Foundation stone screening equipment for road

A screening equipment and cornerstone technology, applied in the fields of sieving, recycling technology, solid separation, etc., can solve the problems of low labor intensity, low efficiency of cornerstone screening, and high labor intensity, so as to reduce labor intensity and improve screening efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

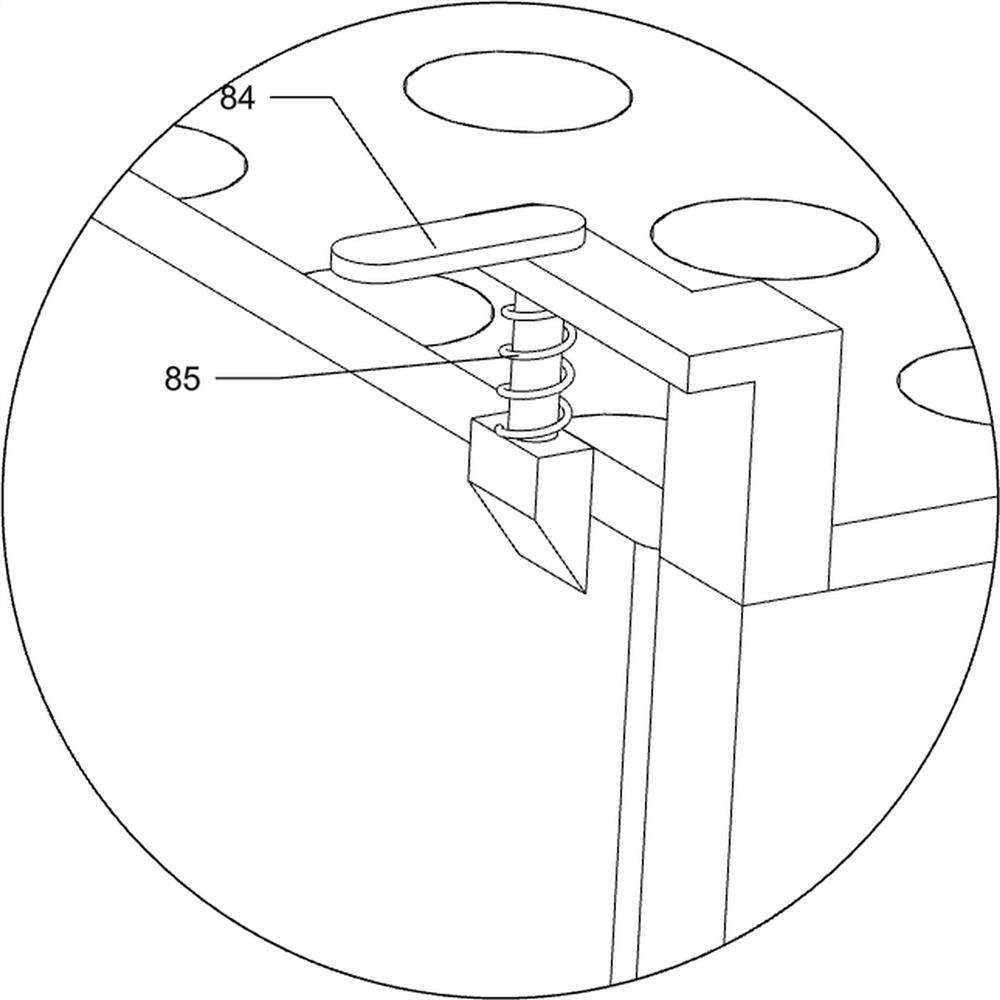

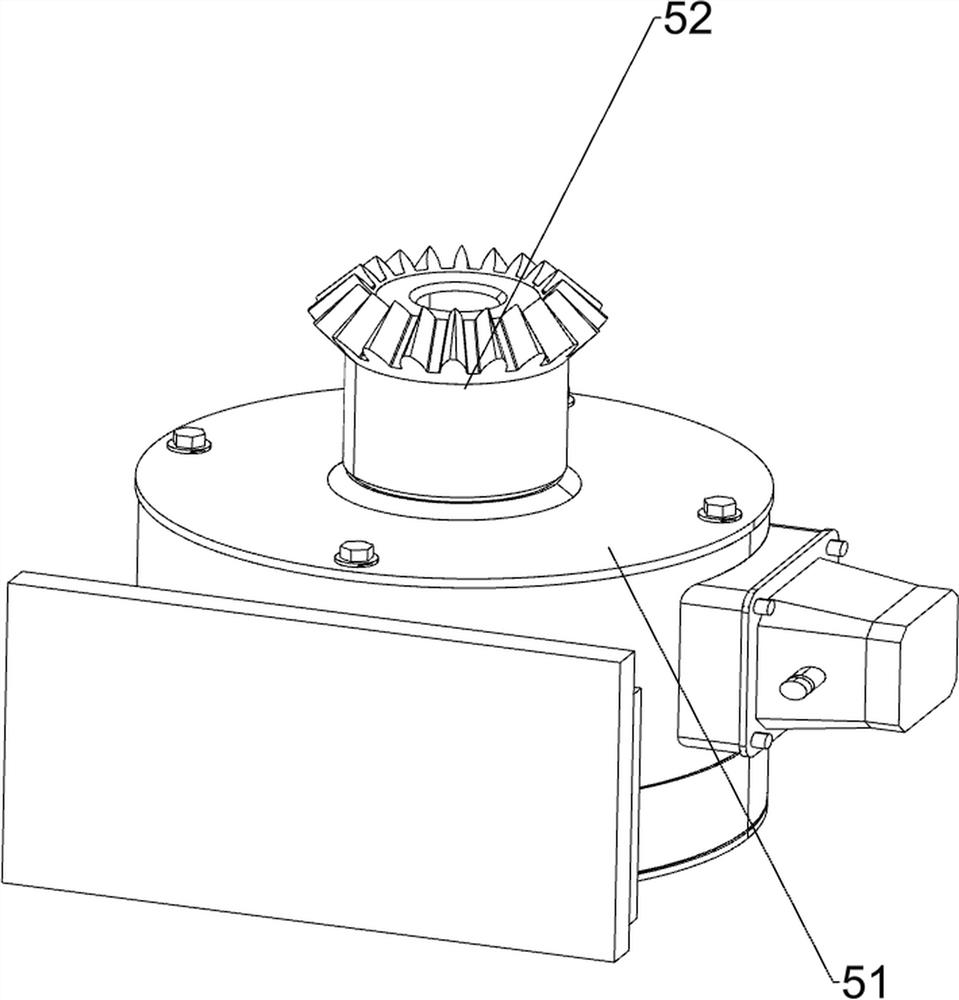

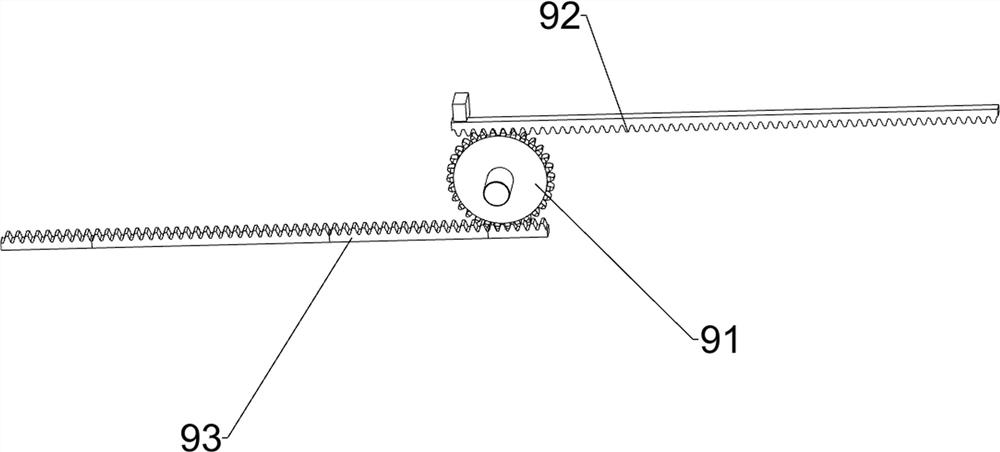

[0029] A kind of foundation stone screening equipment for highway, such as Figure 1 to Figure 3 and Figure 5 to Figure 9 As shown, it includes a bottom plate 1, a mounting frame 2, a material receiving box 3, a material discharging box 4, a driving mechanism 5, a swing mechanism 6, a switch plate mechanism 8, a pushing mechanism 9, a clamping mechanism 10 and a blanking mechanism 11, and the bottom plate The right side of the top of 1 is connected with a driving mechanism 5, the front and rear sides of the top of the base plate 1 are connected with mounting frames 2, and the upper parts of the two mounting frames 2 are connected with a swing mechanism 6, and the middle part of the swing mechanism 6 is slidingly connected with a The material receiving box 3, and the front and rear sides of the material receiving box 3 are all provided with card slots, the bottom of the material receiving box 3 right side is provided with a through hole, and a locking mechanism 10 is connected...

Embodiment 2

[0038] On the basis of Example 1, such as Figure 4 Shown, also comprise ejection mechanism 7, ejection mechanism 7 comprises positioning plate 71, cylinder 72 and support rod 73, the right side of discharging box 4 is connected with two support rods 73, between two support rods 73 Connect with cylinder 72, and the telescoping link of cylinder 72 is connected with the right side of slide plate, and positioning plate 71 is connected between cylinder 72 and the upper part of discharging box 4 right sides.

[0039] When the cornerstone in the discharge box 4 has been screened, people need to push the slide plate to slide to the left, start the cylinder 72 to extend its telescopic rod, and the slide plate drives the first rack frame 92 to slide to the left, and the transmission gear 91 drives the second rack frame 93 and the material receiving box 3 to slide to the right thereupon, after the cornerstone in the material discharging box 4 and the material receiving box 3 has been cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com