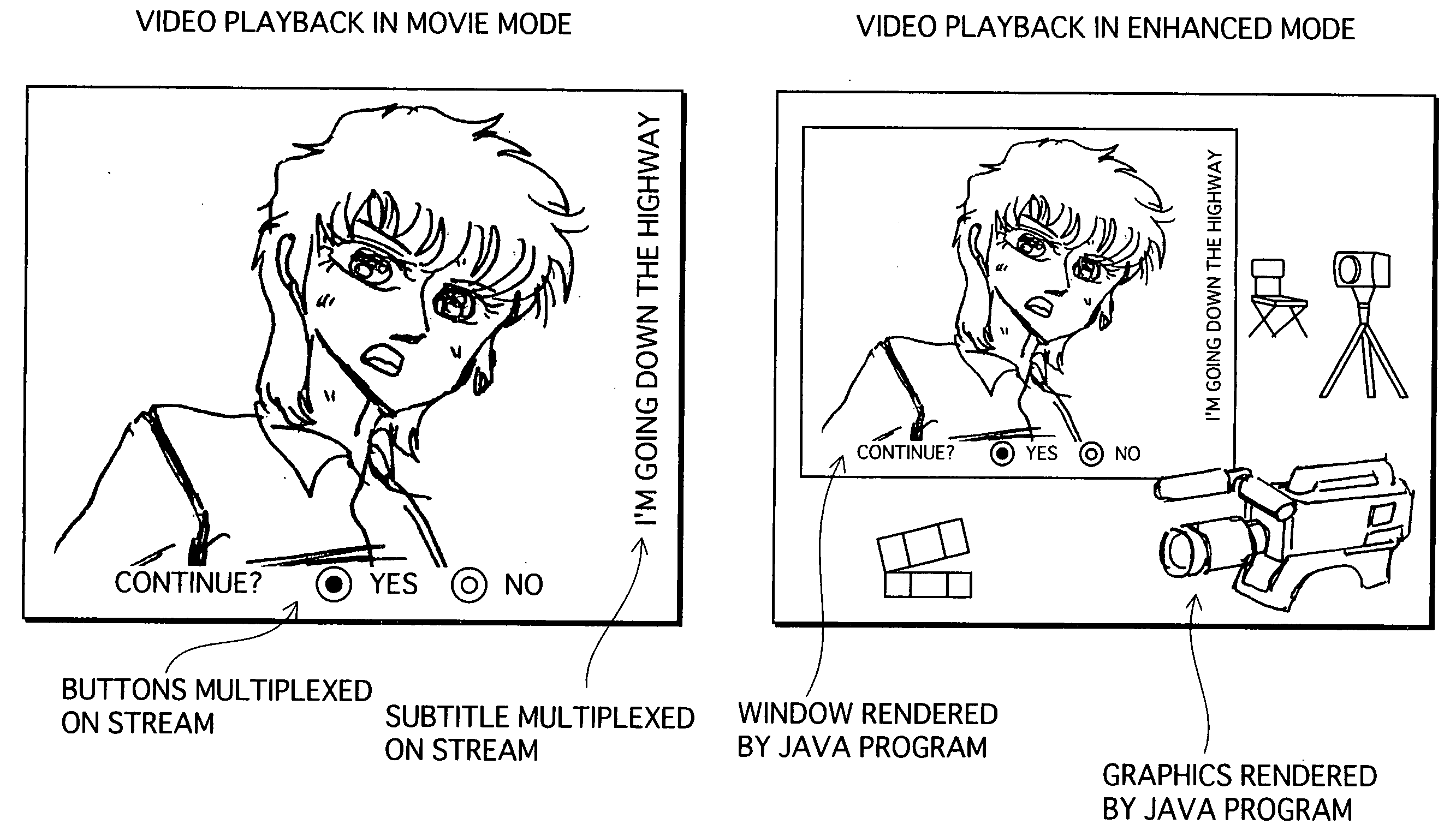

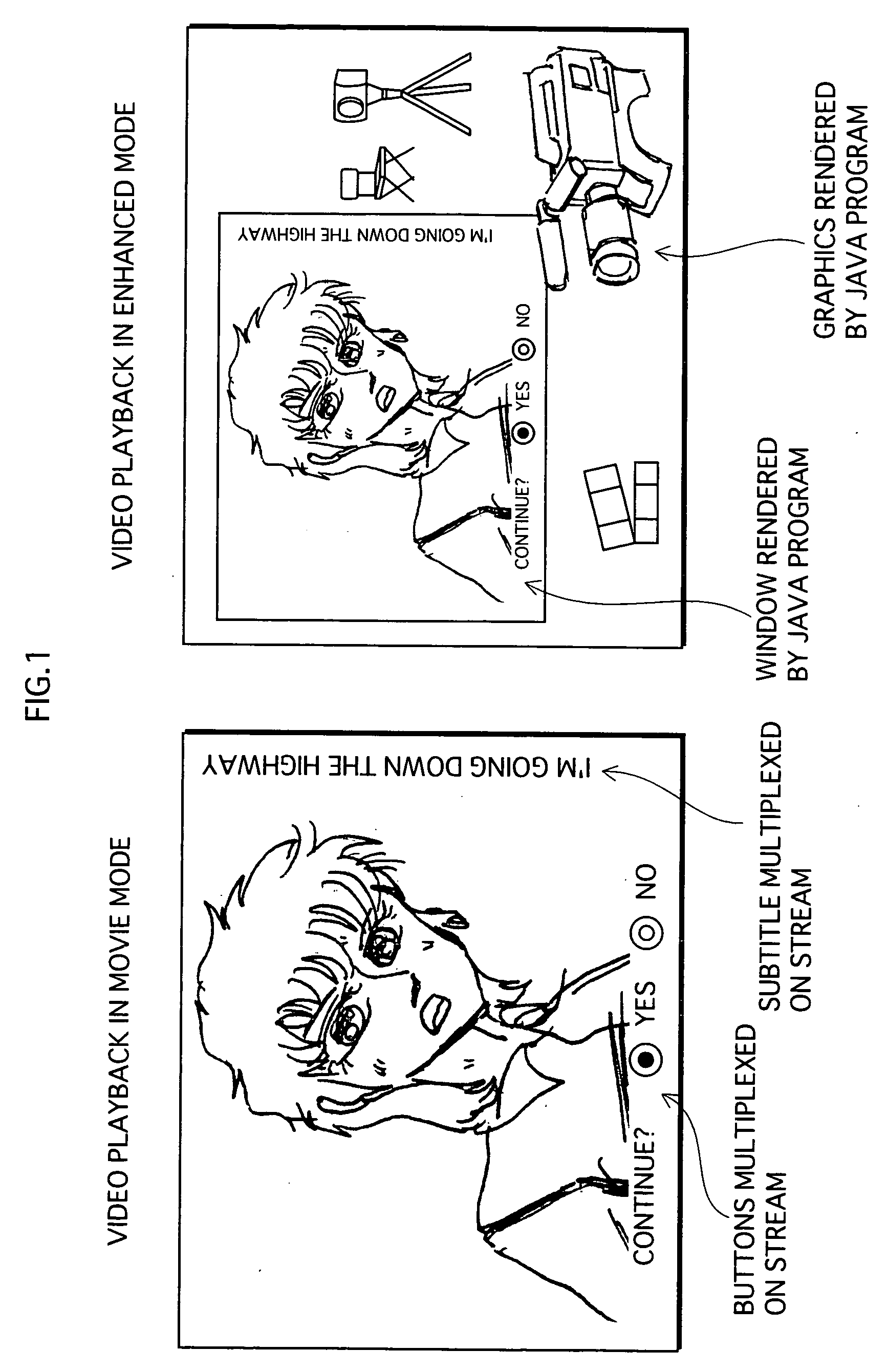

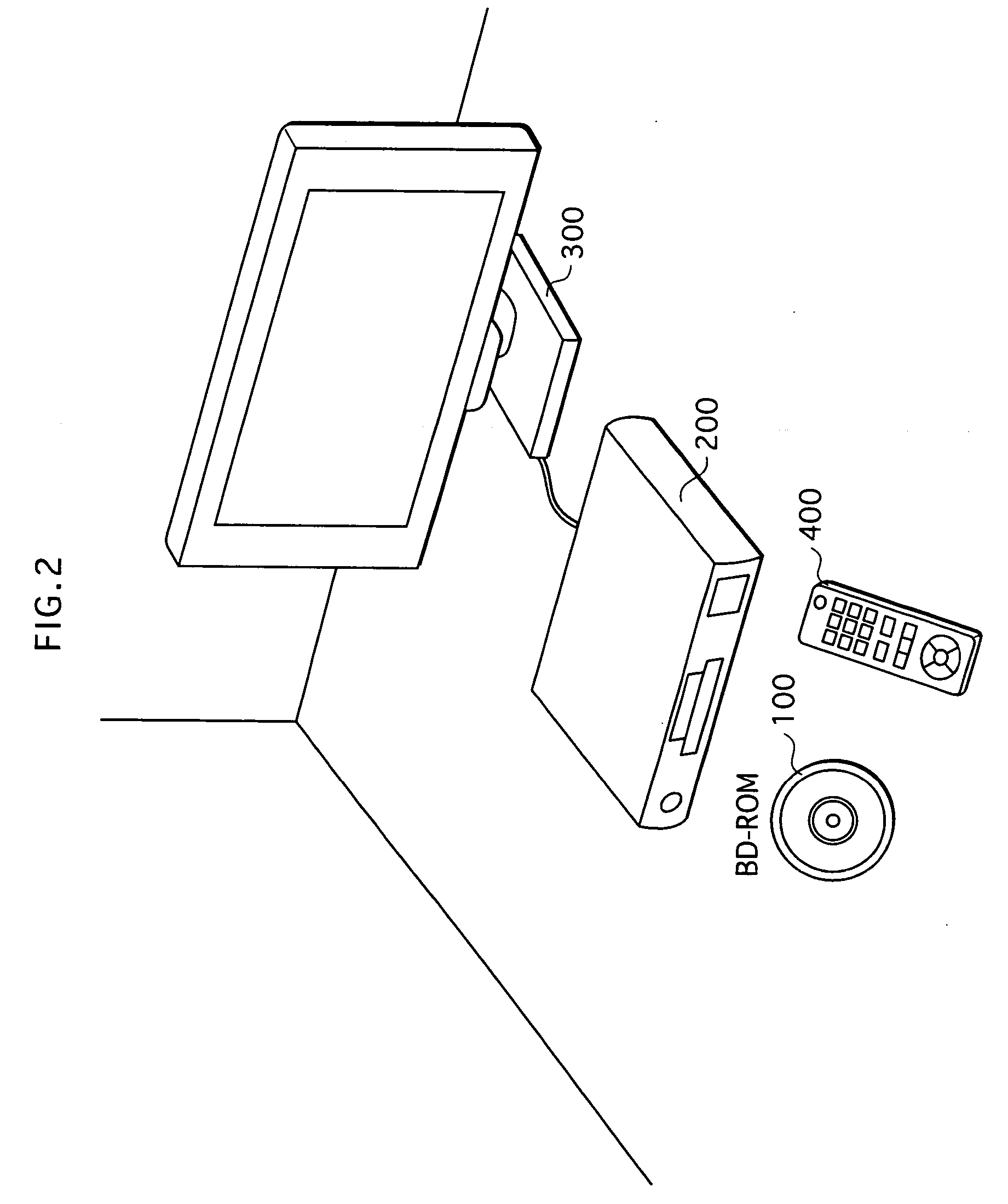

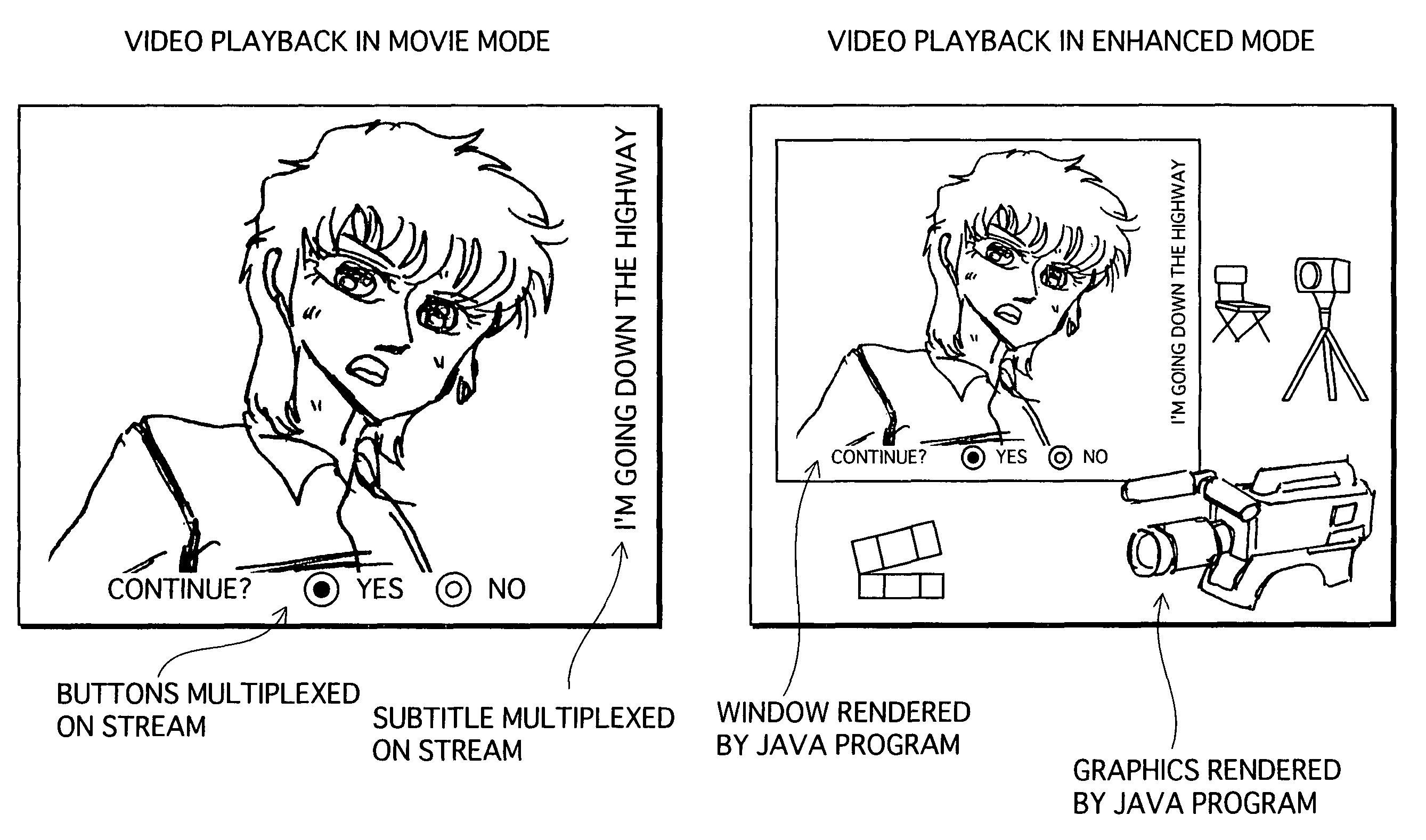

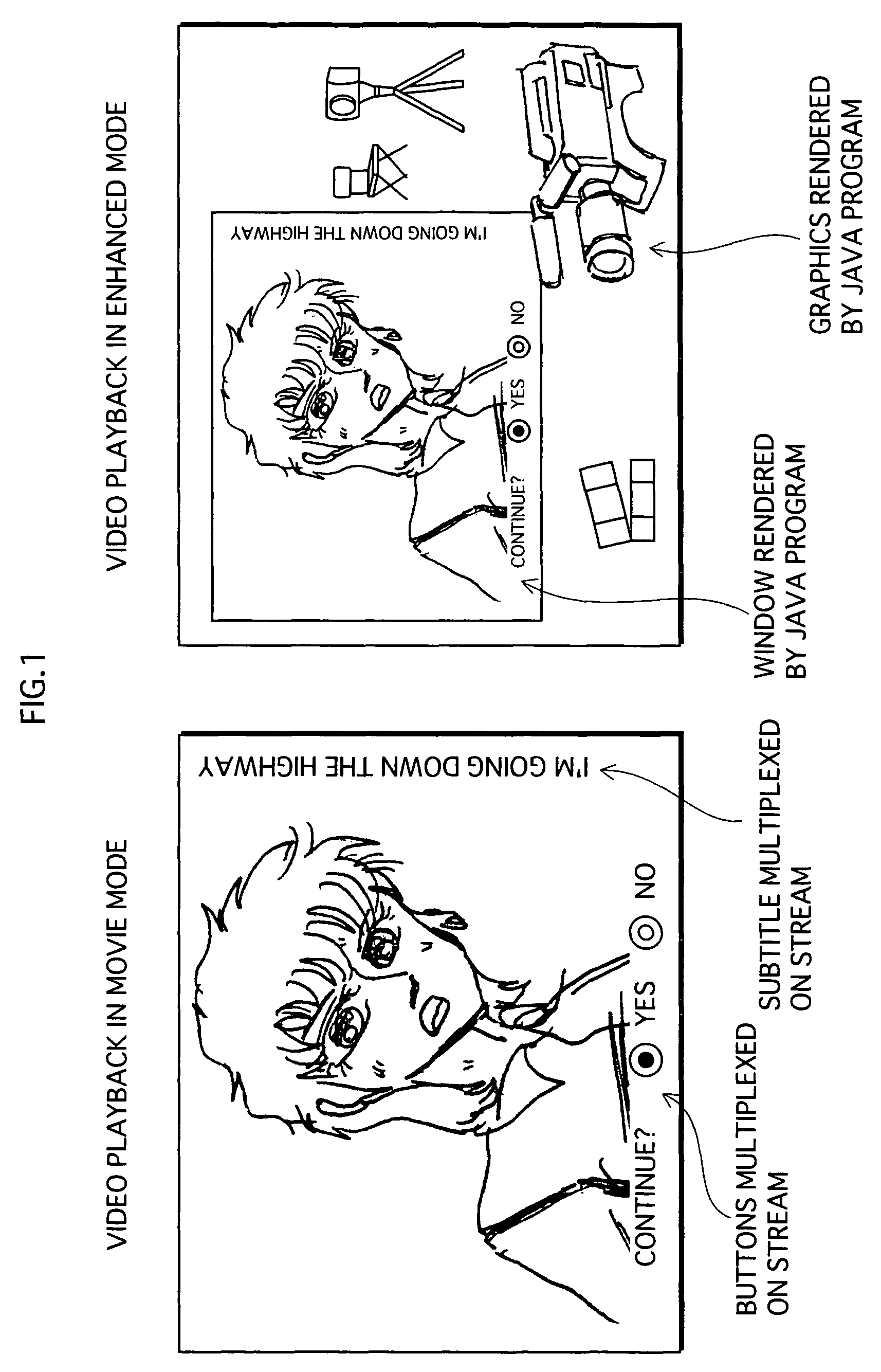

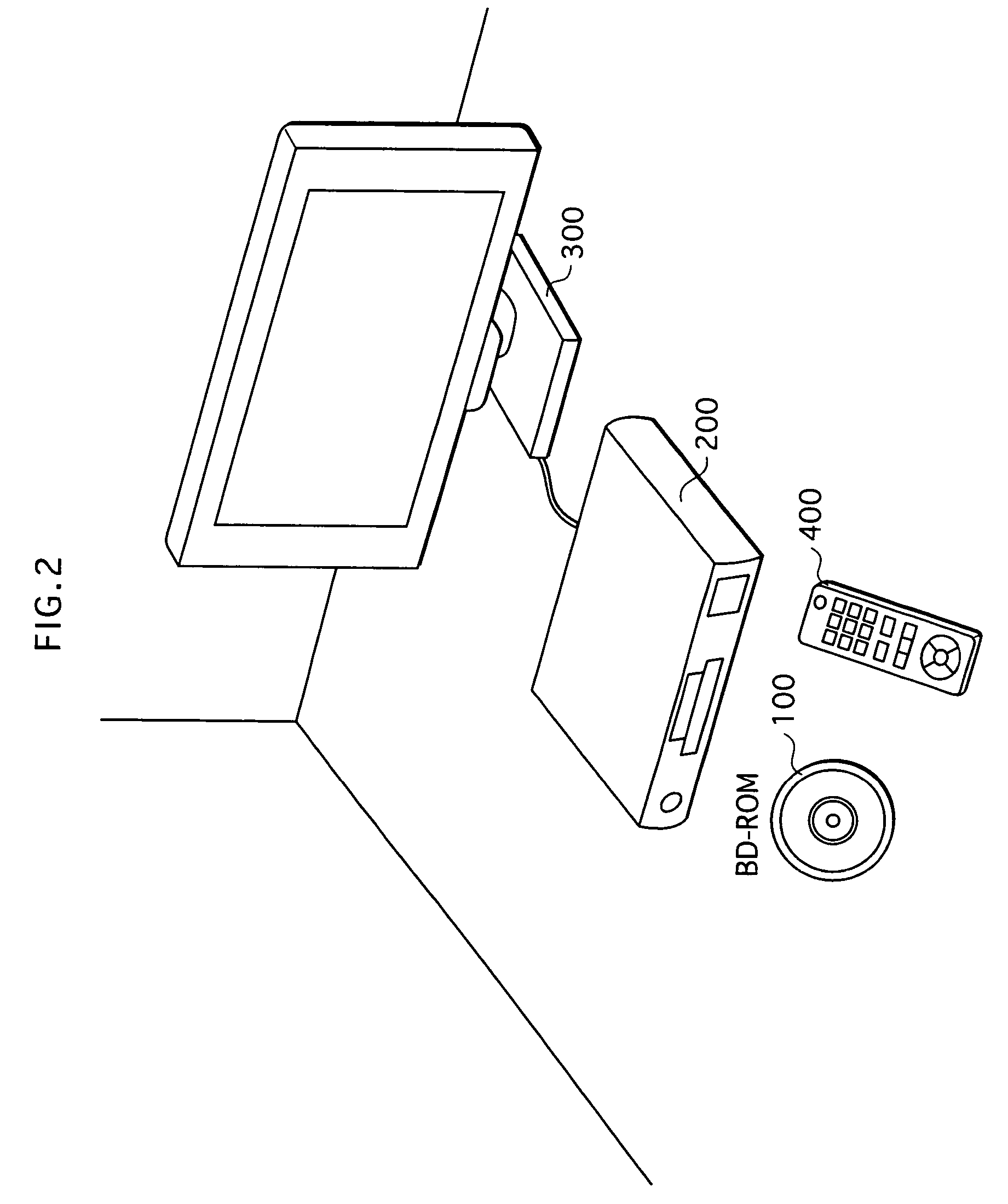

Recording medium, playback apparatus, recording method, program, and playback method

ActiveUS20070230917A1Evenly screenedAvoid playingTelevision system detailsElectronic editing digitised analogue information signalsComputer hardwareRecording media

On a BD-ROM, an AVClip and a plurality of playback section information (PlayItems) are recorded. The AVClip includes a video stream multiplexed with a plurality of elementary streams. The playback section information Playable_PID_entries showing the playback start point and the playback end point in the video stream correlated with the filtering specification of each elementary stream. The filtering specification specifies whether each of the plurality of elementary streams are able to be played back or not.

Owner:PANASONIC CORP

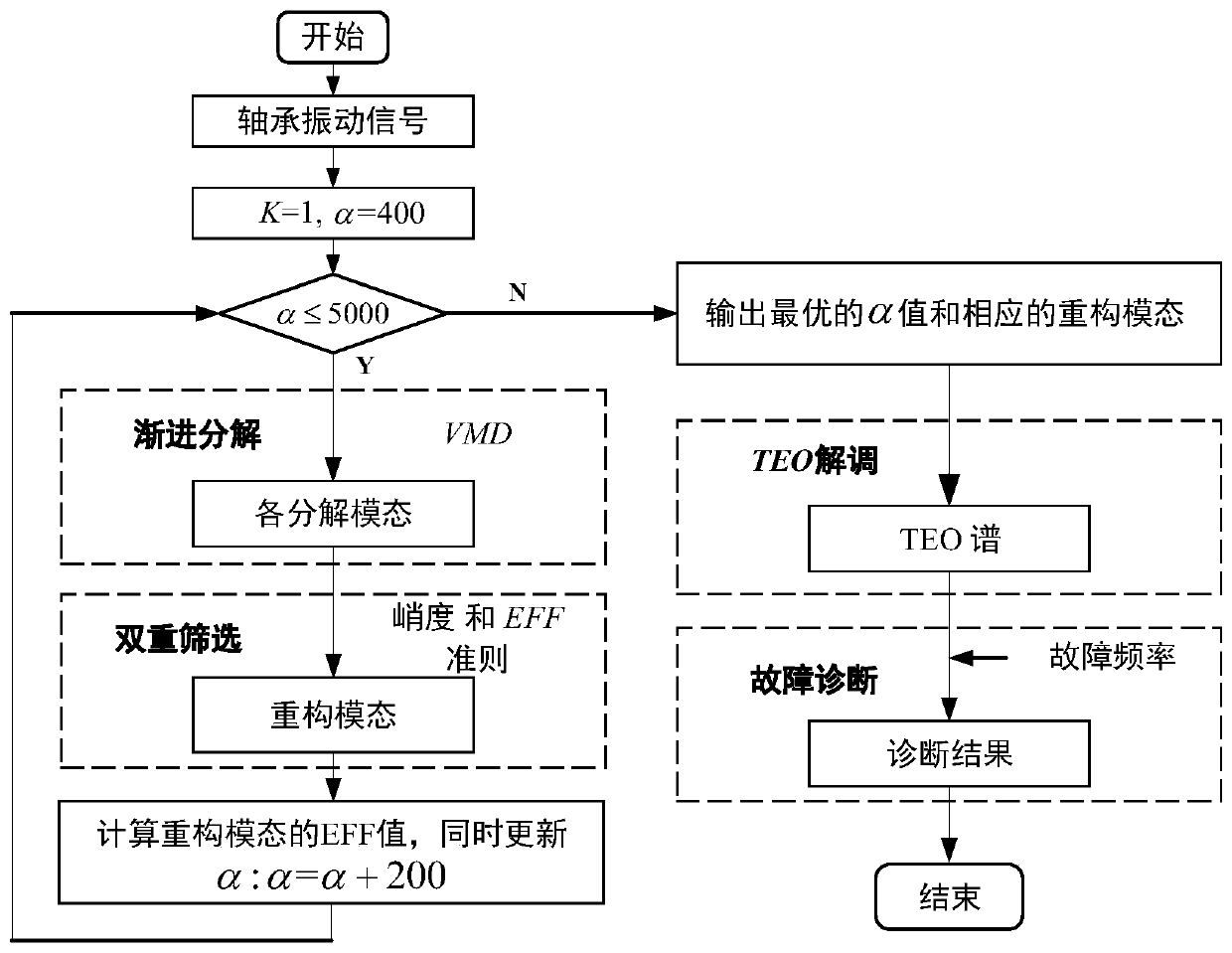

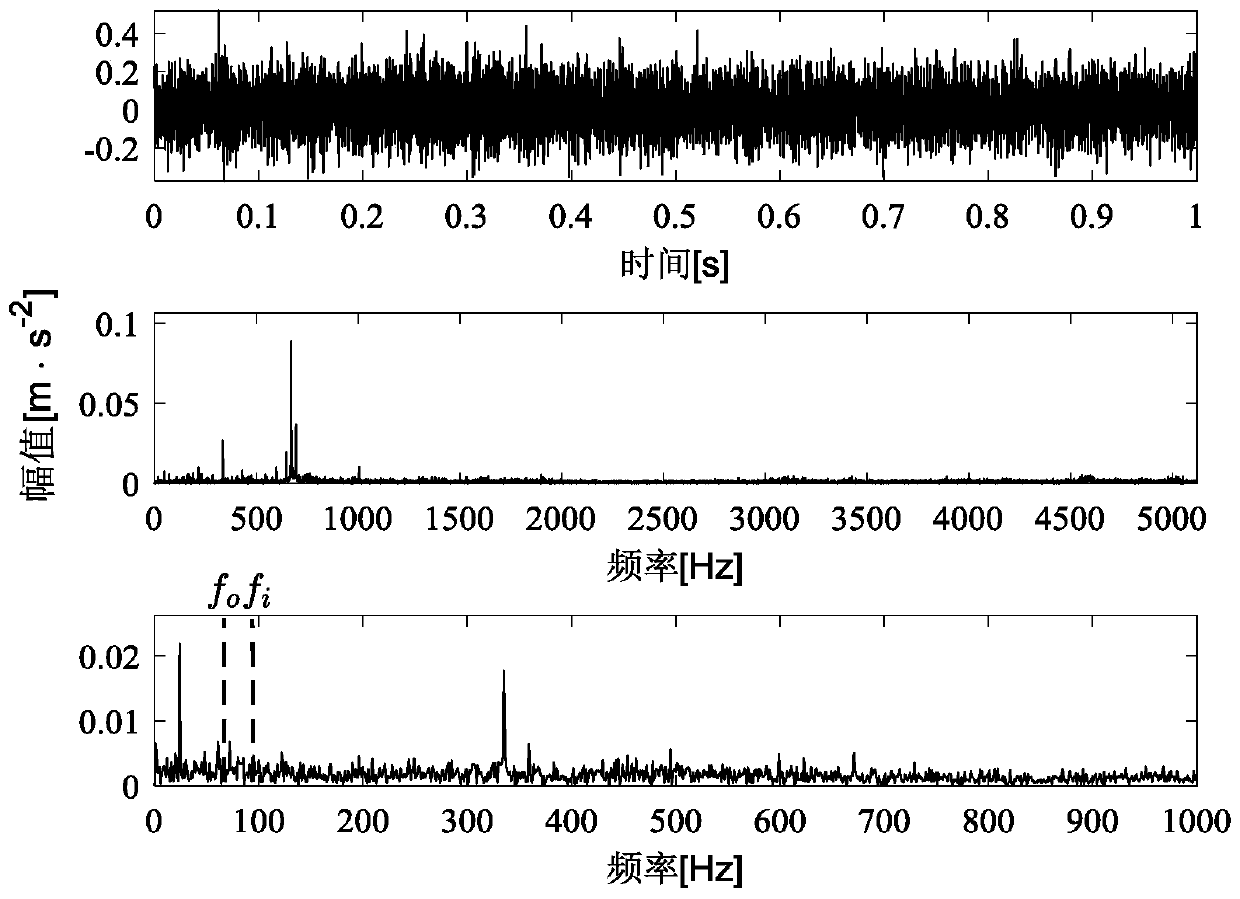

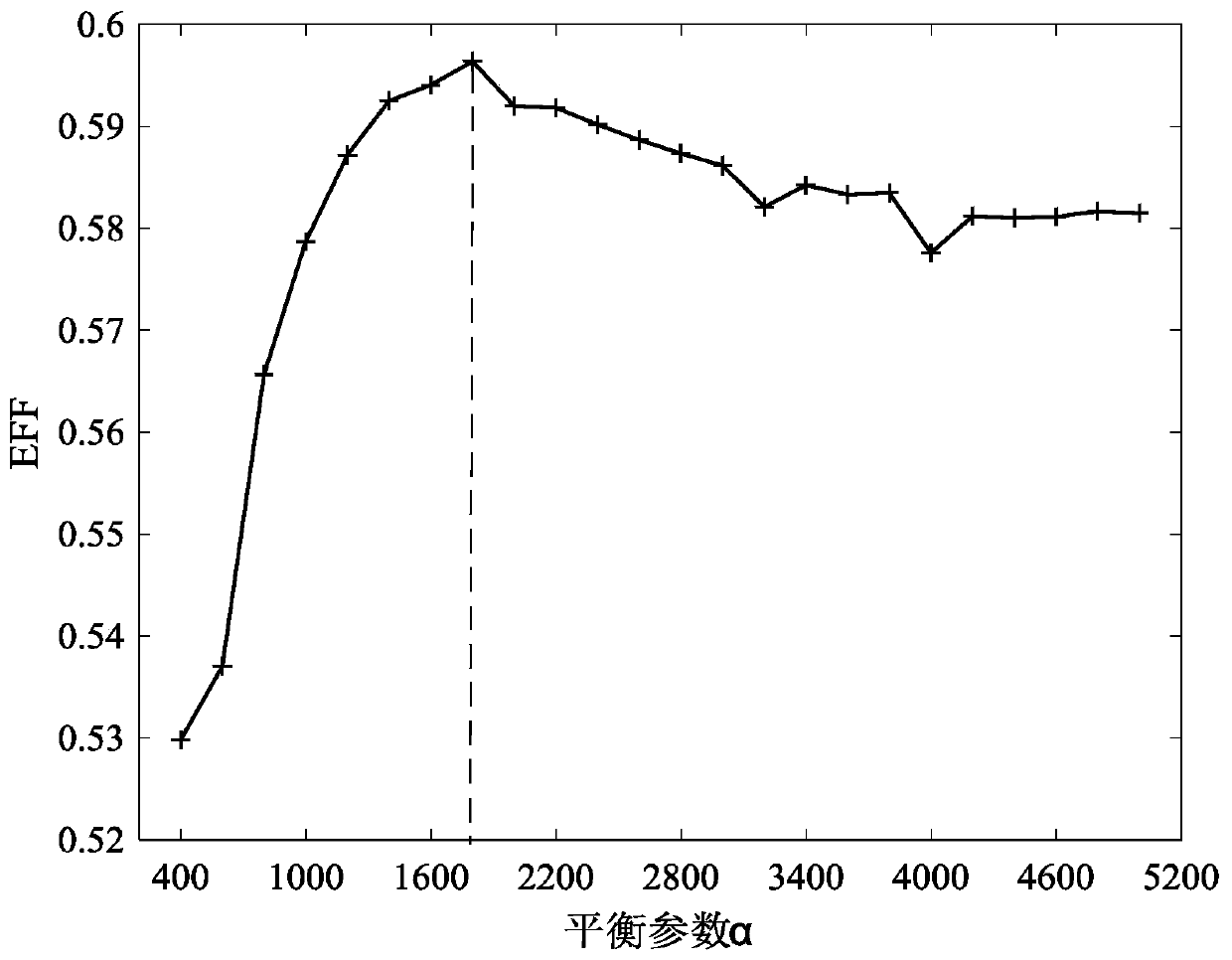

Rolling bearing early composite fault feature extraction method based on progressive VMD

PendingCN111178318AGood periodicityOvercoming the shortcoming of easy failure of fault diagnosisMachine part testingCharacter and pattern recognitionAlgorithmFeature extraction

The invention discloses a rolling bearing early composite fault feature extraction method based on progressive VMD. The method comprises the steps of 1, installing an acceleration sensor near a rolling bearing to collect vibration signals during bearing operation; 2, decomposing the acquired vibration signal by using a progressive VMD to obtain a series of decomposed modes; 3, screening the modesobtained after decomposition by using a dual screening criterion based on kurtosis and an energy fluctuation factor to determine a fault mode, and realizing reconstruction of the fault mode; 4, initializing the range and the search step length of the balance parameter alpha, repeating the step 2 and the step 3 for different alpha values, calculating the EFF value of the reconstruction mode, the maximum EFF value corresponding to the optimal alpha value, and then determining the reconstruction mode under the optimal alpha value; and 5, demodulating the reconstructed mode by using TEO to obtaina TEO spectrum, and obtaining a diagnosis result in combination with the bearing related fault characteristic frequency. On the basis of an EEMD recursion idea, the invention provides a progressive decomposition VMD method.

Owner:SOUTHEAST UNIV

Recording Medium, Playback Apparatus, Recording Method, Program, And Playback Method

ActiveUS20070258698A1Evenly screenedAvoid playingTelevision system detailsElectronic editing digitised analogue information signalsComputer hardwareRecording media

On a BD-ROM, an AVClip and a plurality of playback section information (PlayItems) are recorded. The AVClip includes a video stream multiplexed with a plurality of elementary streams. The playback section information Playable_PID_entries showing the playback start point and the playback end point in the video stream correlated with the filtering specification of each elementary stream. The filtering specification specifies whether each of the plurality of elementary streams are able to be played back or not.

Owner:PANASONIC CORP

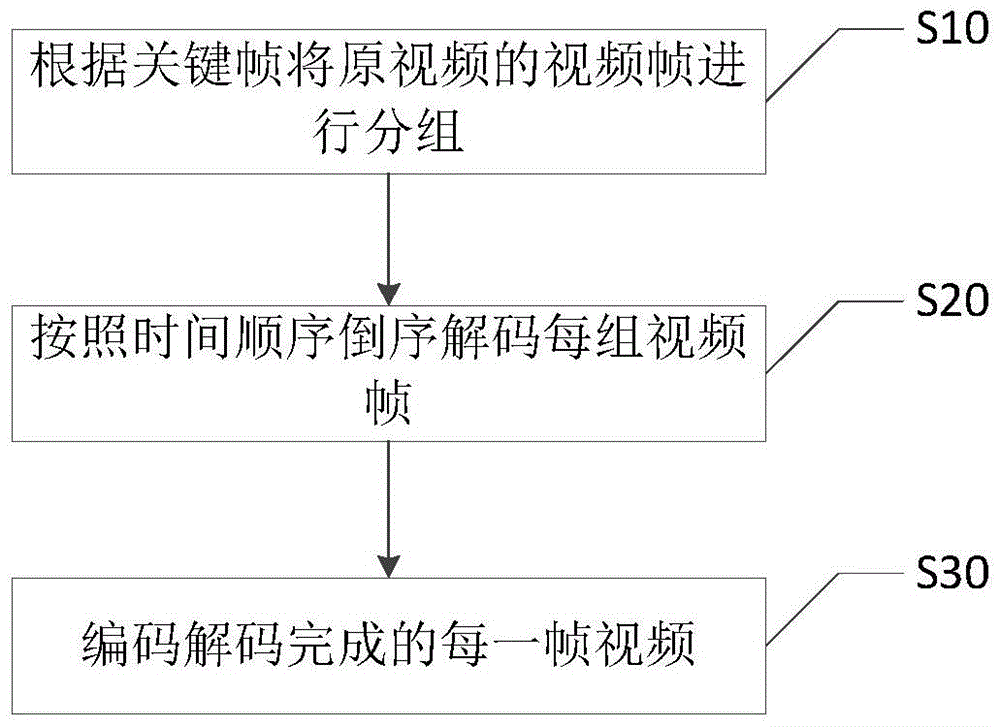

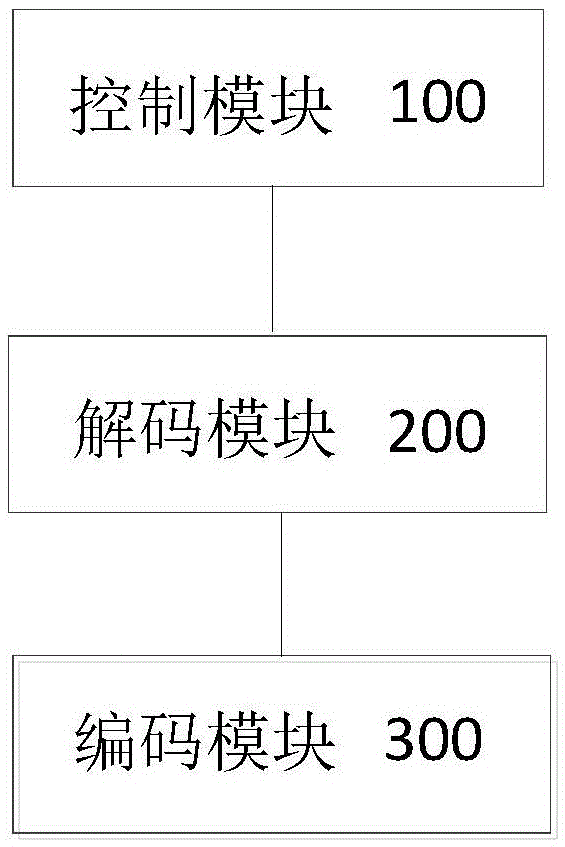

Rewound video generating method and device and play device

InactiveCN105898626AFully screenedClear pictureSelective content distributionComputer graphics (images)Video image

The invention discloses a rewound video generating method and device and a play device, and relates to the field of videos. The method comprises that frames of an original video are grouped according to key frames, and each frame and a non-key frame thereafter form one group; the video frame groups are decoded in inverted time sequence, the last group is decoded at first, and the first group is decoded at last; and video images of all the decoded frames are recoded, the last group of the original video is coded as the first group of a new video, the last but one group of the original video is coded as the second group of the new video, and the rest can be done in the same manner. The new video generated finally is a rewound video relative to the original video. The sequence of frame videos in each video frame group is kept unchanged. Thus, the generated rewound video is complete in frames, clear and coherent, and the realization method is rapid.

Owner:LETV INFORMATION TECH BEIJING

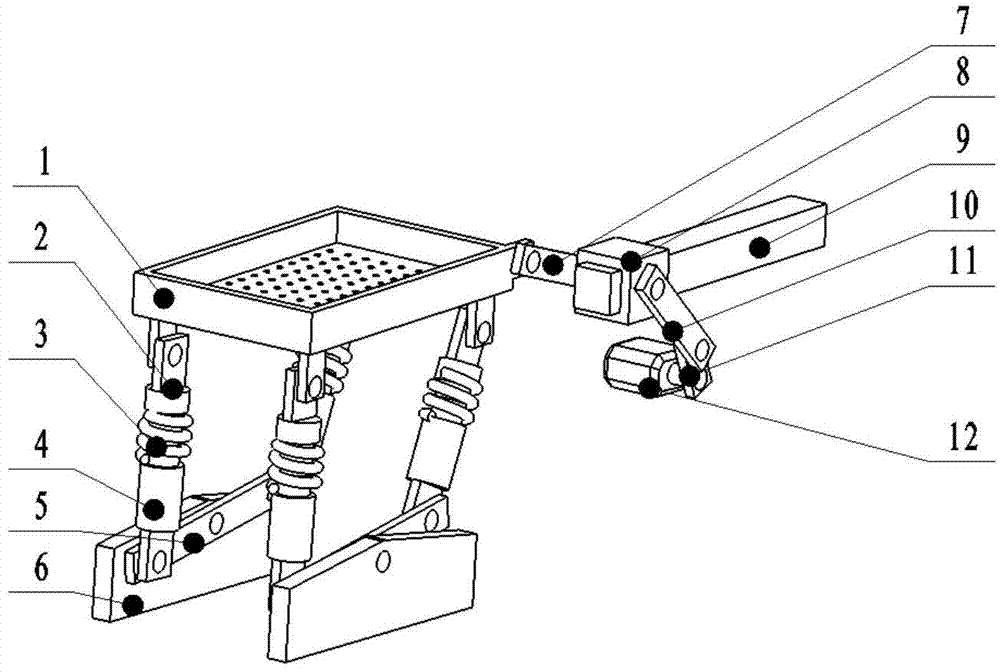

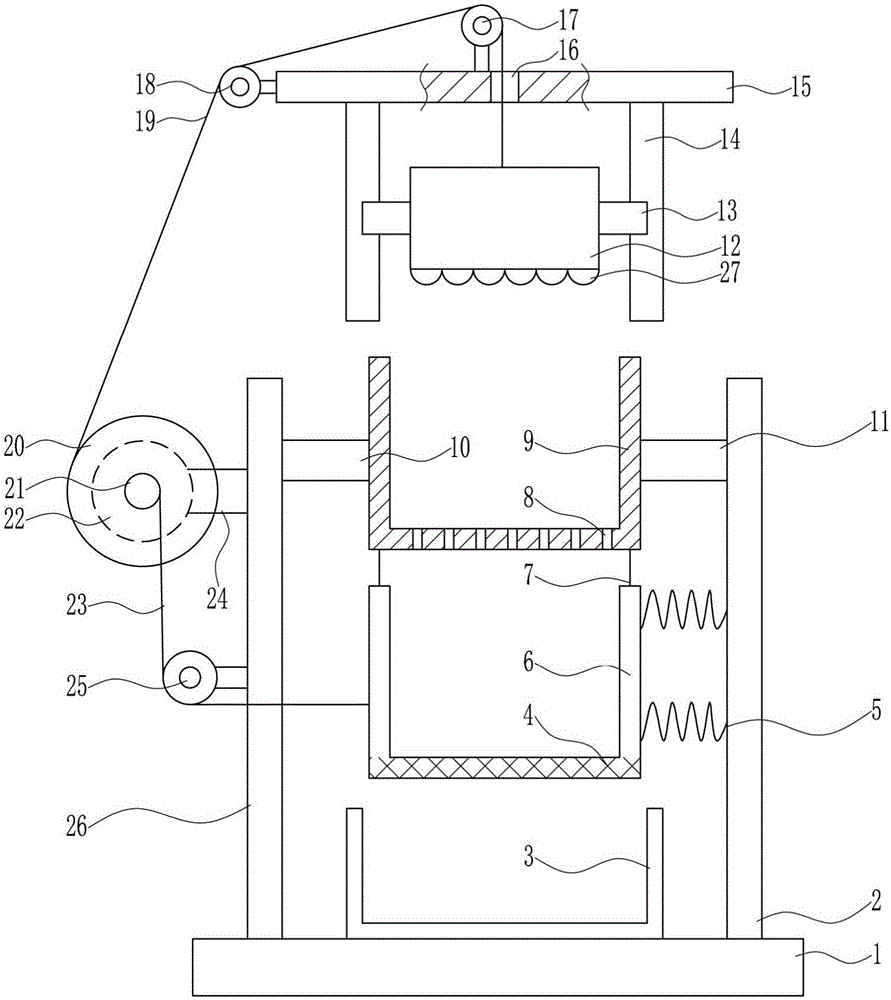

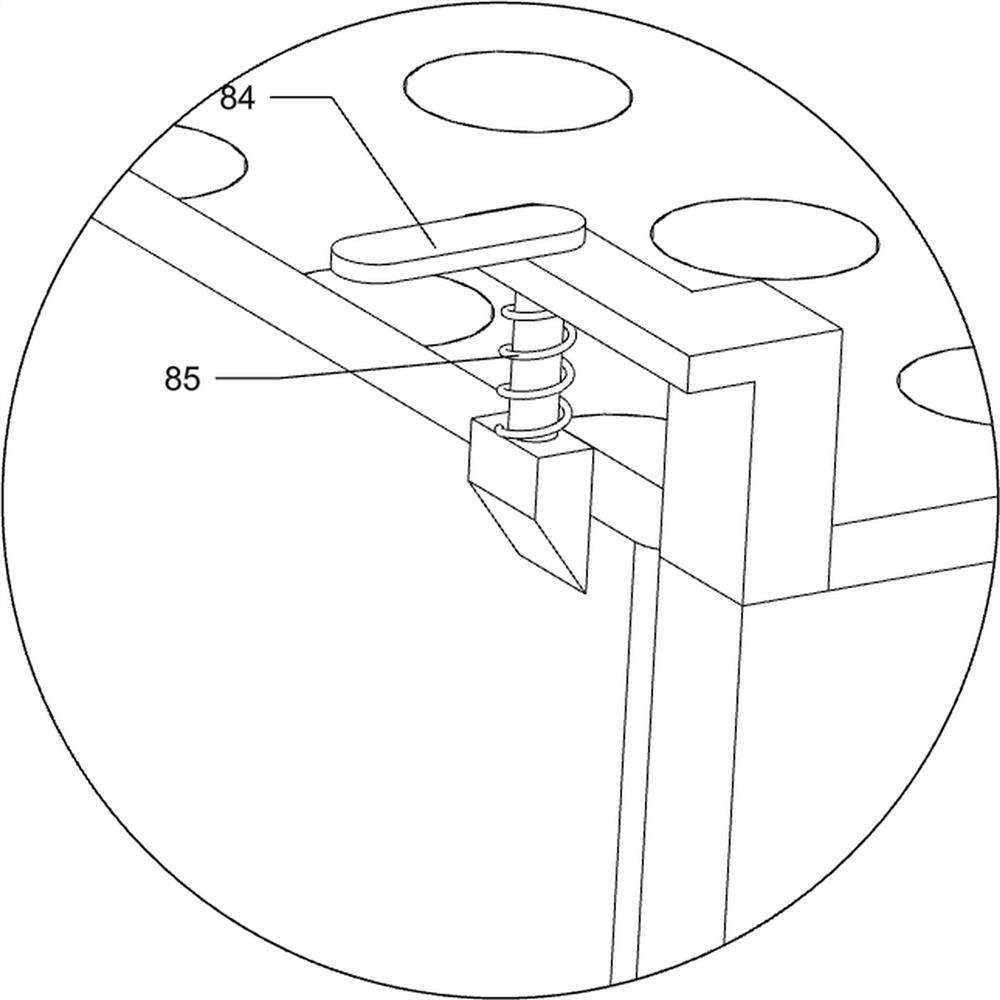

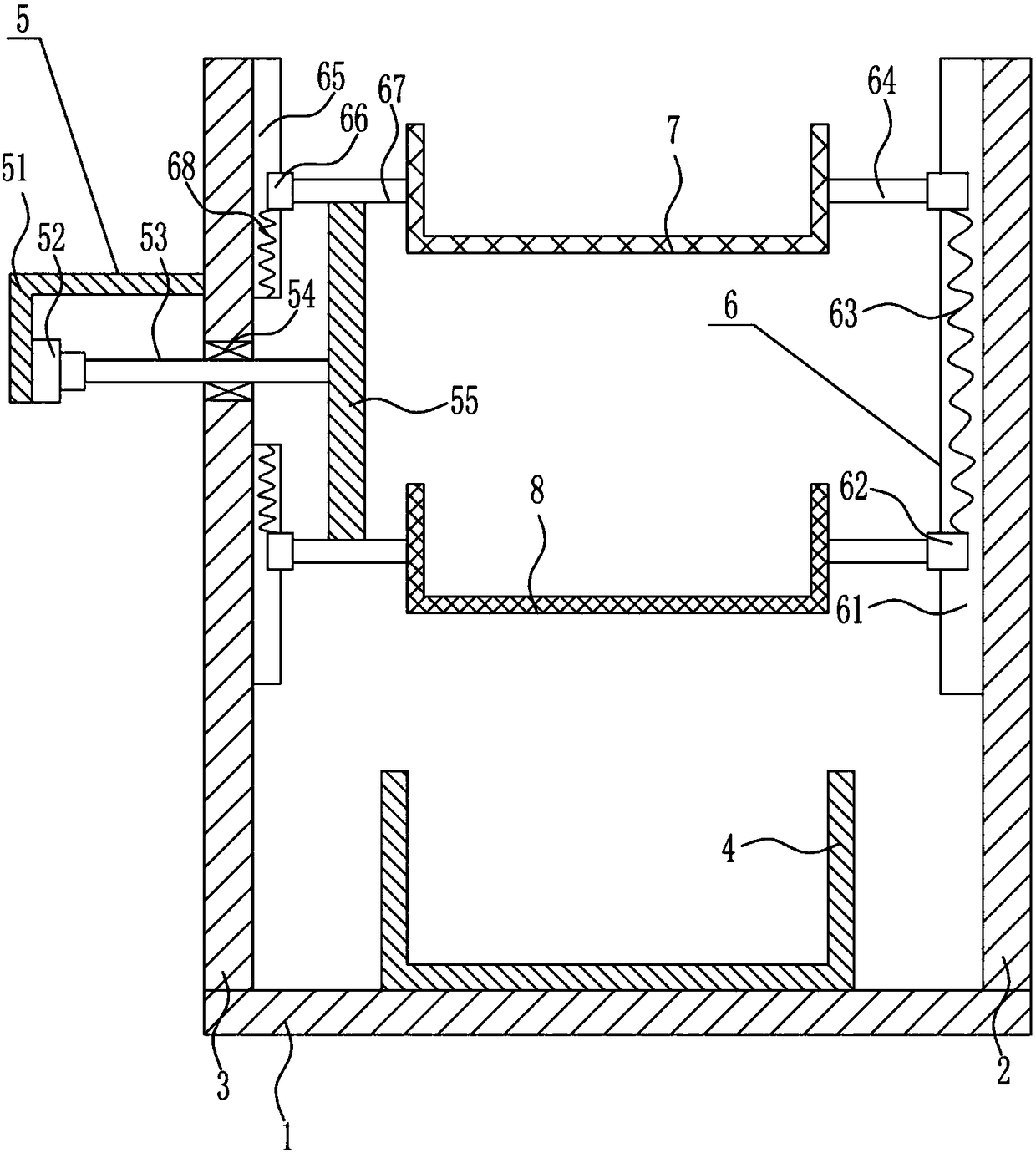

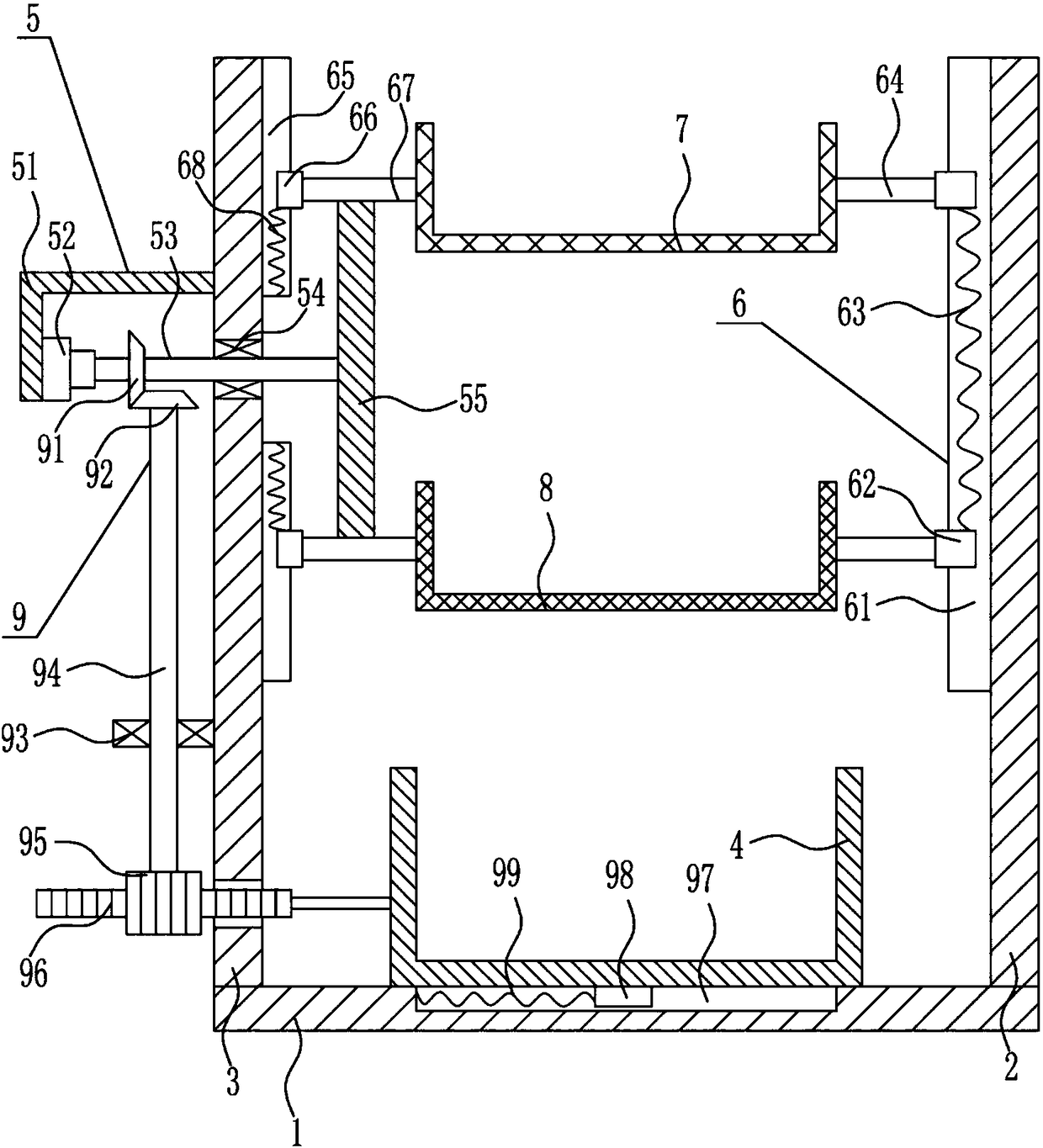

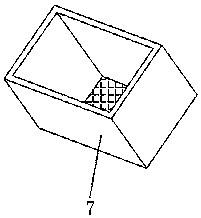

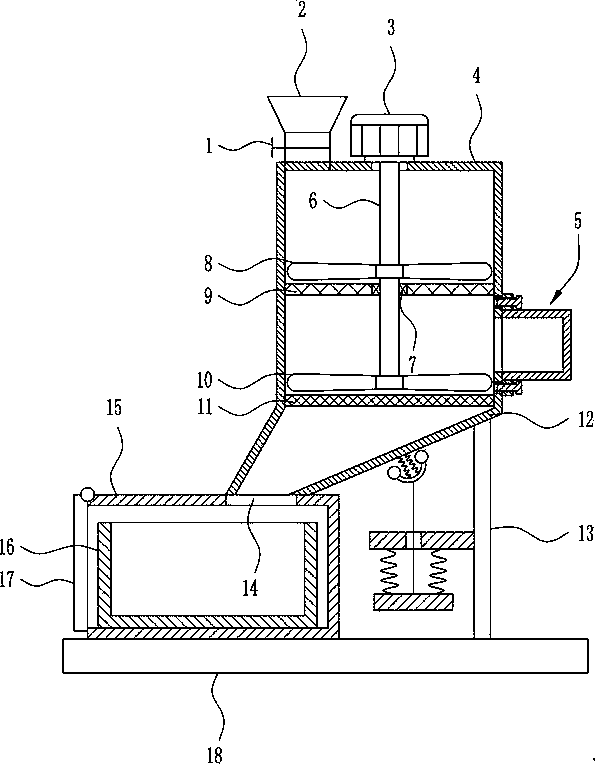

Elastic vibration sieving device

The invention discloses an elastic vibration sieving device, and belongs to the field of production equipment. The elastic vibration sieving device is composed of an alternating-current motor, crank rockers, a sliding block, a fixed guide rail, a carrying sieving platform, a swing rod, a fixing support, upper supporting frames, lower supporting frames and springs. The alternating-current motor is fixed onto the ground and is connected together with the corresponding crank rocker, the crank rocker is connected together with the sliding block through another crank rocker, the sliding block is installed on the fixed guide rail, the carrying sieving platform is connected with the sliding block through the corresponding crank rocker, the four upper supporting frames and the carrying sieving platform are hinged under the carrying sieving platform, the four lower supporting frames and the swing rod are hinged respectively above the fixing support, the swing rod is hinged to the fixing support, the four springs are connected between the four lower supporting frames and the four upper supporting frames, and the upper supporting frames, the lower supporting frames and the springs form a whole. The elastic vibration sieving device has the advantage that swing of the swing rod and vibration of the springs can be used for conducting complex movement to realize evener sieving.

Owner:XUZHOU LIFANG MECHANICAL & ELECTRICAL EQUIP MFG CO LTD

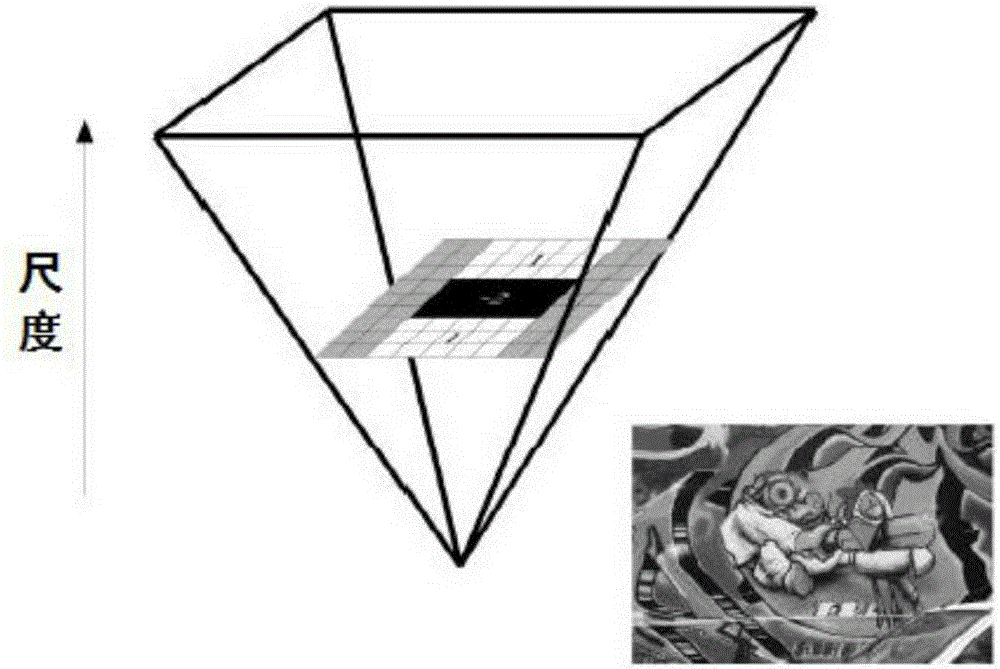

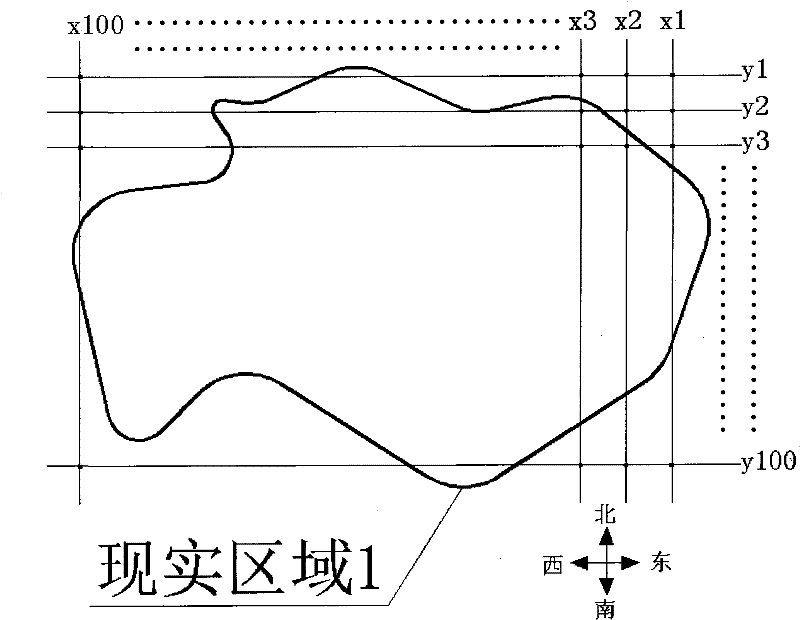

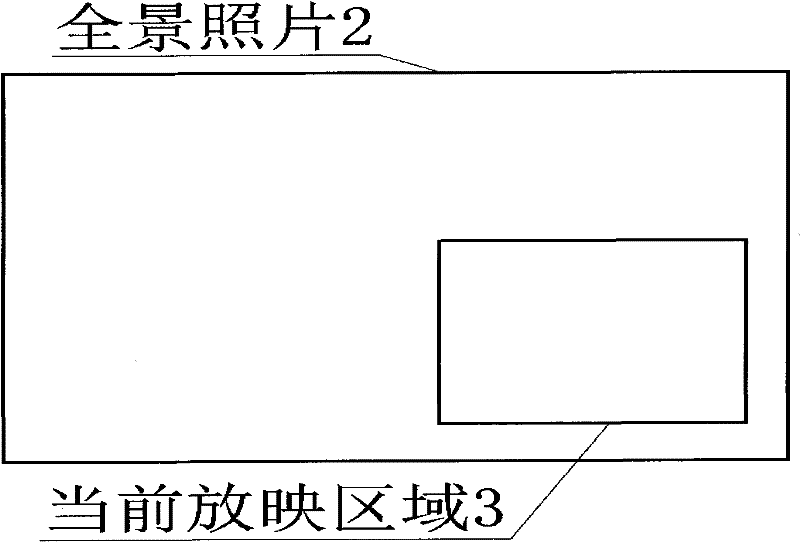

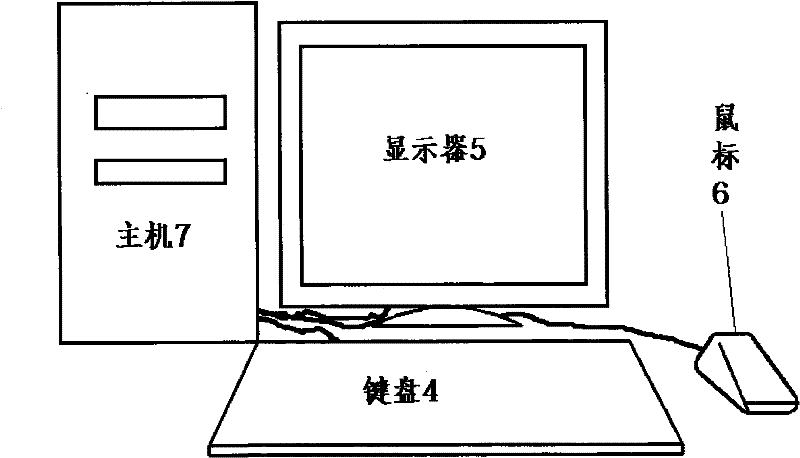

live-action virtual reality method

InactiveCN102262705ASmooth movementChange direction arbitrarilySpecial data processing applicationsComputer graphics (images)Multimedia system

The invention discloses a method for converting an actual scene into a virtual scene in a computer and reproducing it, in particular a method for enabling users to visit scenic spots through a multimedia system: take multiple panoramic photos in the real area, and convert the obtained All the panoramic photos are packaged to obtain the virtual scene data of the real area. When the user accesses the virtual scene data through the special browsing software, he will get a completely real and immersive feeling.

Owner:孟兵

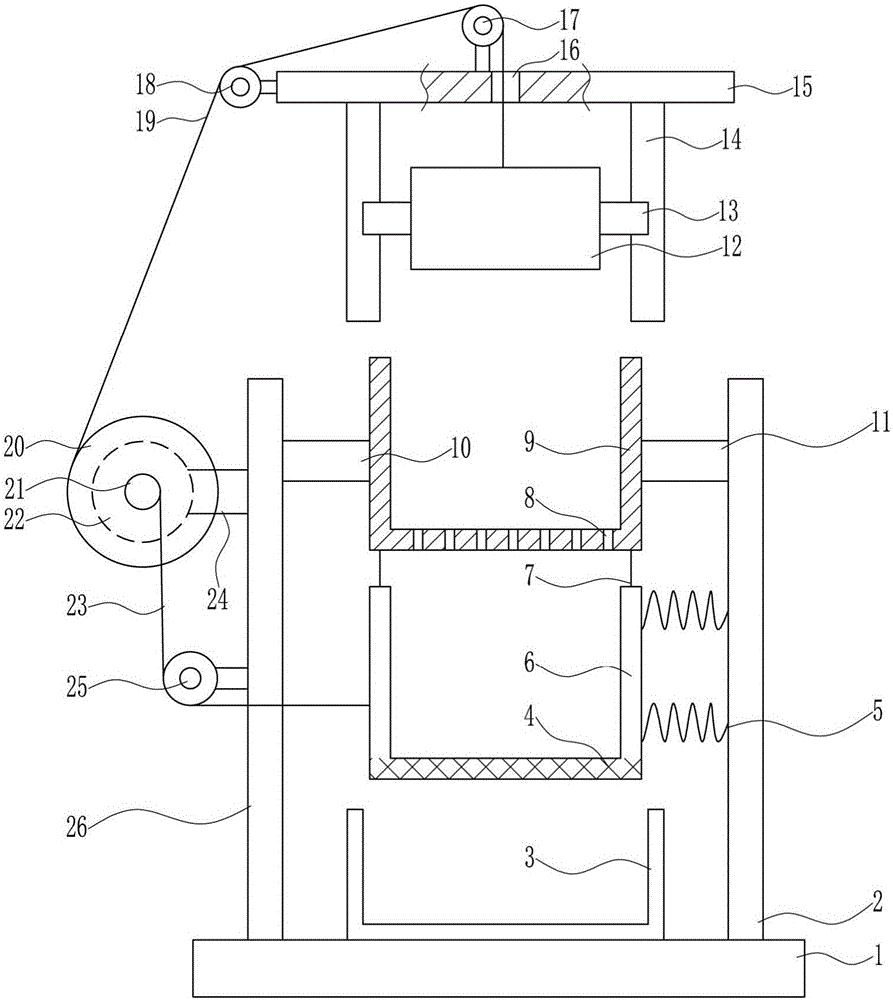

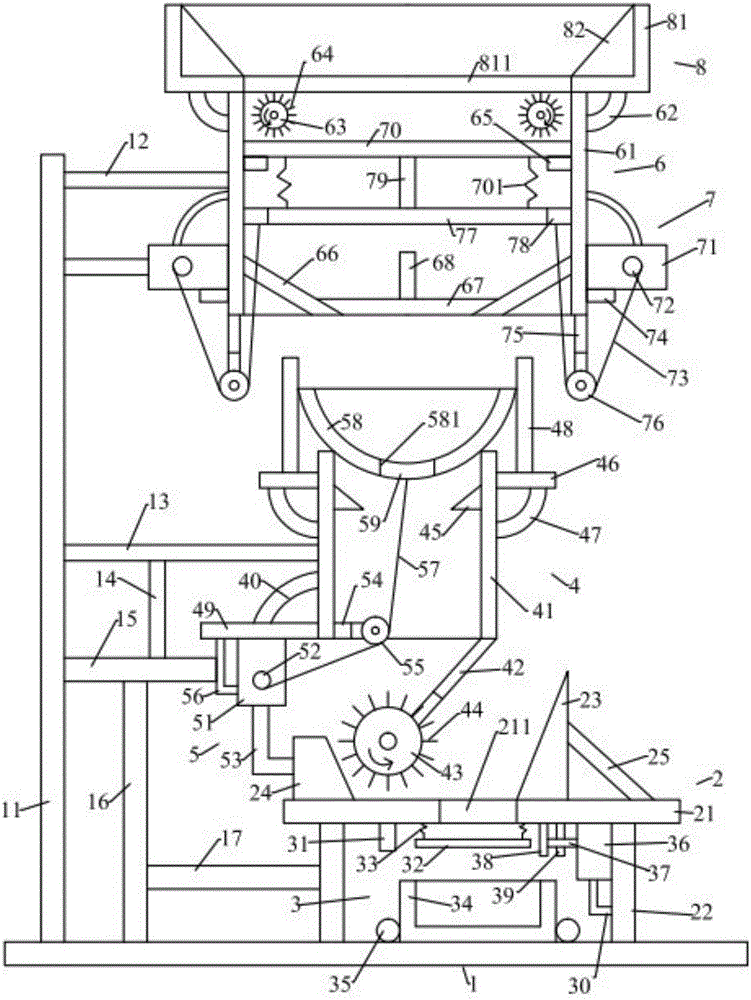

Caked sweet potato powder rolling-sieving device

ActiveCN106824367AEvenly screenedImprove screening efficiencyGrain treatmentsMaterials sciencePulley

The invention relates to a sweet potato powder rolling-sieving device, in particular to a caked sweet potato powder rolling-sieving device, which has the advantages of uniform sieving, high sieving efficiency and easiness in operation. In order to solve the technical problem, the caked sweet potato powder rolling-sieving device provided by the invention comprises a bottom plate, a right side plate, a screen, a spring, a sieving frame, a string, a rolling frame, a first support rod, a second support, a pressing block, a slide block, a slide rail, a top plate, a first pulley, a second pulley, a first stay wire, a large reel, a small reel, a motor, a second stay wire, a third support rod, a third pulley and a left side plate, wherein the left side plate and the right side plate are arranged on the left side and the right side of the bottom plate respectively; the left side plate is positioned on the left side of the right side plate; the left upper side face of the left side plate is provided with the third support rod. By adopting the caked sweet potato powder rolling-sieving device, the effects of uniform sieving, high sieving efficiency and easiness in operation are achieved.

Owner:湖南省绿萱农业科技有限公司

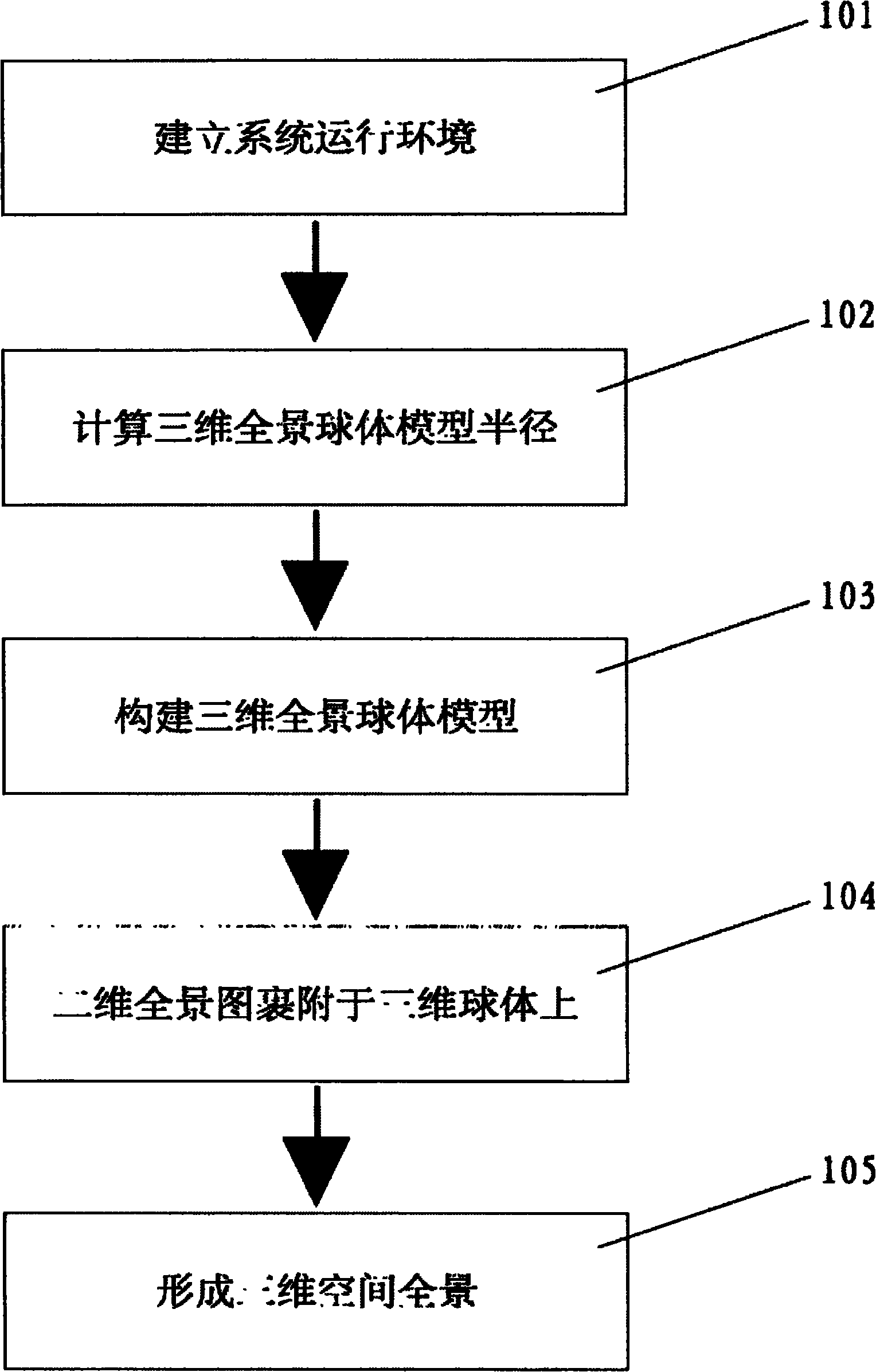

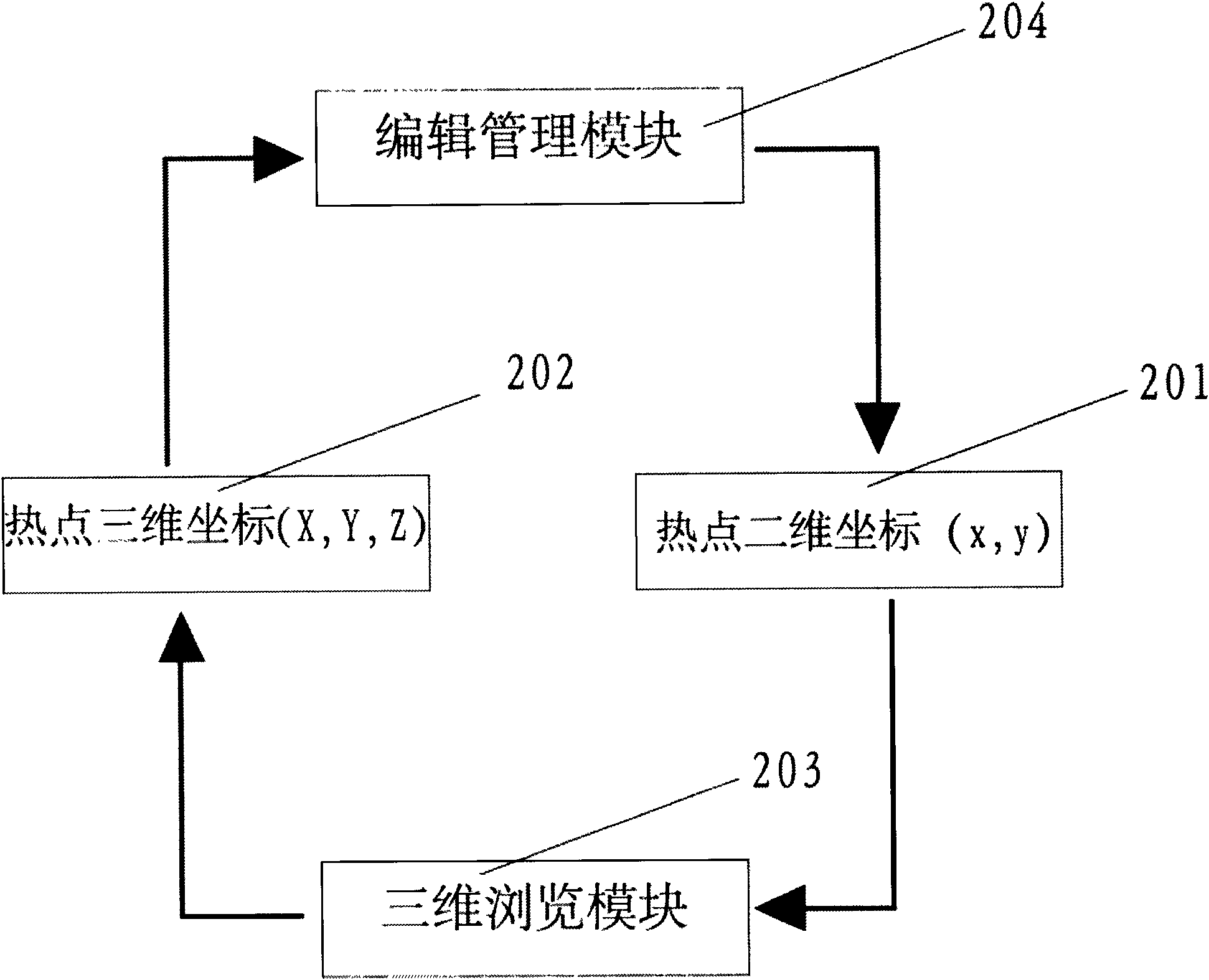

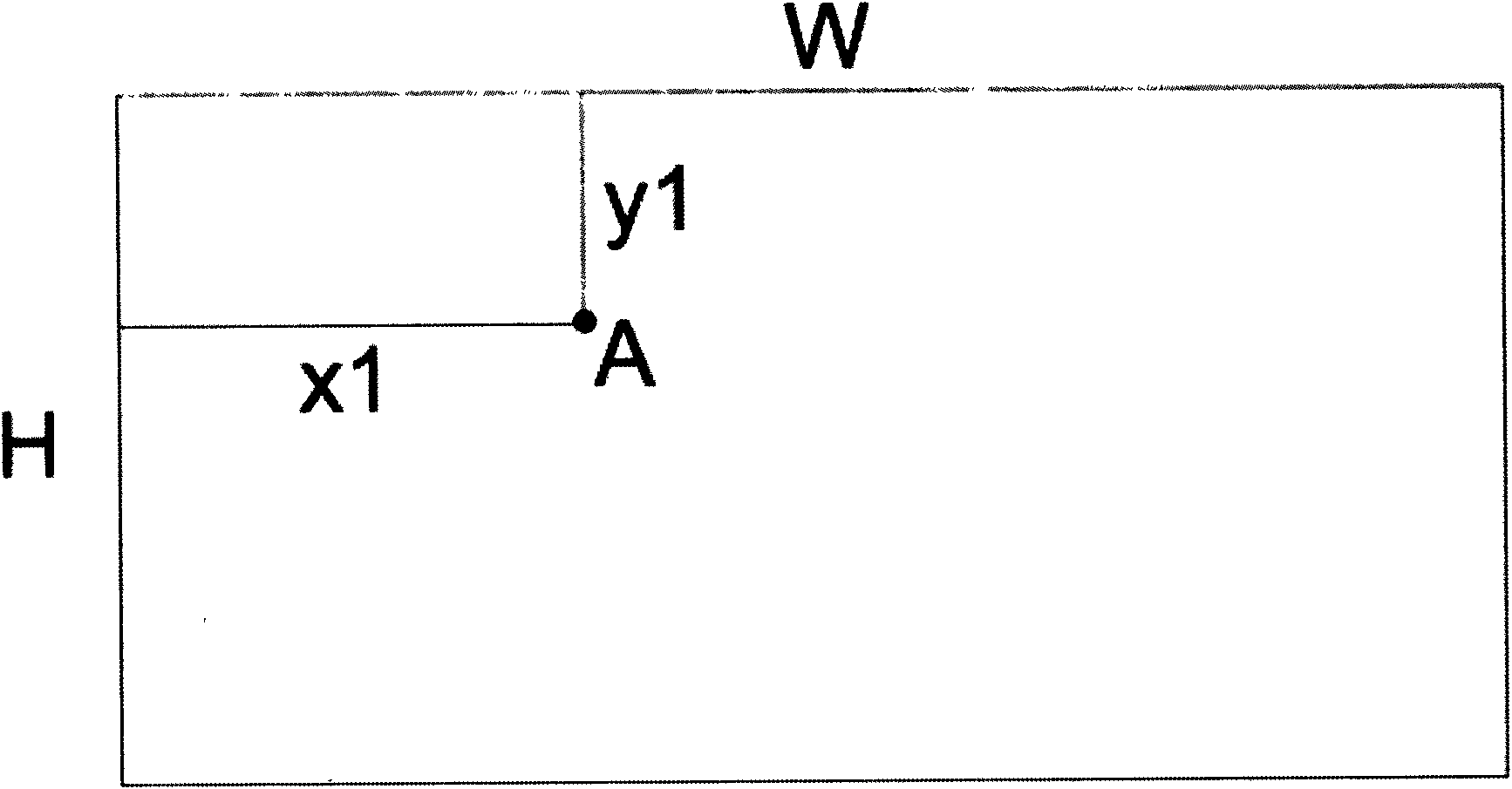

Method and system for browsing panorama by hot spot in three-dimensional panoramic space

The invention belongs to a three-dimensional panoramic technology, and provides a method for browsing a panorama by a hot spot in three-dimensional panoramic space. The method comprises the following steps of: 101, establishing a system operation environment; 102, computing the radius of a three-dimensional panoramic spherical model; 103, establishing the three-dimensional panoramic spherical model; 104, wrapping a two-dimensional panorama on a three-dimensional sphere; and 105, forming the three-dimensional panorama. The invention also provides a three-dimensional panorama browsing system. The system comprises a three-dimensional panorama browsing module and an editing management module. The method and the system show the three-dimensional panorama, have real and smooth picture frames, and can be widely used for the three-dimensional panorama show of any scene.

Owner:上海诚明融鑫科技有限公司

Foundation stone screening equipment for road

ActiveCN112191509AEvenly screenedImprove screening efficiencySievingScreeningArchitectural engineeringStructural engineering

Owner:SHANXI YUANFANG ROAD & BRIDGE GROUP +1

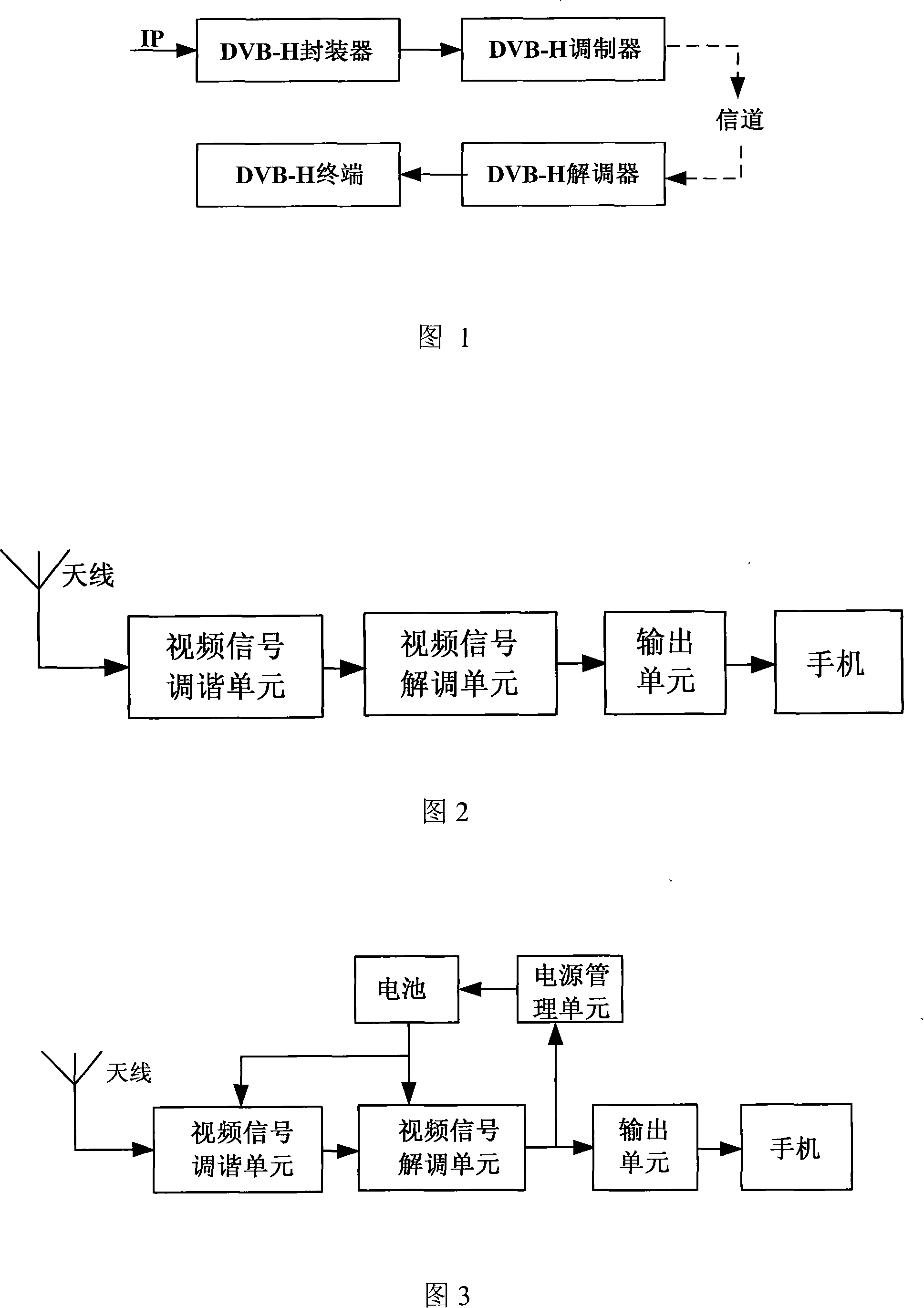

A portable DVB-H based external TV signal receiving device

InactiveCN101150675AEasy to shareAchieve sharingTelevision system detailsTelephonic communicationComputer hardwareDigital television

The invention discloses a portable receiver of external TV signals based on DVB-H, comprising an antenna, a video signal tuned unit, a video signal demodulation unit and an output unit which are connected in order; the video signal tuned unit tunes DVB-H digital TV signals received by the antenna and transmits the signals to the video signal demodulation unit; the video signal demodulation unit demodulates received tuned signals processed by the video signal tuned unit and compacts into video streams; the output unit is used for outputting the video streams to an external portable terminal. The invention does not need any structure changes of prior portable terminals such as mobile phones, only needs a play software to be installed, then is connected with the output unit of the external TV signal portable terminal based on DVB-H, mobile phone digital TV programs provided by traders can be received.

Owner:ZTE CORP

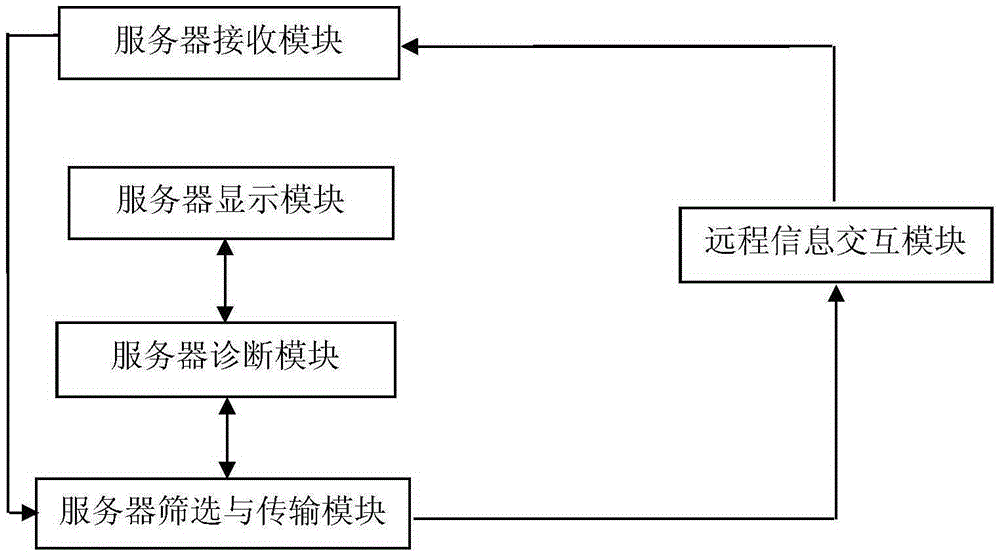

Distributed medical diagnosis system

ActiveCN105404788AEfficient remote medical imaging diagnosis serviceImprove transmission efficiencyTelemedicineSpecial data processing applicationsRemote controlMedical diagnosis

The invention provides a distributed medical diagnosis system to optimize video data transmission speed of mobile terminals such as cell-phones and to improve medical diagnosis efficiency. The distributed medical diagnosis system comprises a server receiving module, a server diagnosis module, a server screening and transmission module and a server displaying module as well as a remote control information interaction module. By the use of the distributed medical diagnosis system, a remote patient can acquire remote medical image diagnosis server with high efficiency through carrying an intelligent mobile terminal (including but not limited to intelligent cell-phones and tablet PCs) and medical workers can stay at a mobile work states; and medical workers can also utilize intelligent mobile terminals to provide remote medical diagnosis service. Besides, smooth images can be achieved without the sacrifice of resolution and image effects during the use of the intelligent mobile terminal, such as the cell-phone, so image transmission efficiency can be improved.

Owner:XUZHOU YONGKANG ELECTRONICS SCI & TECH CO LTD

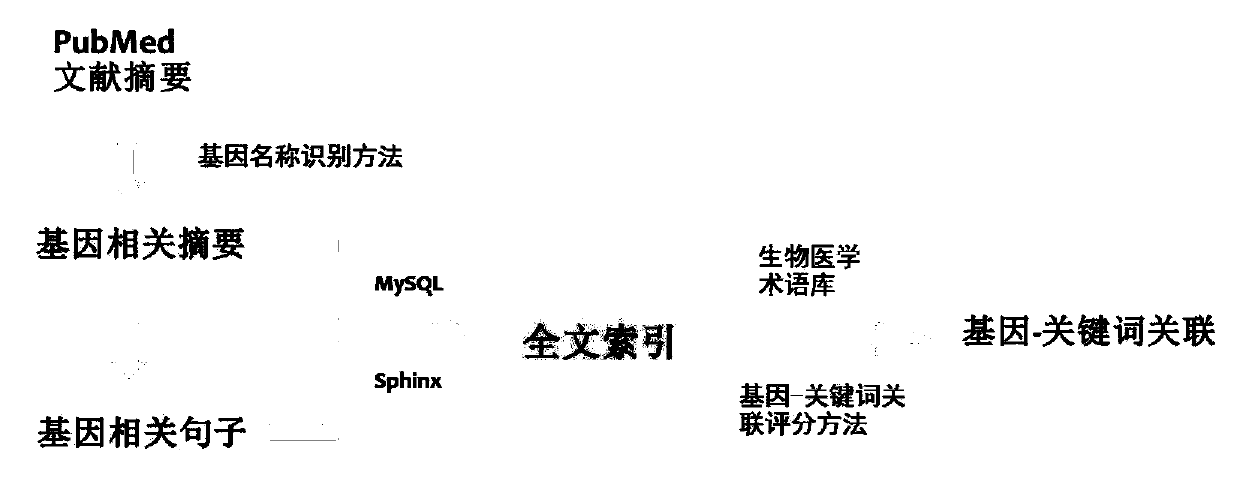

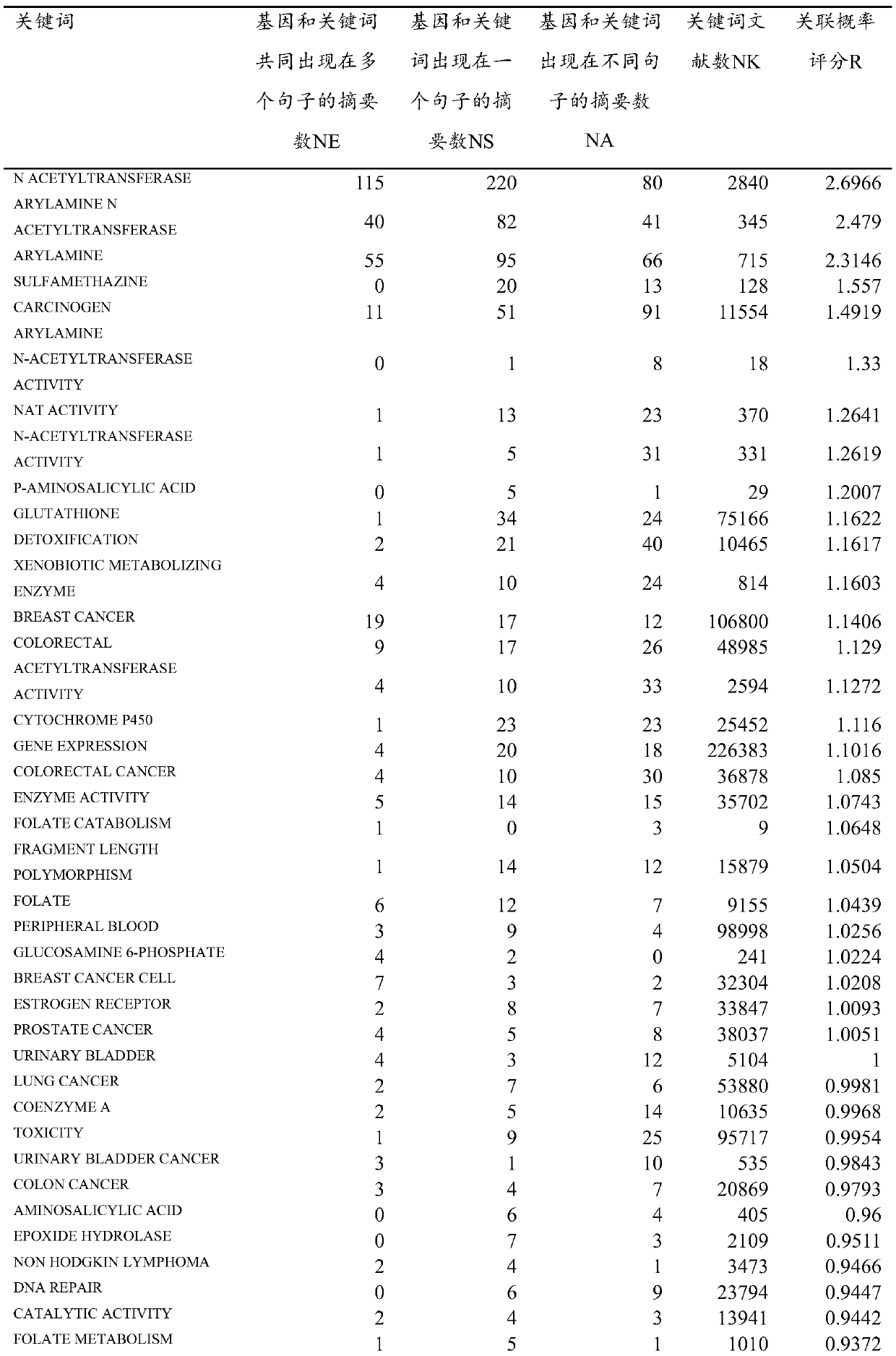

Method for screening gene keywords from PubMed literatures

ActiveCN110349632AEvenly screenedStrong associationBiostatisticsProteomicsVersus geneComputer science

The invention discloses a method for screening gene keywords from PubMed literatures. The invention provides the method for screening gene keywords from a literature database. The method comprises thefollowing steps: identifying gene-related abstracts or / and gene-related sentences from abstracts of the literature database, establishing full-text indexes of gene-related literatures, screening keywords from a term library, obtaining association probability scores of the genes and the keywords through a gene-keyword association score calculation formula, and screening out the keywords closely related to the genes. According to the construction method, on the one hand, a predefined term vocabulary library is broadened, and the terms of other authoritative databases are integrated except for GO terms; on the other hand, a new keyword screening method is introduced for scoring the probability that genes and terms are associated, and the firmer gene-keyword association is screened accordingto the integration of the frequencies that the genes and keywords co-occur in abstracts and sentences.

Owner:SOUTHERN MEDICAL UNIVERSITY +1

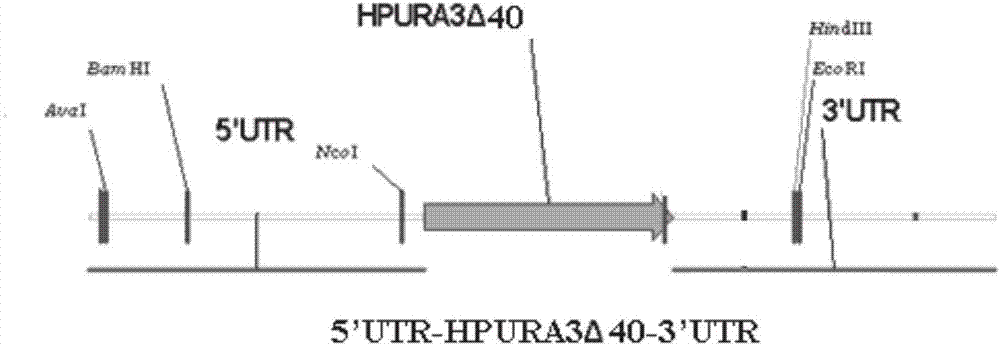

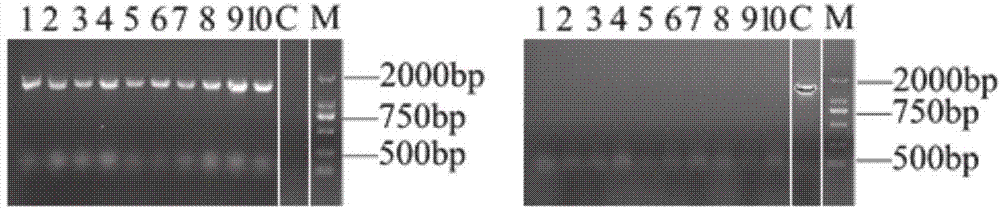

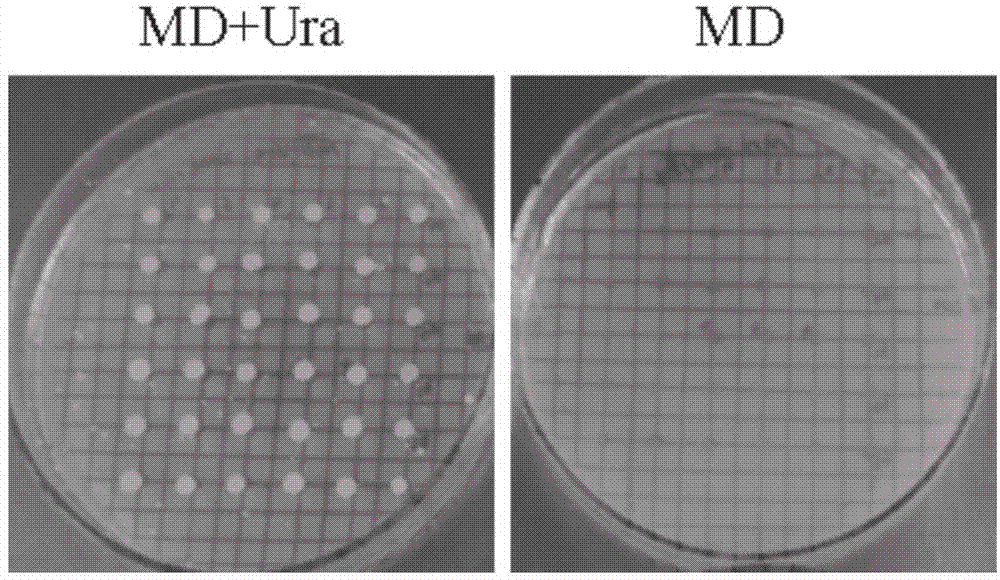

Hansenula polymorpha mutant and application of expression vector of hansenula polymorpha mutant to recombinant protein expression

ActiveCN104745492AMechanism is clearGenetic stabilityFungiVirus peptidesHepatitis B Surface AntigensMutant strain

The invention discloses a hansenula polymorpha mutant and application of an expression vector of the hansenula polymorpha mutant to recombinant protein expression, and aims to provide a genetically stable hansenula polymorpha mutant and application of an exclusive expression vector of the genetically stable hansenula polymorpha mutant to recombinant protein expression. The hansenula polymorpha provided by the invention is a mutant stable strain in which the expression of orotidine-5-phosphate decarboxylase gene (UPA3) is blocked. The exclusive expression vector contains a hansenula polymorpha autonomously replicating sequence and a plurality of selection markers, so that the exclusive expression vector can be stably integrated into the strain at a high copy number. The mutant strain and the expression vector can efficiently express a hepatitis B surface antigen, can be correctly assembled into VLP (Virus Like Particles), are simple in process, are very suitable for industrial production of expression proteins, and have great practical application values.

Owner:JIANGSU THERAVAC BIO PHARMA

Recording medium, playback apparatus, recording method, program, and playback method

ActiveUS8068723B2Evenly screenedAvoid playingTelevision system detailsElectronic editing digitised analogue information signalsComputer graphics (images)Recording media

On a BD-ROM, an AVClip and a plurality of playback section information (PlayItems) are recorded. The AVClip includes a video stream multiplexed with a plurality of elementary streams. The playback section information Playable_PID_entries showing the playback start point and the playback end point in the video stream correlated with the filtering specification of each elementary stream. The filtering specification specifies whether each of the plurality of elementary streams are able to be played back or not.

Owner:PANASONIC CORP

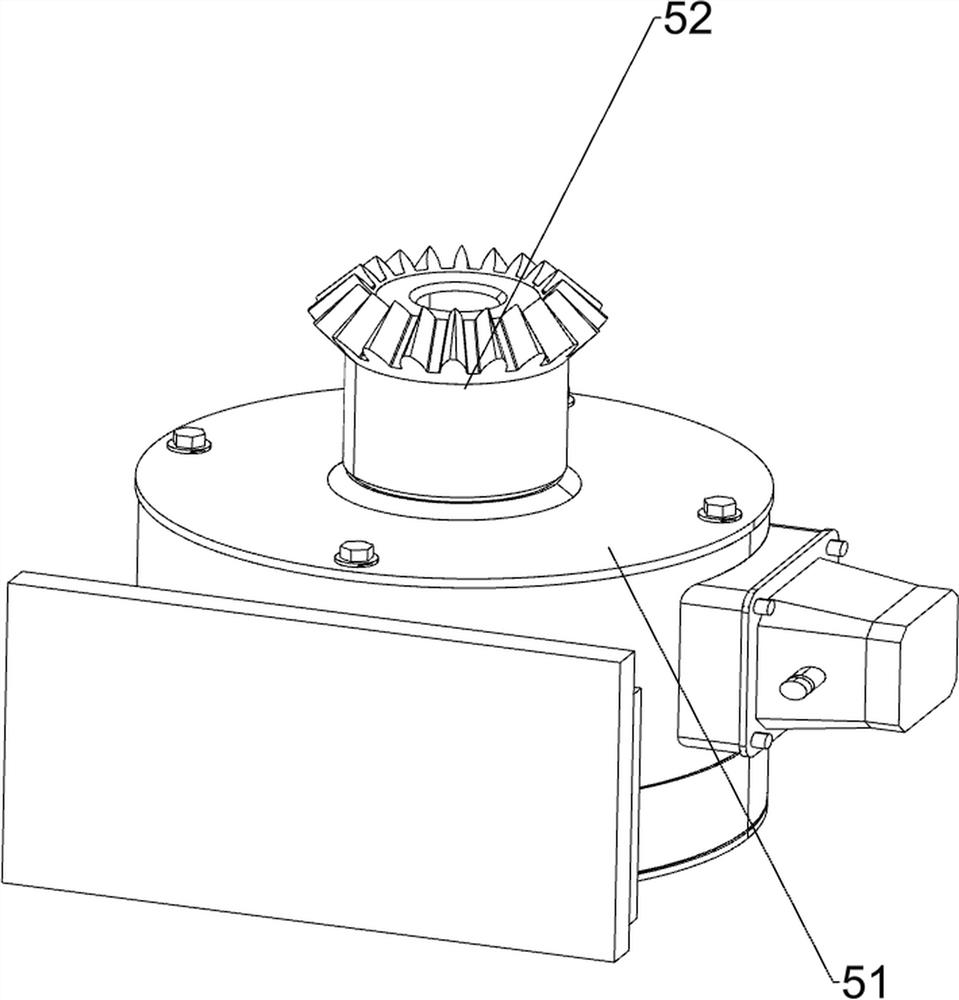

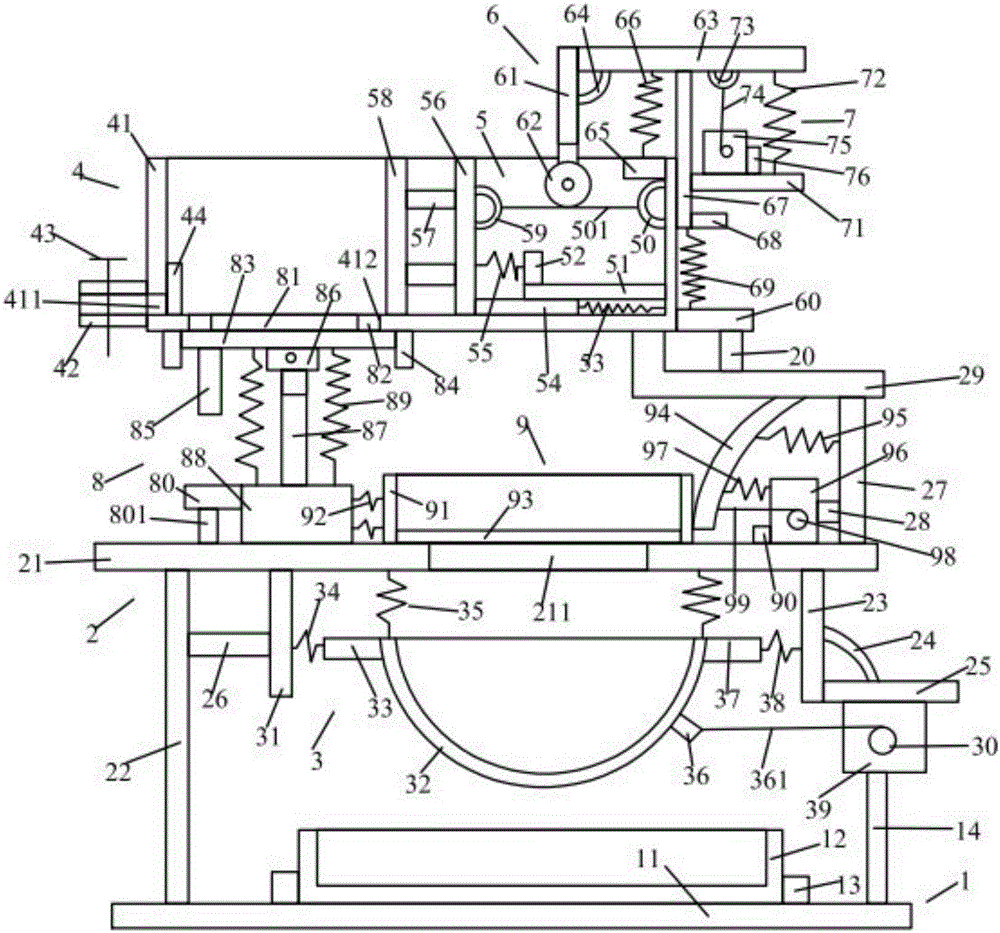

Secondary screening equipment for producing petroleum asphalt

The invention relates to screening equipment, in particular to secondary screening equipment for producing petroleum asphalt. The secondary screening equipment is high in screening efficiency, relatively uniform in screening and capable of achieving comprehensive collection during screening. The secondary screening equipment for producing the petroleum asphalt comprises a bottom plate, a left support, a right support, a collection box, a shaking mechanism, a moving mechanism and the like. The left support is arranged on the left side of the top of the bottom plate, the right support is arranged on the right side of the top of the bottom plate, the shaking mechanism is arranged on the upper portion of the left support, and the moving mechanism is arranged on the right side of the left support and the left side of the right support. A first filter net is connected to the upper portion of the moving mechanism. According to the secondary screening equipment, the shaking mechanism is used as the main power source to drive the moving mechanism to move up and down, so that the first filter net and a second filter net are driven to move up and down, the petroleum asphalt is prevented frombeing accumulated on the first filter net and the second filter net, the screening speed is increased, and the effect of the high screening efficiency is achieved.

Owner:浙江景天园林工程有限公司

Efficient powder screening device for chemical raw materials

InactiveCN106733653AImprove work efficiencyFully screenedSievingGas current separationBristleCompound (substance)

The invention discloses an efficient powder screening device for chemical raw materials. The efficient powder screening device comprises a bottom plate, a supporting plate device, a recycling device, a first frame body device, a first filtering device, a second frame body device, a second filtering device and a feeding device. A first supporting rod, a first transverse rod, a second transverse rod, a third transverse rod, a first vertical rod, a fourth transverse rod, a second vertical rod and a fifth transverse rod are arranged on the bottom plate. The supporting plate device comprises a supporting plate, a second supporting rod, a first concentration block, a second concentration block and a first oblique rod. The recycling device comprises a first limiting rod, a first filtering net, a first spring, a recycling box, a positioning block, a first push plate, a first push rod, a first positioning rod, an electric cylinder and a first support. The first frame body device comprises a first frame body, a first fixing rod, a first wheel, first bristles, a first limiting block, a second fixing rod, a first bending rod, a first vertical plate, a third fixing rod and a second bending rod. The efficient powder screening device can be used for sufficiently screening chemical powder.

Owner:泉州台商投资区尚良建筑装饰有限公司

Calling method and device for orientation sensors of handheld mobile equipment

InactiveCN103324530AImprove experienceEffective fitProgram initiation/switchingCompassesUser needsSensing data

The invention relates to the technical field of handheld mobile devices, in particular to a calling method for orientation sensors of handheld mobile equipment. According to the method, when applications requiring calling of the orientation sensors are first-type applications, gyroscopes are turned off, orientation information, instead of angular motion information, is obtained, and only basic direction indication requirements are met, so that the reaction speed of the equipment is improved, and direction indication effects can be rapidly obtained by the first-type applications. When the applications calling the orientation sensors are not the first-type applications, the gyroscopes are not turned off, and the angular motion information of the gyroscopes is obtained, so that screen effects during rotation of the equipment are improved according to the angular motion information of the gyroscopes, and screens are smooth. Accordingly, different calling methods are used for different gyroscope sensors on account of different applications, relevant sensing data can be obtained by each application according to characteristics of the application, operation effects of the applications are in accordance with user requests, and the user experience is effectively improved.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Chinese herb cleaning and screening equipment in mechanical field

ActiveCN106733880AImprove processing efficiencySpeed up the flowSievingScreeningMechanical fieldChinese herbology

The invention provides Chinese herb cleaning and screening equipment in the mechanical field. The Chinese herb cleaning and screening equipment comprises a bottom plate, a supporting plate device located on the base plate device, a first filtering device located below the supporting plate device, a frame body device located above the supporting plate device, a pushing device located in the frame body device, a lifting device located above the pushing device, a motor device located on the right side of the frame body device, a baffle device arranged on the supporting plate device, and a second filtering device located on the right side of the baffle device. The Chinese herb cleaning and screening equipment can effectively screen Chinese herbs and is high in screening efficiency; meanwhile, flowing of water can be promoted, water is promoted to sufficiently make contact with Chinese herbs, and thus the cleaning effect is ideal; and by promoting vibration of a filter screen, blockage is prevented, screening can be conducted smoothly, and Chinese herb processing efficiency is improved.

Owner:ANHUI CHINA RESOURCES JINCHAN PHARMA CO LTD

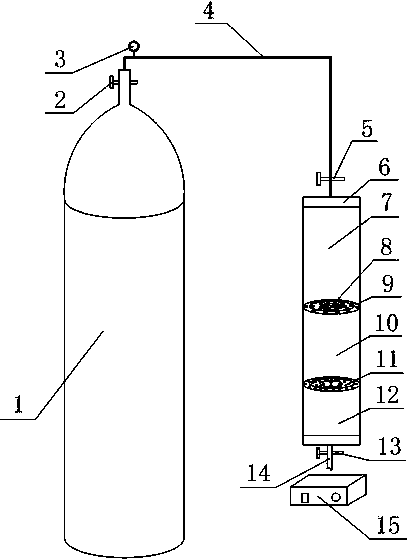

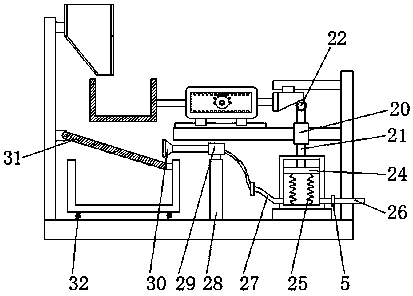

Screening equipment for promoting output of color zone of white-light LED lamp bead and screening method thereof

InactiveCN103433218AStabilize the internal situationGuaranteed puritySievingGas current separationFluorescenceAdhesive

The invention discloses a set of screening equipment for promoting the output of the color zone of white-light LED lamp beads and a screening method of the screening equipment. A plurality of layers of filtering membranes are arranged in the screening equipment, and filtering through holes are formed in all the filtering membranes. The screening equipment is connected with a steel cylinder and a magnetic stirrer, the two filtering membranes with different hole diameters are installed in the screening equipment to form three filtering cavities, and the hole diameter of the upper filtering membrane is larger than the hole diameter of the lower filtering membrane. Fluorescent adhesive having been stirred is added into the first-stage filtering cavity to connect the screening equipment and the steel cylinder in a sealing mode. The magnetic stirrer is started to perform stirring; a first valve, a second valve and a third valve are opened in sequence; when the fluorescent adhesive in the third filtering cavity is stable and does not change, the third valve, the second valve and the first valve are closed in sequence; the fluorescent adhesive in the filtering cavities is taken out in sequence, and then the fluorescent adhesive different in grain diameter and uniform in grain diameter is obtained. According to the equipment and the method, the fluorescent adhesive is screened through air flow, the fluorescent adhesive obtained through the screening is respectively used for manufacturing the LED lamp beads, and thus the output of the color zone of the LED lamp beads can be promoted.

Owner:四川英创力电子科技股份有限公司

Display panel and display device

ActiveCN103995374AEvenly screenedReduce manufacturing costStatic indicating devicesNon-linear opticsScan lineDisplay device

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

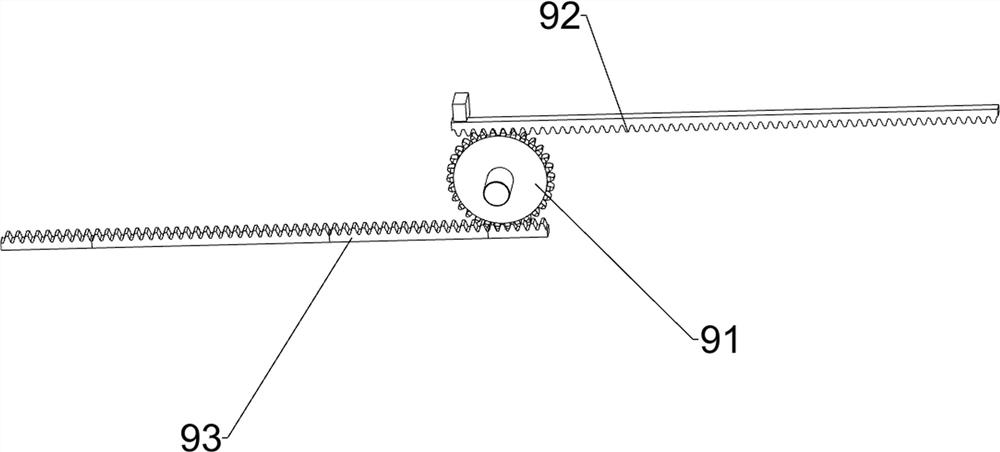

Building sand screening and cleaning device

InactiveCN110102473AEvenly screenedQuick filterSievingGas current separationGear wheelWater storage tank

The invention discloses a building sand screening and cleaning device. The building sand screening and cleaning device comprises a bottom plate, wherein a left support and a right support are separately arranged on two sides of the top of the bottom plate; a water storage tank is arranged on one side of the right support; a feed hopper is fixed at an end of the left support; a screening frame is arranged below the feed hopper; a collection frame is arranged below the screening frame; a horizontal supporting plate is fixed on the top of one side of the right support; a rack frame is arranged above the supporting plate; a driving motor is arranged on the inner side of the rack frame; an incomplete gear is fixedly connected to an output shaft of the driving motor in a sleeving manner; the incomplete gear is connected with the rack frame in an engaged manner; a first sliding track is arranged on the top of the end, which is close to the screening frame, of the supporting plate; a first sliding block which is in sliding connection with the first sliding track is fixed on the bottom of the rack frame; a first connecting rod is fixed on the outer wall of the side, which is close to the screening frame, of the rack frame; and the other end of the first connecting rod is fixedly connected with the screening frame. The building sand screening and cleaning device is convenient and rapid to use, high in screening speed, uniform in screening, thorough in screening and good in cleaning effect.

Owner:卢若望

Coal mine smashing and screening equipment

The invention relates to screening equipment, in particular to coal mine smashing and screening equipment. The coal mine smashing and screening equipment which can uniformly screen coal mine powder and can be conveniently operated by workers is provided by the invention. The coal mine smashing and screening equipment comprises a feeding valve, a feeding hopper, a motor, a screening frame, a detachable blowing mechanism, a rotary shaft, a bearing seat, a thick powder crushing rod, a thick powder filtering net, a thin powder crushing rod, a thin powder filtering net, a discharging hopper, a supporting rod, a recycling frame, a collecting frame, a cover plate and a mounting plate, wherein the recycling frame is fixedly connected to one side of the top of the mounting plate; the cover plate ishinged to one side of the recycling frame; a discharging hole is formed in the top of the recycling frame; and the collecting frame is put inside the recycling frame. By means of the coal mine smashing and screening equipment, the effects that the coal mine powder is uniformly screened, and operation is convenient for the workers are achieved.

Owner:惠州市兴邦新材料科技有限公司

Preparation method for asphalt concrete

ActiveCN112275610AReduced need for uniform sizeEvenly screenedSievingScreeningCrushed stoneMechanical engineering

The invention discloses a preparation method for asphalt concrete. The preparation method comprises the following steps of I, adding heated asphalt into a shell, and controlling a rotating shaft to drive a stirring rod located in the shell to stir asphalt; II, putting gravel blocks into a screen mechanism and controlling a push plate to move leftward to push the gravel blocks to a screen, whereinthe push rod moves leftward to connect a belt wheel assembly connected to the screen mechanism to the rotating shaft; III, controlling an electric push rod to extend out continuously, wherein the electric push rod drives the push plate to push large stones plugged on the screen leftward, and the large stones are crushed by a rotating stone crushing knife and further fall into asphalt through the screen; IV, controlling, by the push rod, the screen mechanism to stop rotating when the gravel blocks are fully screened; and V, continuously controlling the stirring rod to stir asphalt mixed with the gravel blocks for five minutes to prepare the asphalt concrete. The preparation method for asphalt concrete is not only simple to operate, but also can prepare asphalt concrete quickly.

Owner:无锡翔云道桥科技有限公司

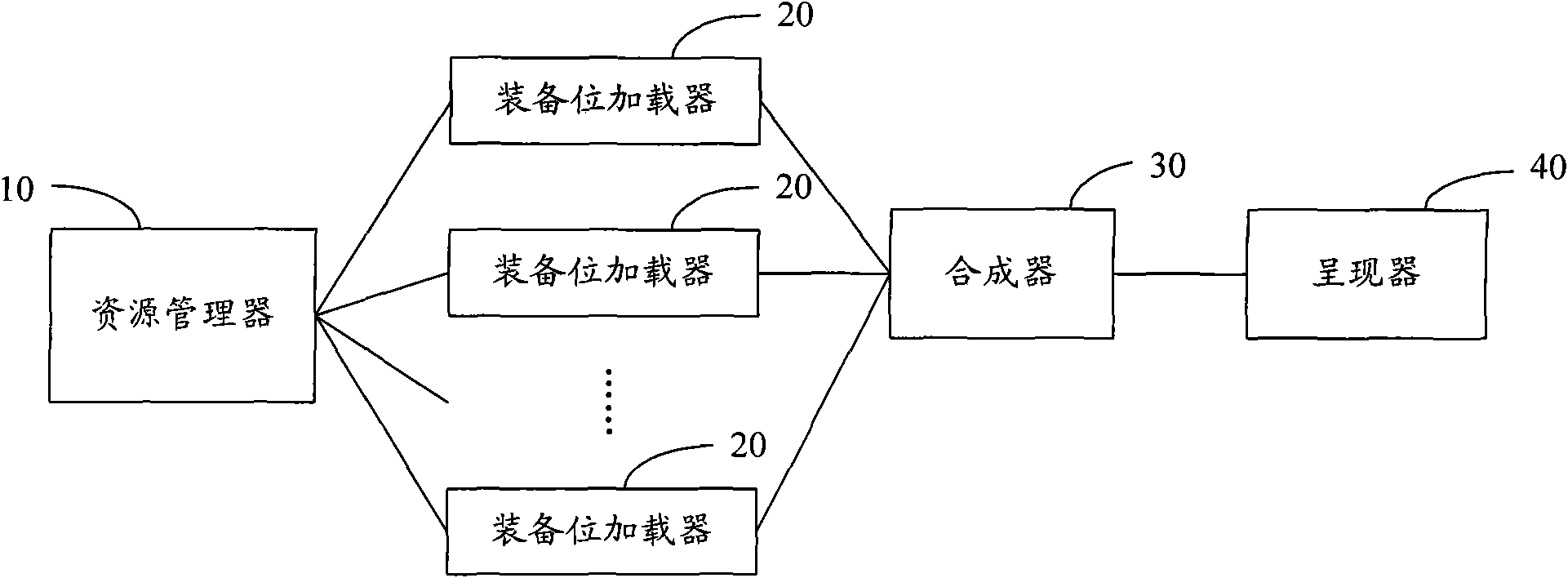

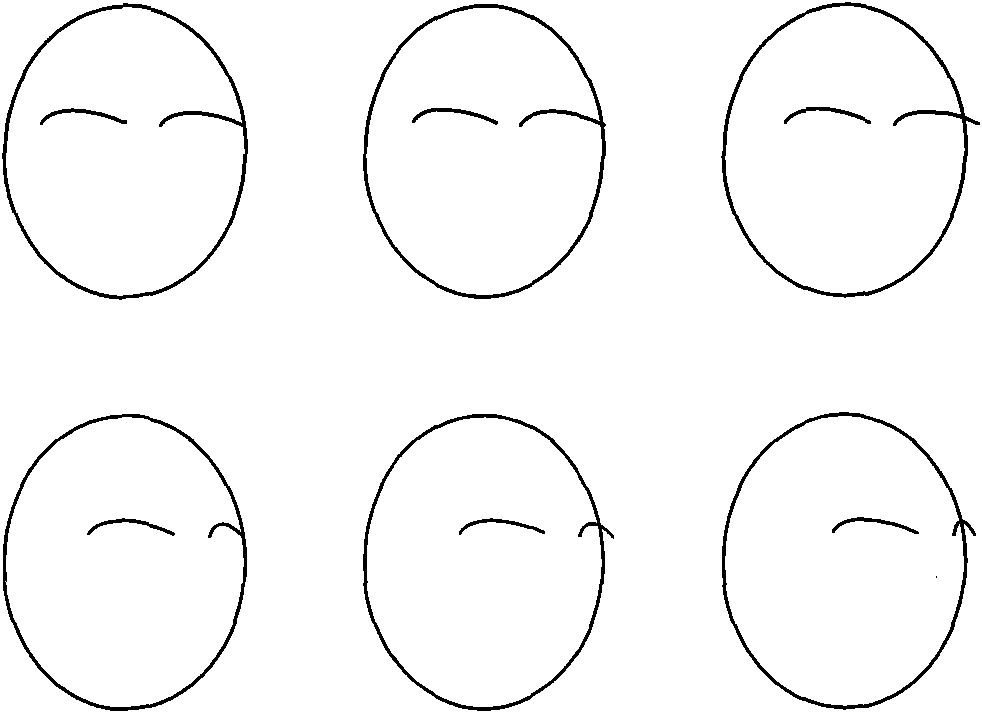

Network virtual-role synthetic system and method

ActiveCN101645175AHigh synthesis efficiencyImprove smoothnessAnimation3D-image renderingResource managementAnimation

The invention provides a network virtual-role synthetic system and method. The system comprises a resource manager, an equipment position loader, a synthesizer and a render, wherein the resource manager is used for providing equipment position resources of virtual roles; the equipment position loader is connected with the resource manager and used for loading the equipment position resources of the virtual roles; the synthesizer is connected with the equipment position loader and used for synthesizing equipment positions of virtual roles in the selected direction and cutting the synthesizing result into frame data; and the presenter is connected with the synthesizer and used for playing the frame data. The method comprises the following steps: loading the equipment position resources of the virtual roles; synthesizing the equipment positions of the virtual roles in the selected direction and cutting the synthesizing result into the frame data; and playing the frame data. The network virtual-role synthetic system and method can increase the synthesizing efficiency, enable the animation of the virtual roles to be smoother and meet the experience requirements of users.

Owner:TENCENT TECH (SHENZHEN) CO LTD

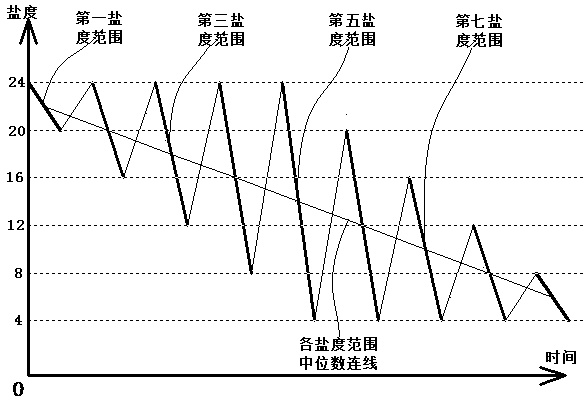

Low-salt-resistant penaeus monodon new species breeding method

ActiveCN108064779AImprove filtering effectUniversal strongClimate change adaptationPisciculture and aquariaLow salinityNatural state

The invention discloses a low-salt-resistant penaeus monodon new species breeding method. Low-salt-resistant penaeus monodon species can be better sorted through breeding in a salinity regulation modewithin multiple stepped ranges. According to the low-salt-resistant penaeus monodon new species breeding method, a stepped range mode, rather than a mode in which a certain low salinity value maintains invariable fundamentally, is adopted, in this way, the process in which the salinity of a breeding water body changes to a low salinity direction naturally can be simulated better, and thus the sorted penaeus monodon species has higher capability to adapt to the situation that the salinity is influenced because river water rises suddenly or rainstorm is heavy in a natural state.

Owner:SOUTH CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI +1

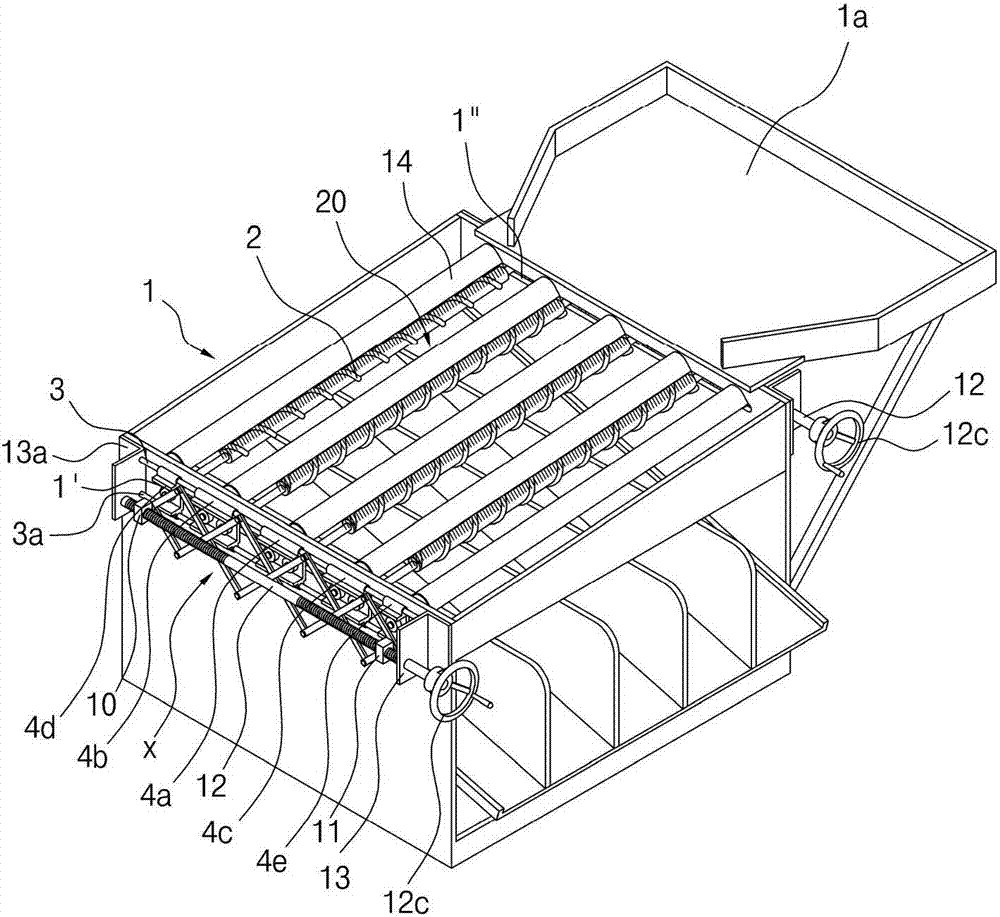

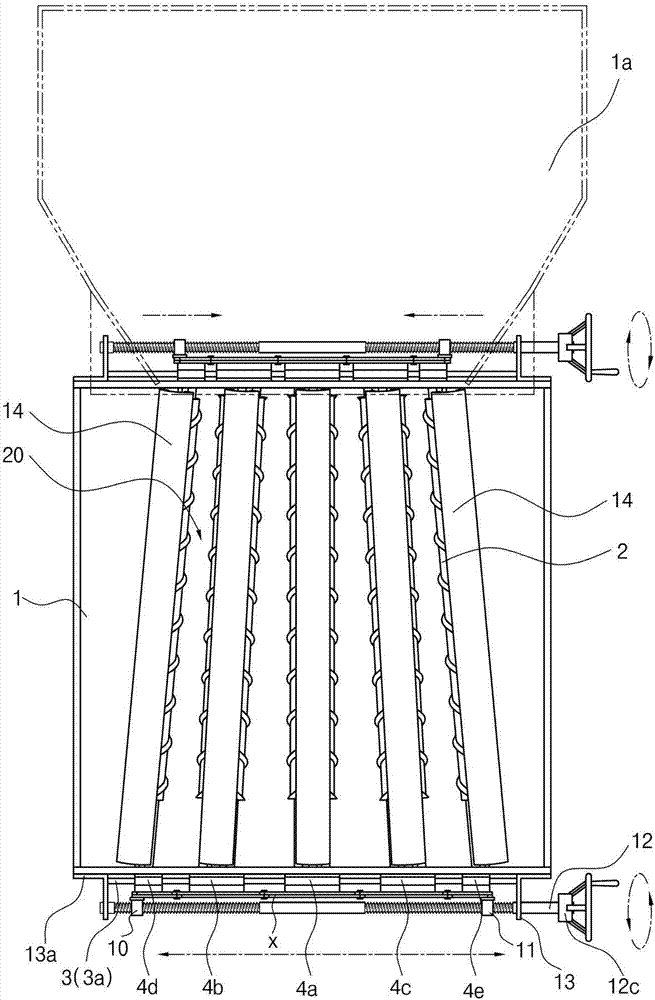

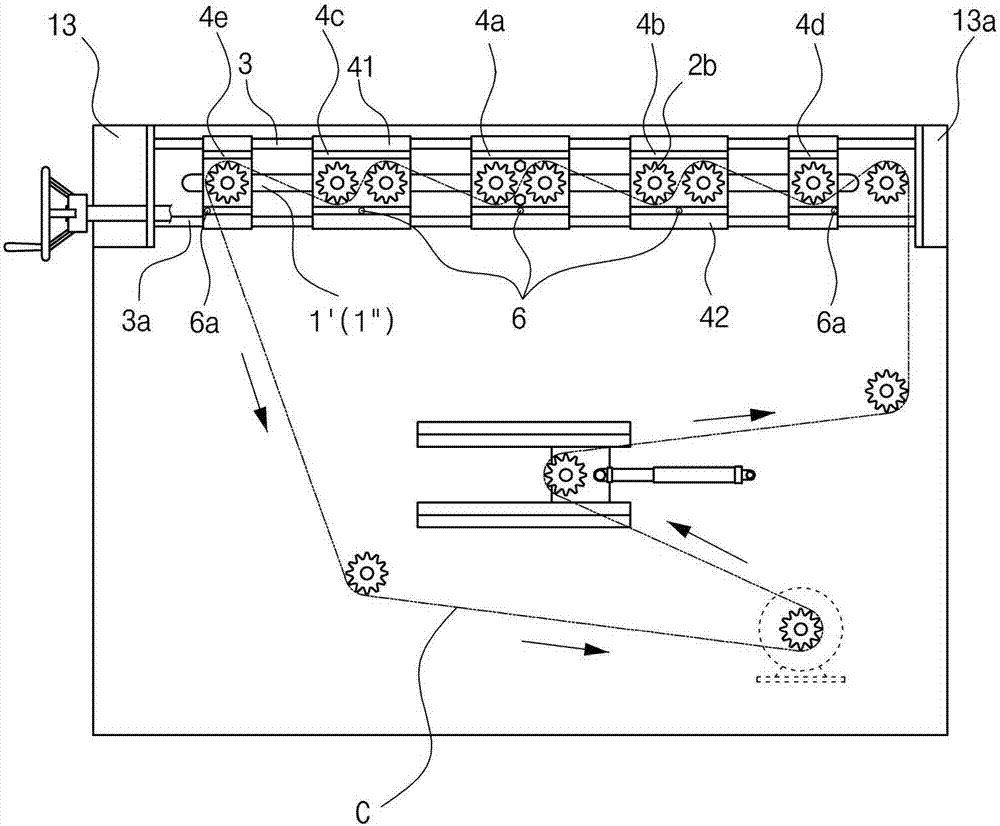

Agricultural product screening machine

InactiveCN107042205AEvenly screenedFast adjustment timeGradingAgricultural engineeringFrictional resistance

The invention relates to an agricultural product screening machine for screening agricultural products according to the size and more detailedly relates to a following agricultural product screening machine. According to the agricultural product screening machine, eight screening rollers are arranged on the upper face of a screening machine body for screening roller arrangement, four screening passages are formed between the screening rollers accordingly, and the rollers making contact with the screening passages are mounted in the mode that the rollers rotate form the bottom to the upper portion, so that damage caused due to frictional resistance of screened bodies passing through the screening passages and the screening rollers is minimized; and separation prevention pieces formed by brushes are arranged on the sides of the screening passages, connecting pieces assembled in an X shape are connected with supporting pieces used for supporting shaft seals of the screening rollers so as to enable left screw nuts and right screw nuts on the two sides to move inwards and outwards so that the distances of the screening passages can be simultaneously adjusted, the distances of the screening passages are precisely and rapidly adjusted accordingly, the agricultural products passing through the screening passages are prevented from breaking away from the screening passages, and thus efficient and safe screening is achieved.

Owner:权益三

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com