Patents

Literature

36results about How to "Fast adjustment time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Particle characterization

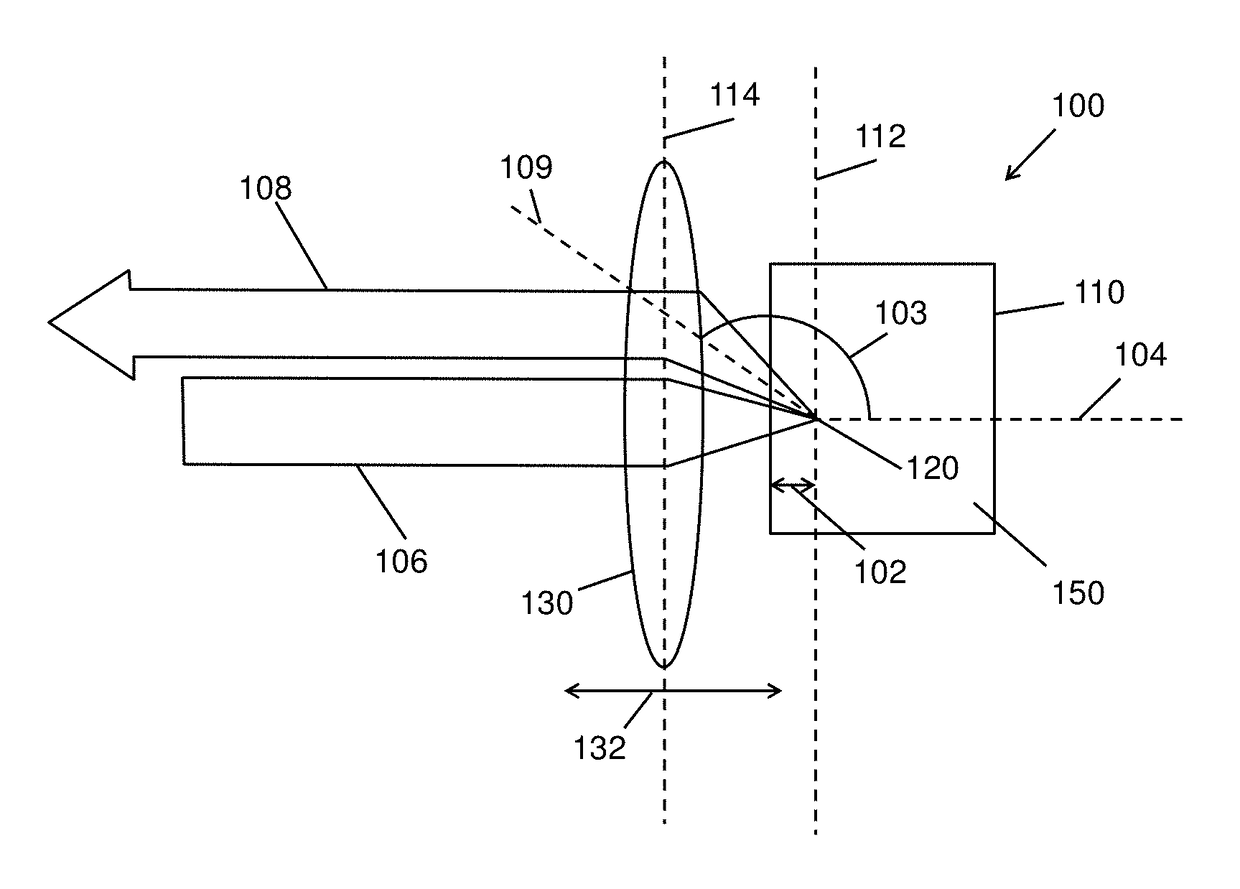

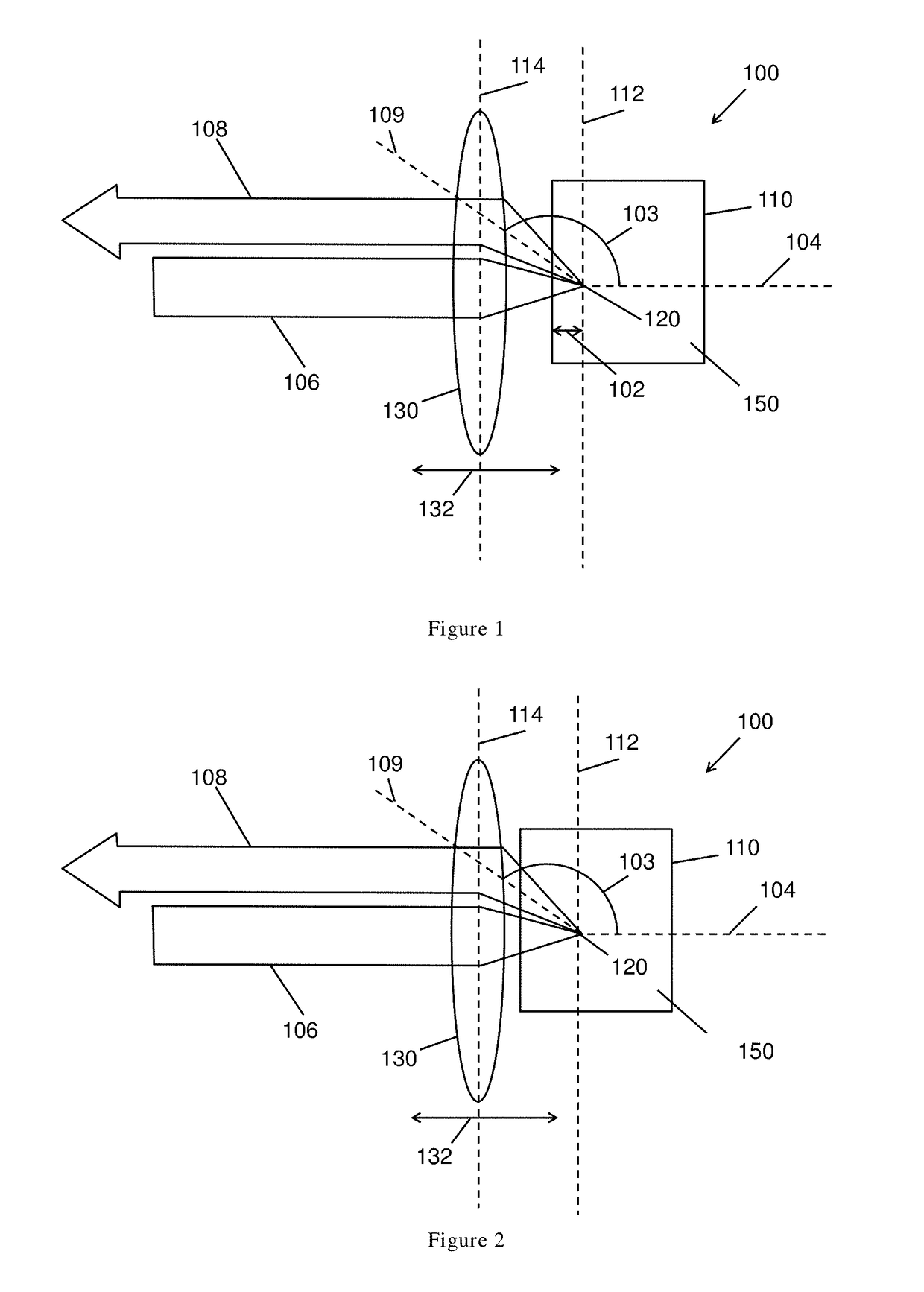

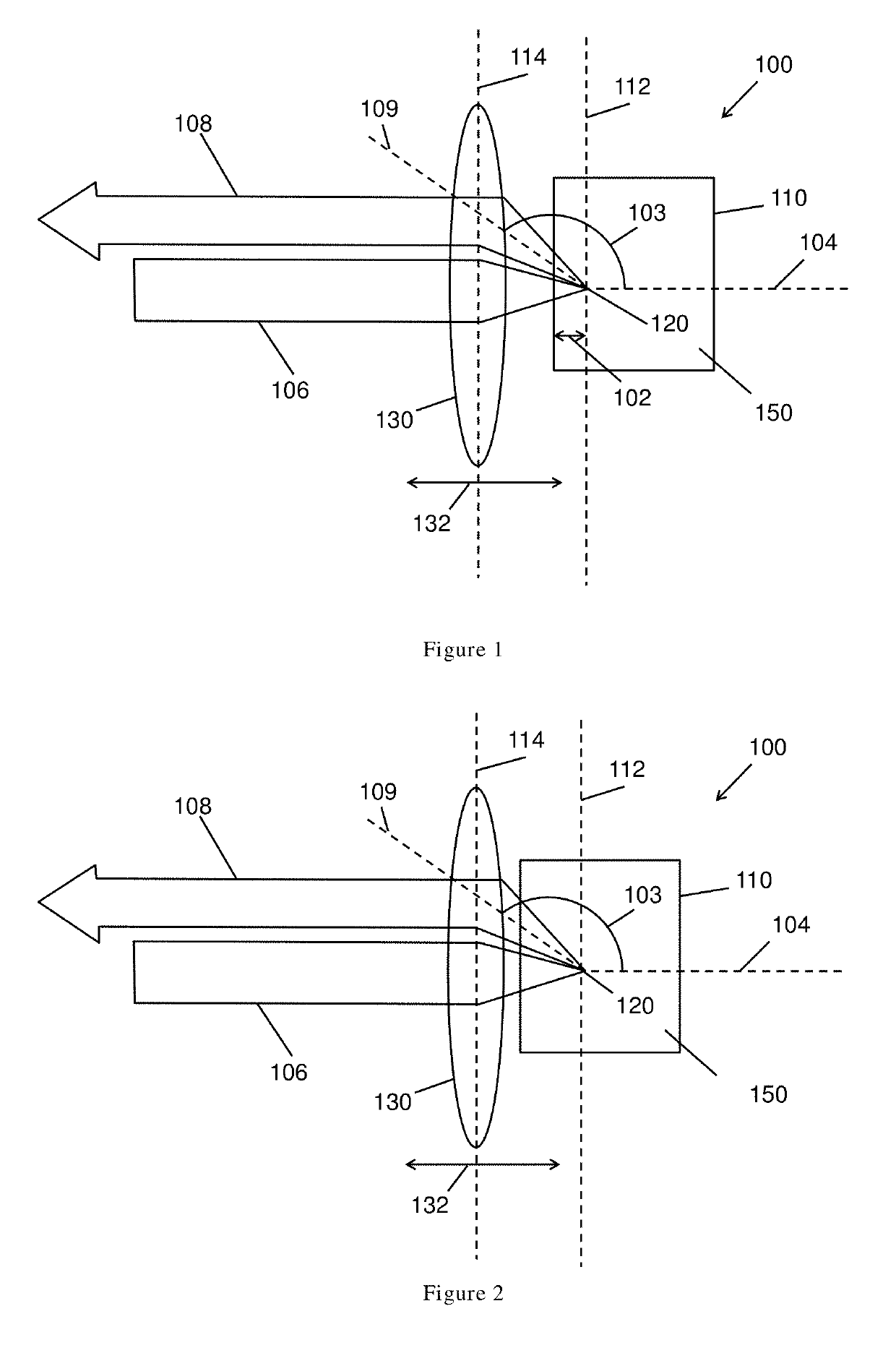

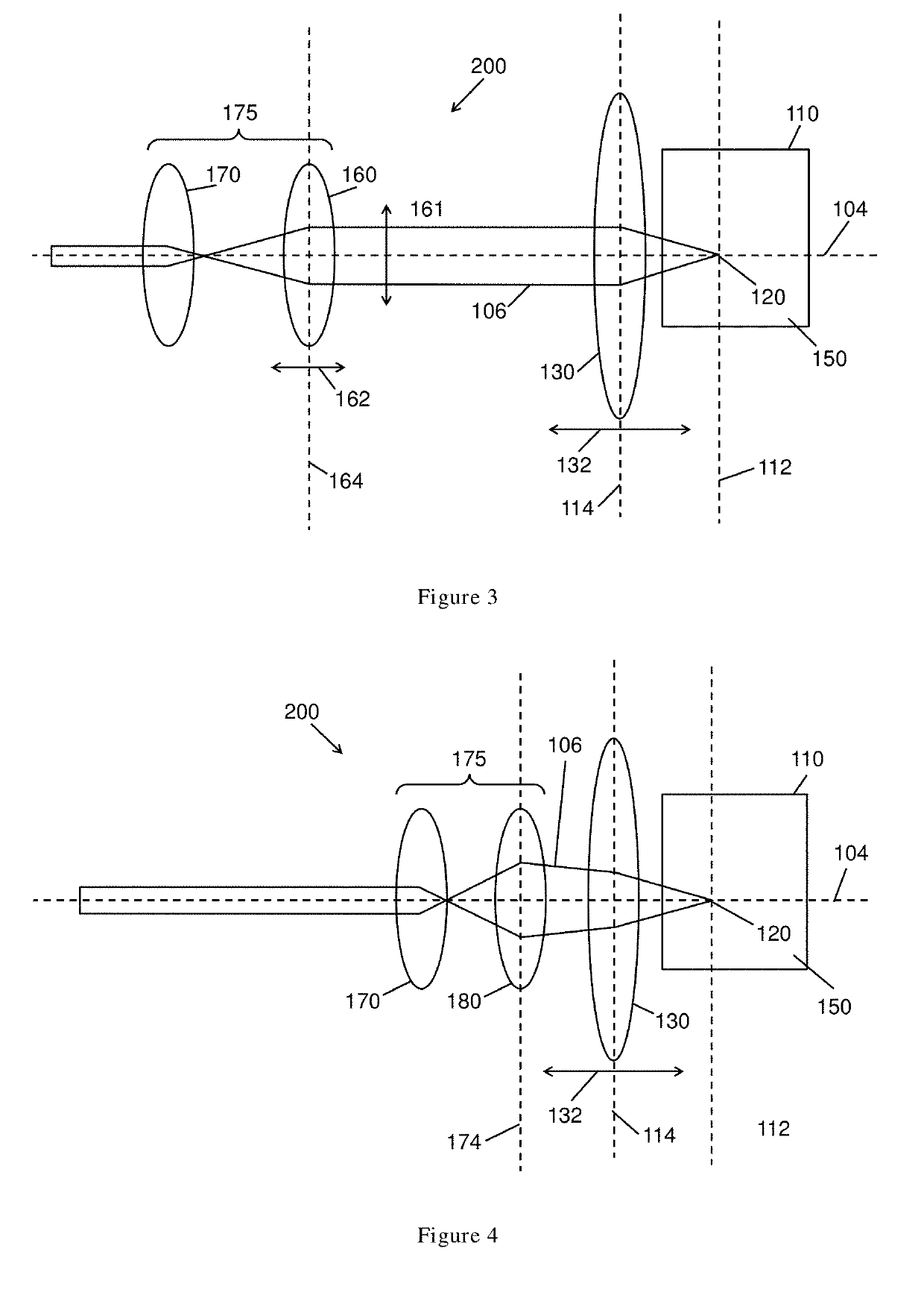

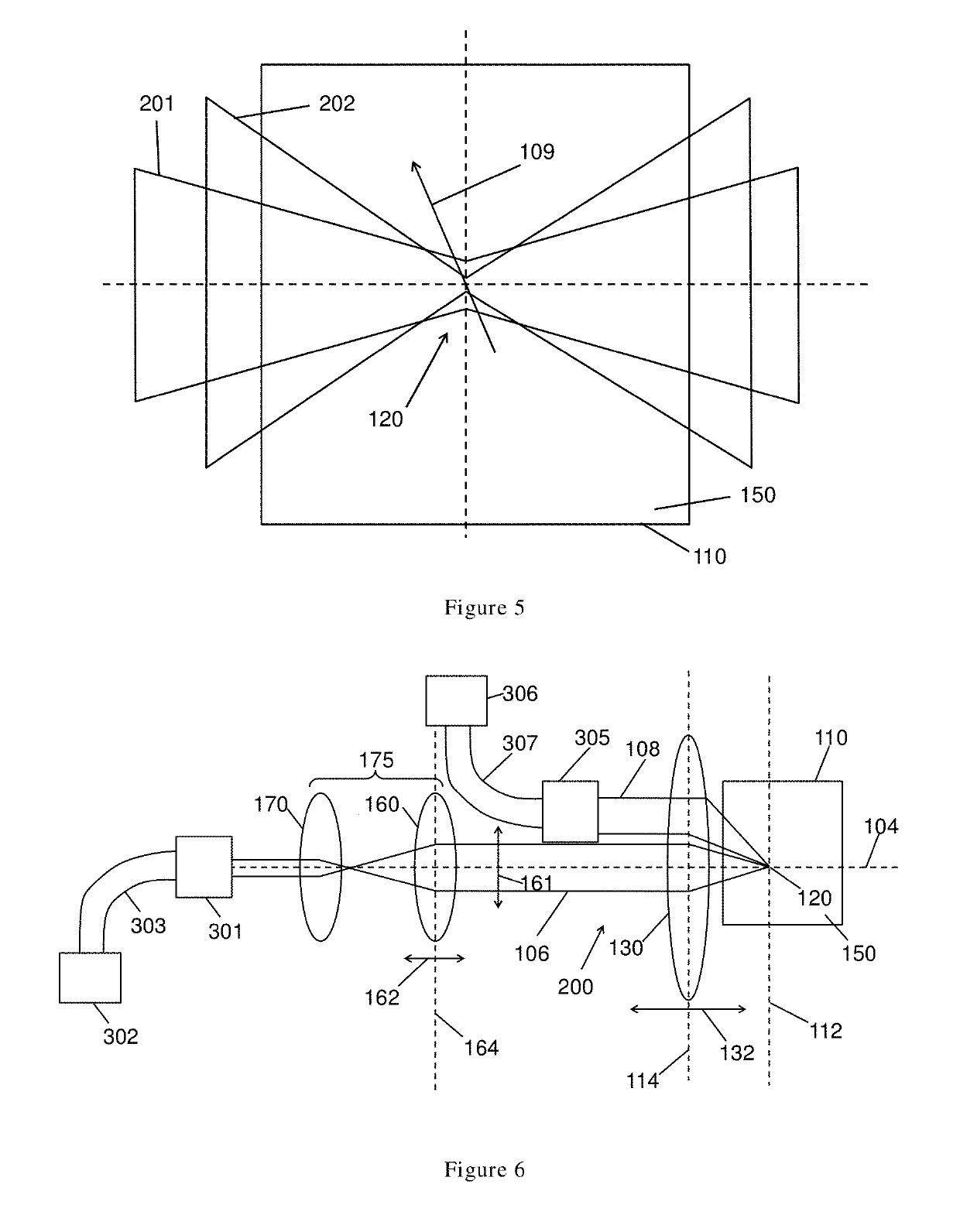

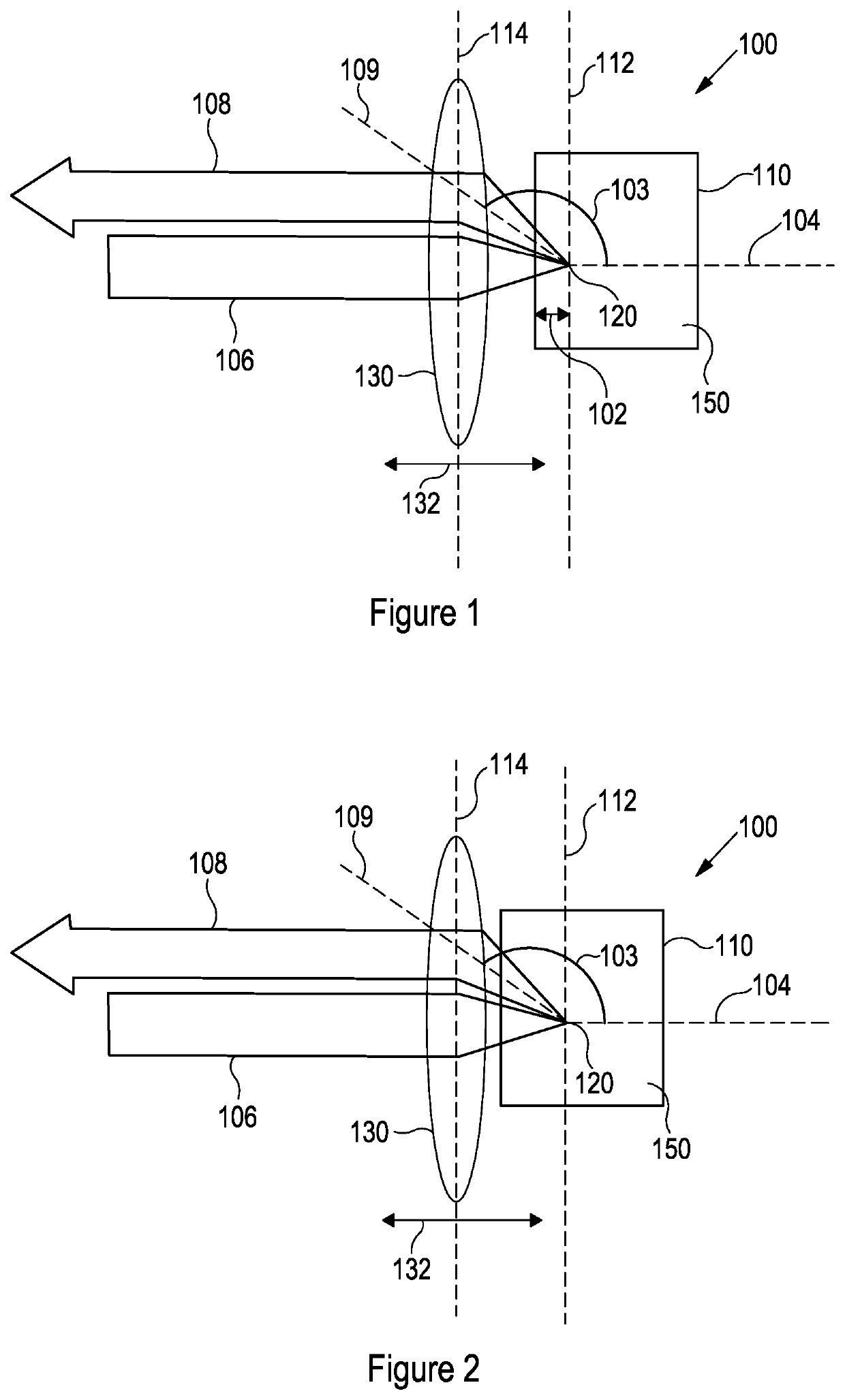

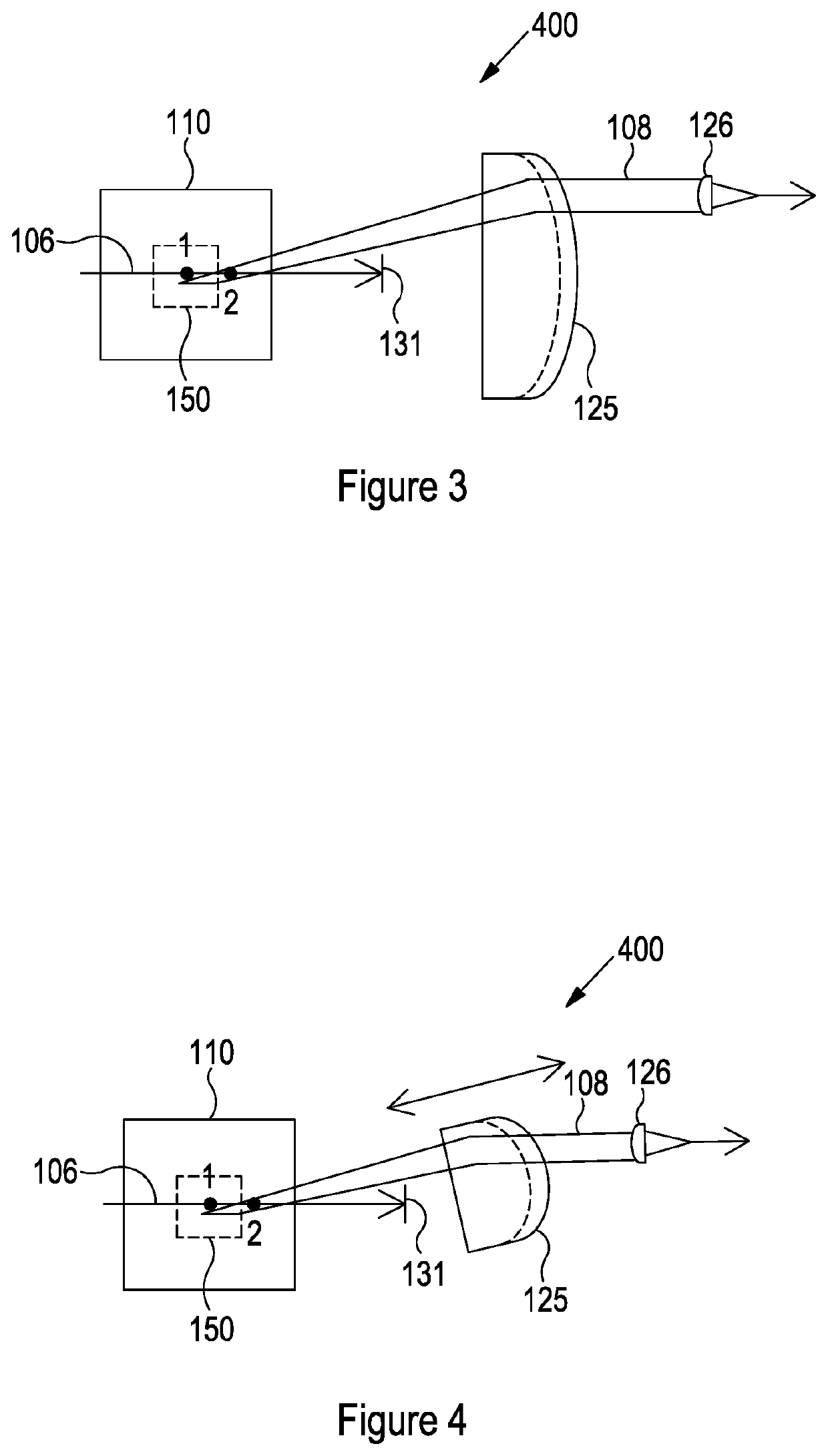

ActiveUS20170307495A1Improve signal-to-noise ratioEasy to optimizeMaterial analysis by electric/magnetic meansScattering properties measurementsLight beamLight source

A particle characterization apparatus comprising: a light source for illuminating a sample with a light beam; a detector arranged to detect scattered light from the interaction of the light beam with the sample; and a focus tuneable lens arranged to collect the scattered light for the detector from a scattering volume and / or to direct the light beam into the sample.

Owner:MALVERN INSTRUMENTS

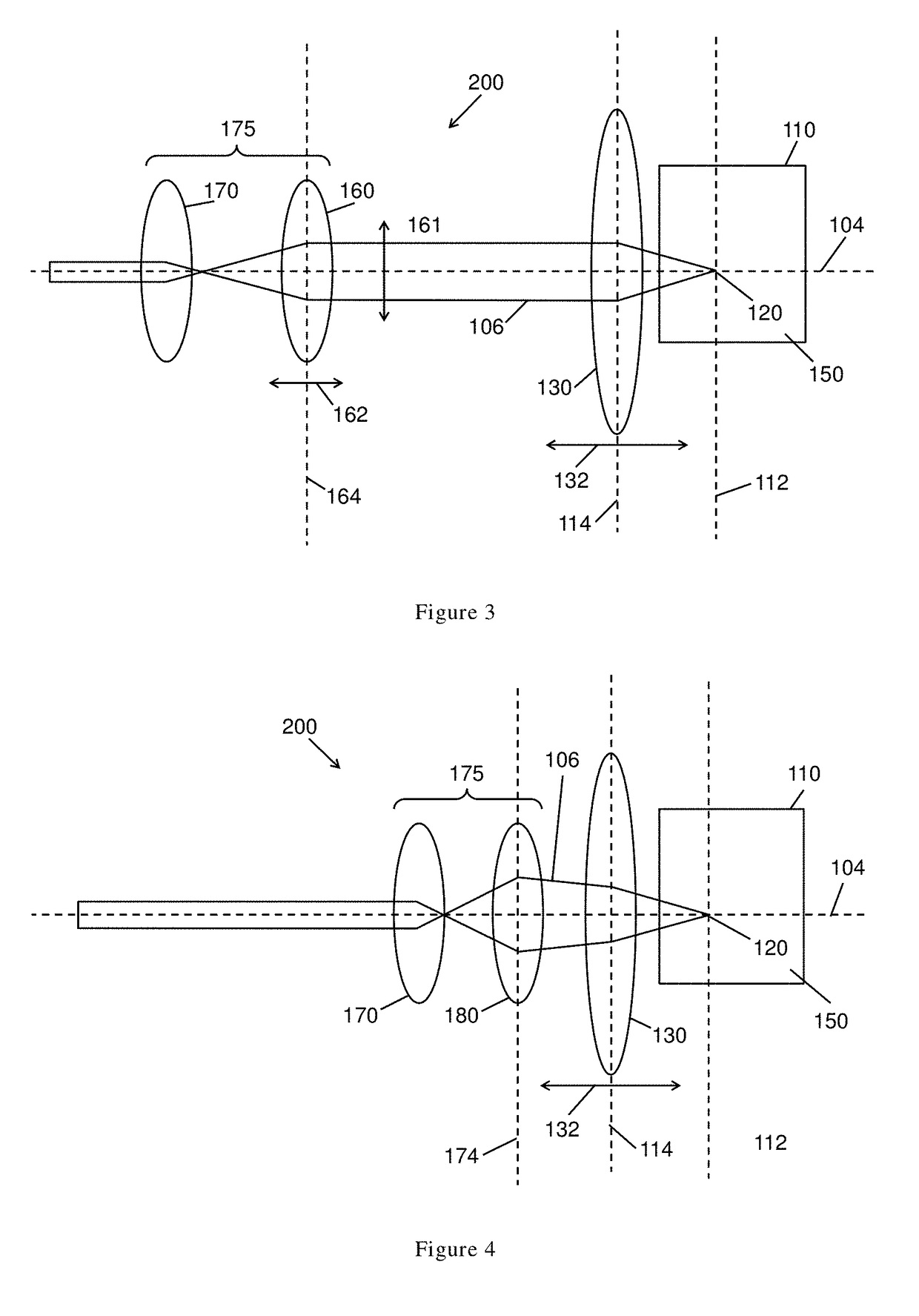

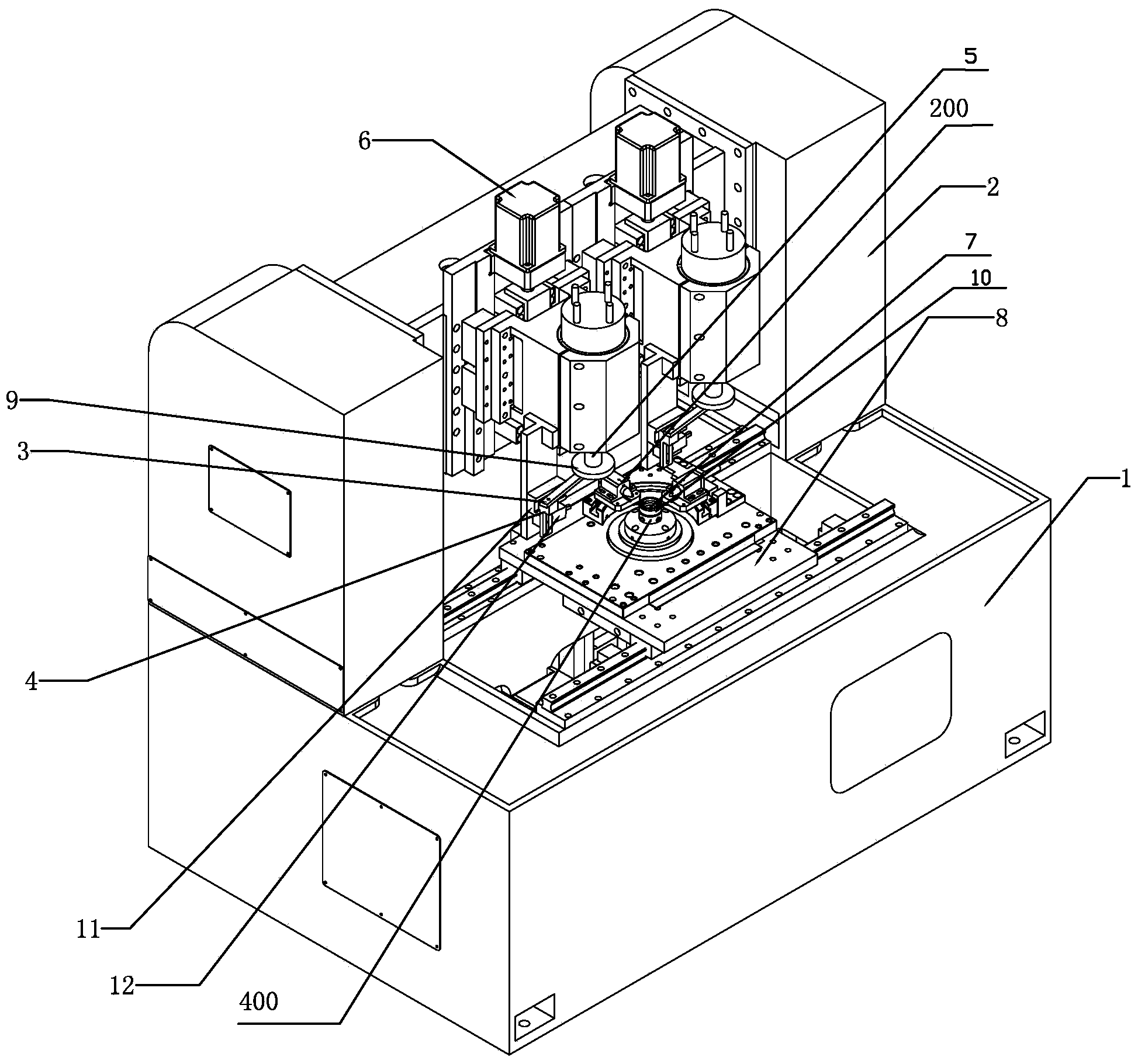

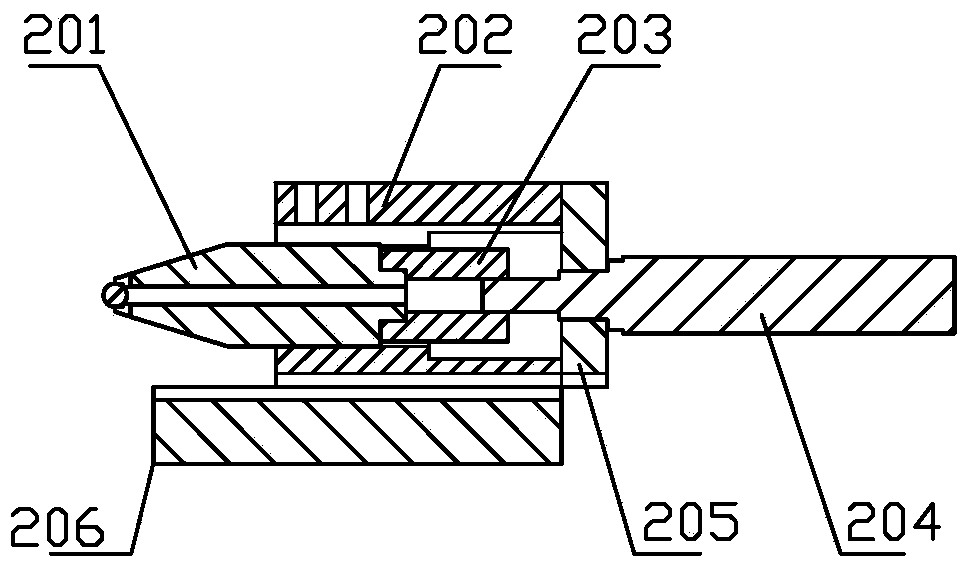

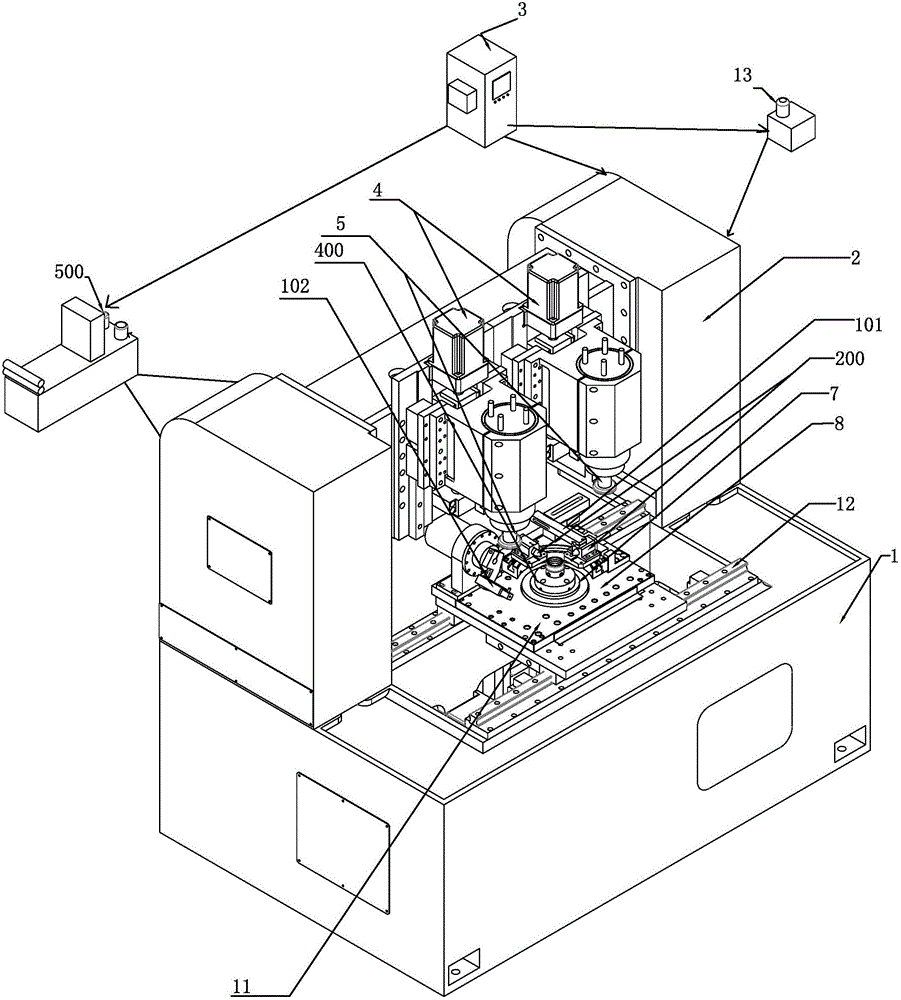

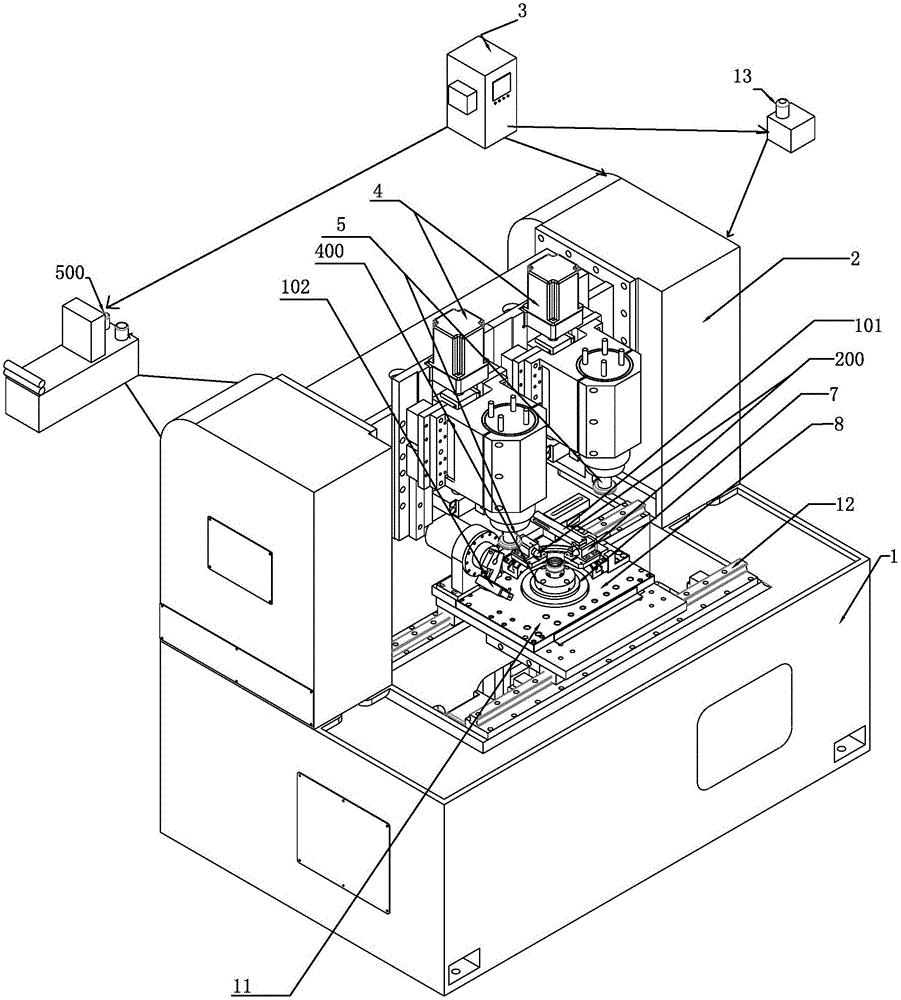

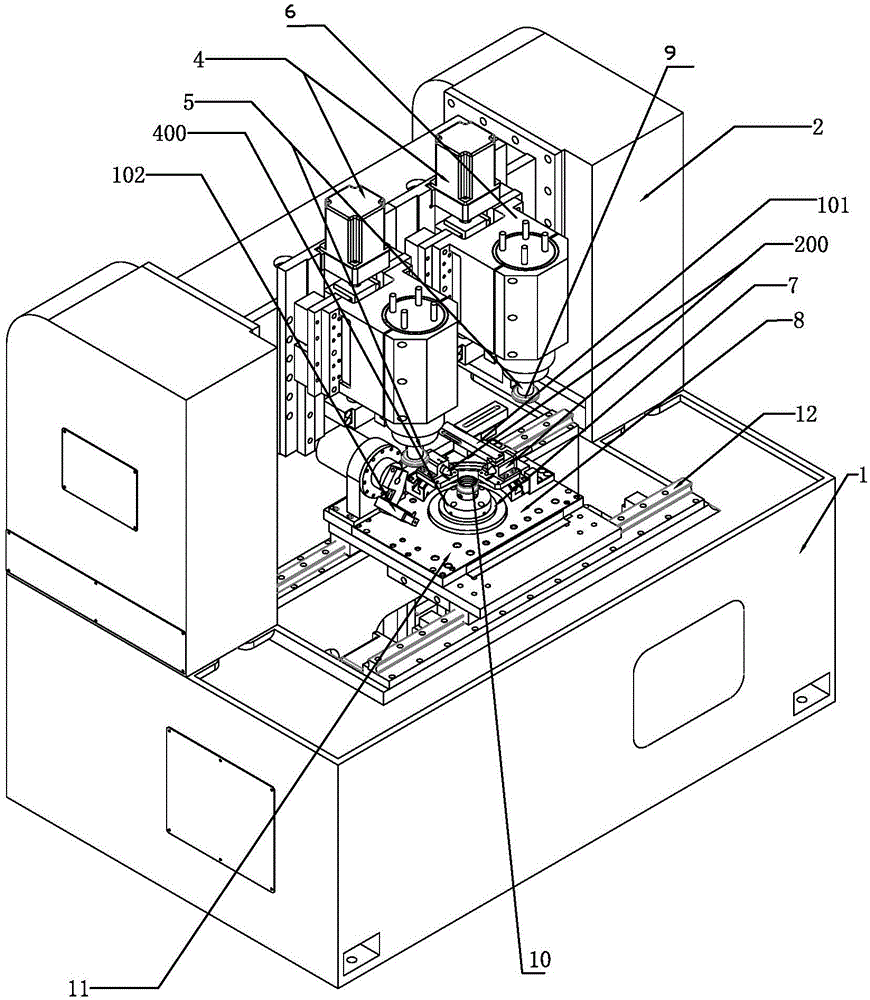

Ultra-precision machine special for machining nuclear power bearing rings

ActiveCN103659567AConvenient and quick displacement adjustmentHigh adjustment accuracySuperfinishing machinesGrinding work supportsElectricityEngineering

An ultra-precision machine special for machining nuclear power bearing rings comprises a machine tool base, a lathe bed, a hydraulic system, an electronic control system, a servo system, electric main shafts, rotary head lifting mechanisms, a workpiece shaft, rotary head movable rods, sliding blocks, a workpiece translational mechanism, a supporting component, a magnetic pole, a rotary eccentric wheel, the nuclear power bearing rings, rotary head slide ways and oil stone clamps. The number of the electric main shafts and the number of the rotary head lifting mechanisms are both two sets, and the electric main shafts and the rotary head lifting mechanisms are all arranged above the workpiece translational mechanism. Each set of electric main shaft independently works and moves up and down through a corresponding rotary head lifting mechanism. The rotary eccentric wheel is arranged on the lower end portions of the electric main shafts, and the electric main shafts drive the rotary eccentric wheel to rotate. The ultra-precision machine is used for more conveniently and quickly machining the nuclear power bearing rings, on the premise of guaranteeing machining precision, time for replacing mechanical parts and debugging the machining size in the prior art can be saved, machining can be continued as long as the magnetic pole is replaced, and machining efficiency is effectively improved.

Owner:大连大友高技术陶瓷有限公司

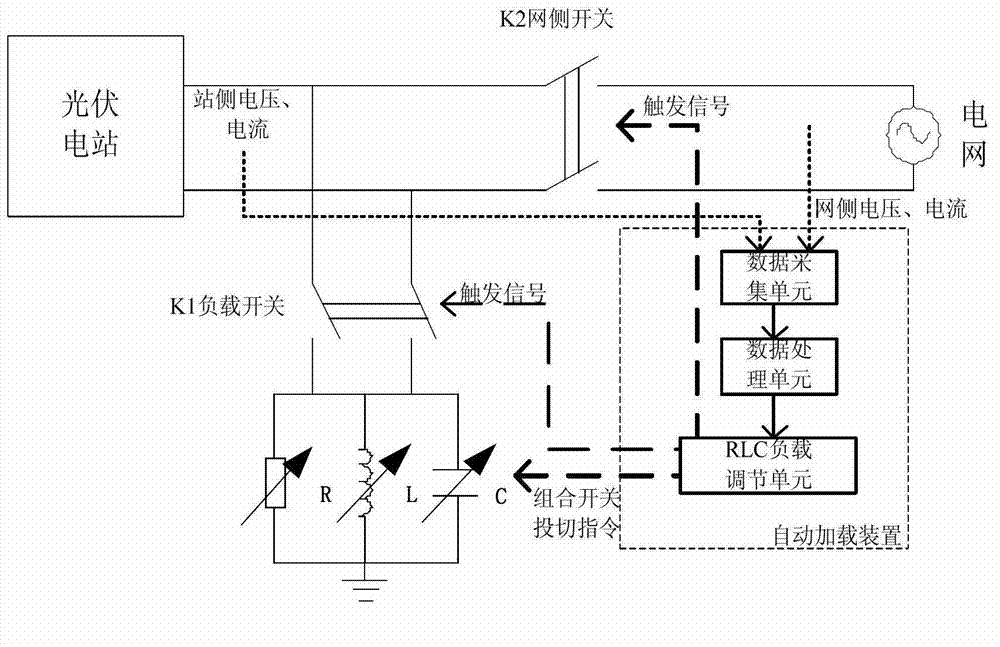

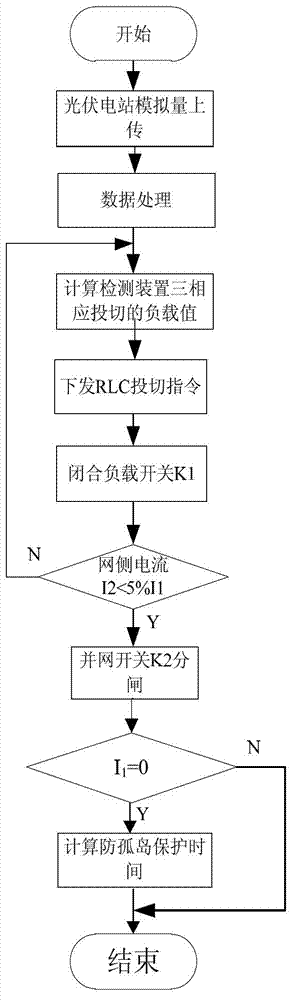

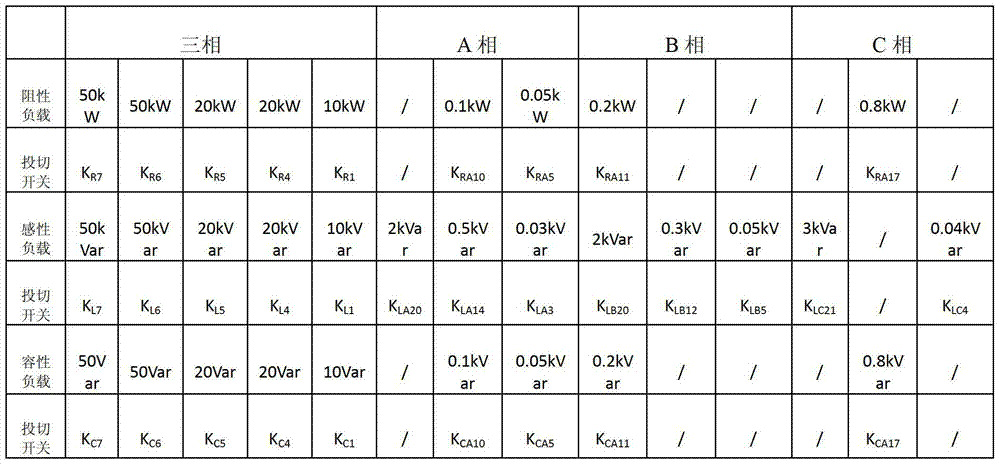

Device and method for automatically loading anti-islanding protection test system

ActiveCN103323695AConvenient anti-islanding protection capability testReduce load matching errorElectrical testingSingle network parallel feeding arrangementsResonancePhotovoltaic power station

The invention provides a device and method for automatically loading an anti-islanding protection test system. The device comprises a data acquisition unit, a data processing unit and a RLC load adjusting unit, wherein the data acquisition unit, the data processing unit and the RLC load adjusting unit are sequentially connected. The RLC load adjusting unit respectively controls a load switch K1, a network side switch K2 and a combination switching switch of the RLC load adjusting unit through output signals. The corresponding automatic loading method is used for detecting the output power of a photovoltaic system on line and in real time, RLC loads are rapidly, automatically and accurately adjusted, resonance of three-phase independent alternating current electric equipment is generated, and the testing process is convenient to conduct, fast and accurate.

Owner:STATE GRID CORP OF CHINA +2

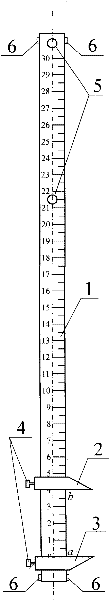

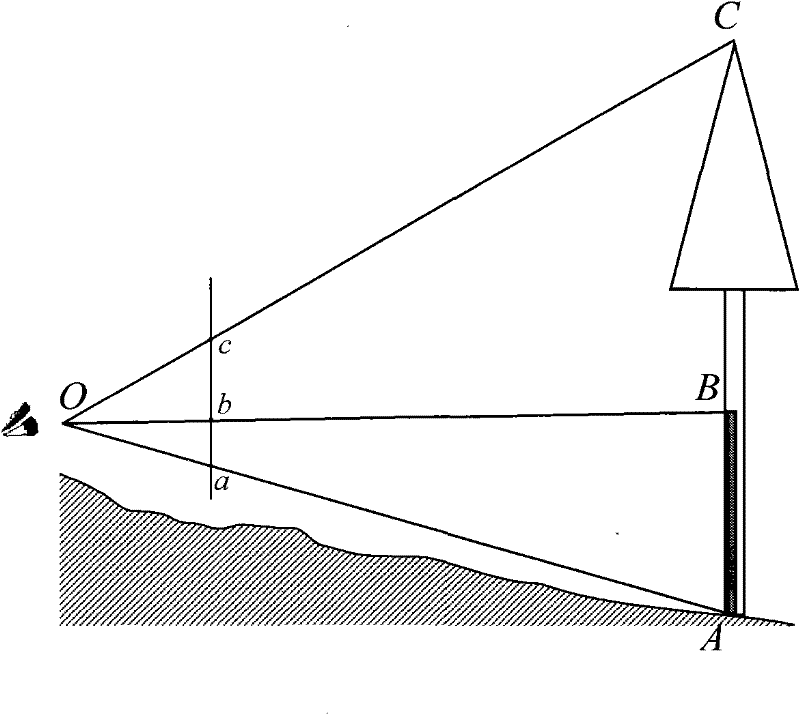

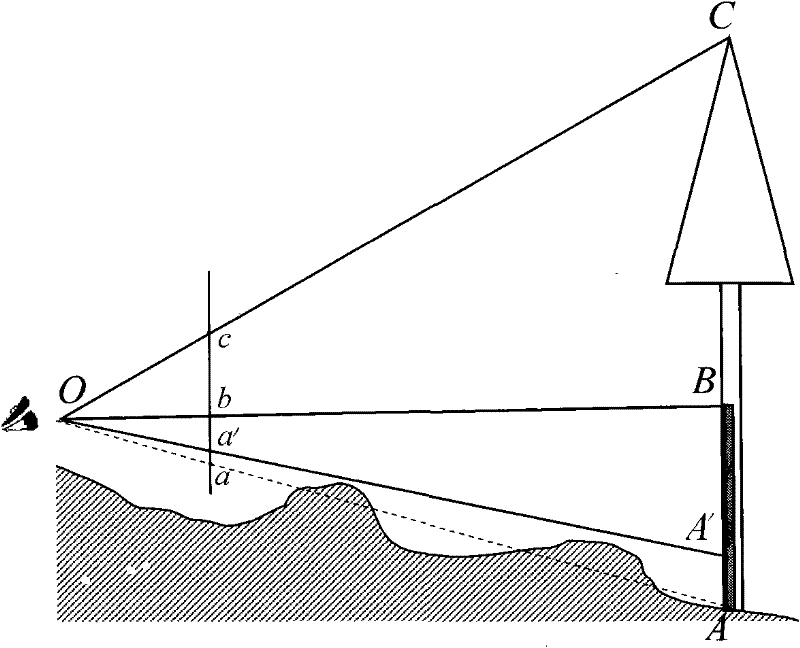

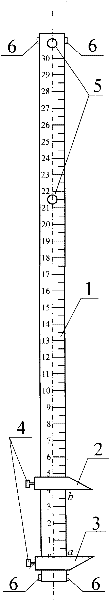

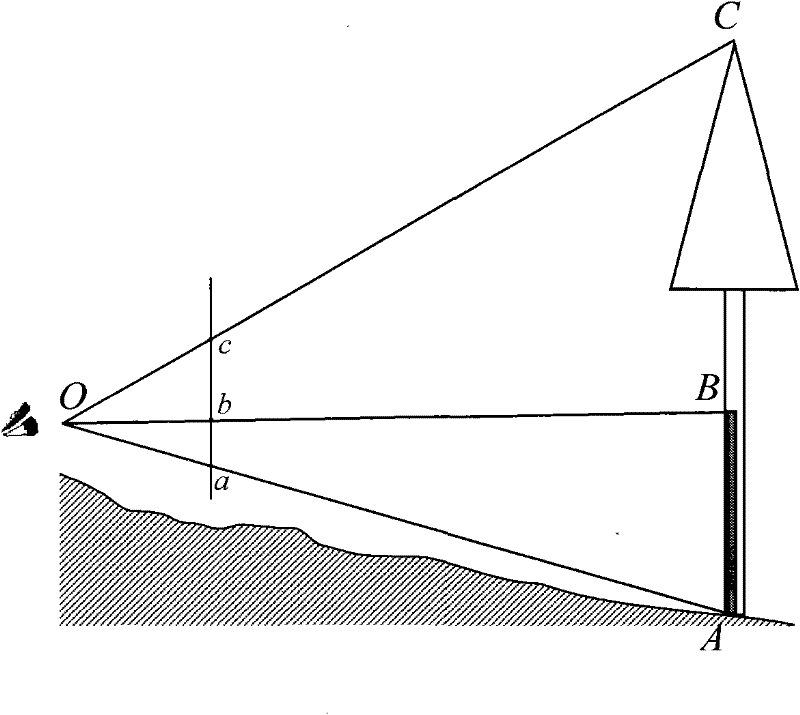

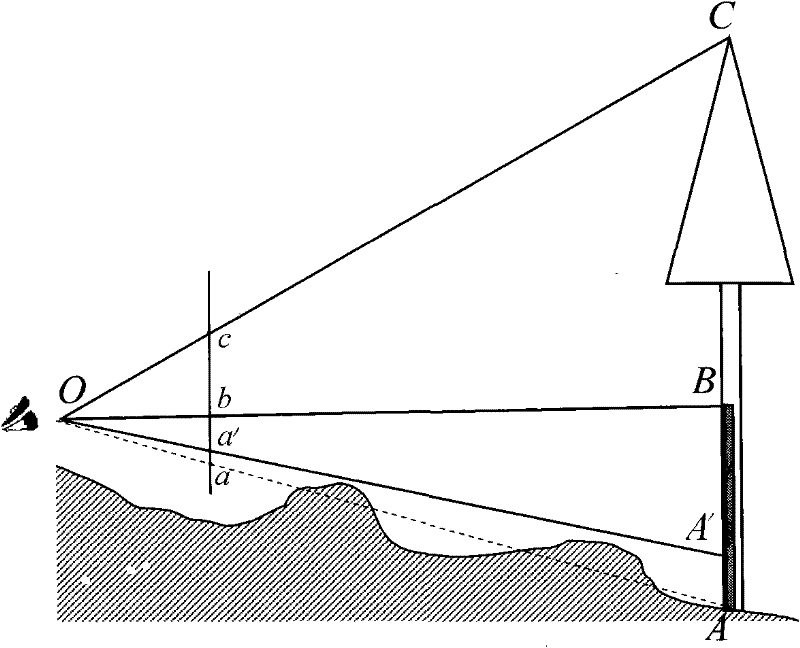

Device for efficiently measuring tree height

InactiveCN101749988AImprove work efficiencyEasy to useRulers for direct readingMeasurement deviceComputer science

Owner:SHANDONG AGRICULTURAL UNIVERSITY

Particle characterization

ActiveUS10365198B2Easy to adjustMore reliableScattering properties measurementsMaterial analysis by electric/magnetic meansLight beamLight source

A particle characterization apparatus comprising: a light source for illuminating a sample with a light beam; a detector arranged to detect scattered light from the interaction of the light beam with the sample; and a focus tuneable lens arranged to collect the scattered light for the detector from a scattering volume and / or to direct the light beam into the sample.

Owner:MALVERN INSTRUMENTS

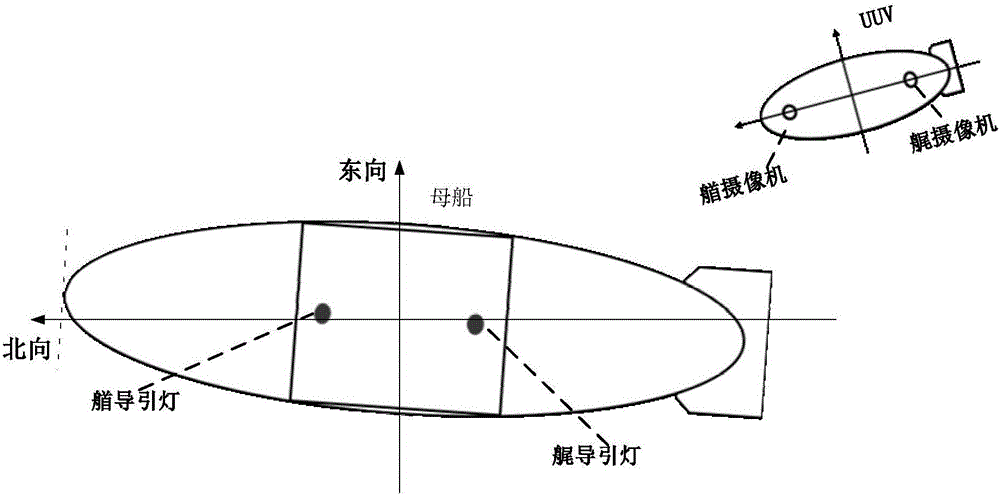

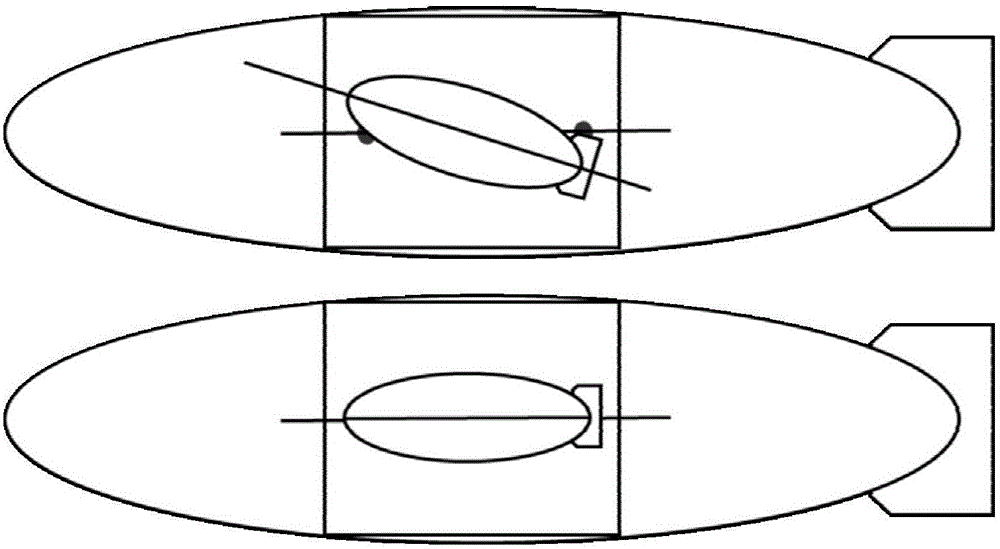

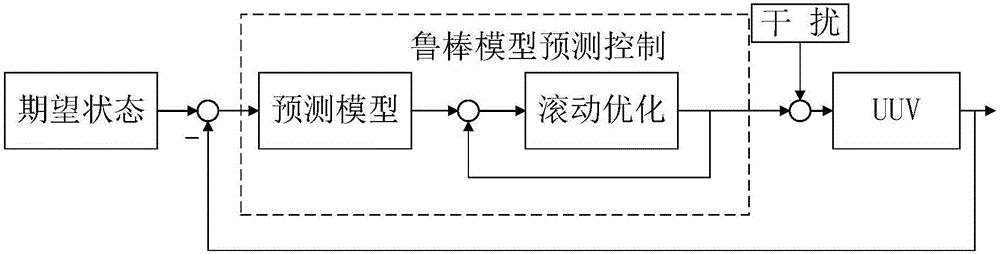

UUV positioning-to-line recovery method based on robustness constraint model prediction control

The present invention provides a UUV positioning-to-line recovery method based on robustness constraint model prediction control, and relates to an underwater mother ship piggyback carrying UUV autonomous recovery method. The objective of the invention is to solve the problems that an underwater recovery UUV method is mainly configured to recover a UUA aiming at a static recovery platform and the UUV and the recovery platform are collided caused by unstable factors such as too large overshoot and too long accommodation time. The UUV positioning-to-line recovery method comprises: firstly, obtaining the UUA and the mother ship state information, building an error prediction model, and calculating the system matrix of a partial time prediction error dynamic equation and partial time state prediction errors; performing rolling optimization in the constraint condition, solving an optimization problem; and then calculating a controlled quantity and newly predicting the model and repeatedly performing the rolling optimization procedure until the positioning-to-line procedure of the UUV and the mother ship. The UUV positioning-to-line recovery method based on robustness constraint model prediction control is applicable to the autonomous recovery of an underwater mother ship piggyback carrying UUV.

Owner:HARBIN ENG UNIV

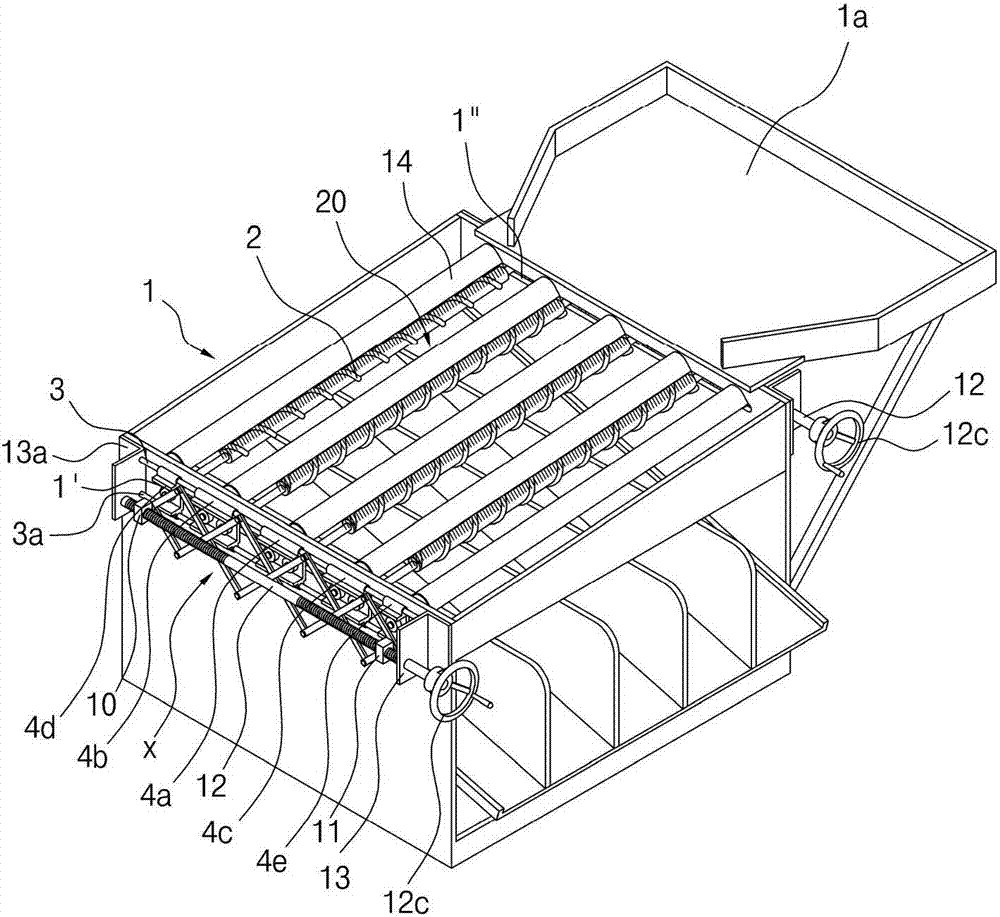

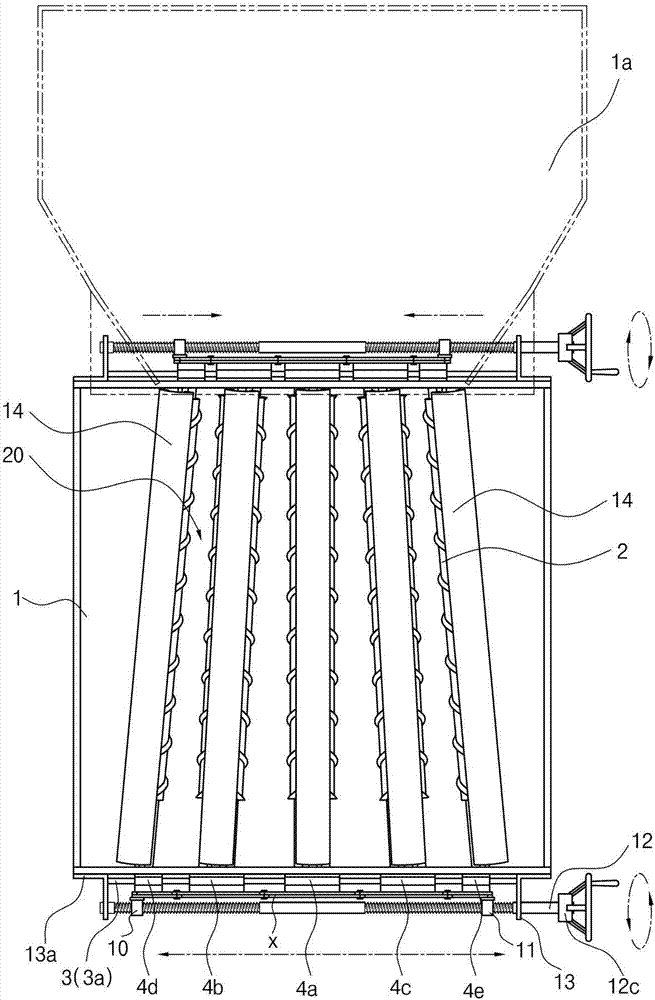

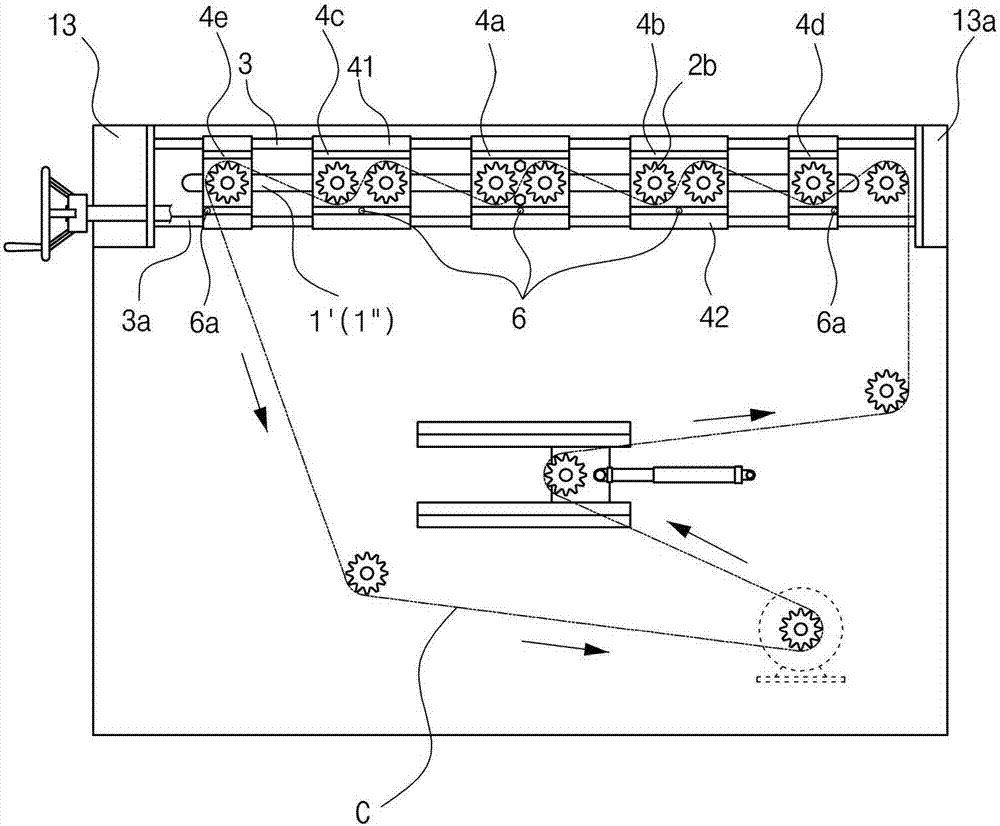

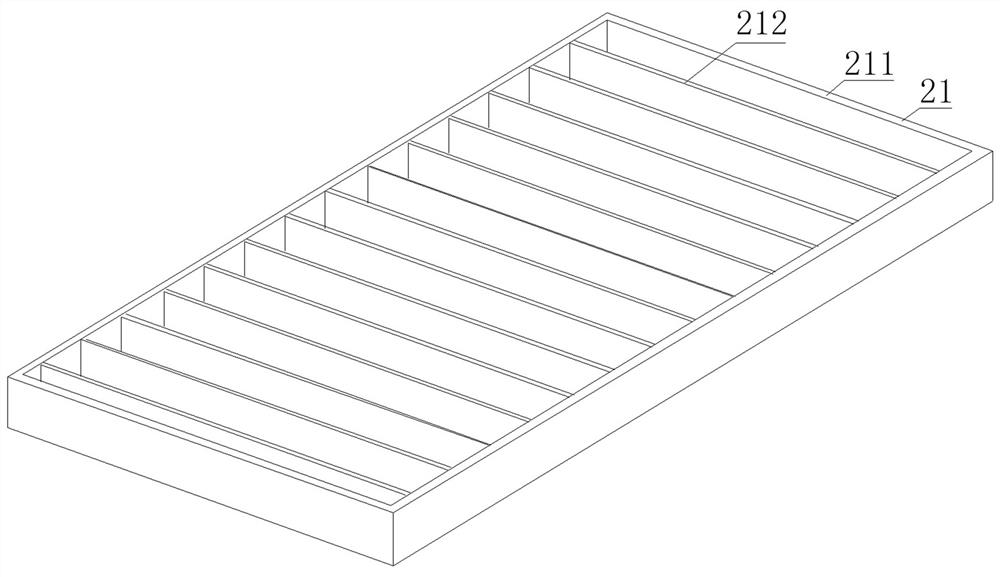

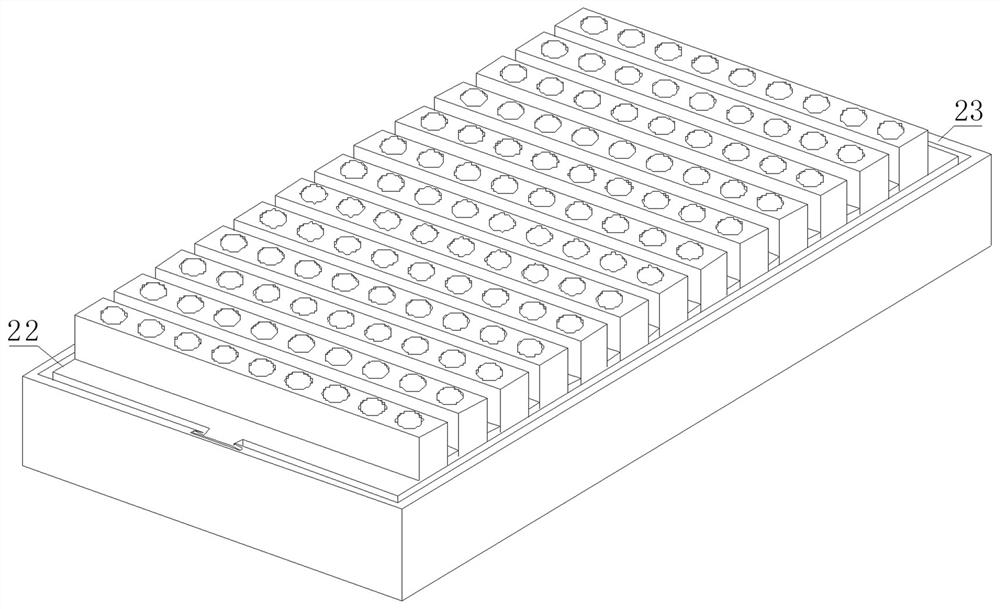

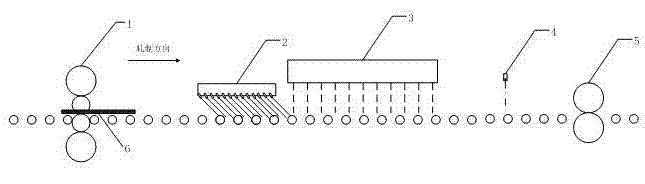

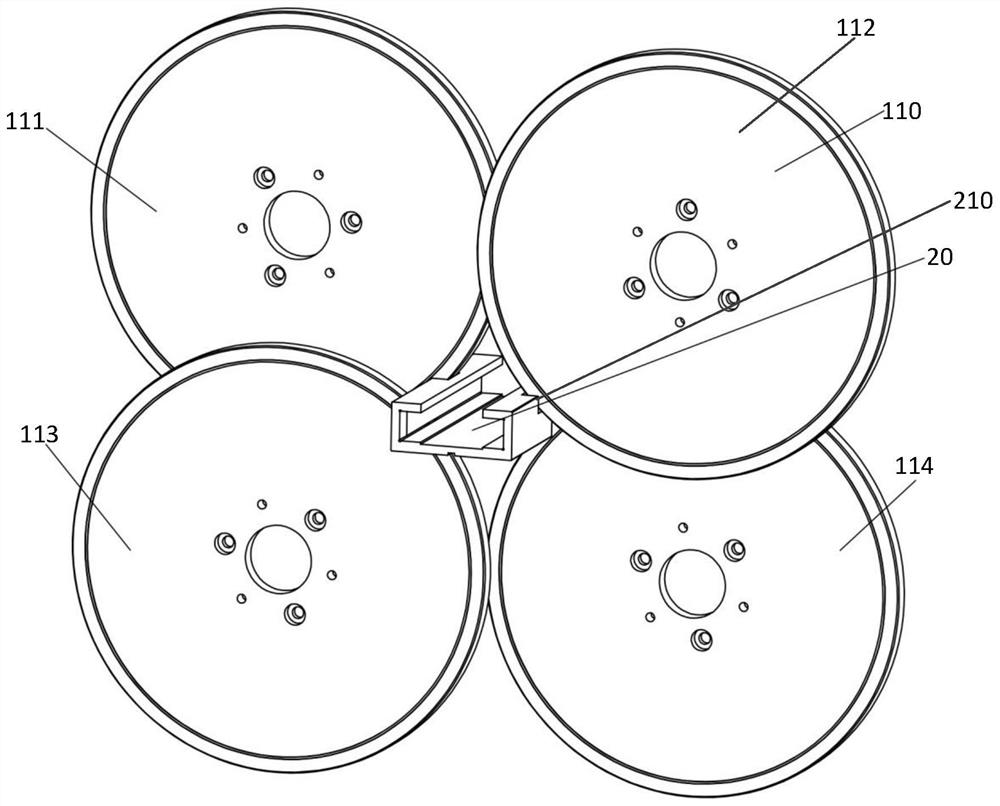

Agricultural product screening machine

InactiveCN107042205AEvenly screenedFast adjustment timeGradingAgricultural engineeringFrictional resistance

The invention relates to an agricultural product screening machine for screening agricultural products according to the size and more detailedly relates to a following agricultural product screening machine. According to the agricultural product screening machine, eight screening rollers are arranged on the upper face of a screening machine body for screening roller arrangement, four screening passages are formed between the screening rollers accordingly, and the rollers making contact with the screening passages are mounted in the mode that the rollers rotate form the bottom to the upper portion, so that damage caused due to frictional resistance of screened bodies passing through the screening passages and the screening rollers is minimized; and separation prevention pieces formed by brushes are arranged on the sides of the screening passages, connecting pieces assembled in an X shape are connected with supporting pieces used for supporting shaft seals of the screening rollers so as to enable left screw nuts and right screw nuts on the two sides to move inwards and outwards so that the distances of the screening passages can be simultaneously adjusted, the distances of the screening passages are precisely and rapidly adjusted accordingly, the agricultural products passing through the screening passages are prevented from breaking away from the screening passages, and thus efficient and safe screening is achieved.

Owner:权益三

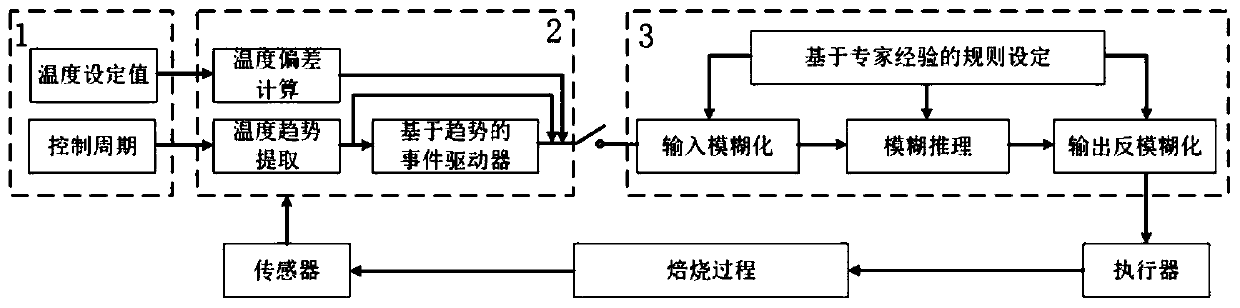

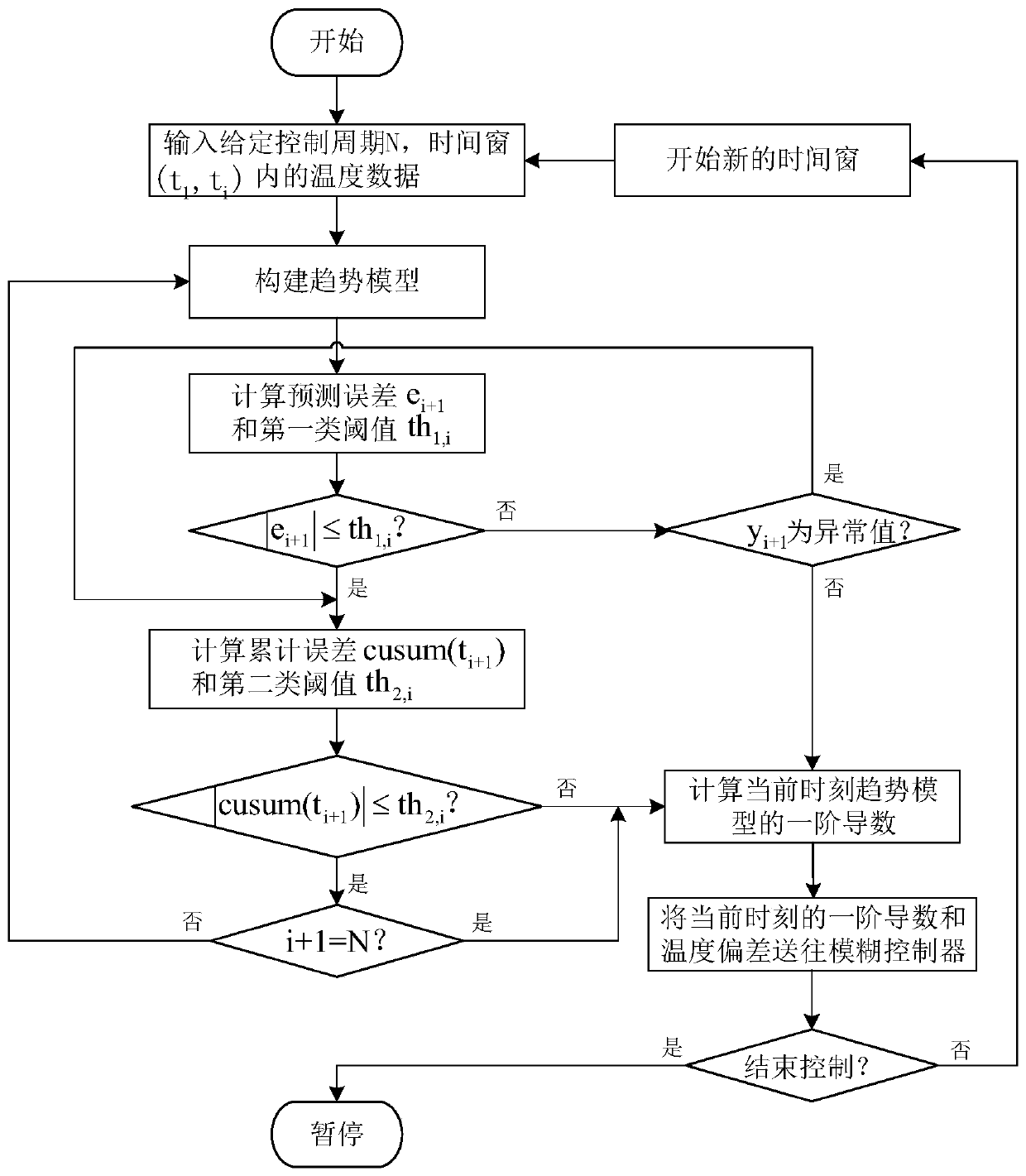

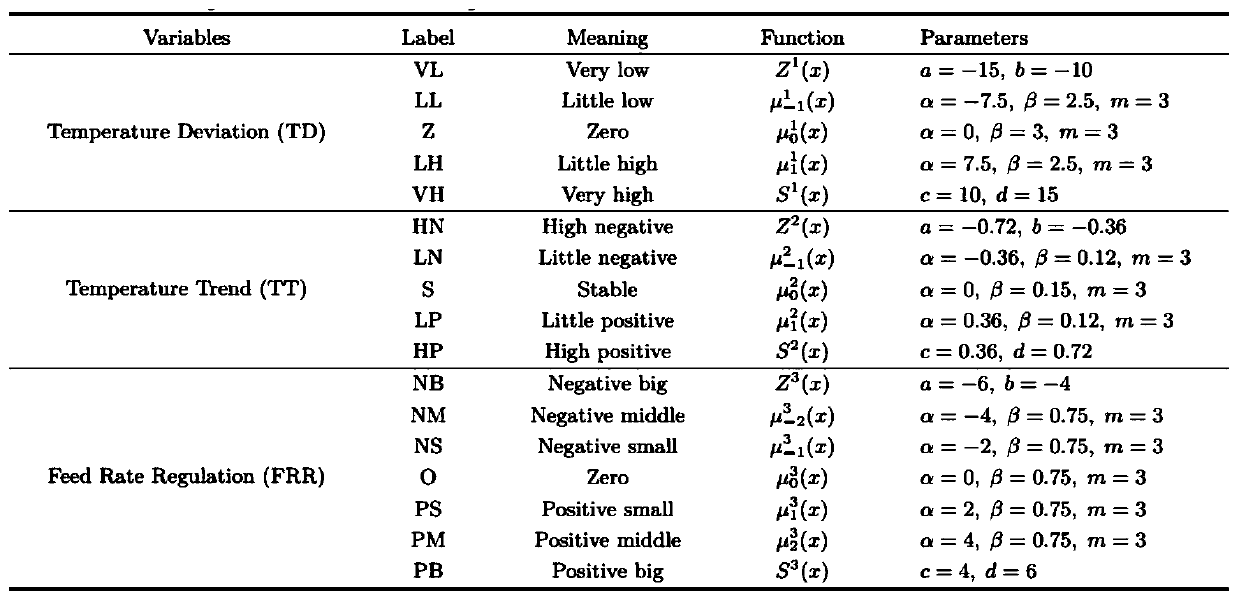

Fuzzy control method for zinc smelting and roasting process based on trend event driving

The invention provides a fuzzy control method for a zinc smelting and roasting process based on trend event driving. By setting a temperature set value and a control period N, and according to a real-time sampling temperature value of a sensor, a temperature deviation is calculated and a temperature trend is extracted, when a working condition changes or a preset control period is reached, fuzzy control is performed in time according to the temperature trend and the temperature deviation, and the problem of difficulty in assessing the working condition and decrease of control performance of afuzzy controller caused by dynamic characteristics of a roasting process and on-site environment constraints is improved.

Owner:CENT SOUTH UNIV

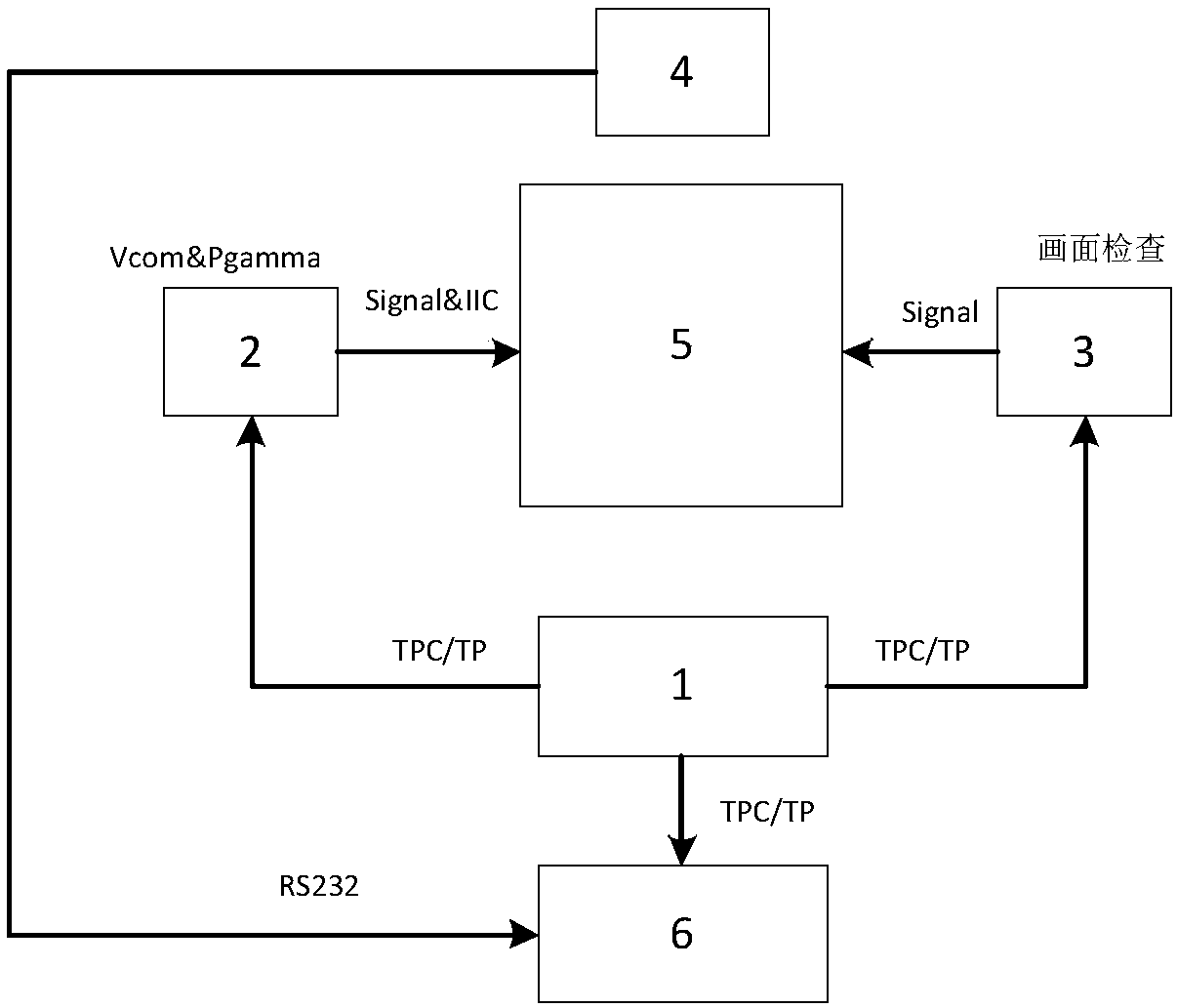

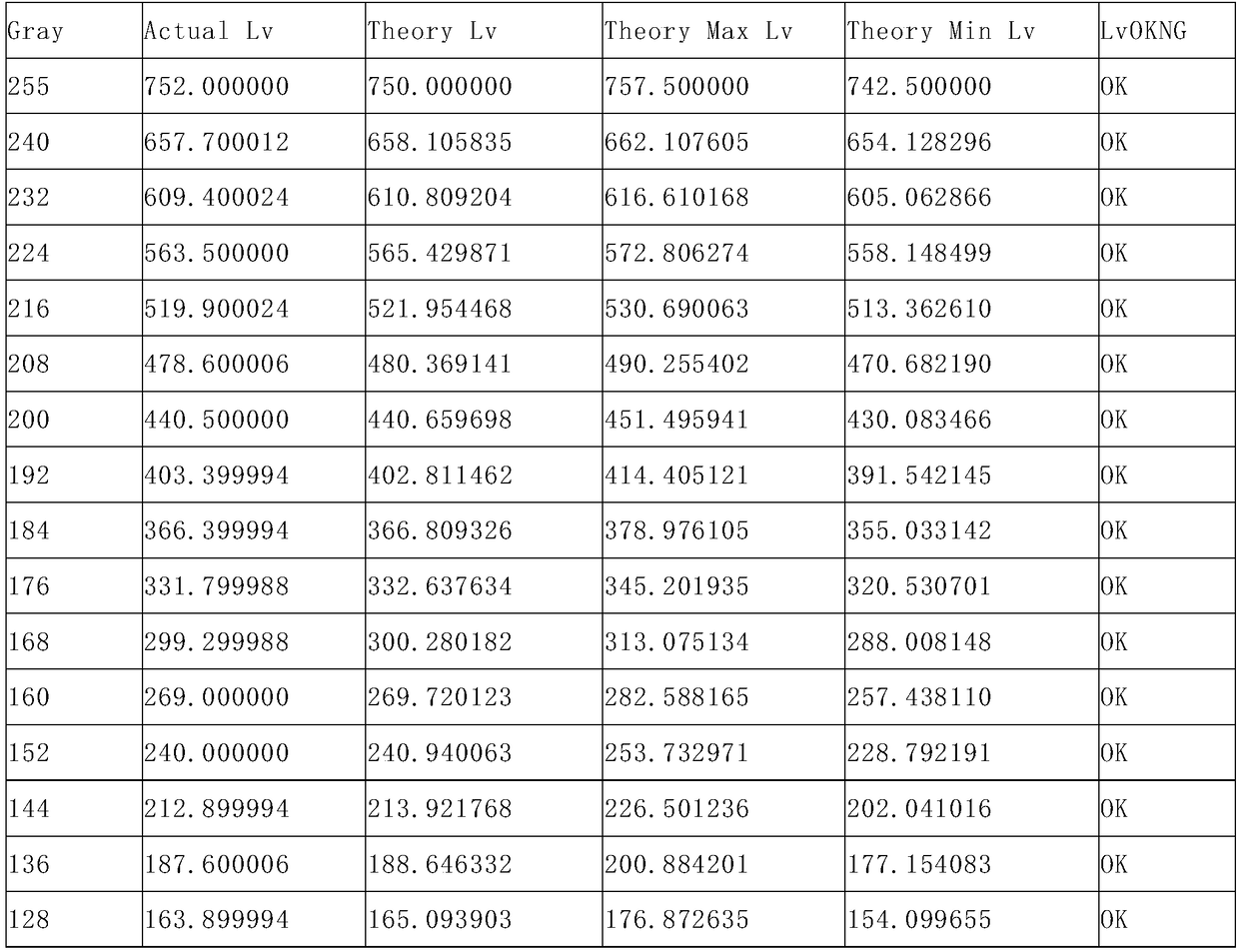

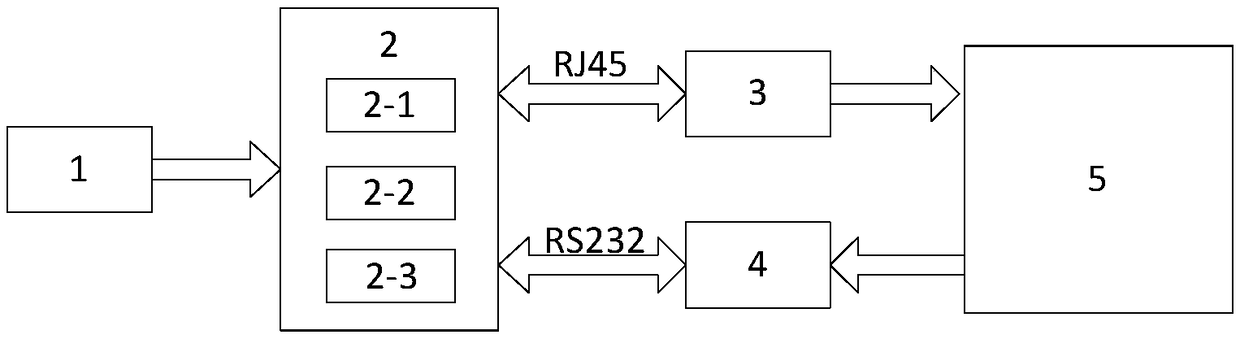

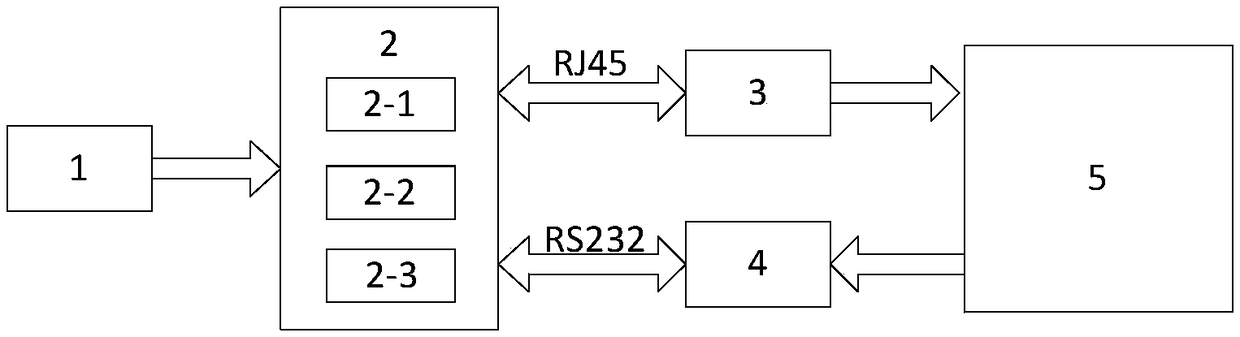

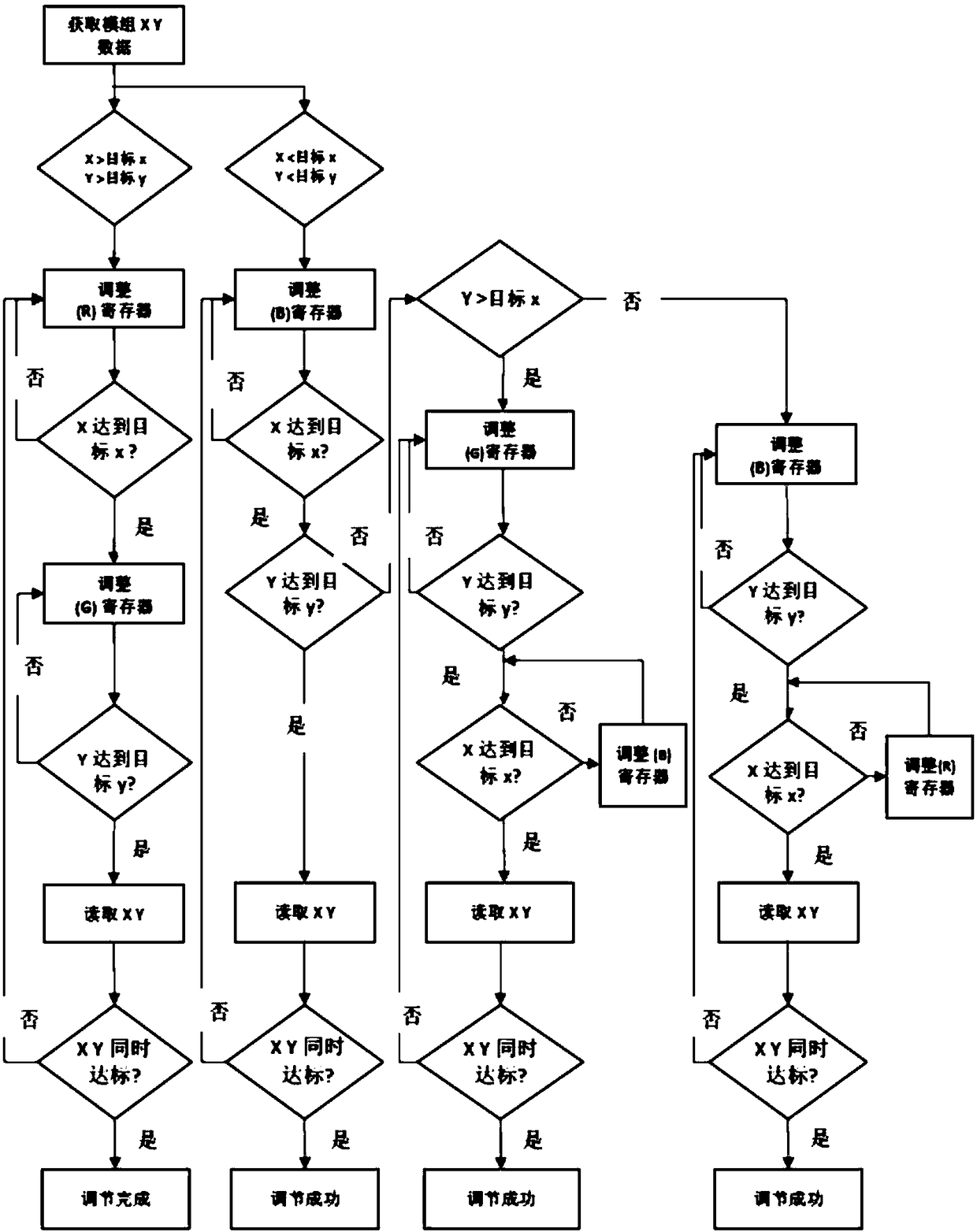

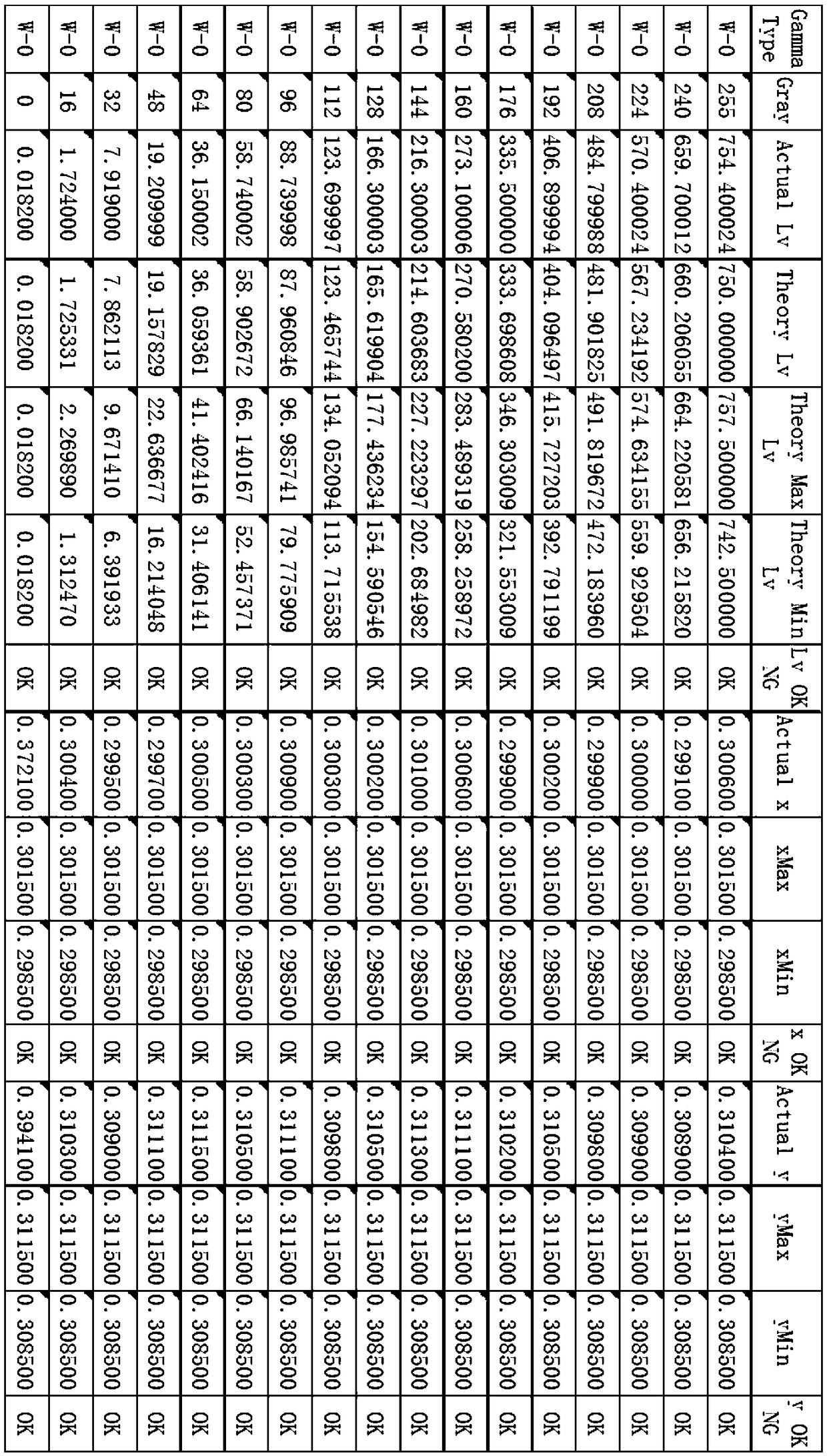

P-GAMMA automatic adjusting method and device based on large and medium-size modules

ActiveCN108648707AFast adjustmentHigh pass rate of brightnessStatic indicating devicesNon-linear opticsPass rateNegative voltage

The invention discloses a P-GAMMA automatic adjusting method and an automatic adjusting device based on large and medium-size modules. The method comprises the following steps: configuring Flicker parameters and P-Gamma adjusting parameters; configuring each binding point of the modules as well as corresponding register addresses; adjusting a VCOM register until searching out a VCOM value corresponding to the minimum Flicker value; sequentially adjusting Gamma adjusting on each binding point of the modules, in a Gamma adjusting process, adjusting corresponding positive voltage value V+ and negative voltage value V- corresponding to the binding point under a precondition of keeping symmetry of positive pressure and negative pressure, and implementing in a circulating mode until bright values of the modules are within a target brightness error range; implementing backward reading and verifying; and implementing OTP burning. The device comprises a PC, an adjusting PG, a picture check PG,an optical measuring instrument and modules. According to the method and device provided by the invention, a passing rate of quantitative grayscale brightness is guaranteed, namely brightness meets apassing rate of 255 greyscale brightness of a Gamma2.2 curve and under a condition that errors are within 0.2. Based upon experimental results, it is indicated that the device has the characteristicsof being high in adjusting speed and high in brightness passing rate.

Owner:WUHAN JINGCE ELECTRONICS GRP CO LTD

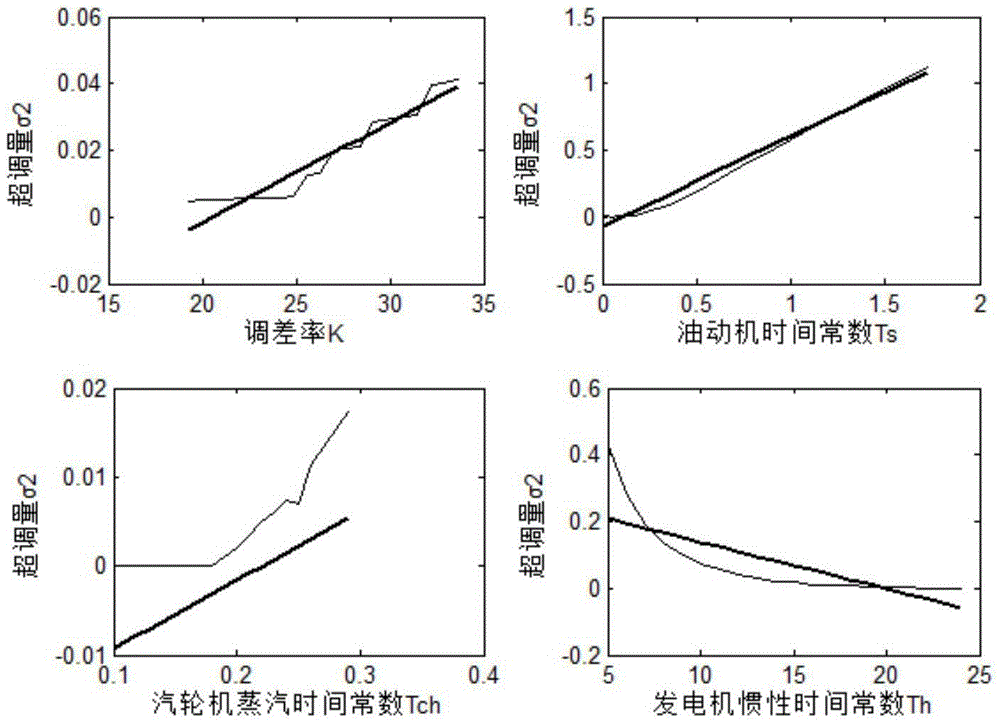

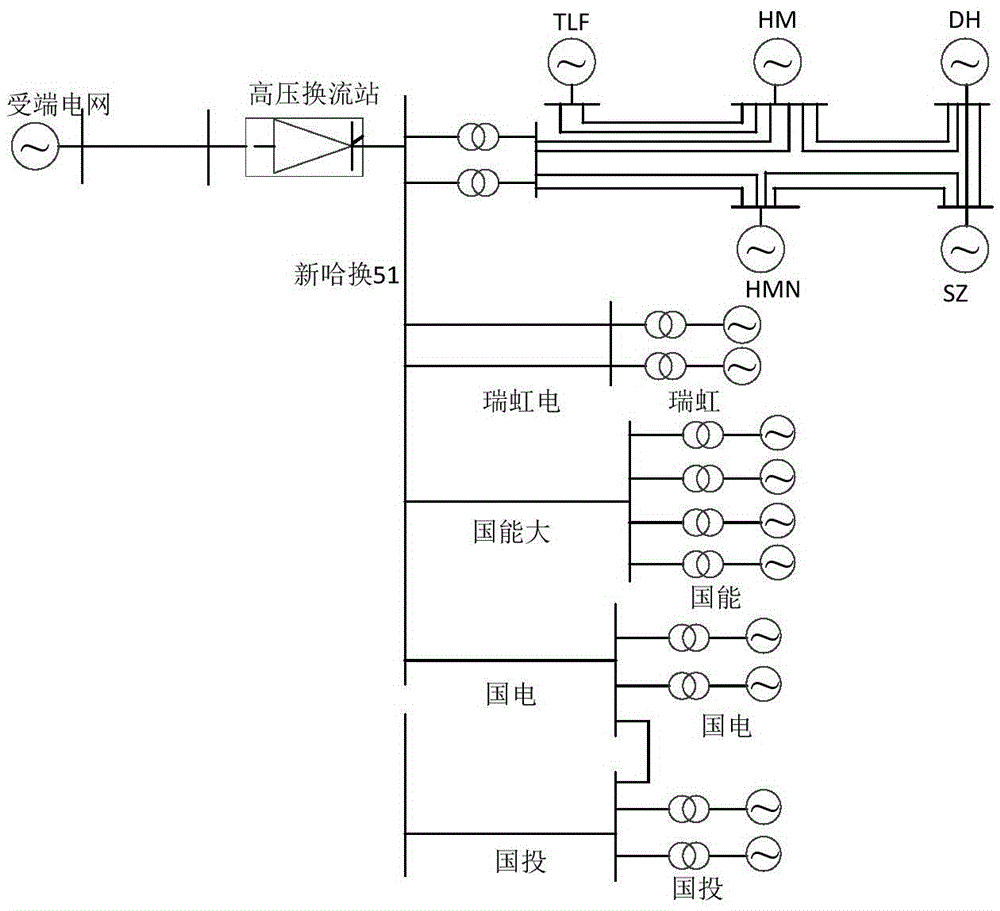

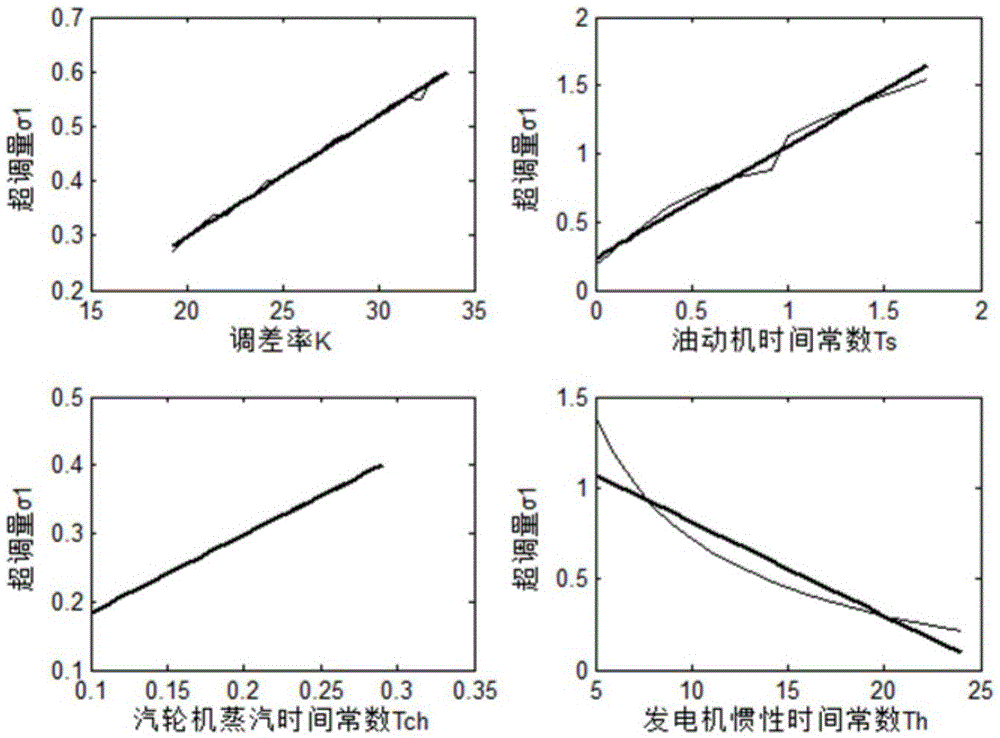

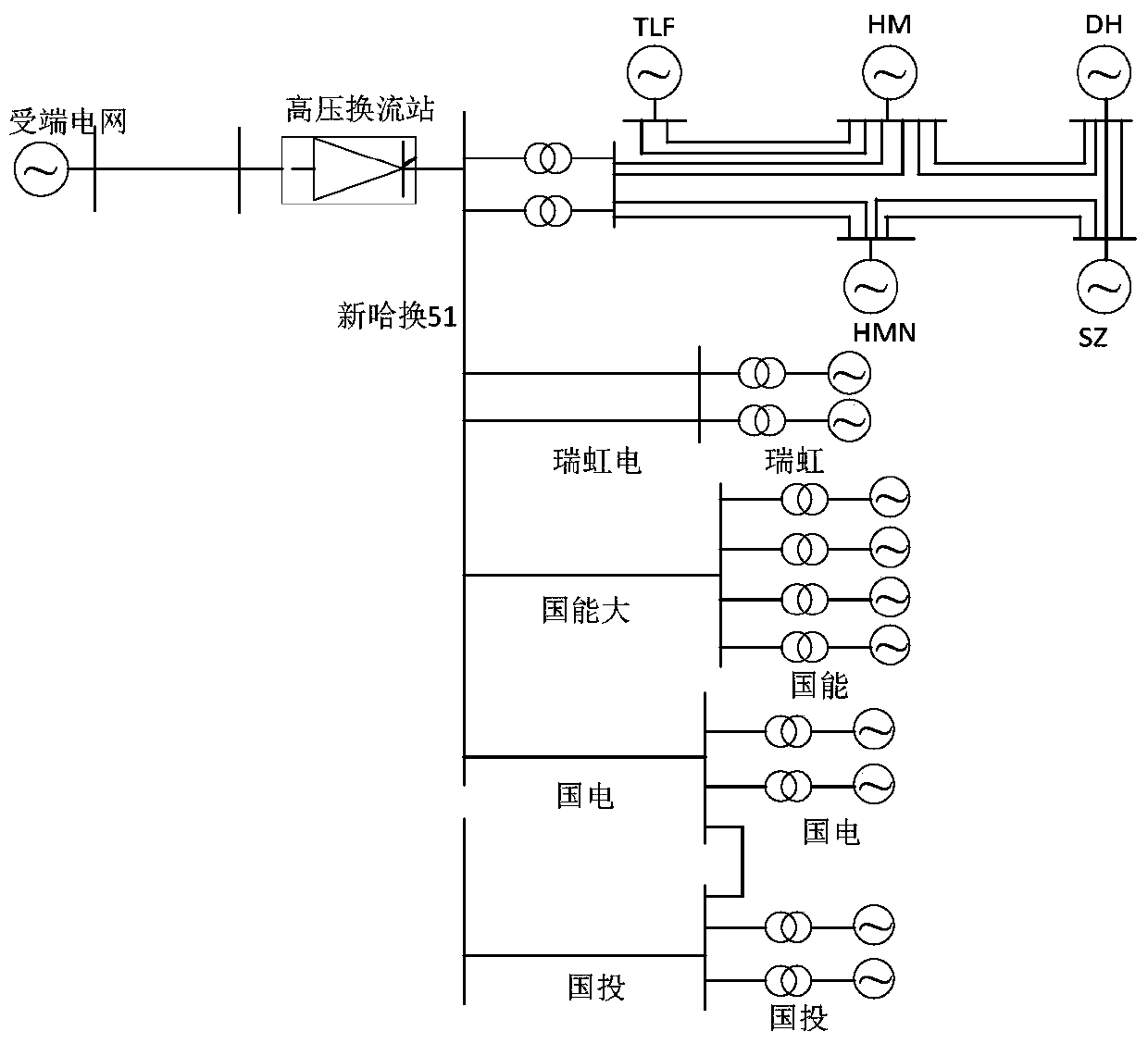

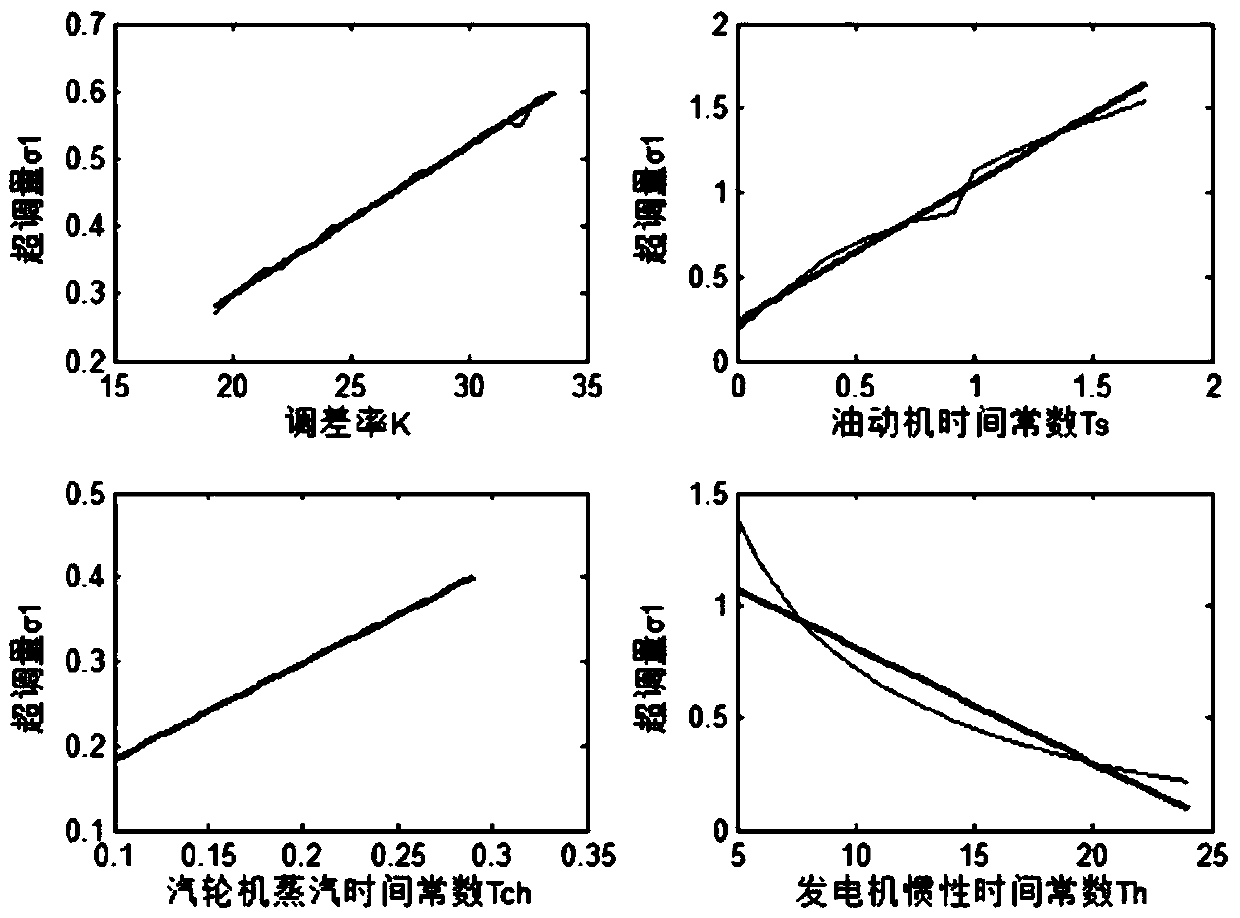

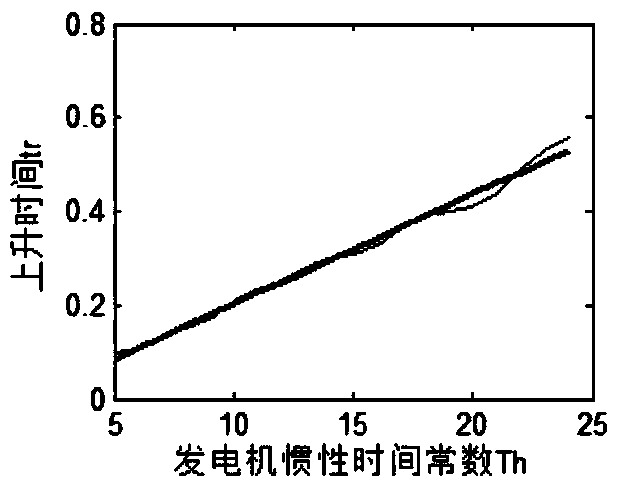

Multivariable fitting-based parameter optimization modeling method for generator speed regulating system

InactiveCN105490266AImprove primary FM performanceImprove unsatisfactory problemsElectric generator controlAc network circuit arrangementsTime constantModelling methods

The invention discloses a multivariable fitting-based parameter optimization modeling method for a generator speed regulating system. The method comprises the following steps: firstly, by a multivariable fitting method, fitting the relationship between three performance indexes, namely percent overshoot, rise time and regulating time, of primary frequency modulation of a generator and four control parameters, namely unit regulation power, a hydraulic servo-motor time constant, a turbine steam time constant and a generator inertia time constant; with the obtained multivariable fitting formula of the primary frequency modulation as an equality constraint, control parameter value ranges and other conditions as inequality constraints and the optimal primary frequency modulation performance of the fine speed regulating system as a final target, searching the speed regulating system parameter with the optimal primary frequency modulation performance by a multi-target and multi-constraint nonlinear optimization method; and building an optimized generator speed regulating system model.

Owner:STATE GRID GASU ELECTRIC POWER RES INST +3

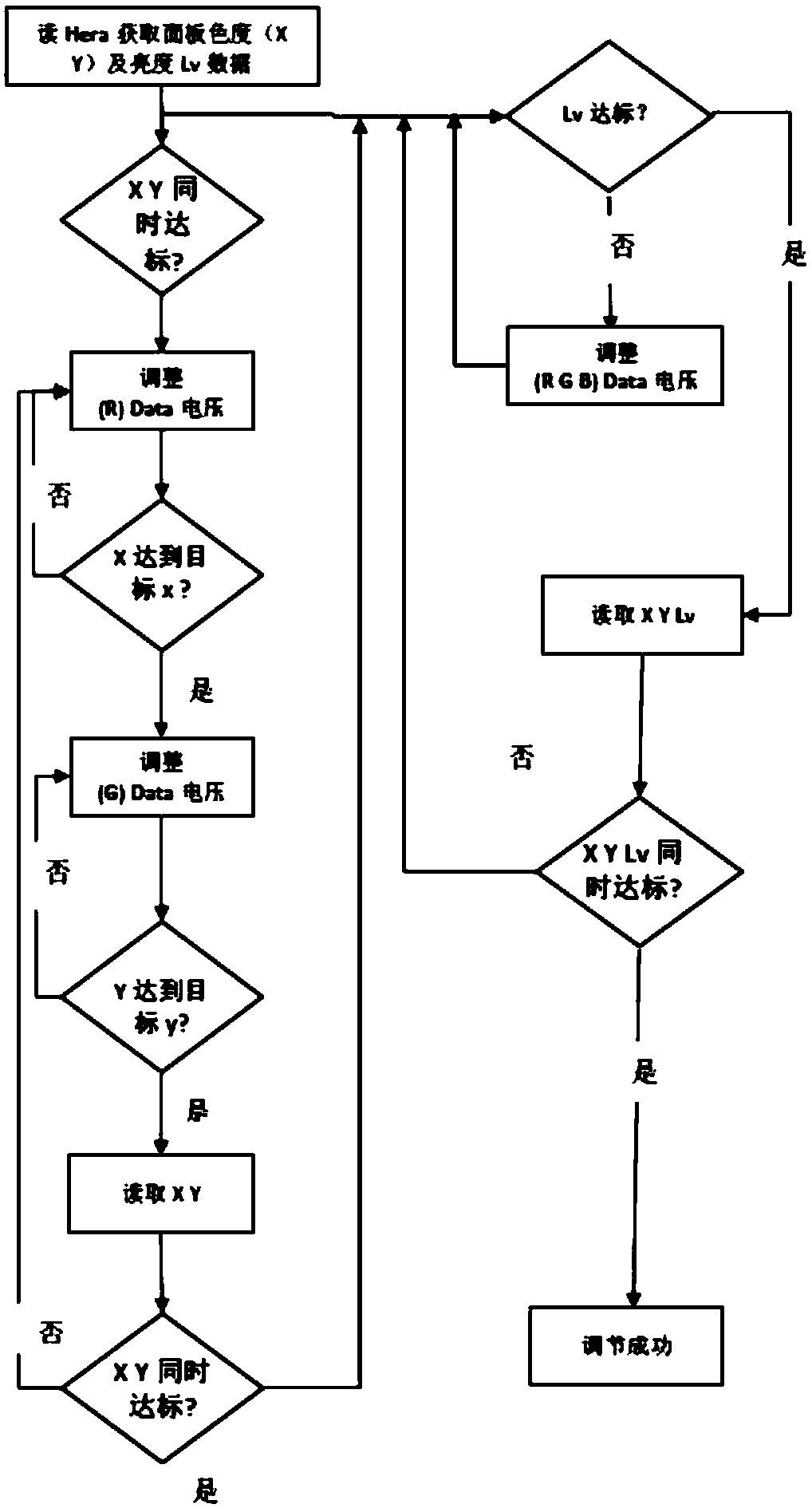

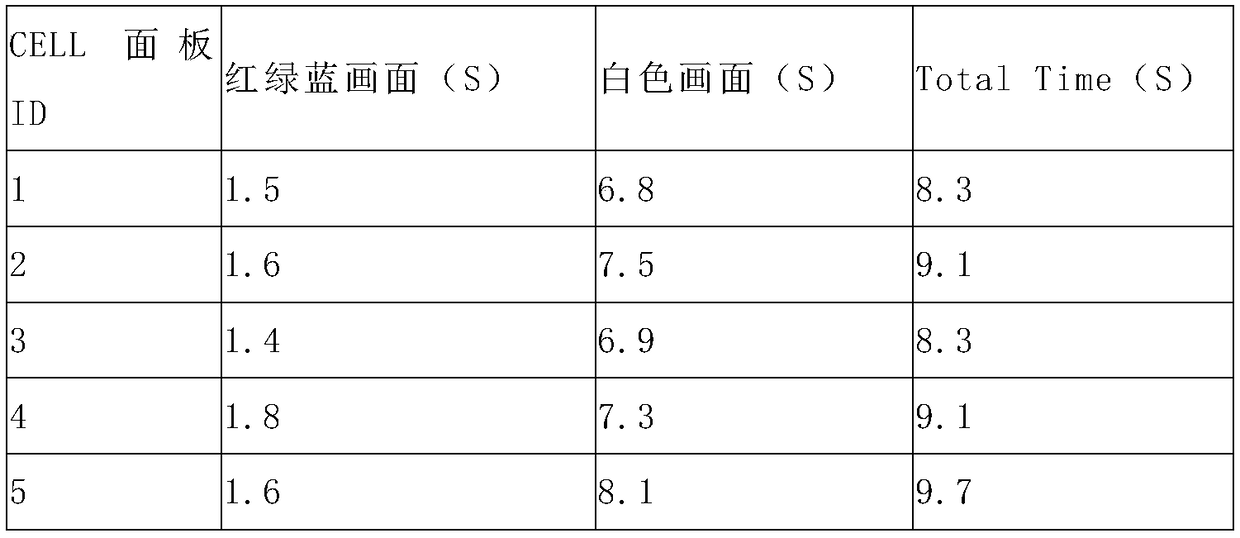

Gamma automatic calibration method and system of OLED CELL panels

InactiveCN108665848AShort adjustment timeFast adjustment timeStatic indicating devicesTest efficiencyCells panel

The invention discloses a Gamma automatic calibration method and system of OLED CELL panels. The method comprises the following steps of: configuring device parameters, a white picture and a red-green-blue picture adjusting parameter; performing wave-type conversion and binding Data voltage according to the CELL panel wave file and the pixel lighting principle; adjusting the Data voltage corresponding to the red, green and blue pictures to adjust the chroma and performing loop execution until the target chromaticity value and the corresponding data voltage value are searched, and performing white picture Gamma adjustment until the current brightness value is within the target brightness value error range; reading back the state brightness and the chroma of each binding point of the CELL panel, and recording and storing the Data voltage value corresponding to each state; inputting the saved Data voltage value to the CELL panel for screen detection. The system comprises a PC, a TEMS, a lighting device, an optical tester and a CELL panel. The Gamma automatic calibration method has the advantages of simple operation, high chroma and high brightness passing rate and high test efficiency, and is convenient for large-scale use in the factory.

Owner:WUHAN JINGCE ELECTRONICS GRP CO LTD

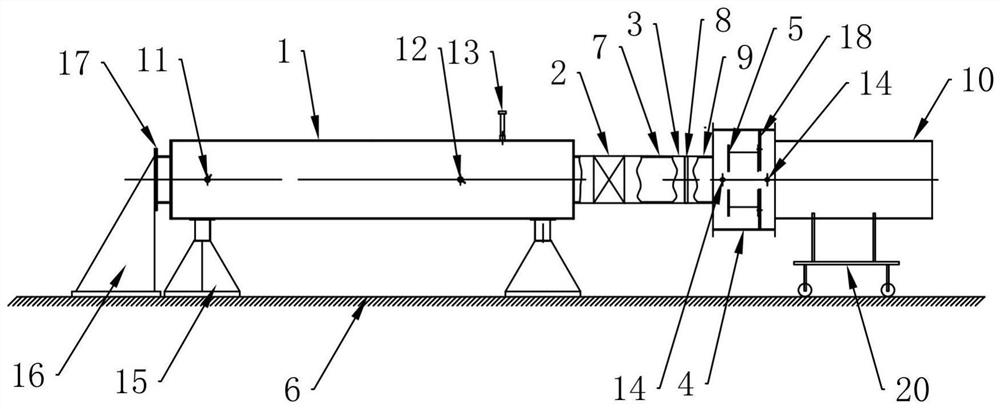

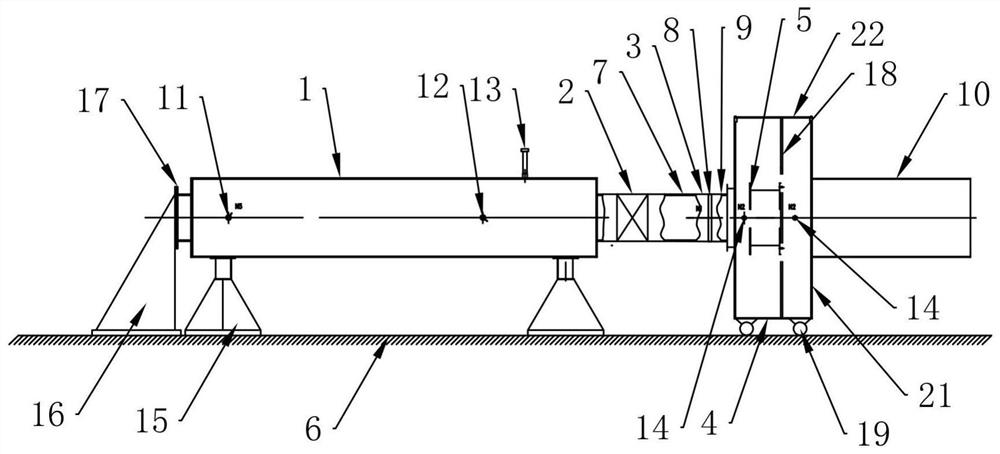

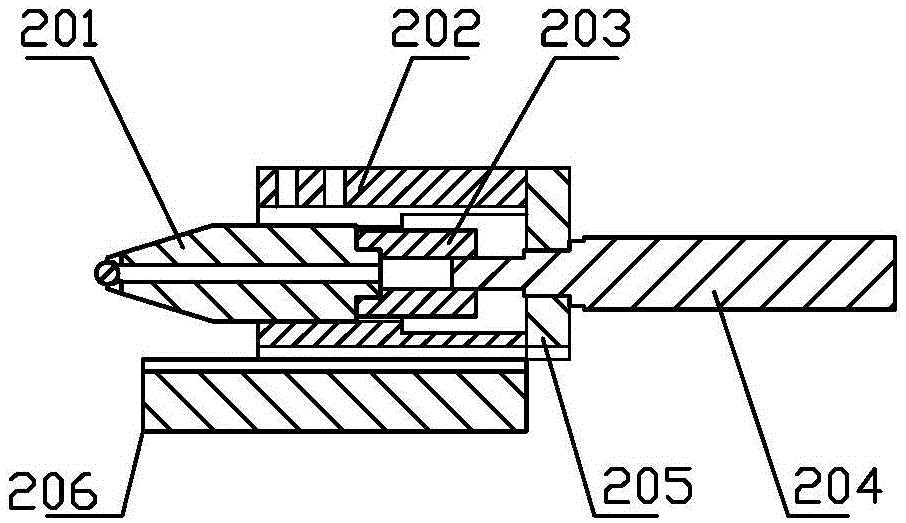

Controllable shock wave testing device

A controllable shock wave test device disclosed by the present invention comprises a gas storage tank, a quick-opening valve, a buffer assembly and an installation tank which are connected in sequence, the buffer assembly comprises a transition pipe, at least one flow limiting plate and a buffer pipe which are connected in sequence, the gas storage tank is provided with a gas inlet valve and a pressure relief valve, a test piece is installed in the installation tank, the gas storage tank is provided with at least one pressure sensor, and the pressure sensor is connected with the gas storage tank. And at least one shock wave sensor is arranged at each of two ends of the test piece in the mounting tank. The device is simple in structure and high in experiment efficiency, the action duration of shock waves can be adjusted according to test requirements, the device is completely different from a traditional TNT explosive shock wave test and a detonation type shock tube test, replacement of a rupture disk is avoided, the test progress is greatly accelerated, for a standard shock wave chamber test room, manpower needed by the test can be reduced by 70% or above, and the test efficiency is improved. The labor hour of a single laboratory is saved by more than 4000 hours per year, and the cost of more than 0.2 billion RMB can be saved for the same type of laboratories in the whole society every year.

Owner:上海震业环境科技有限公司

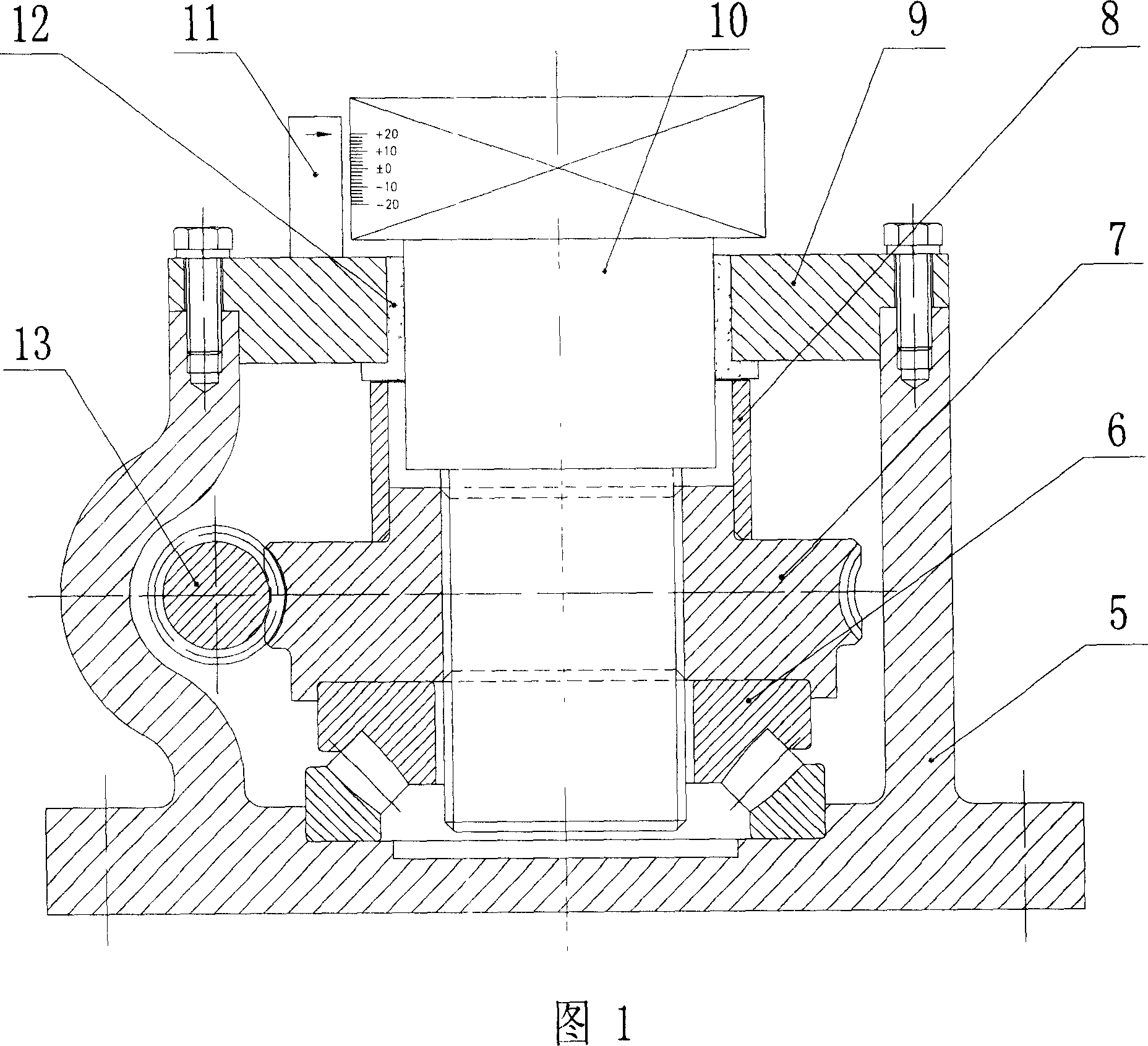

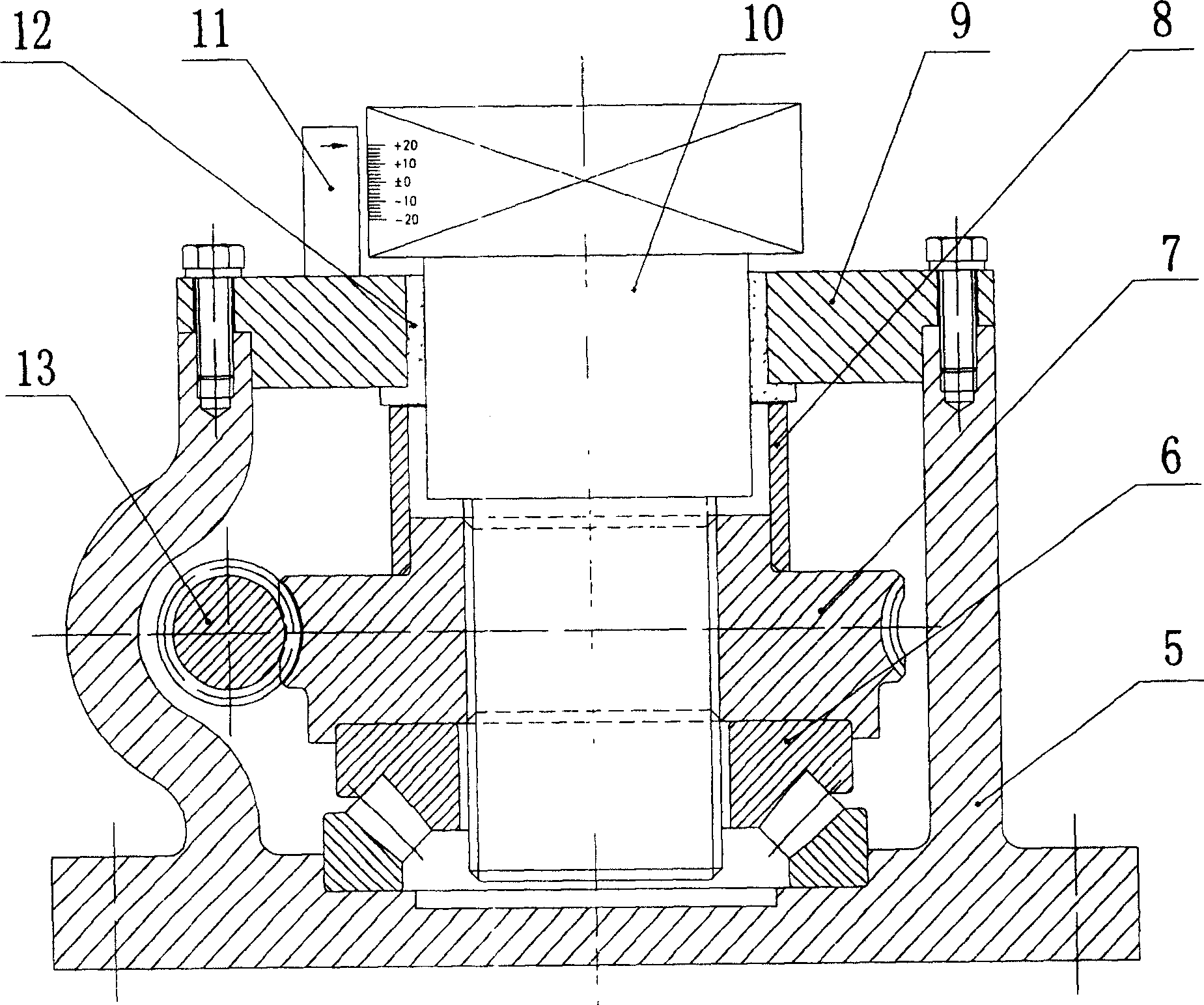

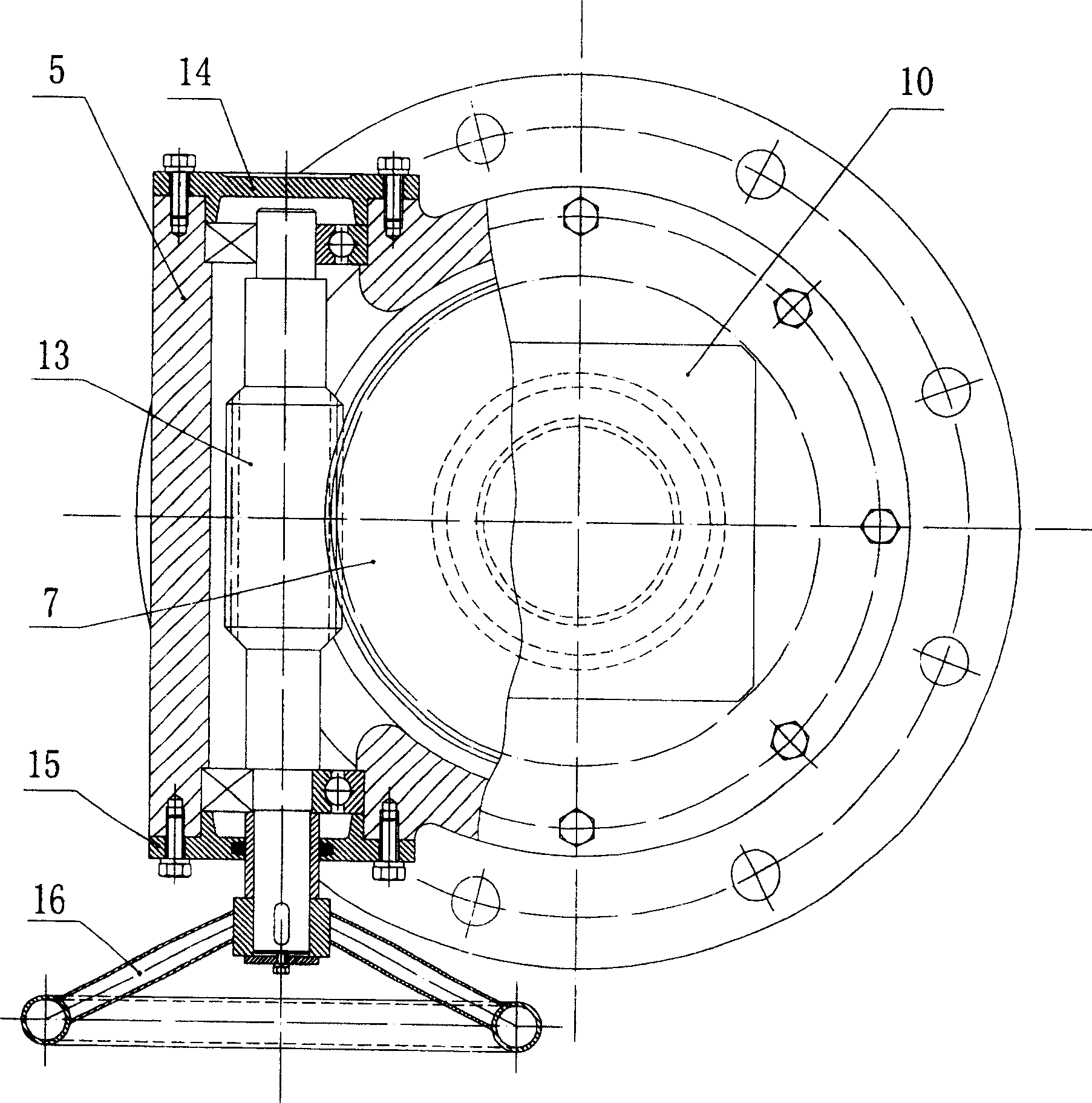

Levelling equipment for vacuum chamber

This invention relates to a leveling device for vacuum chamber, which comprises a housing, a pneumatic thrust bearing, a worm gear, a guide cover, a screw prop, and a worm rod. The lower part of the screw prop runs through the guide hole in the guide cover, and is in the chamber of the housing. The lower end of the worm gear is connected with the housing via the pneumatic thrust bearing. The screw prop has external threads, and is locked in the internal threads of the worm gear. The lower end of the screw prop runs through the screw prop hole in the pneumatic thrust bearing. The worm rod and the worm gear are meshed. Both ends of the worm rod are connected with the housing via bearings. One end of the worm rod is connected with the hand wheel or the output axis of the speed reduction motor. The guide cover and the housing are fixing-connected. The leveling device has such advantages as high production efficiency and simple structure, and can level with load.

Owner:WISDRI ENG & RES INC LTD

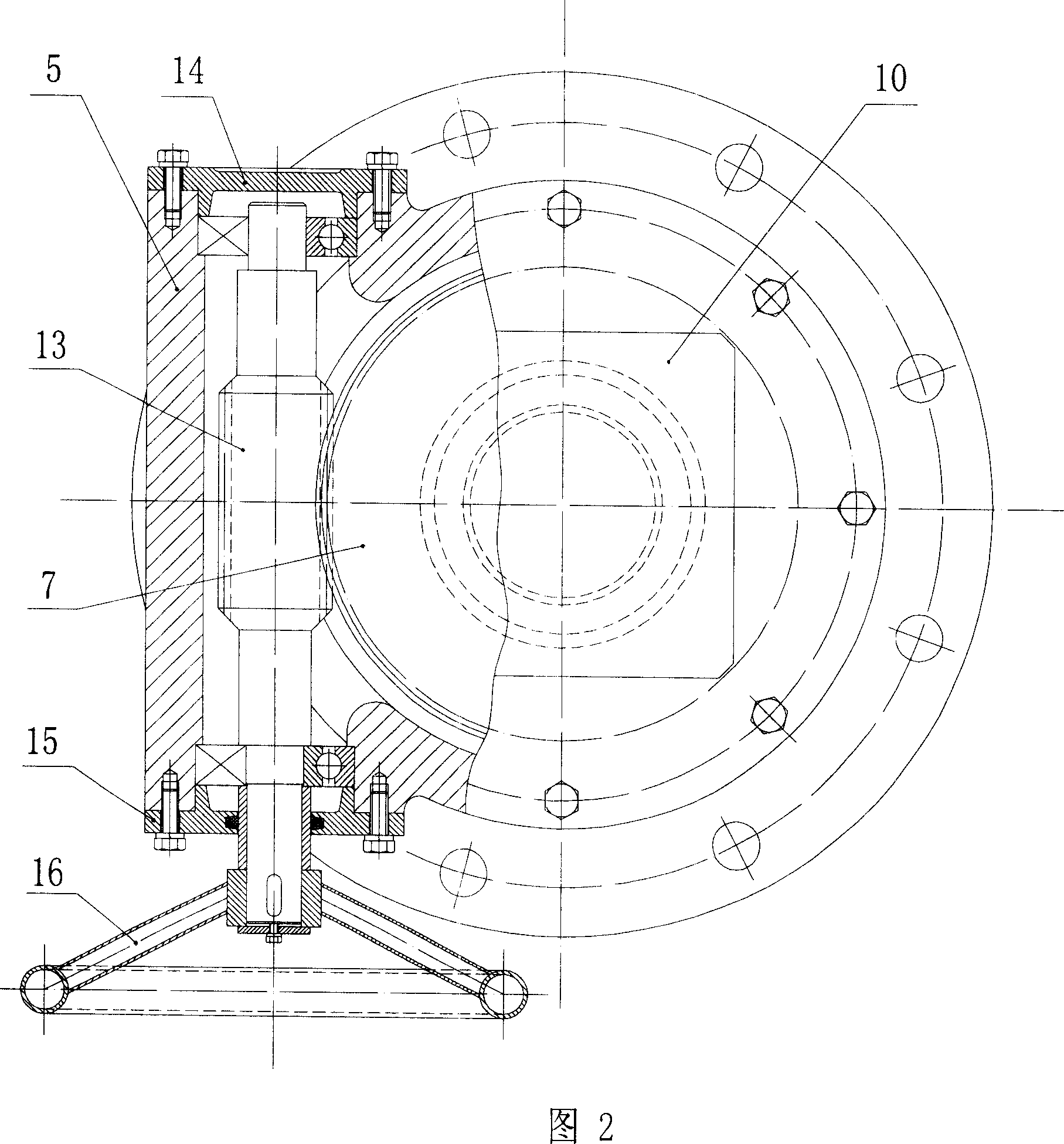

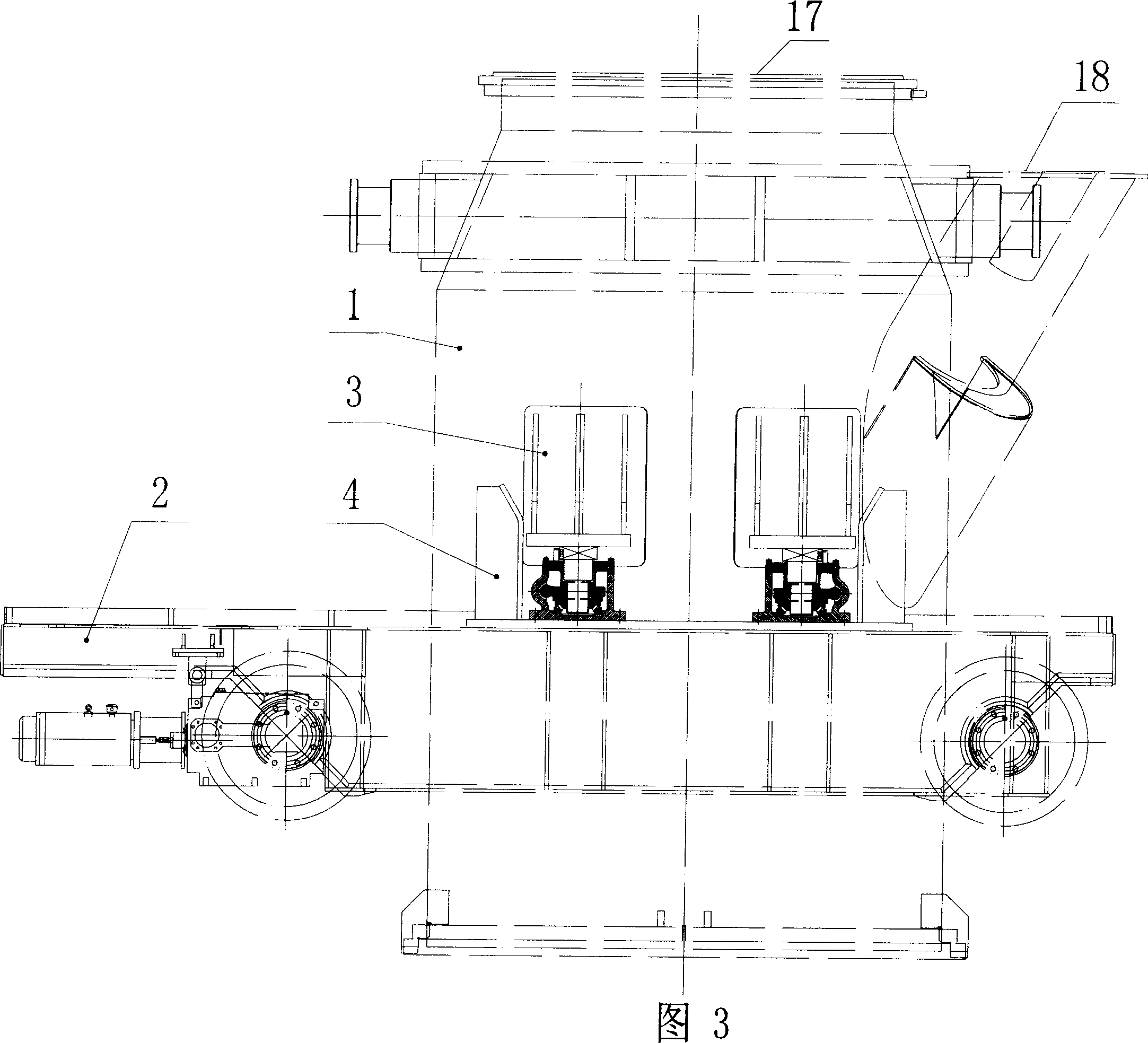

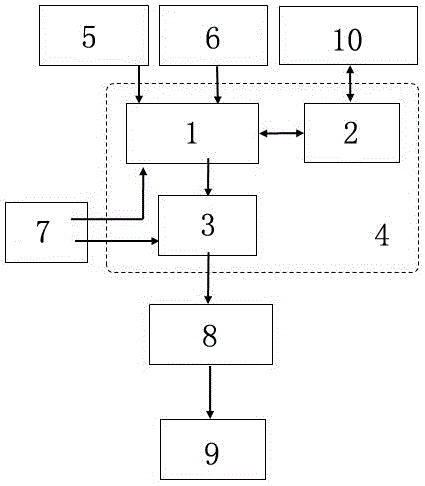

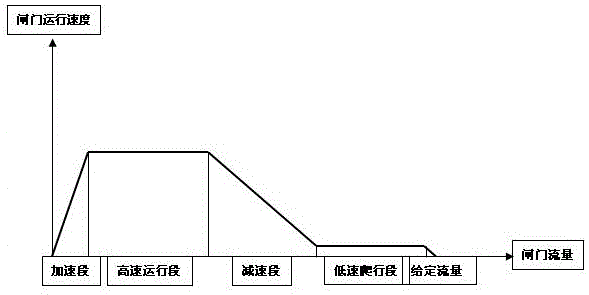

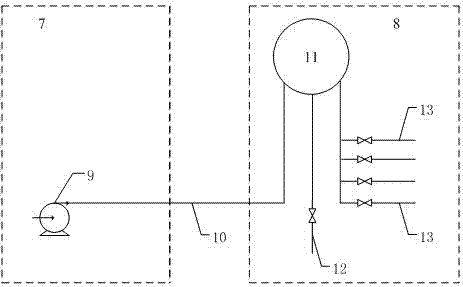

Method and apparatus for automatically adjusting electric gate vale

PendingCN106354165AAccurate flowFlow automaticFlow control using electric meansCommunication interfaceFrequency changer

The invention relates to a method and an apparatus for automatically adjusting an electric gate valve, belonging to the technical field of water measurement and measurement and control of a gate valve in the water conservancy industry. According to a technical scheme, the apparatus comprises a gate valve controller (1), a communication interface (2) and a frequency converter (3), wherein the gate valve controller is respectively connected with the communication interface and the frequency converter; and the apparatus also comprises a gate position sensor (5), a water level sensor (6) and a power supply (7) which are respectively connected with the gate valve controller (1); the number of the water level sensor is at least one; the frequency converter is respectively connected with the power supply and a gate valve deceleration motor (8); and the gate valve deceleration motor is connected with a gate valve opening and closing machine (9). The method and the apparatus for automatically adjusting the electric gate valve have the beneficial effects that by adjusting the speed of the gate valve, gate valve water measurement and monitoring parameters are used for setting a value according to the requirement so as to realize the variable-frequency PI adjustment of the gate: high-speed running, low-speed approaching, tail-end crawling and precise flow, and the flow of the gate valve is automatically and precisely adjusted.

Owner:唐山现代工控技术有限公司

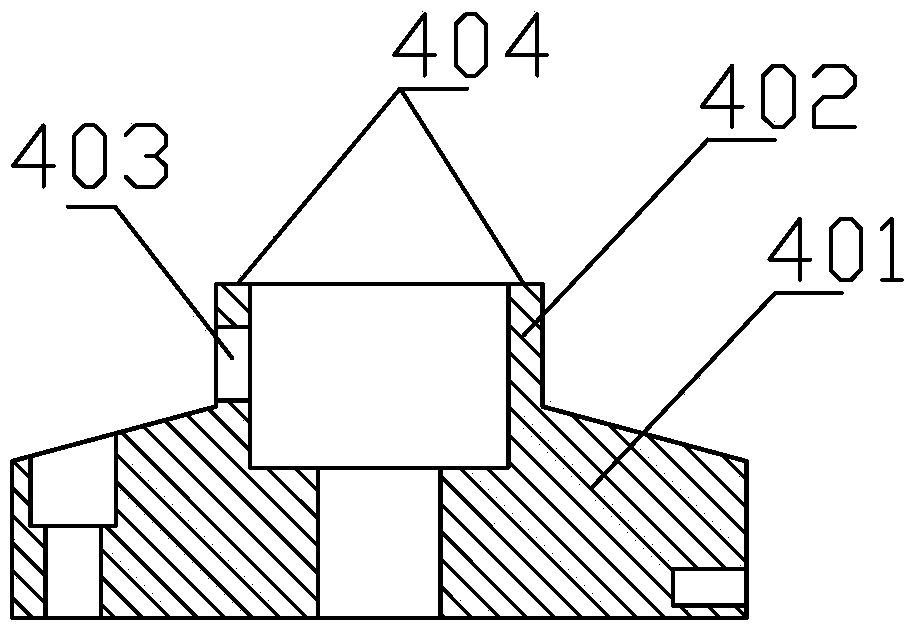

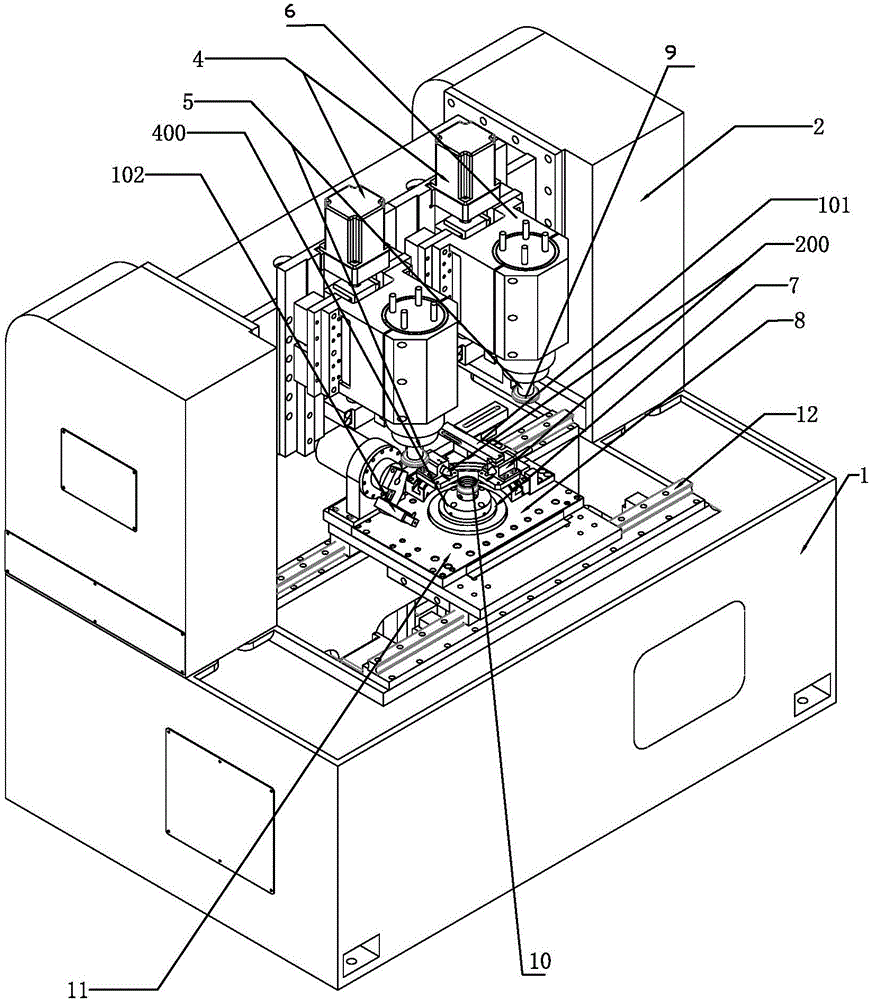

Universal grinding machine for nuclear power bearing outer ring processing

ActiveCN103639875BLower skill requirementsHigh adjustment accuracyAbrasive surface conditioning devicesGrinding machinesRobotic armMagnetic poles

A universal grinder special for nuclear power bearing outer race machining comprises a machine tool base, a machine tool body, a hydraulic system, an electric control system and a servo system and further comprises electric spindles, spindle lifting mechanisms, a workpiece shaft, a grinding wheel dresser, a workpiece shifting mechanism, a support assembly, a mechanical arm, a magnetic pole, a grinding wheel, a cutting liquid circulation system and a nuclear power bearing outer race. On the premise that machining accuracy is ensured, time for replacing mechanical parts and adjusting machining size can be saved, machining can be conducted continuously by simply replacing the magnetic pole, and machining efficiency can be effectively improved.

Owner:大连大友高技术陶瓷有限公司

Device for efficiently measuring tree height

InactiveCN101749988BImprove work efficiencyEasy to useRulers for direct readingComputer scienceTree based

Owner:SHANDONG AGRICULTURAL UNIVERSITY

AF-ACC-AG adjustment and calibration method and system based on TTL module

InactiveCN108766376AShort adjustment timeFast adjustment timeStatic indicating devicesProcessor registerTransistor

The invention discloses an AF (Auto Flicker)-ACC (Auto Color Coordinate)-AG (Auto Gamma) adjustment and calibration method and system based on a TTL (Transistor TransistorLogic) module. The AF-ACC-AGadjustment and calibration method based on a TTL module includes the steps: configuring equipment parameters, AF, ACC, and AG adjustment parameters, white frame, and red, green and blue frame adjustment parameters; configuring binding points and corresponding register addresses; analyzing configuration, writing an initial value of a register into the module, acquiring the current optical parameters of the module, comparing the current parameters of the module with the target value, according to the IC characteristic and the AF-ACC-AG algorithm, rewriting the module register value, and performing loop execution until the current parameters of the module are in the error range of the target value; analyzing the white frame configuration, and performing white balance and Gamma adjustment on the white frame of the binding point until the current luminance value is in the error range of the target luminance value; reading back the luminance and chroma of the state of each binding point, according to the reading back result, performing fine adjustment until the luminance value and the chromatic value under the state of each binding point, and recording the register value corresponding toeach state; and solidifying the adjusted register value into EEProm of the TTL module. The AF-ACC-AG adjustment and calibration method and system based on a TTL module have the characteristic of highpercent of pass, and can improve the quality of the outgoing TTL module.

Owner:WUHAN JINGCE ELECTRONICS GRP CO LTD

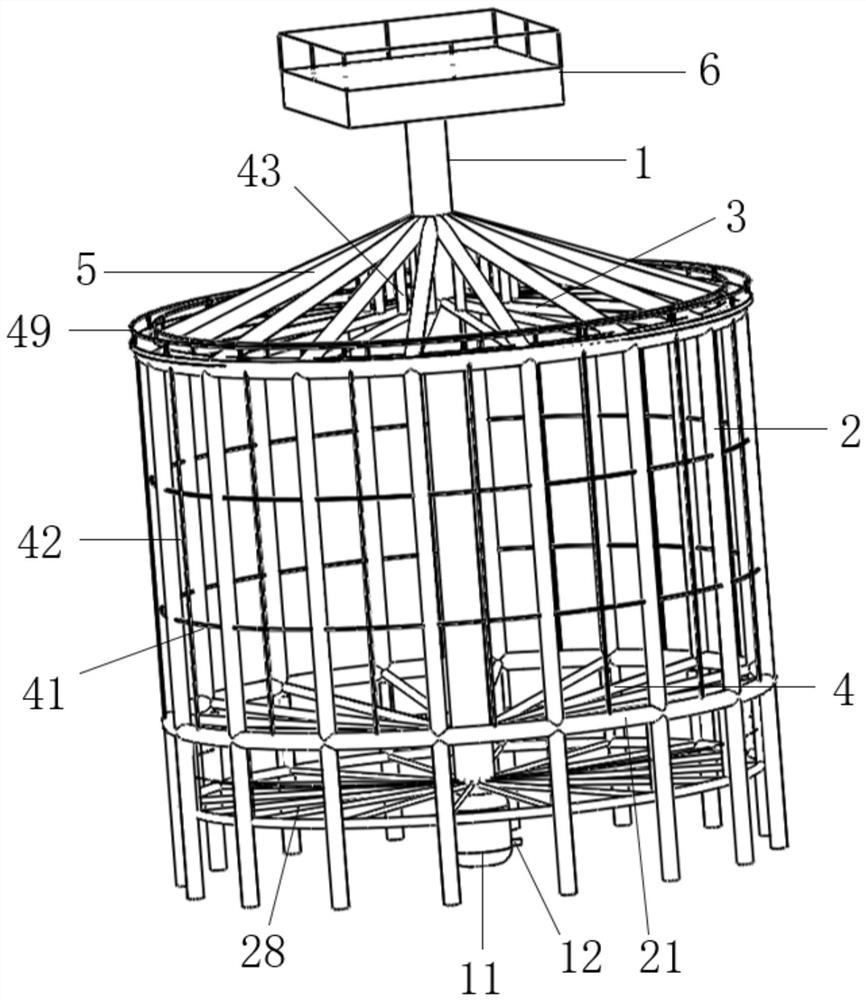

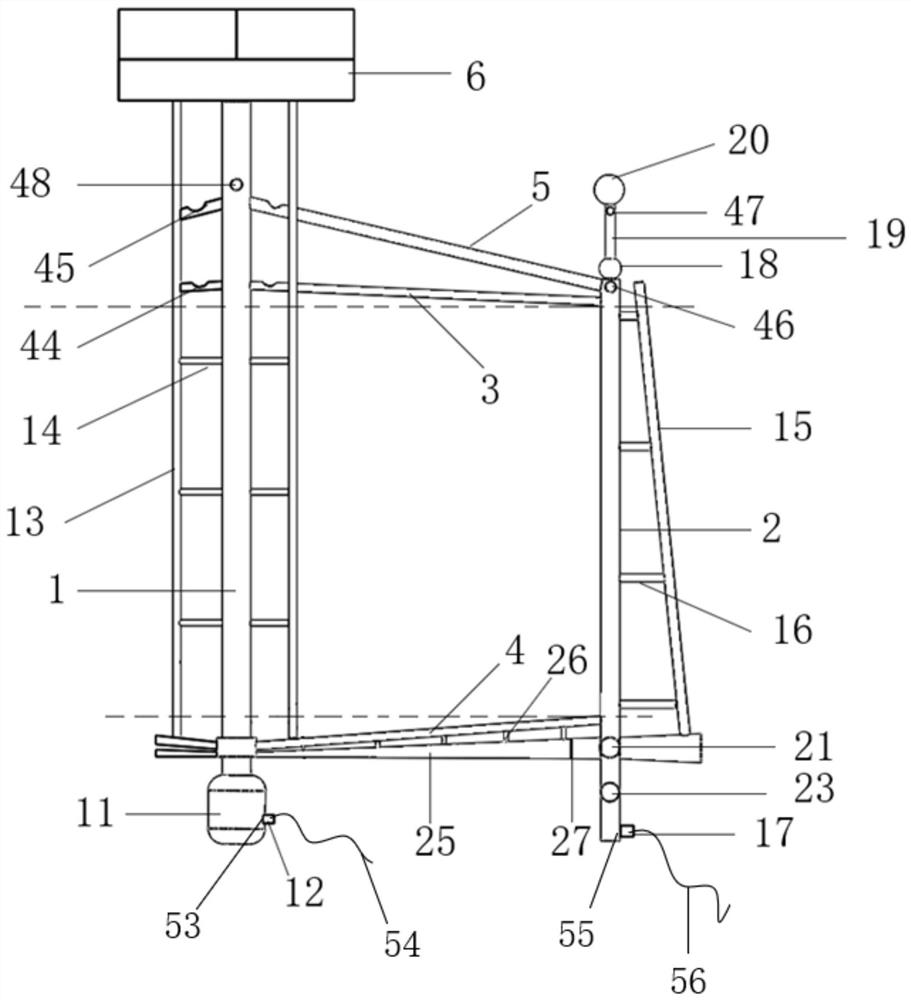

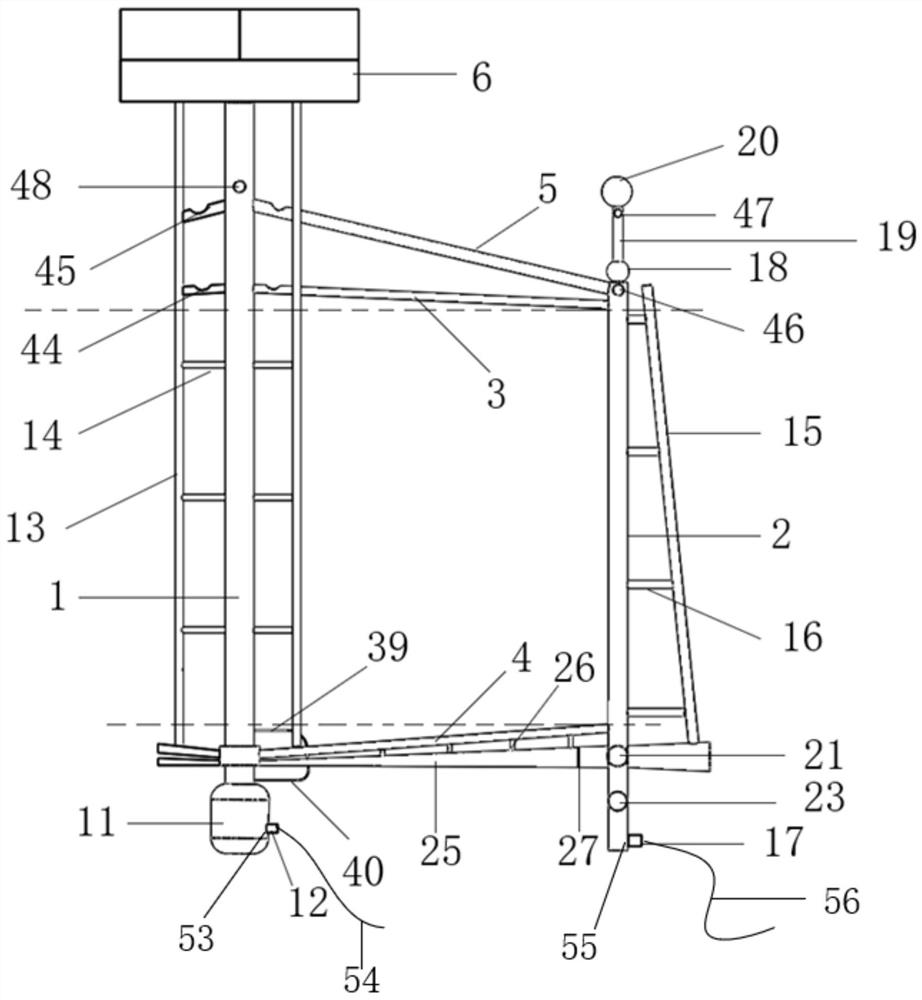

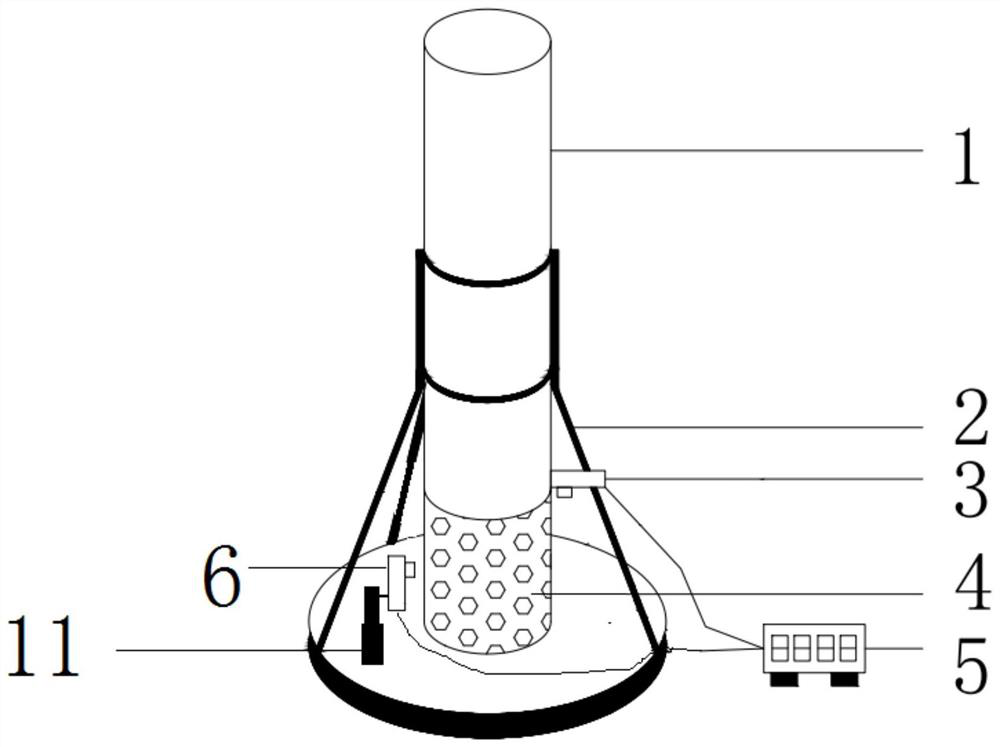

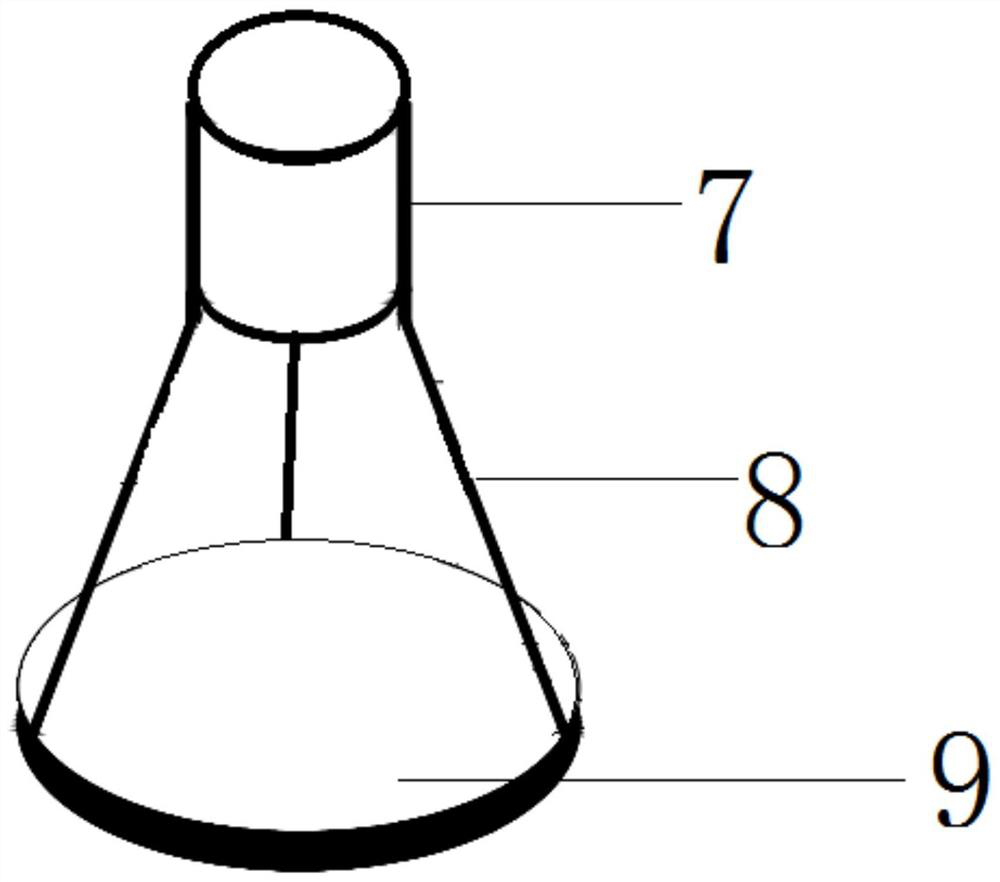

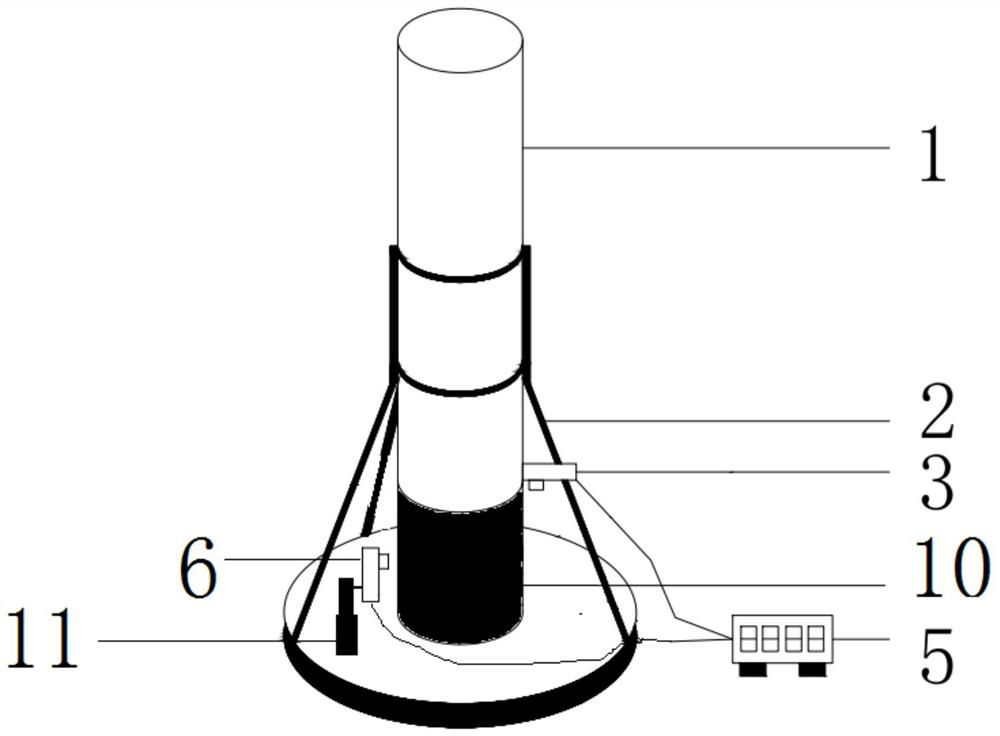

Environment-friendly multifunctional deep-sea breeding device

PendingCN113994908AAvoid destructionGrow fastClimate change adaptationPisciculture and aquariaMarine aquacultureFishery

An environment-friendly multifunctional deep-sea breeding device relates to the technical field of marine aquaculture. The device comprises: a central column and a plurality of upright columns, wherein the upright columns surround the central column in the middle in a regular polygon shape, the upper ends of the upright columns are connected with the upper end of the central column through first supporting pipes, and the lower ends of the upright columns are connected with the lower end of the center column through second supporting pipes. The device further comprises an adjusting mechanism that can adjust the device to ascend and descend stably. Thus, compared with the prior art, growth environment of fishes can be prevented from being damaged by typhoons owing to the fact the device can be adjusted to ascend and descend stably through an adjusting mechanism; the top center and the bottom center of the device protrude outwards to form a triangular shape so as to enable the device to be firmer and higher in typhoon resisting capacity, and reduce water resistance when the device ascends or descends; a netting at the bottom of the device can ascend to the position above the water surface, so that the net can be conveniently and thoroughly dried, and the dirty calling period is prolonged.

Owner:莱州市善隆海洋科技有限公司

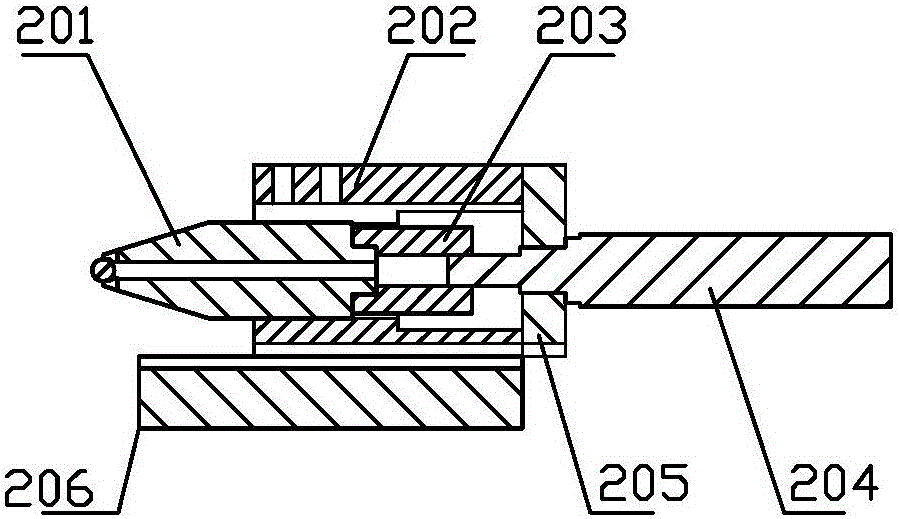

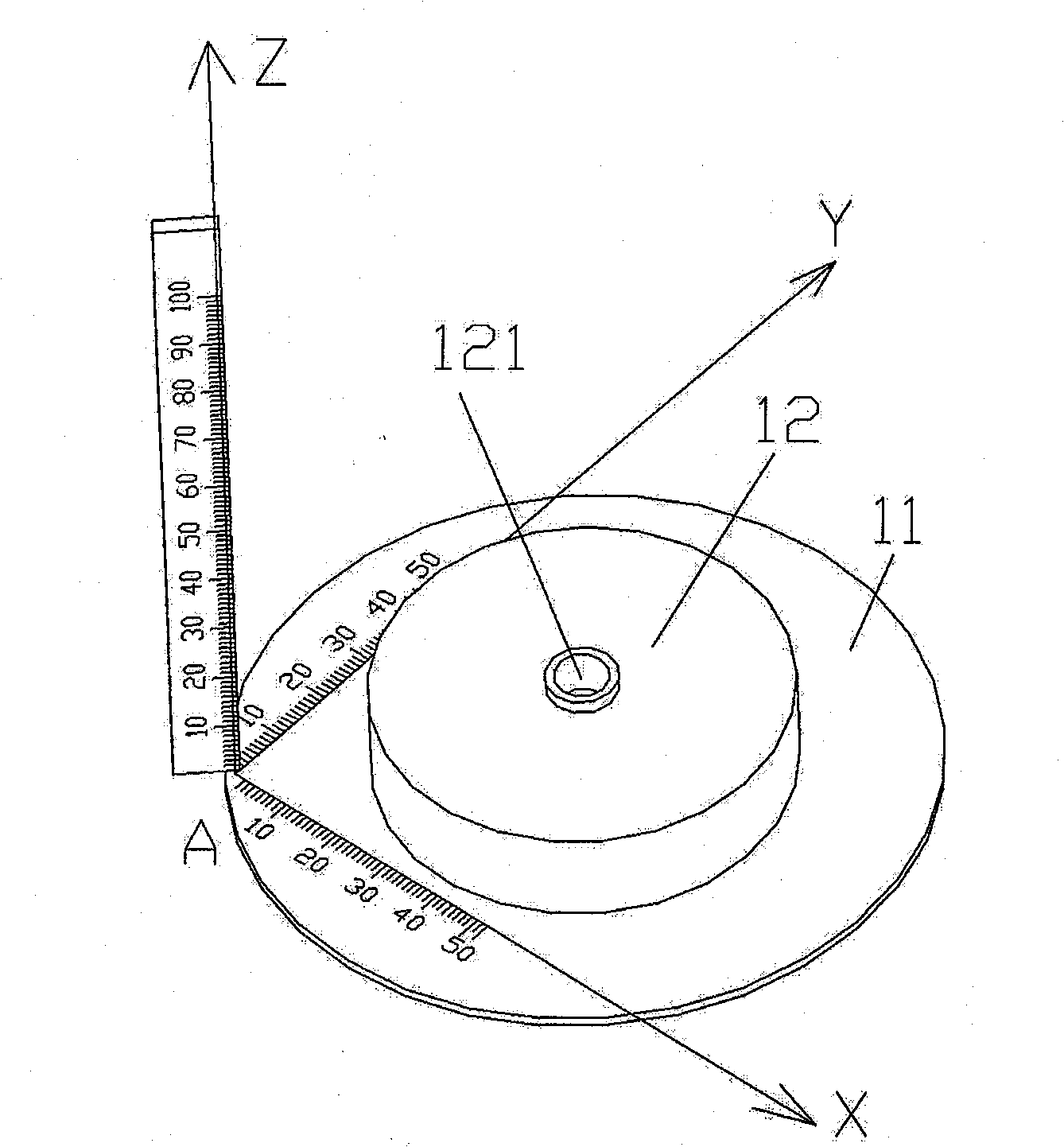

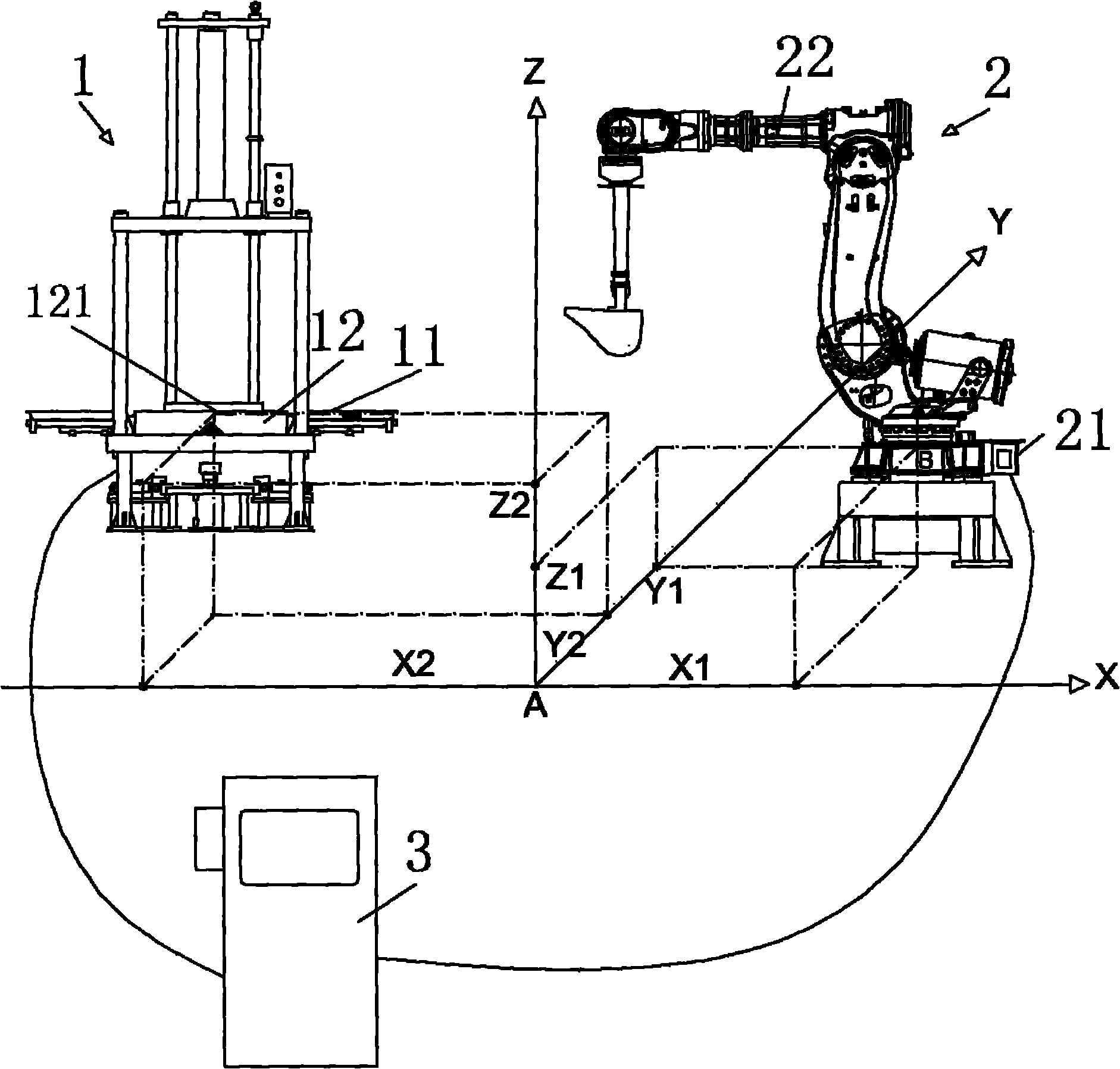

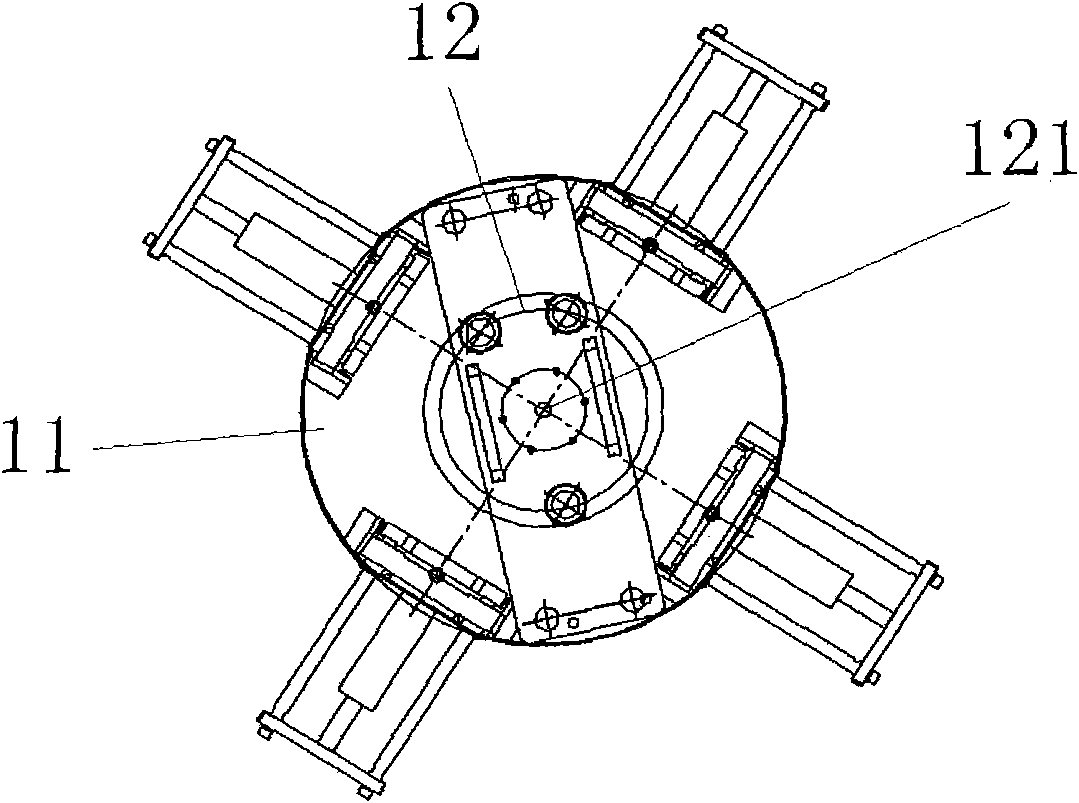

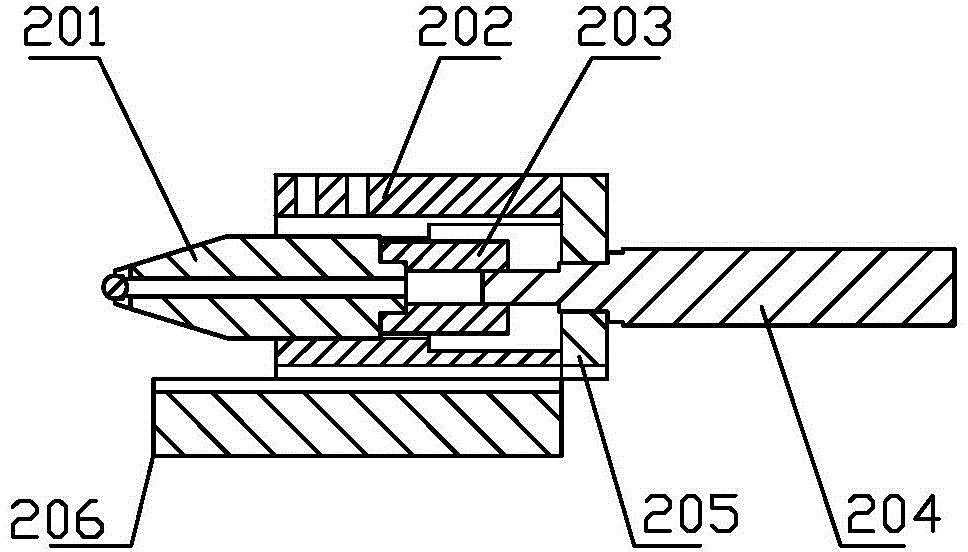

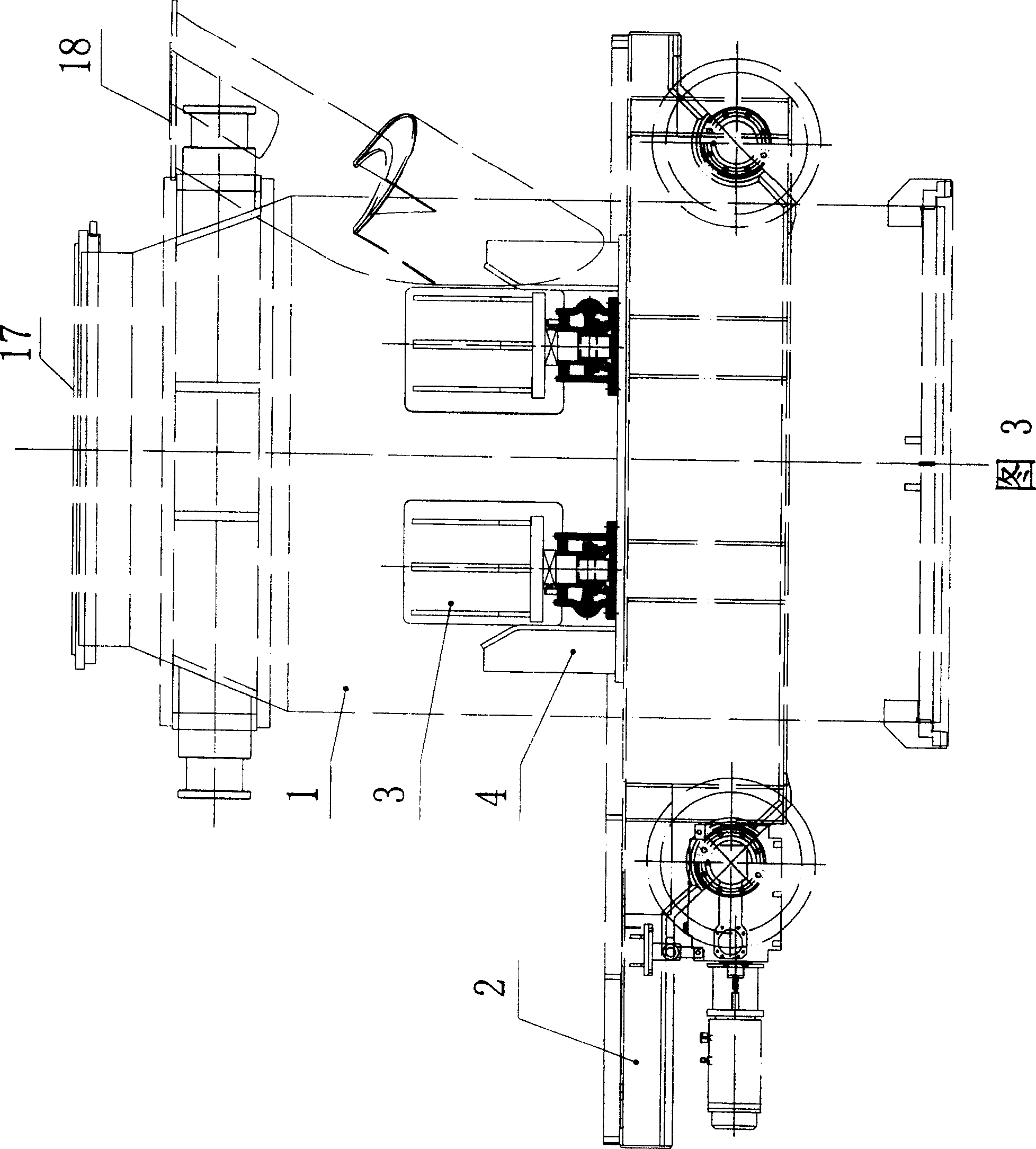

Gravity casting automatic pouring system and method thereof for quickly searching pouring point

ActiveCN101992293BFast adjustment timeLower requirementMolten metal pouring equipmentsNumerical controlControl engineering

The invention relates to a gravity casting automatic pouring system. In the invention, three-dimensional coordinate values between a three-dimensional coordinate original point and a self datum point of a pouring robot and three-dimensional coordinate values between the three-dimensional coordinate original point and the center of a die pouring port are input into a robot host or a pouring systemhost and calculated and analyzed by a numerical control program in the robot host or a program in the system host, and then a command signal is sent out to control a motor to drive a pouring arm to do three-dimensional motions. A method for quickly searching a pouring point of the gravity casting automatic pouring system comprises the following steps of: measuring the three-dimensional coordinatevalues between the three-dimensional coordinate original point and the self datum point of the pouring robot and three-dimensional coordinate values between the three-dimensional coordinate original point and the center of the die pouring port and inputting the values into the robot host; calculating and analyzing the values by the numerical control program in the robot host or the program in thesystem host; and then sending out the command signal to accurately finding out the center of the pouring port. The invention greatly prolongs the robot adjustment time after die replacement and has extremely low requirement on a user who does not need to have skills to operate the robot, thus the operation is convenient and visual.

Owner:ZHEJIANG WANFENG TECH DEV CO LTD

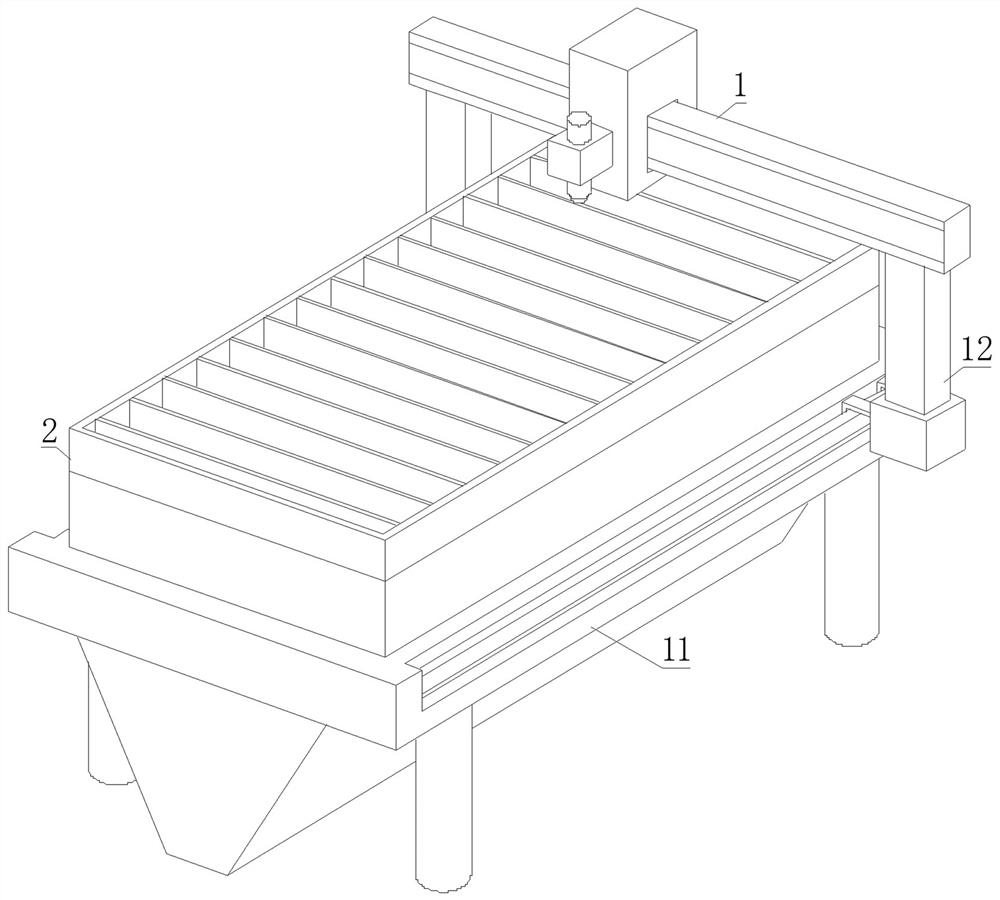

Plasma numerical control cutting production line

PendingCN112276319AEasy and fast adjustmentSave human effortPlasma welding apparatusNumerical controlProduction line

The invention discloses a plasma numerical control cutting production line, comprising a cutting machine and a placing table. A pair of electric hydraulic columns are fixedly mounted in an inner cavity of a mounting groove main body; one end of each electric hydraulic column is fixedly mounted on the bottom surface of the inner cavity of the mounting groove main body, and the other end is fixedlymounted on the bottom surface of an auxiliary movable plate; when an operator needs to align a metal plate, the electric hydraulic columns can be started to jack up the auxiliary movable plate, so that a sliding ball mounting block penetrates through a gap reserved between square blades to jack up the metal plate; and a plurality of sliding balls are arranged on the top surface of the sliding ballmounting block, so that the position of the metal plate can be conveniently and rapidly adjusted, the manpower is saved, the adjustment time is shortened, and the working efficiency is improved.

Owner:日照兴业汽车配件股份有限公司

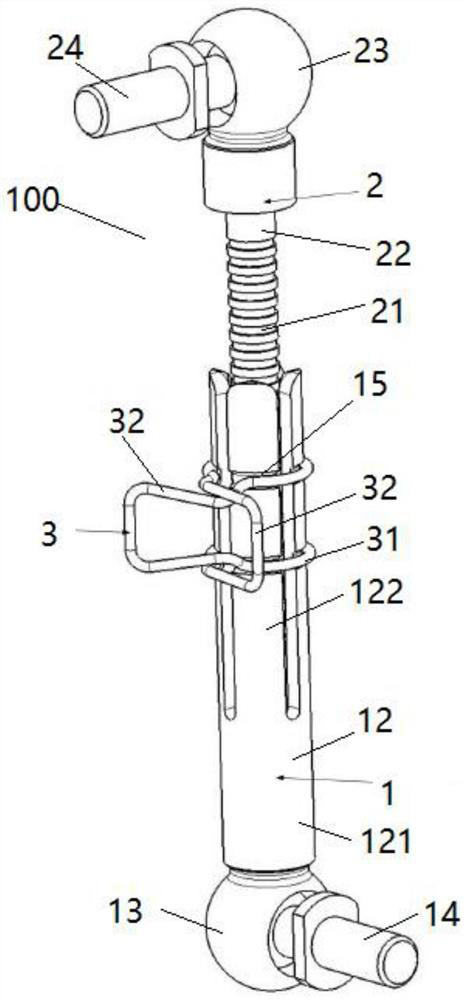

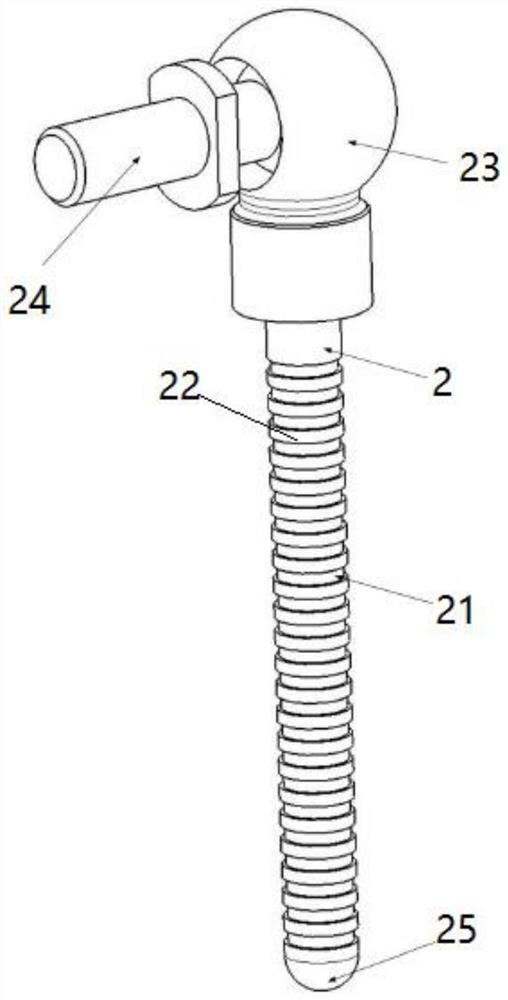

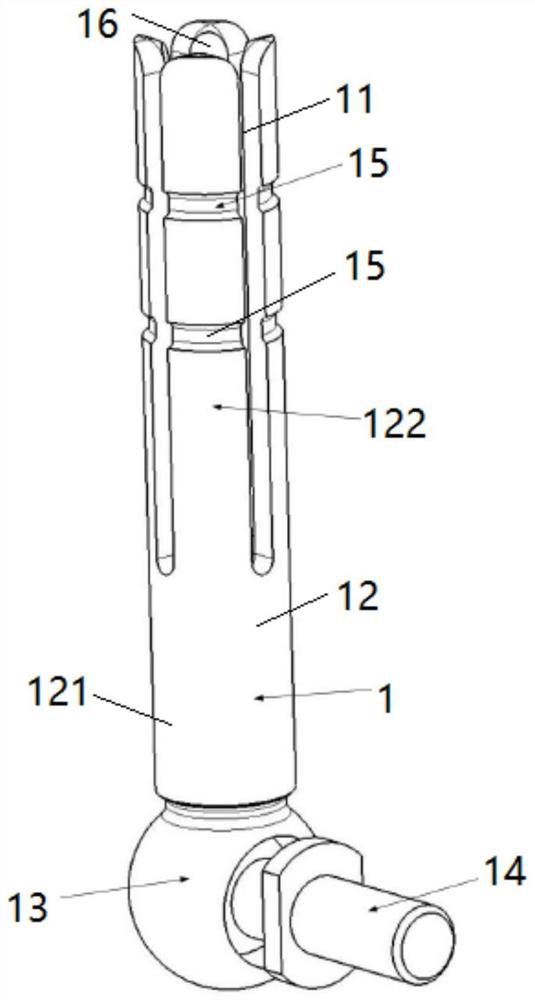

Suspension altitude valve connecting rod, using method, suspension structure and vehicle

ActiveCN114084231AEasy to operateFast adjustment timeConnecting rodsLoading-carrying vehicle superstructuresEngineeringStructural engineering

Owner:DONGFENG COMML VEHICLE CO LTD

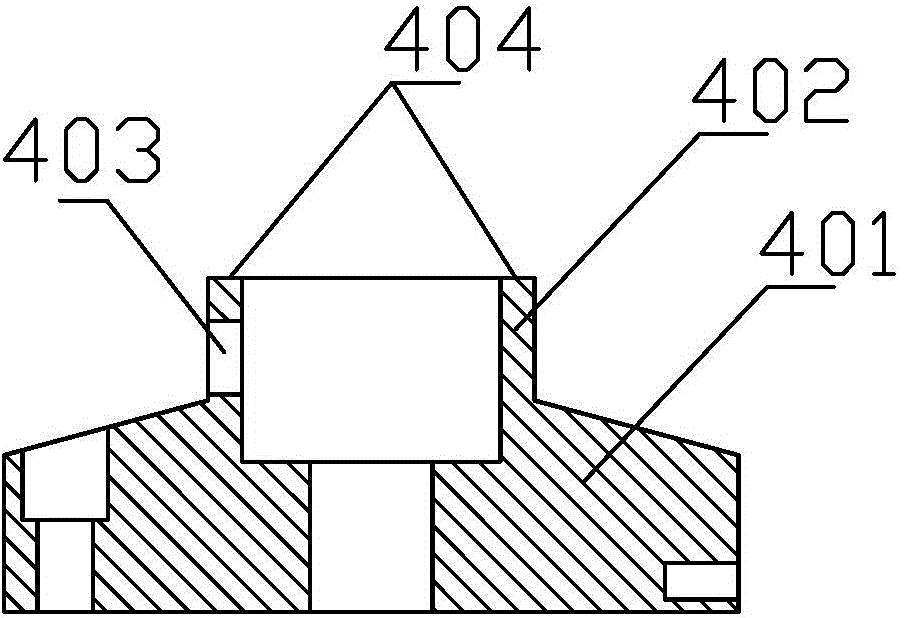

A 3D printing concrete constructability test device and method

ActiveCN108827827BFast adjustment timeAvoid blindnessFlow propertiesLaser sensorMechanical engineering

The invention provides a 3D printed concrete constructability test device and method. The device consists of a bracket, a load container, a moulding die and a laser displacement detector. The upper part of the bracket is a support sleeve, the bottom is a base plate, and the support sleeve is fixedly connected to the base plate through support rods. The load container has an opening upper part anda sealed bottom, and passes through the support sleeve. The moulding die is used for making a to-be-tested mortar model. The laser displacement detector includes two laser displacement sensors and a display screen, a longitudinal laser sensor is fixedly installed on a side wall of the load container, a horizontal laser sensor is disposed on the base plate through a movable fixation apparatus, andthe display screen is connected to the two laser displacement sensors through a wire. The device and method provided by the invention can completely simulate the printing situation in the actual process, and achieve ultra-high reduction of deformation in the printing process, and can make a vertical deformation curve in the loading procedure visible directly, and by simulating the printing time interval of different layers, can study the influence of interlayer printing time interval on constructability, and provide reference for determining the vertical printing rate.

Owner:CENT SOUTH UNIV

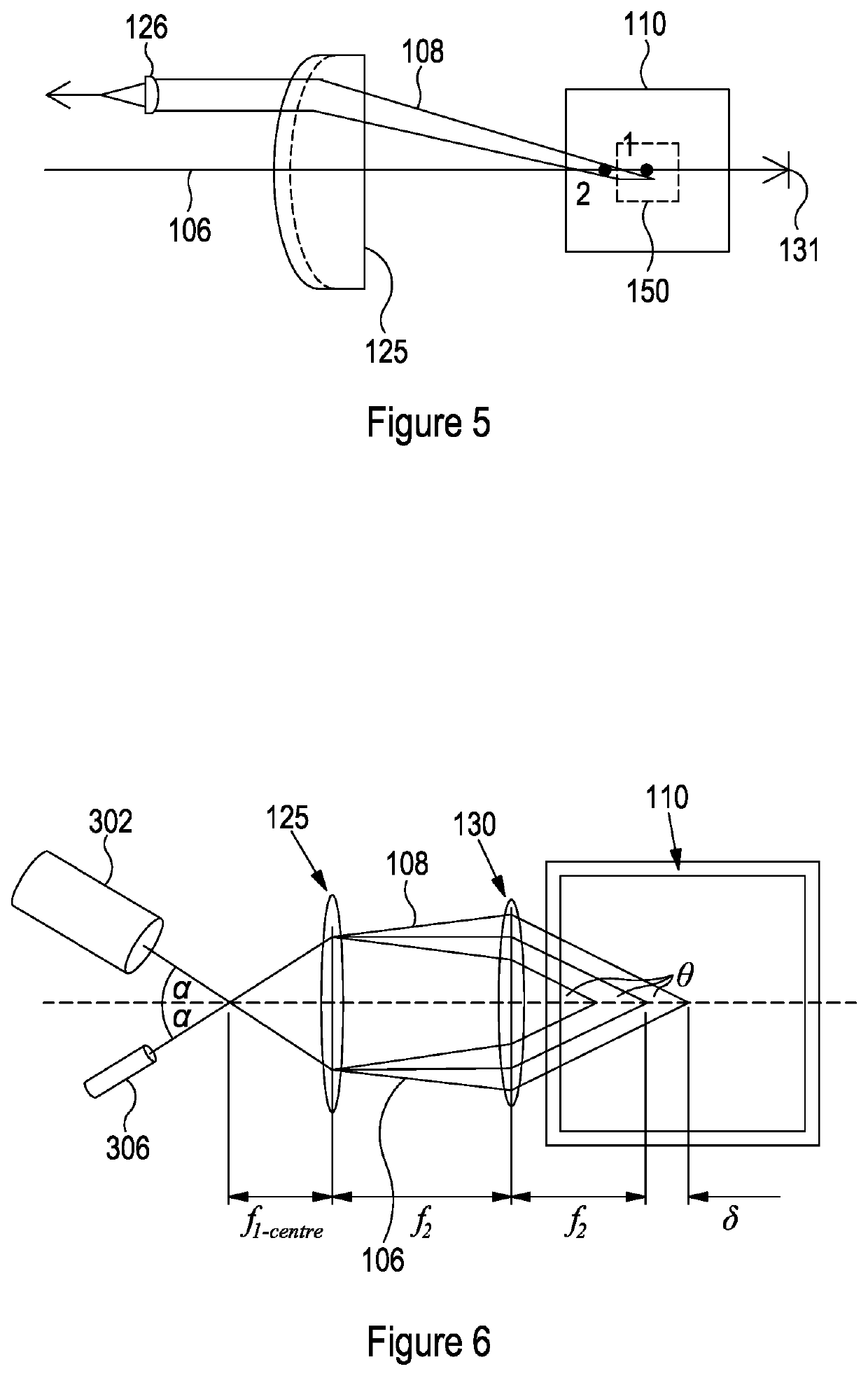

Particle characterisation with a focus tuneable lens

ActiveUS20200166446A1Reduces multiple scatteringSimilar relaxation timeScattering properties measurementsMaterial analysis by electric/magnetic meansLight beamElectrode pair

A particle characterisation apparatus comprising: a light source for illuminating a sample with a light beam; a detector arranged to detect scattered light from the interaction of the light beam with the sample; a focus tuneable lens arranged to collect the scattered light for the detector from a scattering volume and / or to direct the light beam into the sample, a sample holder with an opposed pair of electrodes and configured to hold a sample in position in a measurement volume between the pair of electrodes such that a planar surface of the sample is aligned orthogonally to the electrode surfaces, the planar surface adjacent to the scattering volume, wherein adjustment of the focus tuneable lens results in adjustment of the relative position of the planar surface and the scattering volume by moving the scattering volume.

Owner:MALVERN INSTRUMENTS

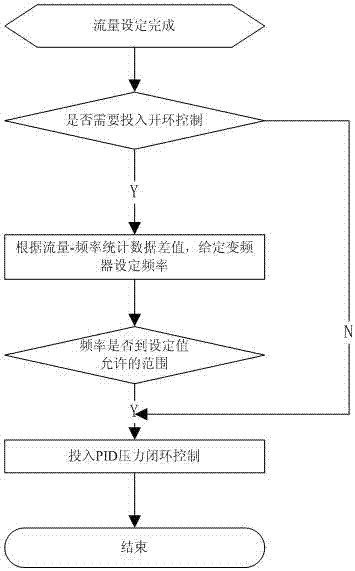

Method for accelerating stabilizing speed of ultra-fast cold variable frequency pump water pressure system

ActiveCN102426462BFast adjustment timeQuick responseFlow control using electric meansFrequency changerLoop control

The invention provides a method for accelerating stabilizing speed of an ultra-fast cold variable frequency pump water pressure system. The method comprises an ultra-fast cooling device and a rolling production line of conventional layer flow cooling equipment and is characterized by comprising the following steps of: revising PID (Proportion Integration Differentiation) closed-loop control parameters to assure that an adjustment response curve reaches a water pressure allowed control range within a first water pressure oscillation period so that single closed-loop control can be realized; meanwhile, first giving the frequency of a frequency converter by using open-loop control according to an actual statistic flow-frequency curve, accelerating the response speed of the frequency converter and then automatically switching the frequency converter to closed-loop control so as to assure the control precision. According to the invention, the cooling water circulating cost is saved and thelater maintenance is more convenient; the single closed-loop control mode and the mode of first adopting open-loop control and then adopting closed-loop control can be selected according to the fieldsituation; the PID response curve of a closed-loop control system is more suitable for lag characteristic of the water system and shorter time is required for adjustment; and in the method of first adopting open-loop control and then adopting closed-loop control, the oscillation of the frequency converter during giving the frequency in a closed-loop way is reduced by first giving the frequency ofthe frequency converter in an open-loop way; and then the stable precision of the system is assured by using closed-loop control.

Owner:NORTHEASTERN UNIV LIAONING

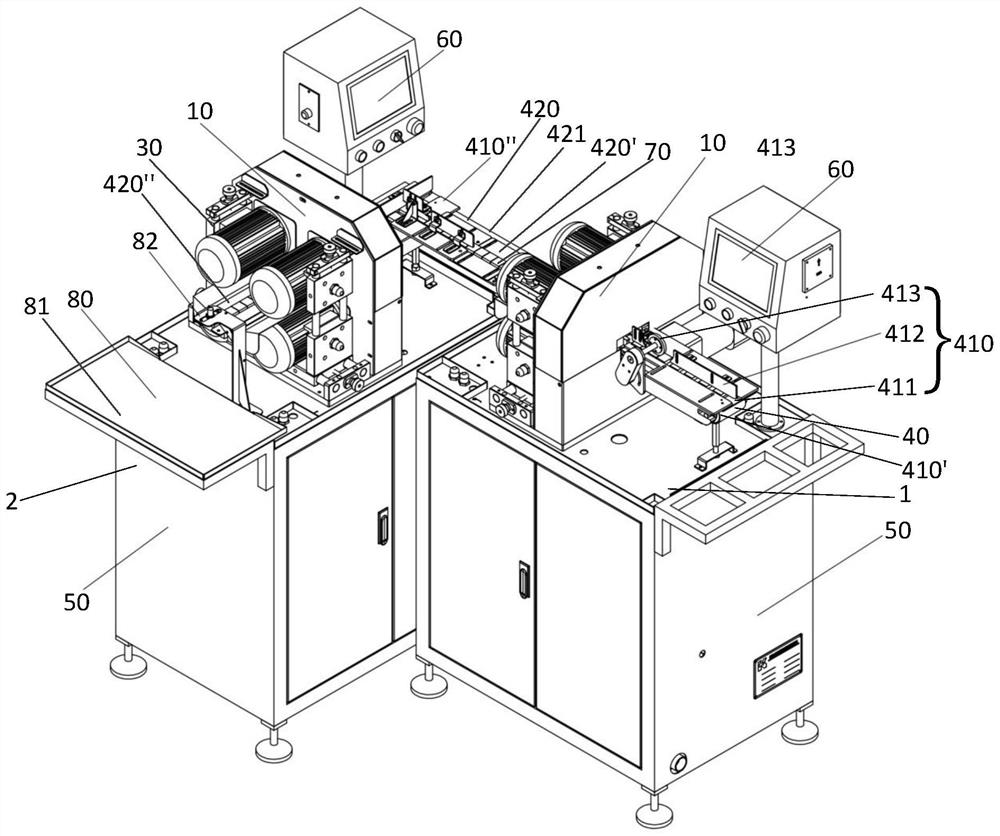

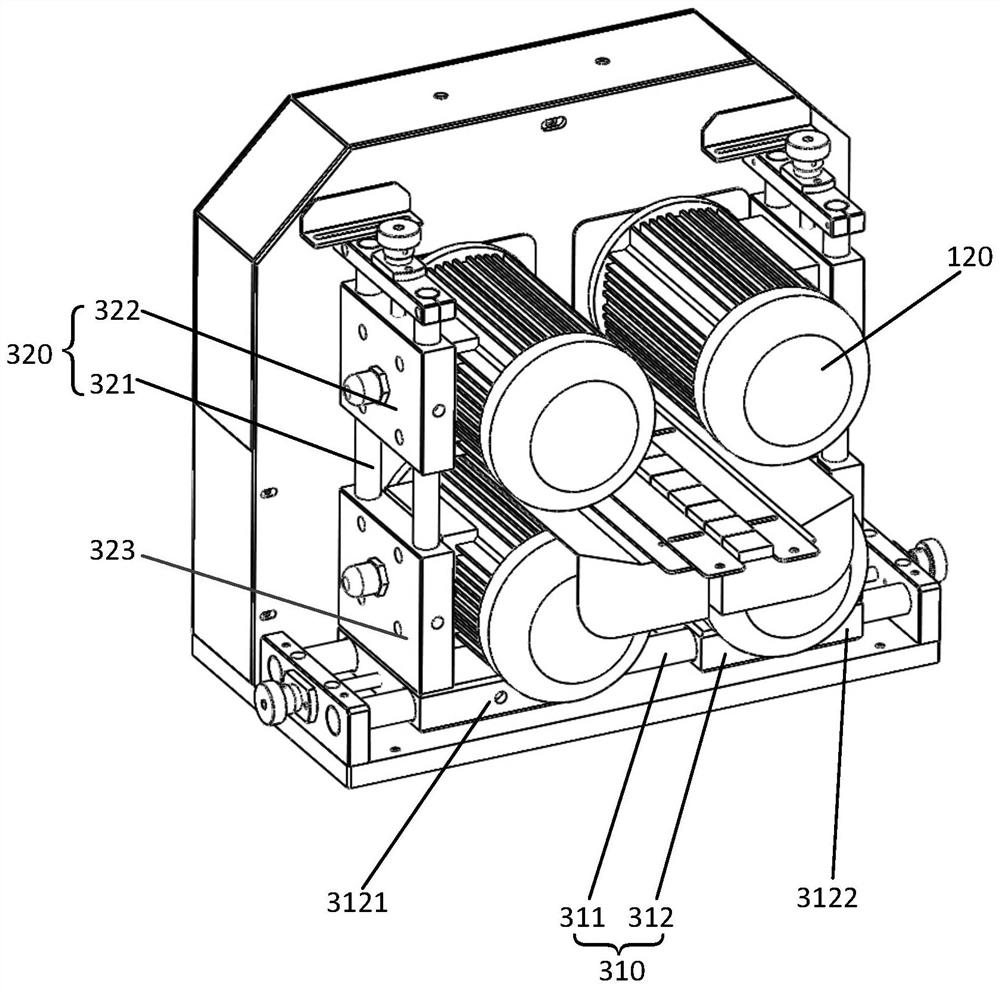

Magnetic material chamfering system and chamfering method

PendingCN114260779AAchieve continuous chamferingQuick changeEdge grinding machinesGrinding machine componentsChamfer distanceEngineering

The invention provides a magnetic material chamfering system and method, and the system comprises front-section chamfering equipment which is disposed along a first direction as a feeding direction, and rear-section chamfering equipment which is disposed at the rear section of the front-section chamfering equipment and is disposed along a second direction which is used as the feeding direction and is perpendicular to the first direction. The output end of the front-section chamfering equipment is connected with the input end of the rear-section chamfering equipment, the front-section chamfering equipment and the rear-section chamfering equipment are respectively provided with the chamfering mechanisms, each chamfering mechanism is used for chamfering four edges parallel to the feeding direction, and after a workpiece is chamfered by the front-section chamfering equipment, the chamfering mechanisms are used for chamfering the four edges parallel to the feeding direction. And the direction of the workpiece is not changed, and the workpiece is conveyed to the rear-section chamfering equipment from the input end of the rear-section chamfering equipment to be chamfered. The chamfering precision is high, the chamfering distance is shortened, arrangement is more compact, the chamfering efficiency is high, chamfering adjustment is more convenient, the whole machine adjustment time is short, tools can be conveniently and rapidly replaced, and consumed time is less.

Owner:烟台力凯数控科技有限公司

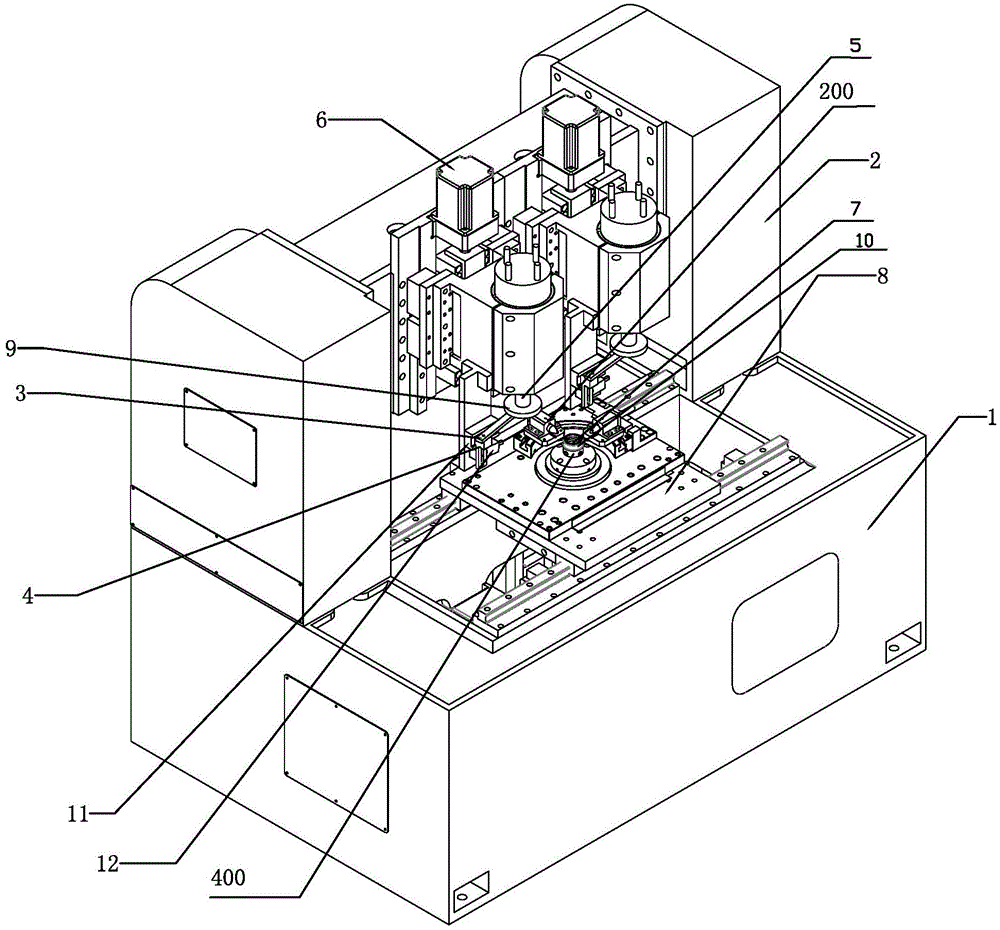

Nuclear Power Bearing Ring Processing Special Superfinishing Machine

ActiveCN103659567BGuaranteed machining accuracyShorten the timeSuperfinishing machinesGrinding work supportsElectricityMachine parts

An ultra-precision machine special for machining nuclear power bearing rings comprises a machine tool base, a lathe bed, a hydraulic system, an electronic control system, a servo system, electric main shafts, rotary head lifting mechanisms, a workpiece shaft, rotary head movable rods, sliding blocks, a workpiece translational mechanism, a supporting component, a magnetic pole, a rotary eccentric wheel, the nuclear power bearing rings, rotary head slide ways and oil stone clamps. The number of the electric main shafts and the number of the rotary head lifting mechanisms are both two sets, and the electric main shafts and the rotary head lifting mechanisms are all arranged above the workpiece translational mechanism. Each set of electric main shaft independently works and moves up and down through a corresponding rotary head lifting mechanism. The rotary eccentric wheel is arranged on the lower end portions of the electric main shafts, and the electric main shafts drive the rotary eccentric wheel to rotate. The ultra-precision machine is used for more conveniently and quickly machining the nuclear power bearing rings, on the premise of guaranteeing machining precision, time for replacing mechanical parts and debugging the machining size in the prior art can be saved, machining can be continued as long as the magnetic pole is replaced, and machining efficiency is effectively improved.

Owner:大连大友高技术陶瓷有限公司

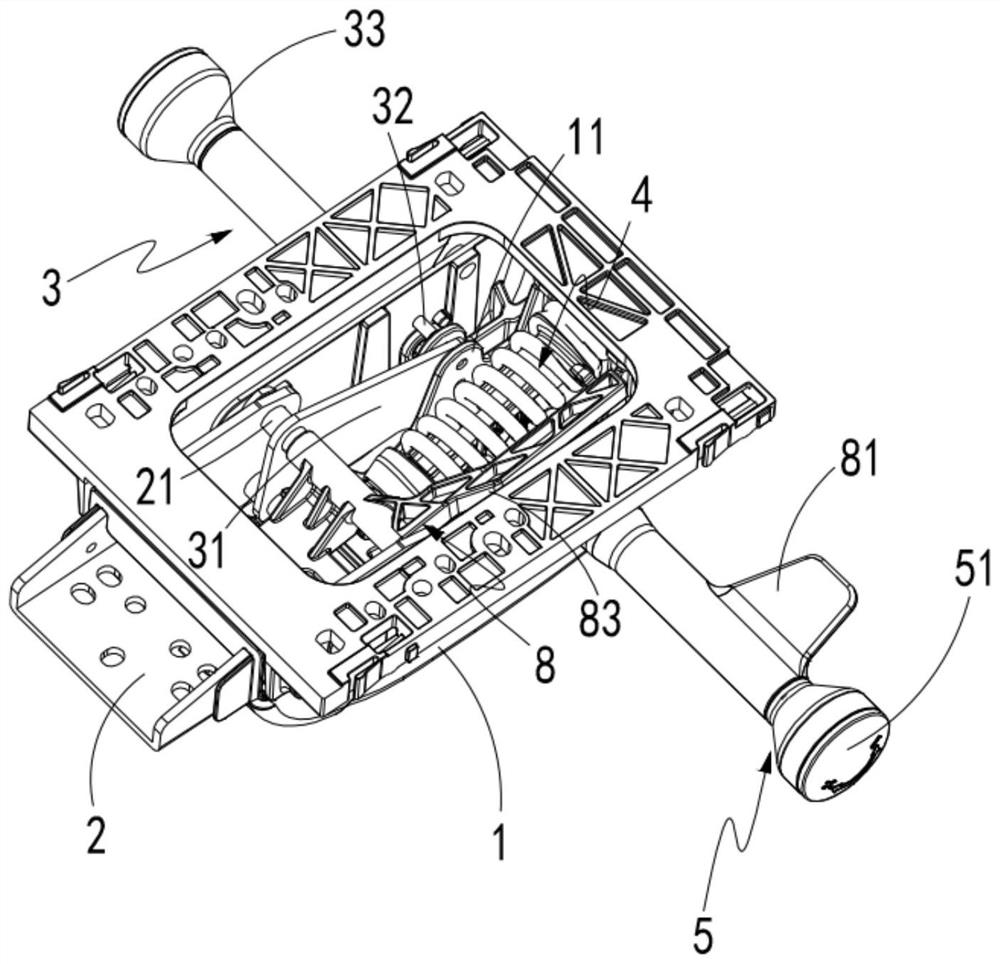

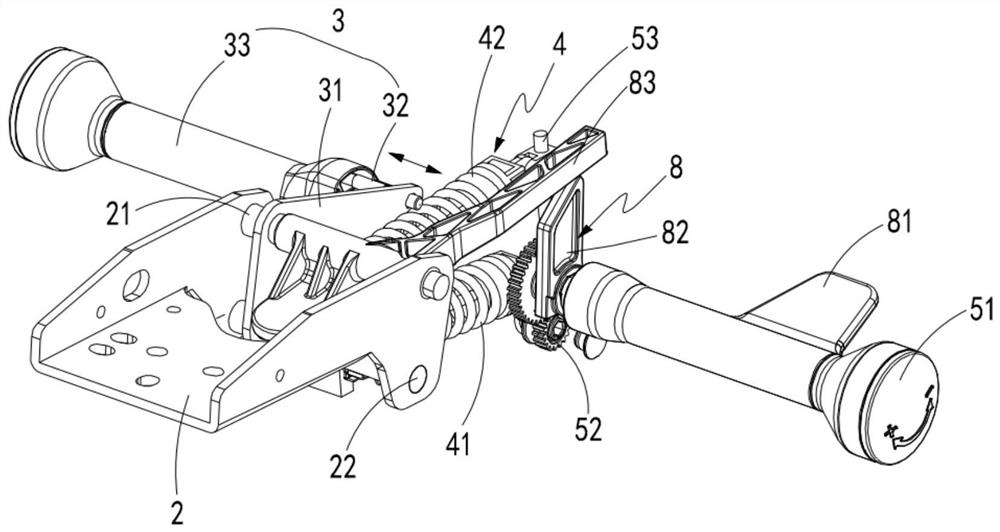

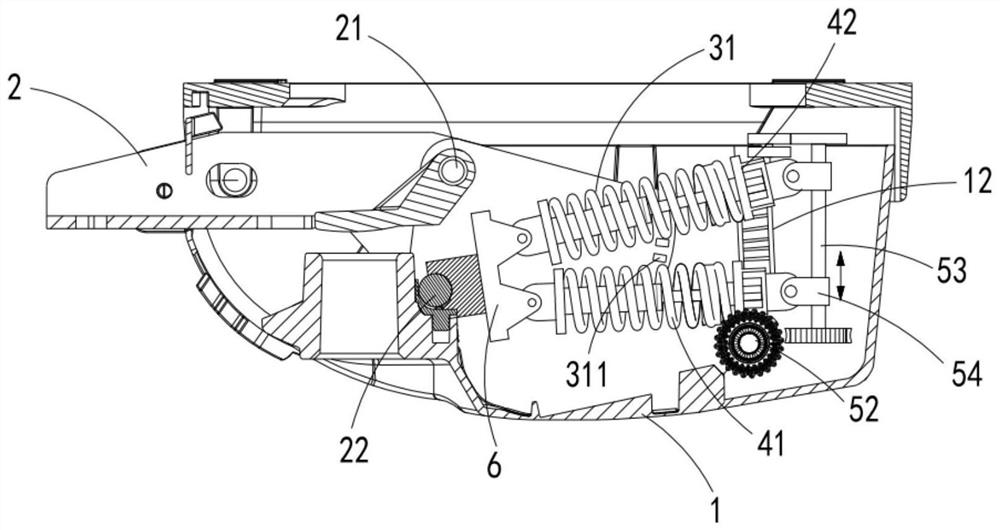

Multifunctional adjusting device of swivel chair chassis and using method thereof

PendingCN112603085AQuick adjustmentIncrease elasticityStoolsAdjustable chairsIndustrial engineeringKingpin

The invention relates to the technical field of swivel chairs, in particular to a multifunctional adjusting device for a swivel chair chassis and a using method thereof.The device comprises a shell and a backrest mounting plate, the backrest mounting plate is hinged to the shell through a main pin shaft, a jacking shaft parallel to the main pin shaft is arranged on the backrest mounting plate, and an elastic assembly, an adjusting assembly and a pushing block are arranged in the shell; the elastic assembly comprises a first spring and a second spring, one end of the first spring and one end of the second spring jointly abut against the adjusting assembly, and the adjusting assembly adjusts the included angle between the first spring and the second spring; the method comprises the following steps: step 1, an unlocking process; step 2, an elastic adjustment procedure, wherein the procedure comprises included angle adjustment and effective turn number adjustment; and 3, a lifting adjustment procedure. The included angle between the first spring and the second spring is rapidly adjusted through the adjusting assembly, meanwhile, the adjusting method of the unlocking procedure, the elastic adjusting procedure and the lifting adjusting procedure is matched with included angle adjustment and effective turn number adjustment, adjustment is rapid, and elasticity is large.

Owner:ZHEJIANG TAIFENG FURNITURE

Parameter optimization modeling method of generator speed control system based on multivariable fitting

InactiveCN105490266BImprove primary FM performanceImprove unsatisfactory problemsElectric generator controlAc network circuit arrangementsPerformance indexFrequency modulation

The invention discloses a multivariable fitting-based parameter optimization modeling method for a generator speed regulating system. The method comprises the following steps: firstly, by a multivariable fitting method, fitting the relationship between three performance indexes, namely percent overshoot, rise time and regulating time, of primary frequency modulation of a generator and four control parameters, namely unit regulation power, a hydraulic servo-motor time constant, a turbine steam time constant and a generator inertia time constant; with the obtained multivariable fitting formula of the primary frequency modulation as an equality constraint, control parameter value ranges and other conditions as inequality constraints and the optimal primary frequency modulation performance of the fine speed regulating system as a final target, searching the speed regulating system parameter with the optimal primary frequency modulation performance by a multi-target and multi-constraint nonlinear optimization method; and building an optimized generator speed regulating system model.

Owner:STATE GRID GASU ELECTRIC POWER RES INST +3

Universal grinding machine for nuclear power bearing inner ring processing

ActiveCN103639872BLower skill requirementsHigh adjustment accuracyAbrasive surface conditioning devicesGrinding machinesMachine partsMechanical components

A universal grinding machine special for nuclear power bearing inner race machining comprises a machine tool base, a machine tool body, a hydraulic system, an electric control system and a servo system and further comprises electric spindles, spindle lifting mechanisms, a workpiece shaft, a grinding wheel dresser, a workpiece shifting mechanism, a support assembly, a mechanical arm, a magnetic pole, grinding wheels, a cutting liquid circulation system and a nuclear power bearing inner race. Two sets of the electric spindles and the spindle lifting mechanisms are provided and installed on the upper portion of the workpiece shifting mechanism, each electric spindle works independently and moves vertically through the corresponding spindle lifting mechanism, the grinding wheel is installed on the lower end portion of each electric spindle, and the electric spindle drives the grinding wheel to rotate. Under the premise that machining accuracy is ensured, time for replacing mechanical parts and adjusting machining size is saved, machining can be conducted continuously by simply replacing the magnetic pole, and machining efficiency can be effectively improved.

Owner:大连大友高技术陶瓷有限公司

Levelling equipment for vacuum chamber

This invention relates to a leveling device for vacuum chamber, which comprises a housing, a pneumatic thrust bearing, a worm gear, a guide cover, a screw prop, and a worm rod. The lower part of the screw prop runs through the guide hole in the guide cover, and is in the chamber of the housing. The lower end of the worm gear is connected with the housing via the pneumatic thrust bearing. The screw prop has external threads, and is locked in the internal threads of the worm gear. The lower end of the screw prop runs through the screw prop hole in the pneumatic thrust bearing. The worm rod and the worm gear are meshed. Both ends of the worm rod are connected with the housing via bearings. One end of the worm rod is connected with the hand wheel or the output axis of the speed reduction motor. The guide cover and the housing are fixing-connected. The leveling device has such advantages as high production efficiency and simple structure, and can level with load.

Owner:WISDRI ENG & RES INC LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com