Gamma automatic calibration method and system of OLED CELL panels

An automatic adjustment and panel technology, applied to instruments, static indicators, etc., can solve problems such as poor accuracy and consistency, low efficiency of manual adjustment, performance bottleneck of intelligent equipment detection system, etc., to achieve short adjustment time and high test efficiency , Ease of use on a large scale

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

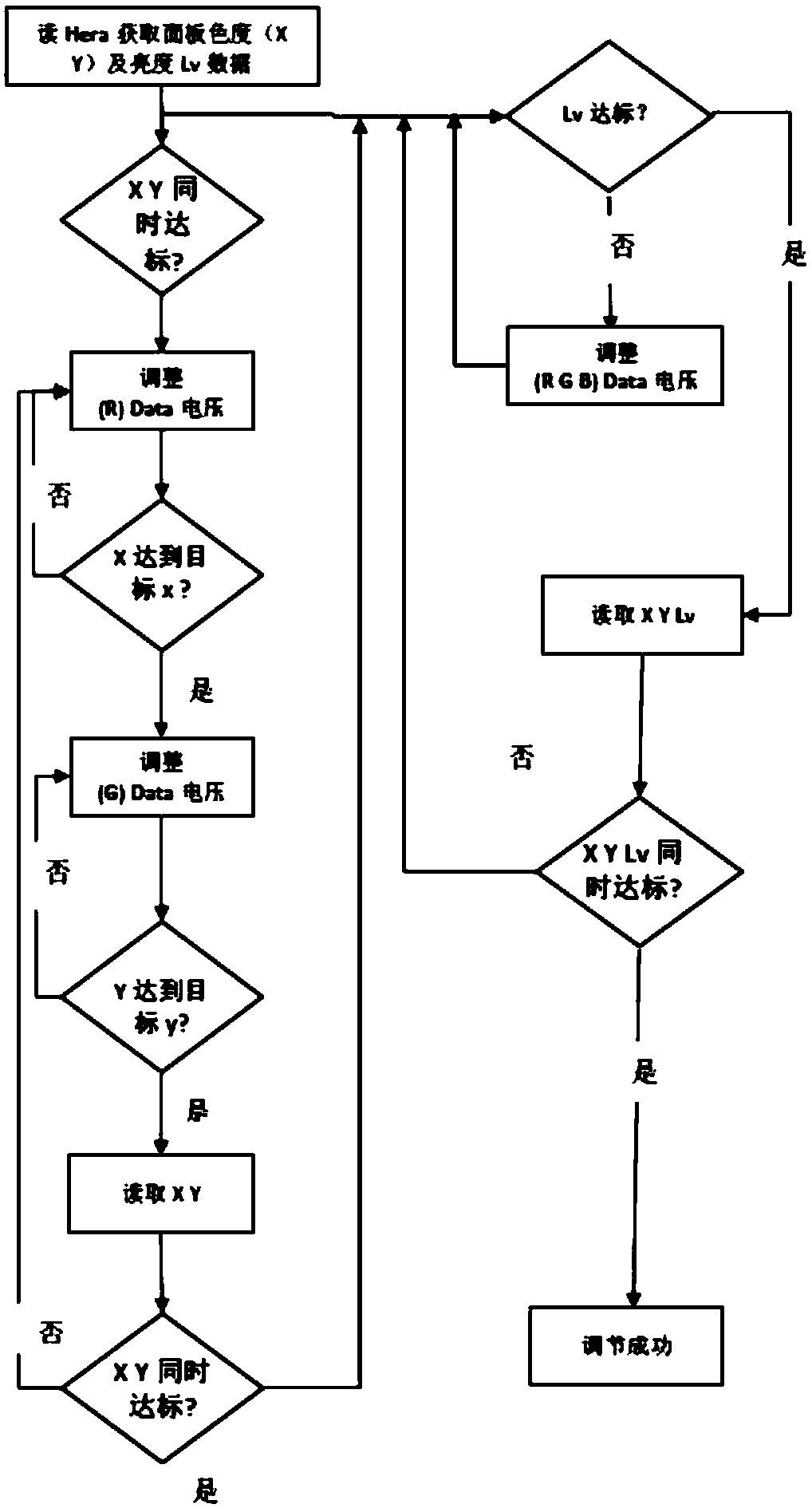

[0057] A method for automatically adjusting Gamma of an OLED CELL panel proposed by the present invention comprises the following steps:

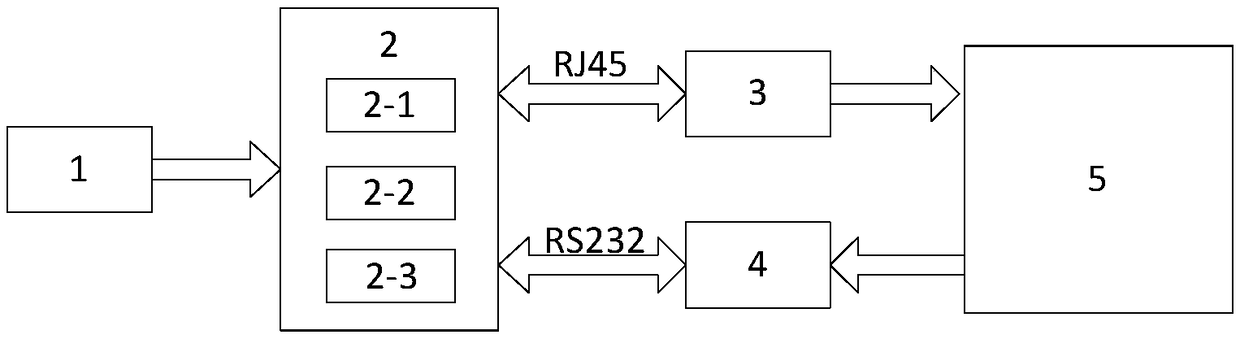

[0058] Step 1, perform routine configuration, calibration and basic function test on the optical tester 4 . This device adopts optical tester 4 as Admesy Hera equipment.

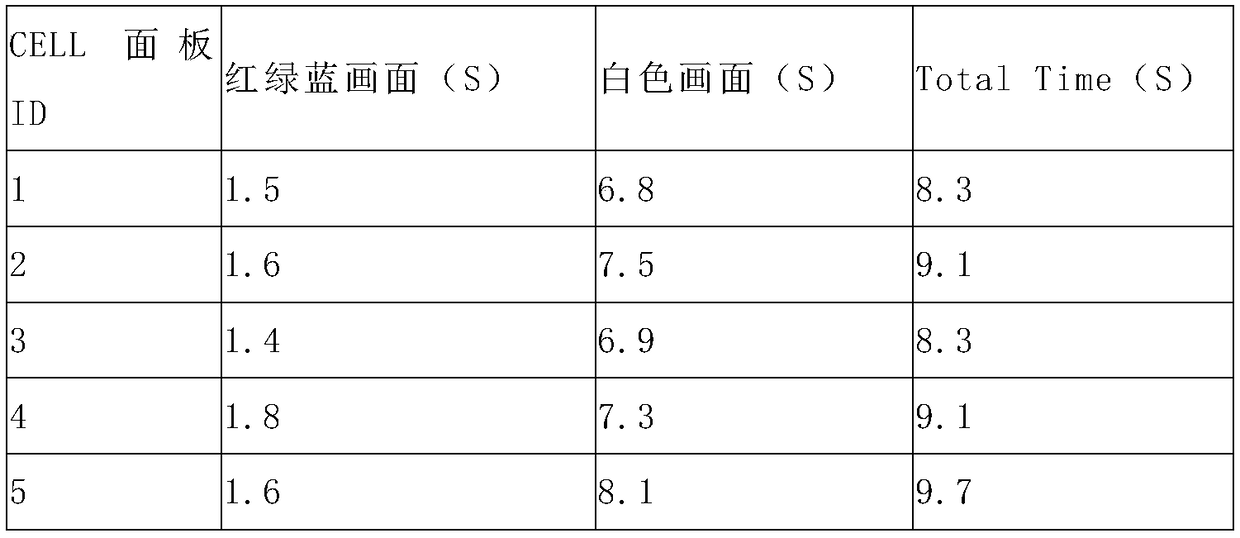

[0059] Step 2, configure white screen and red, green and blue screen adjustment parameters.

[0060] Step 3: Perform waveform conversion and Data voltage binding according to the CELL panel waveform file and pixel lighting principle; the purpose of waveform conversion is to keep the red, green, and blue Data voltages independent of each other for Gamma adjustment. The lighting device 3 used in this device is PG600A.

[0061]Perform waveform conversion and Data voltage binding for each binding point of CELL panel 5, and perform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com