Coal mine smashing and screening equipment

A screening equipment and technology for coal mines, applied in grain processing and other directions, can solve the problems of inability to uniformly screen and inconvenient for workers to operate, and achieve the effects of uniform screening of coal powder, saving workers' energy and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

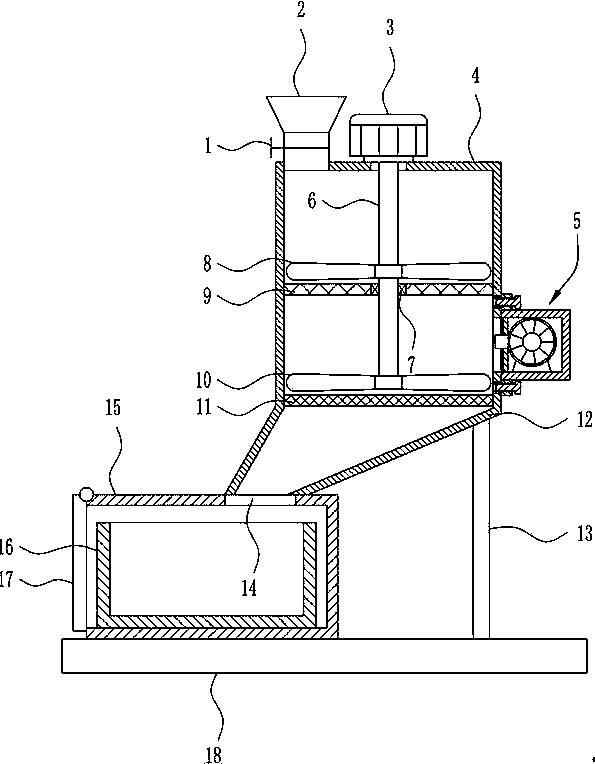

[0023] Referring to accompanying drawing, a kind of coal mine crushing and screening equipment, such as Figure 1-5 As shown, it includes feed valve 1, feed hopper 2, motor 3, screening frame 4, detachable blowing mechanism 5, rotating shaft 6, bearing seat 7, coarse powder crushing rod 8, coarse powder filter 9, fine powder Crushing rod 10, fine powder filter screen 11, discharge hopper 12, support rod 13, recovery frame 15, collection frame 16, cover plate 17 and installation plate 18; recovery frame 15 is fixed on the top side of the installation plate 18, cover plate 17 Hinged on one side of the recovery frame 15, the top of the recovery frame 15 is provided with a discharge hole 14, the collection frame 16 is placed inside the recovery frame 15, the support rod 13 is fixed on the other side of the top of the installation plate 18, and the discharge hopper 12 is fixed on the support The top of the rod 13, the screening frame 4 is affixed to the top of the discharge hopper ...

Embodiment 2

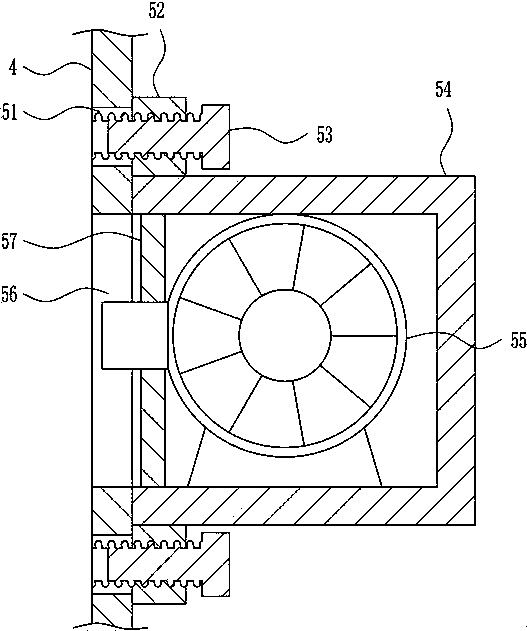

[0026] This embodiment is similar to Embodiment 1. Further, the detachable blowing mechanism 5 includes nuts 52, screws 53, mounting frames 54, air pumps 55 and partitions 57; the side of the screening frame 4 away from the recovery frame 15 is provided with threads The hole 51, the through hole 56, the screw 53 is screwed to the threaded hole 51 through the nut 52, the installation frame 54 is fixed on one side of the nut 52, the partition 57 is fixed on the inside of the installation frame 54 in a detachable manner; the air pump 55 is fixed At the bottom of the installation frame 54, and the output end of the air pump 55 runs through the partition 57; so when the air pump 55 is energized, the gas generated by the air pump 55 enters the screening frame 4 from the through hole 56 through the partition 57, blowing up the air in the screening frame 4 Coal mineral powder, screw 53, nut 52, threaded hole 51 cooperate with each other, be convenient to the dismounting and installatio...

Embodiment 3

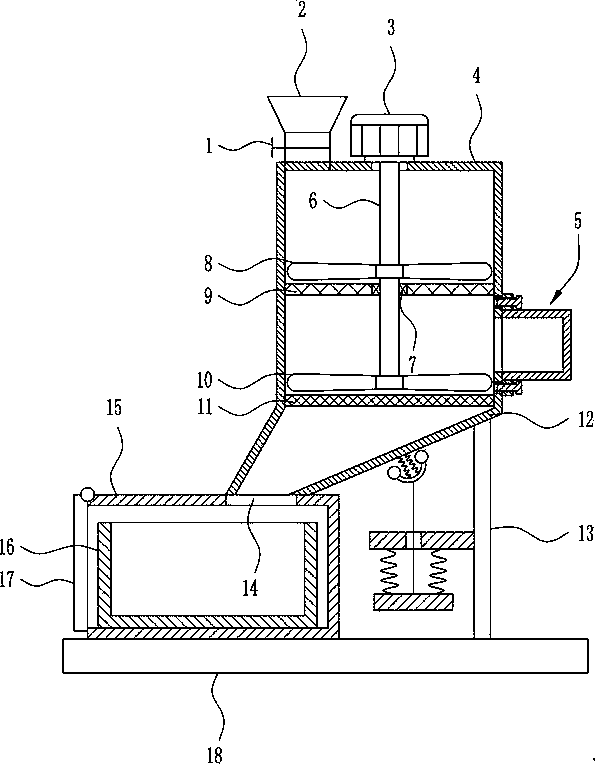

[0028] This embodiment is similar to Embodiment 1. Further, the coal mine powder screening equipment also includes a knocking ball 19, an arc rod 20, a first elastic member 21, a guide plate 22, a second elastic member 23, a pedal 24 and Pull wire 25; one end of the first elastic member 21 is fixedly connected to the bottom of the discharge hopper 12, and the other end is fixedly connected to the top of the arc rod 20; the knocking ball 19 is fixed to both ends of the arc rod 20, and the guide plate 22 is fixed to the support rod 13 at the bottom of one side; one end of the second elastic member 23 is affixed to the bottom of the guide plate 22, and the other end is affixed to the top of the pedal 24, and the pedal 24 is connected to the bottom of the arc rod 20 through a pull wire 25; so the worker steps on the pedal 24. The pedal 24 moves under the action of the second elastic member 23, thereby driving the arc-shaped rod 20 to move under the action of the first elastic membe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com