Controllable shock wave testing device

A test device and shock wave technology, which is applied in the direction of shock test, measuring device, machine/structural component test, etc., can solve the problems that the shock wave action time cannot be adjusted, the broken diaphragm interferes with the experimental flow field, and the shock wave pressure control is inconvenient. Achieve the effects of saving labor hours, speeding up the test progress, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

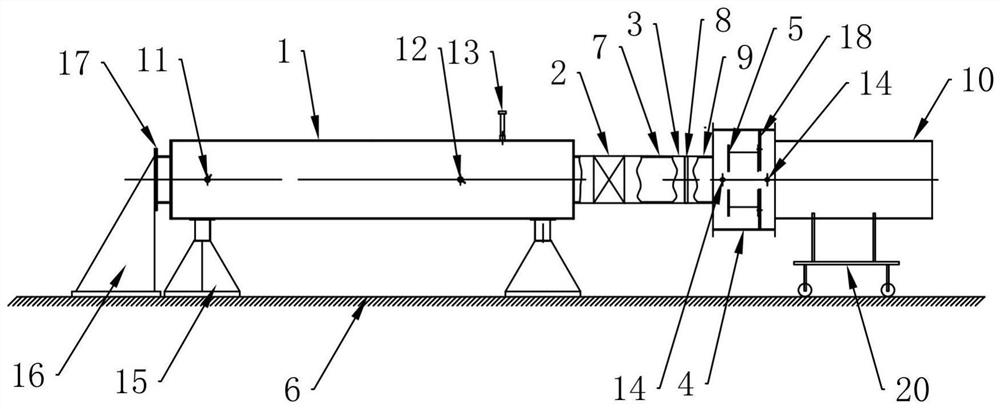

[0024] figure 1 A general structure diagram of the first embodiment of a test device of a controllable shock wave according to the present invention, such as figure 1 As shown, a test device of a controllable shock wave is shown, including a gas storage tank 1 sequentially connected, a quick-opening valve 2, a buffer assembly 3, and a mounting tank 4, which is provided on the gas storage tank 1. The air valve 11 and the pressure relief valve 12 are mounted in the mounting tank 4, and the gas storage tank 1 is provided with at least one pressure sensor 13, and the mounting tank 4 is located at both ends of the test member 5, and at least one shock wave sensor. 14.

[0025] Further, as a preferred embodiment, the buffer assembly 3 includes a transition tube 7 sequentially connected, at least one restricted flow plate 8 and a buffer tube 9, a transition tube 7 and a fast-opening valve 2 connection, buffer tube 9 and the mounting tank 4 connect.

[0026] Further, as a preferred embod...

Embodiment approach

[0029] In a further embodiment of the invention, please continue to see Figure 1 to 2 As shown, the current limiting plate 8 is a hole plate. Preferably, the current limiting plate 8 is a current limiting plate 8 that can be configured as needed as needed.

[0030] In a further embodiment of the present invention, the test device of the controllable shock waves further includes: a wind tube 10, a wind tube 10 is connected to the mounting tank 4, and the wind tube 10 is inserted with the buffer tube 9.

[0031] In a further embodiment of the invention, the gas storage tank 1, the transition tube 7, and the buffer tube 9 are coaxial.

[0032] Preferably, the intake valve 11 and the pressure relief valve 12 are located on the side wall of the gas storage tank 1.

[0033] In a further embodiment of the present invention, a fixed base 15 is provided at the bottom of the gas storage tank 1, and the gas storage tank 1 is provided with a buffer seat 16, and the buffer seat 16 is provided ...

no. 2 example

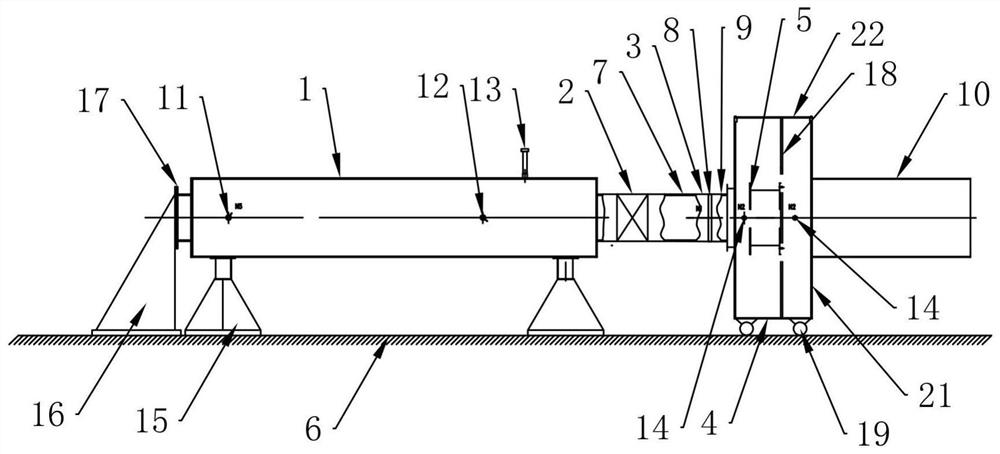

[0053] Such as figure 2 Distance figure 2 A general structure diagram of a second embodiment of a test device of a controllable shock wave according to the present invention, the main structure of the present embodiment is substantially identical to the first embodiment, and is different in that the movable support device is a plurality of roller 19.

[0054] Preferably, the mounting tank 4 includes a tank 21 and a can cover 22, which can be mounted on the mounting frame 18 by opening the can cover 22.

[0055] Preferably, the roller 19 is provided at the bottom of the mounting tank 4.

[0056] The mounting tank 4 of the present embodiment includes: the can body 21 and the can cover 22, and the mounting frame 18 and the bottom arrangement roller 19 are disposed. When the test piece 5 is installed, the mounting tank 22 is opened, and then the test member 5 from the mounting tank 4 The top is lifted, the operator mounts the test member 5 into the mounting frame 18 in the can body 21...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com