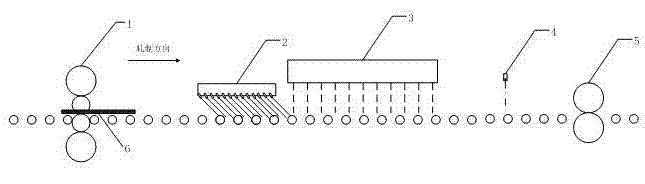

Method for accelerating stabilizing speed of ultra-fast cold variable frequency pump water pressure system

A technology of water pressure system and stable speed, applied in the metallurgical field, can solve the problems of water system response lag, restricting economic benefits, affecting production rhythm, etc., to shorten the adjustment time, save power resources, and facilitate future maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

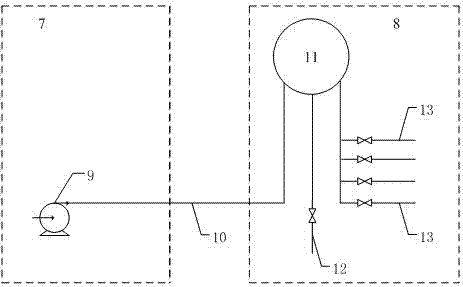

Method used

Image

Examples

Embodiment 1

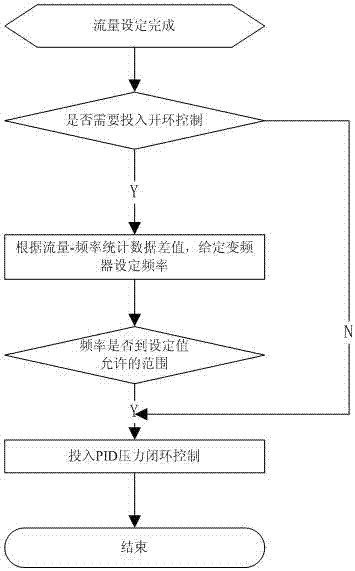

[0027] Take the external interference of the maximum water flow change of ultra-fast cooling is small, and the closed-loop control system is used alone as an example. Step 1: Modify the proportional-integral-derivative (PID) parameters of the hydraulic closed-loop system through the program.

[0028] Step 2: Adjust the PID parameters to a water pressure of 0.5MPa±0.02MPa where the response curve reaches a stable dead zone in the first water pressure oscillation cycle; due to the lagging characteristics of the water system response, the PID parameter debugging goal of step 1 is not optimal Response curves of engineering parameters, but after the first entry of water pressure.

[0029] Step 3: Calculate the final stable inverter frequency of the pumping station under different flow rates. Through repeated tests, manually count the relationship between the ultra-fast cooling set flow rate and the water supply pump frequency, and write the statistical data as shown in Table 1. In ...

Embodiment 2

[0032]Taking the external interference of the maximum water flow change of ultra-fast cooling as an example, using the open-loop first and then closed-loop control system as an example, the stable dead zone is water pressure 0.5MPa±0.02MPa, using the best engineering PID parameters, the response curve is in the second oscillation The cycle is stable, the proportional parameter P is 1.4, the integral parameter is 10s, and the water pressure stabilization time is 54s; and the optimized PID parameter, the response curve is stable in the first oscillation cycle, the proportional parameter P is 1.05 integral parameter is 16.5s, and the water pressure stabilization time is 25s.

[0033] Table 1

[0034] Ultra-fast cold flow Variable frequency pump frequency 1508 40.93 1808 41.00 2467 41.46 2536 41.58 2536 41.81 2647 41.91 2700 41.98 2850 42.35 3376 43.63 3590 44.29 3794 44.98 3996 45.13 4100 45.65 4480 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com