Ultra-precision machine special for machining nuclear power bearing rings

A bearing ring and superfinishing machine technology, applied in the field of superfinishing machines, can solve the problems of increased scrap of processed workpieces, cumbersome and complicated, long adjustment time, etc., to achieve convenient and quick displacement adjustment, reduced skill requirements, and improved adjustment accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

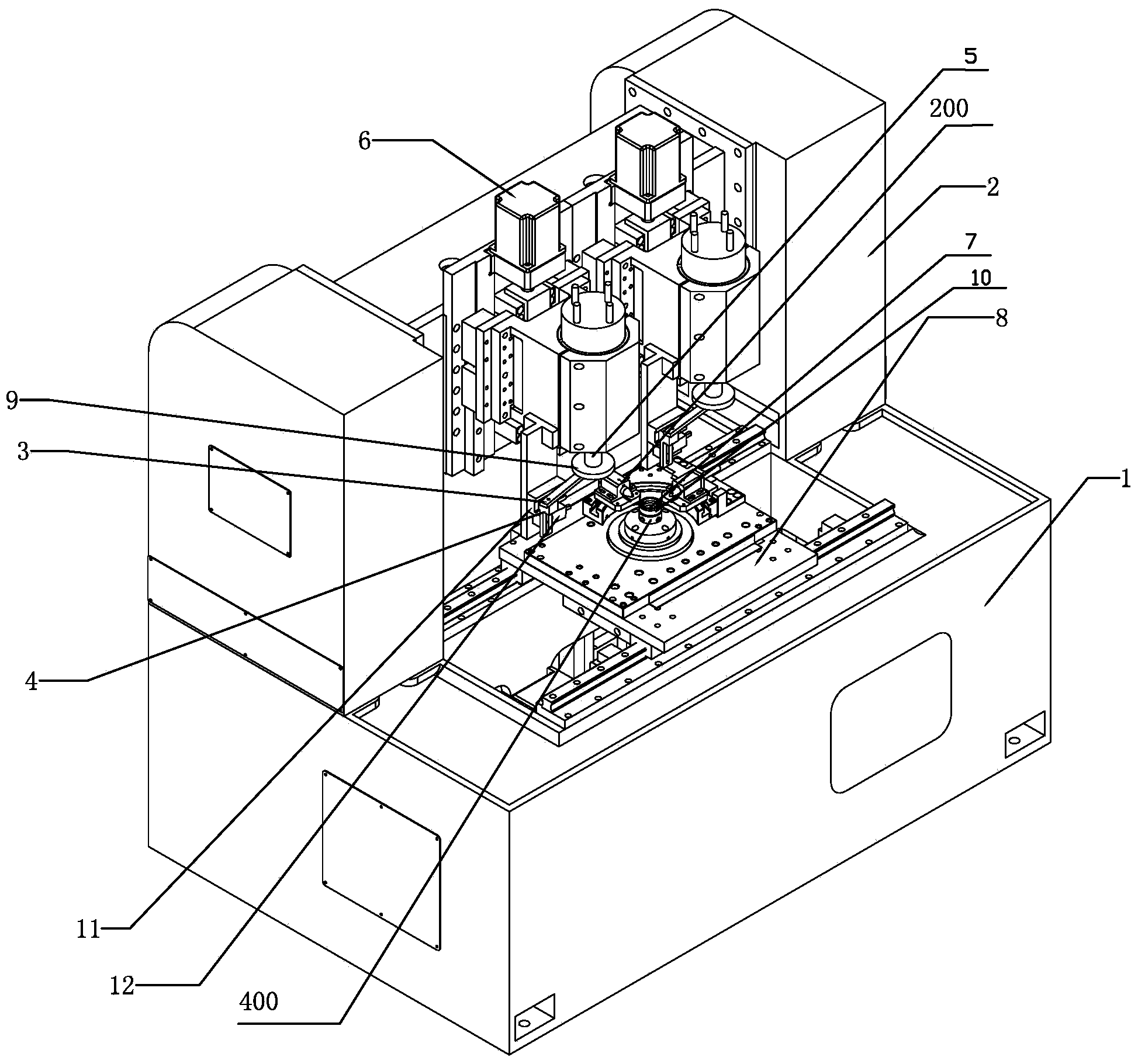

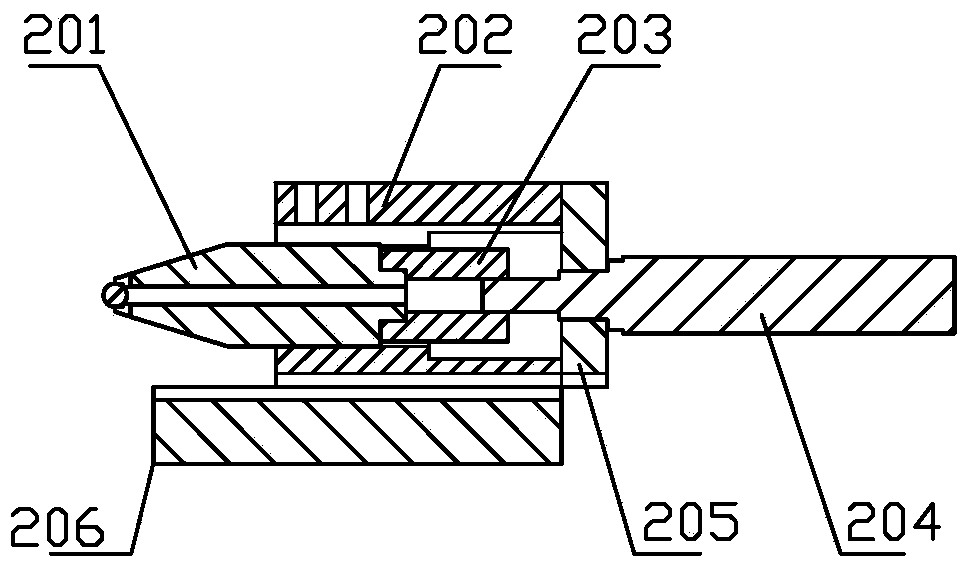

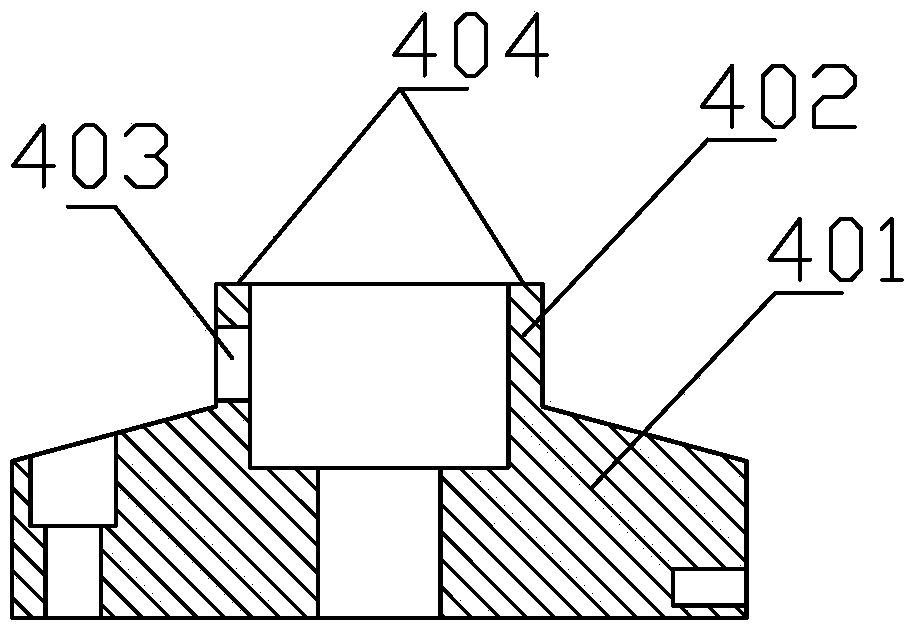

[0026] A special superfinishing machine for nuclear power bearing ring processing, including a machine base 1, a bed 2, a hydraulic system, an electric control system, and a servo system, and is characterized in that it also includes an electric spindle 5, a swing head lifting mechanism 6, and a workpiece shaft 7 , Swing head movable rod 3, slider 4, workpiece translation mechanism 8, support assembly 200, magnetic pole 400, rotating eccentric wheel 9, nuclear power bearing ring 10, swing head slideway 11, oilstone clamp 12;

[0027] The electric spindle 5 and the swing head lifting mechanism 6 are two sets, which are respectively installed above the working translation mechanism 8. Each set of electric spindle 5 works independently and moves up and down through the swing head lifting mechanism 6. The lower end of the electric spindle 5 rotates the eccentric wheel 9, The electric spindle drives the rotating eccentric wheel 9 to rotate;

[0028] The rotating eccentric wheel 9 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com