Patents

Literature

90 results about "Dynamic neural network" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Improvement method for selective catalytic reduction flue gas denitrification and ammonia injection control system

ActiveCN104826492AEasy to controlSimple structureDispersed particle separationControl signalOptimal control

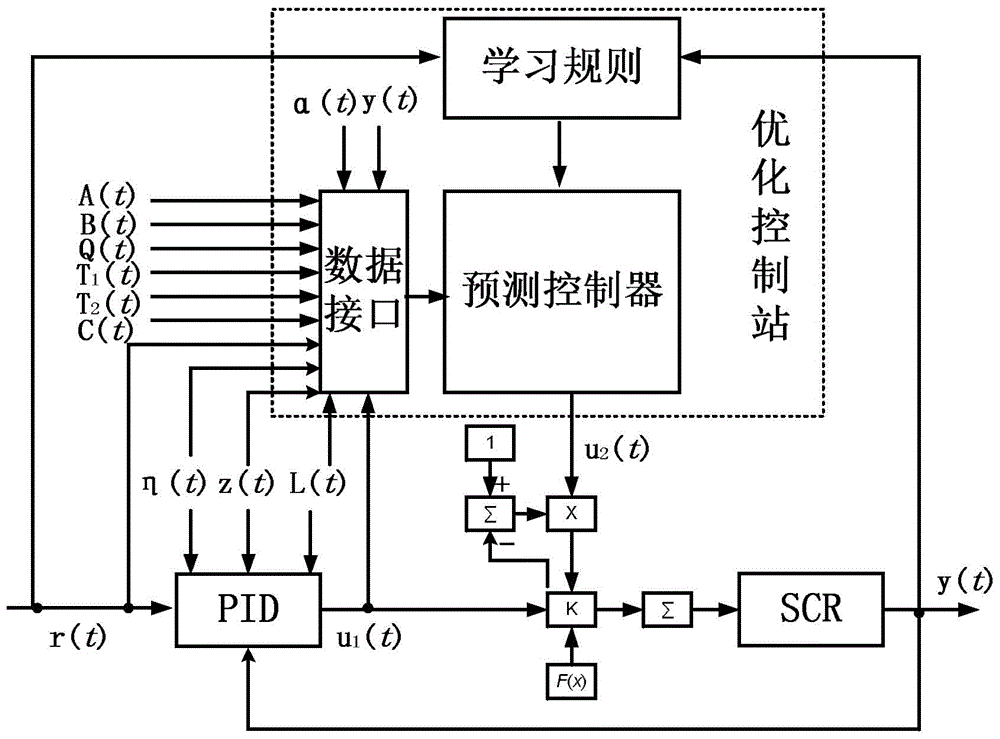

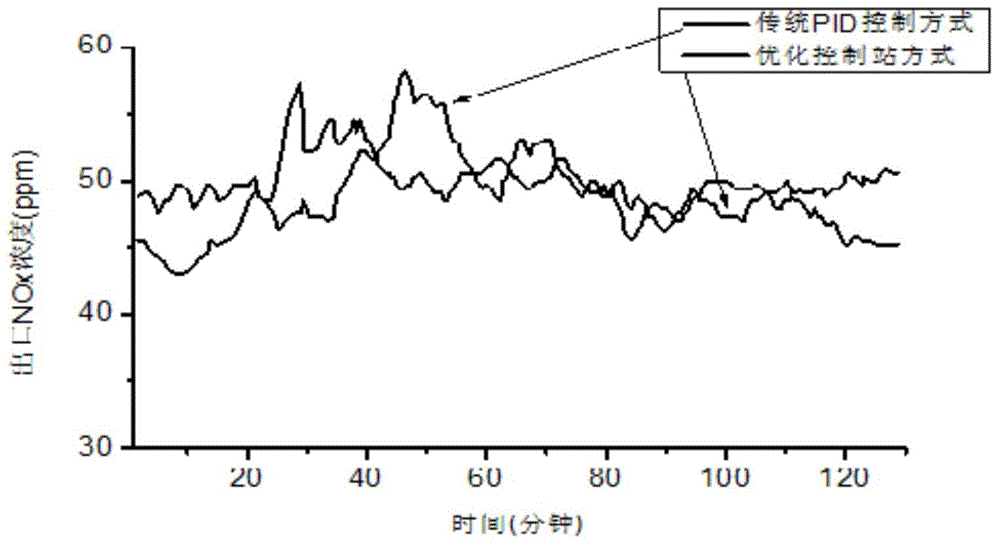

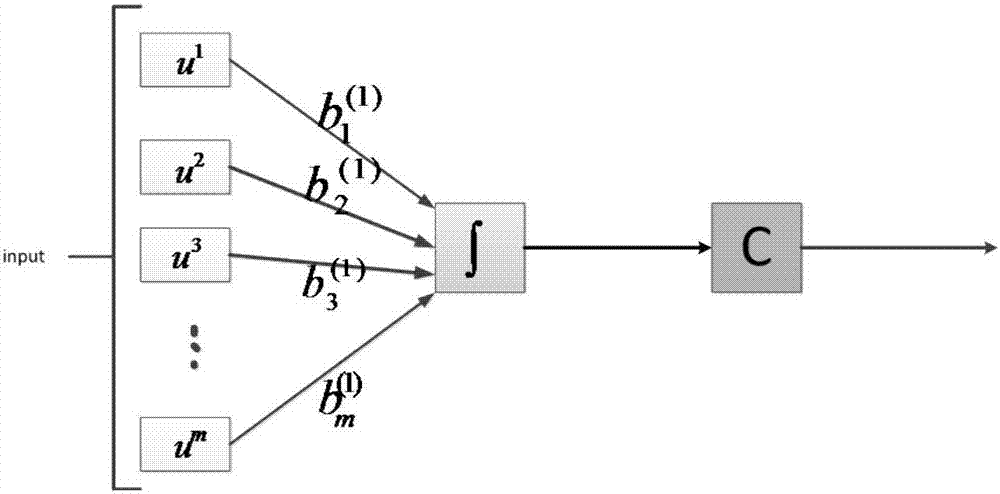

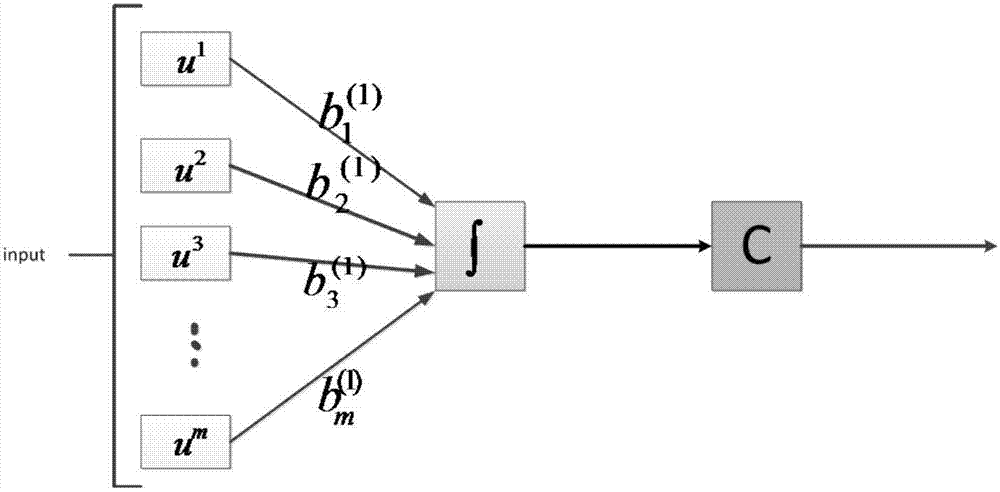

The invention provides an improvement method for a selective catalytic reduction flue gas denitrification and ammonia injection control system. An optimal control station is introduced into an original flue gas denitrification and ammonia injection control system. In an optimal control station module, parameters affecting coal fired boiler NOx generation amount and an original PID controller output ammonia injection amount control signal, and a dynamic neural network, an output sensitivity method is utilized to construct neuron in hidden layer, through comprehensive learning of the PID controller and the introduced parameters, and according to the output amount of the PID controller and the introduced parameters affecting boiler NOx generation amount, integrated computation is carried out to form dynamic compensation control quantity. In denitrification and ammonia injection amount control logic, the original PID controller is taken as the main controller, and the dynamic neural network ammonia injection amount prediction controller is adopted as the revision controller so as to obtain the adjustment amount of optimal ammonia injection amount, thus promoting reliable and economical operation of the denitrification system.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

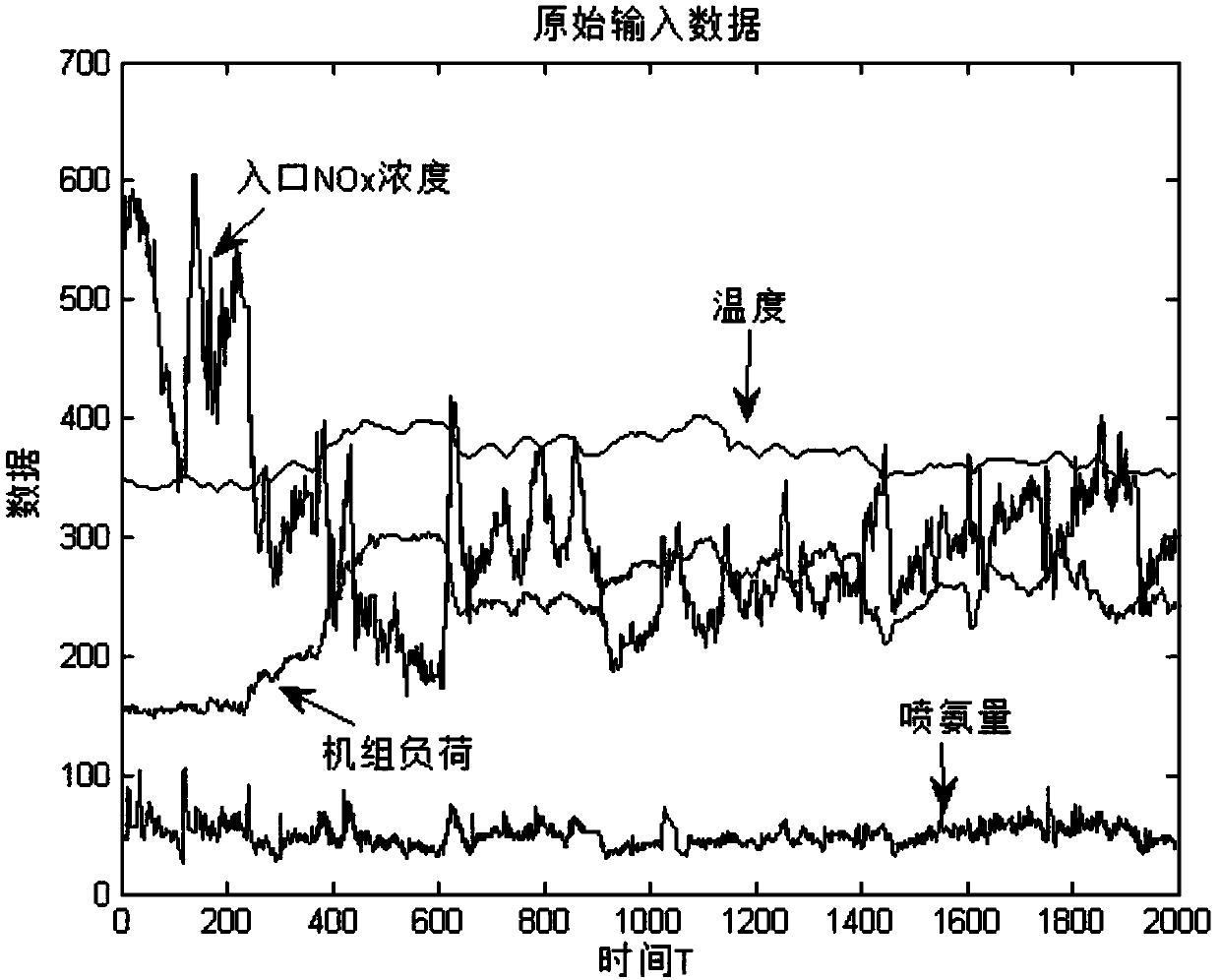

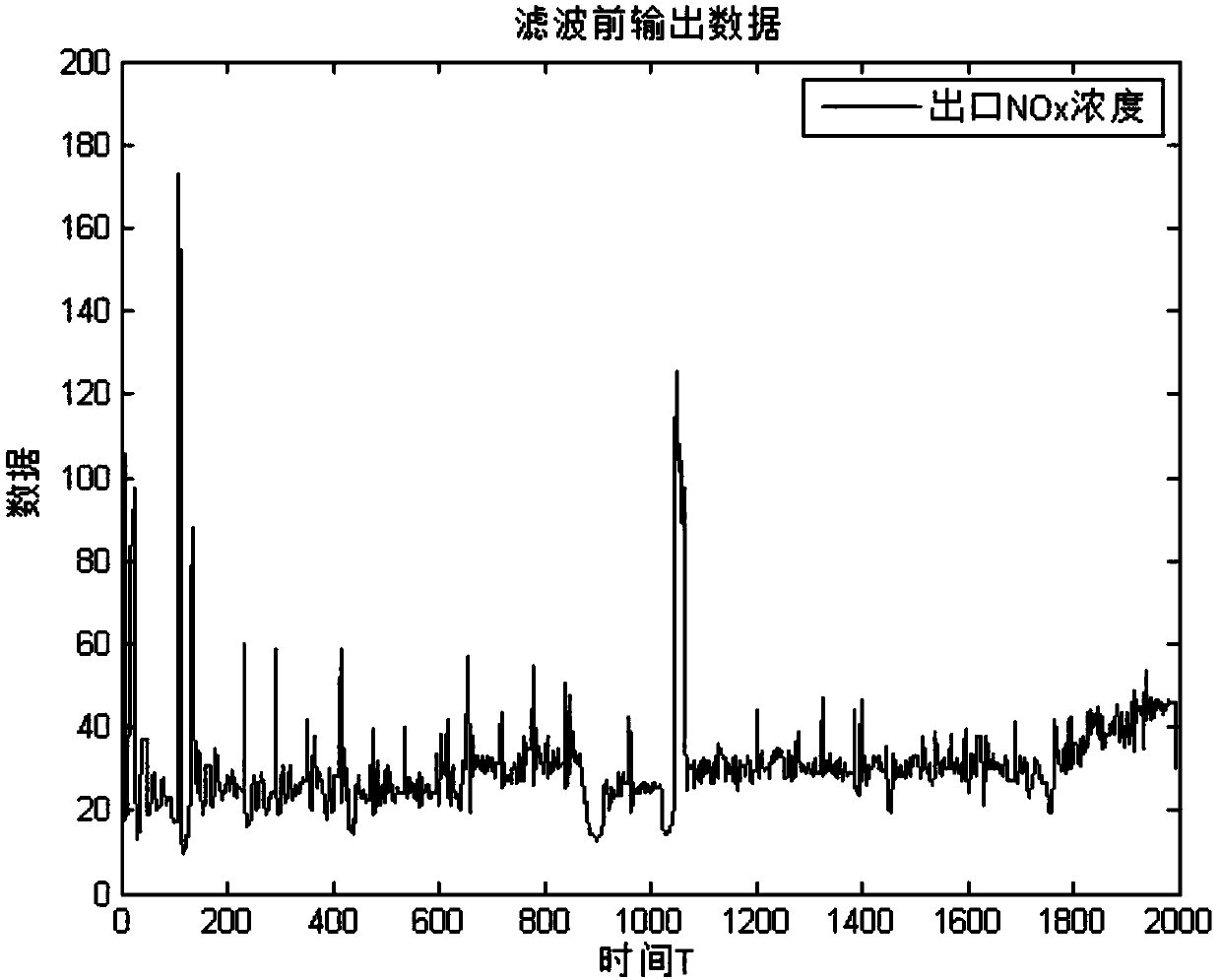

SCR flue gas denitration control method for coal-fired unit based on neural network predictive control

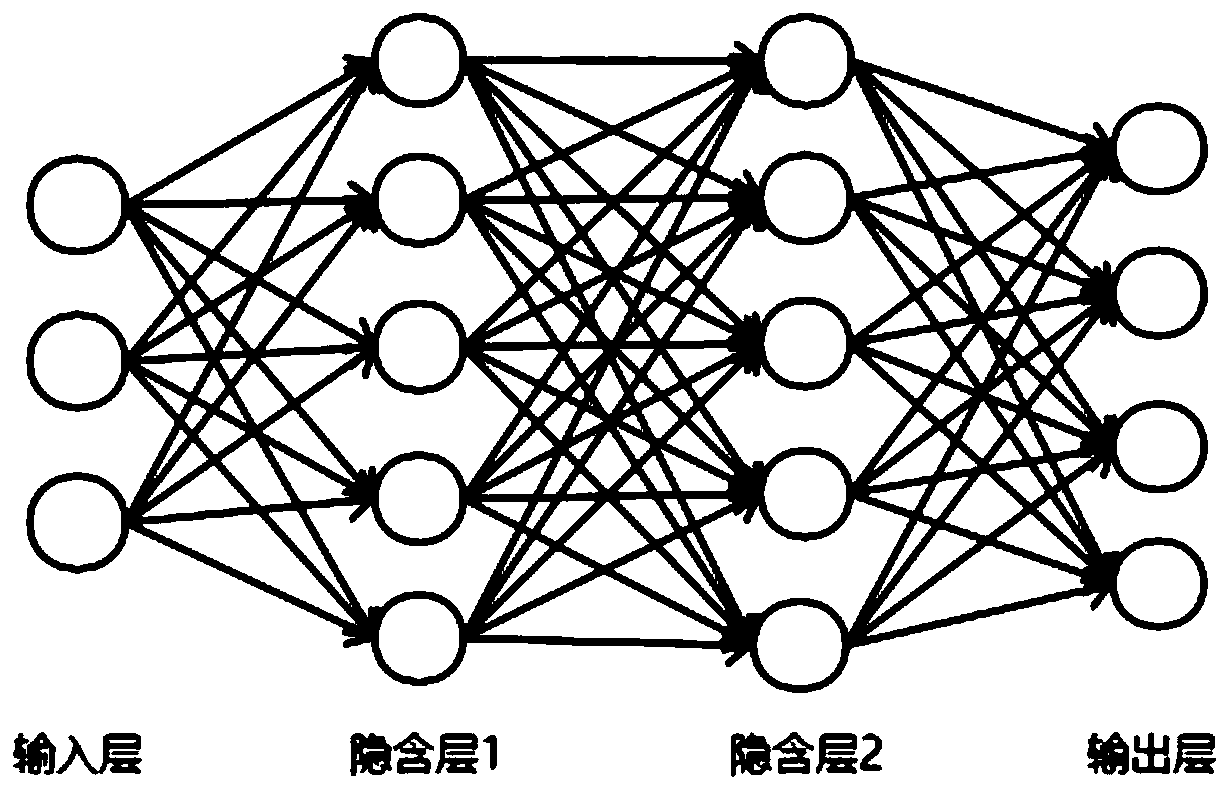

InactiveCN107694337ATraversalDenseDispersed particle separationNeural architecturesDynamic neural networkFlue gas

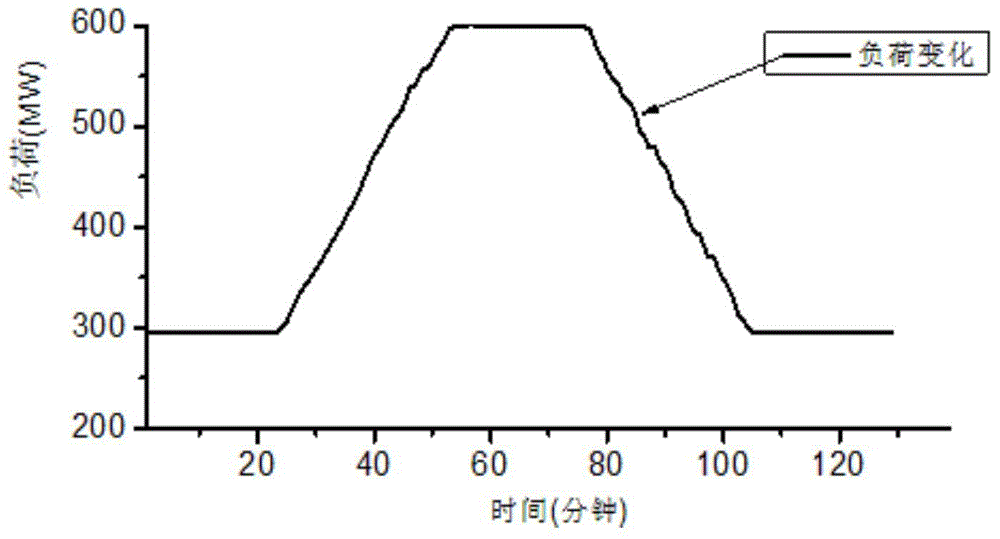

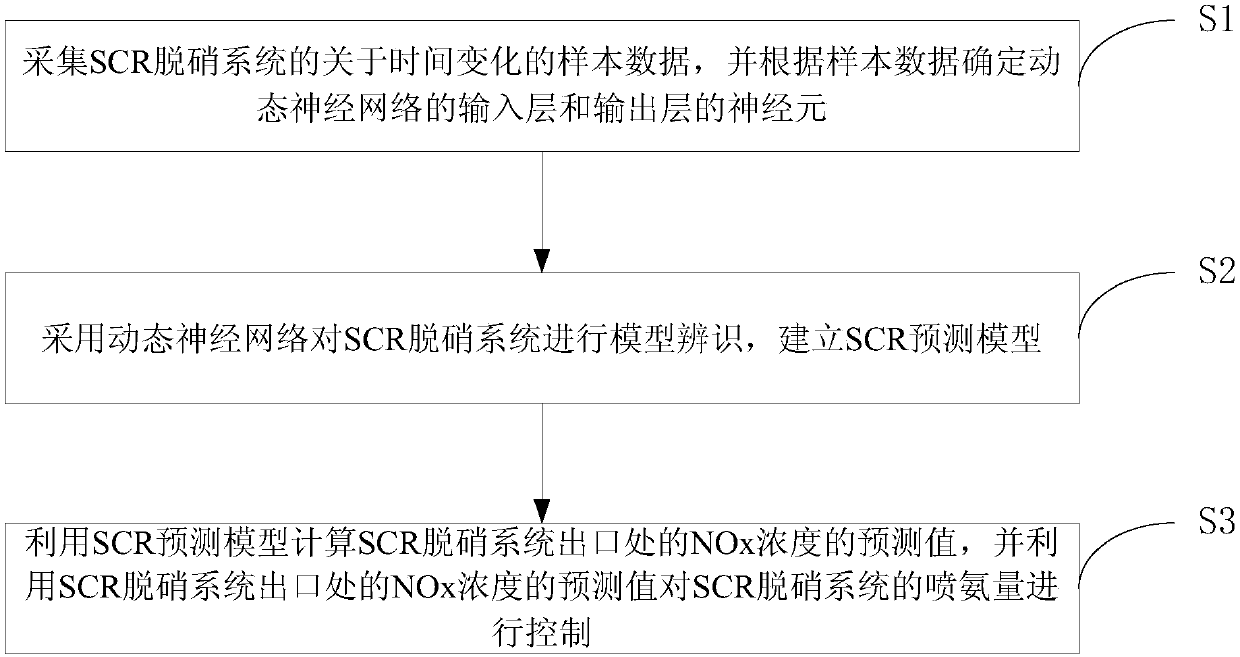

The invention relates to an SCR flue gas denitration control method for a coal-fired unit based on neural network predictive control and belongs to the technical field of flue gas denitration. The SCRflue gas denitration control method comprises the following steps: S1, acquiring sample data related to time variation of an SCR denitration system, and determining nerve cells of an input layer andan output layer of a dynamic neural network according to the sample data; S2, adopting the dynamic neutral network to perform model identification on the SCR denitration system and building an SCR prediction model; S3, utilizing the SCR prediction model to calculate a predicted value of the concentration of NOx at the outlet of the SCR denitration system, and utilizing the predicted value of the concentration of NOx at the outlet of the SCR denitration system to control the ammonia spray amount of the SCR denitration system. By use of the SCR flue gas denitration control method, the concentration of a nitric oxide at the outlet can be substantially kept unchanged, requirements can be accurately satisfied in real time on formulation of the ammonia spray amount, the problems of waste of a reductant and increase of ammonia escape are solved, and the accuracy in predicting and controlling the ammonia spray amount is greatly improved.

Owner:JILIN ELECTRIC POWER RES INST +3

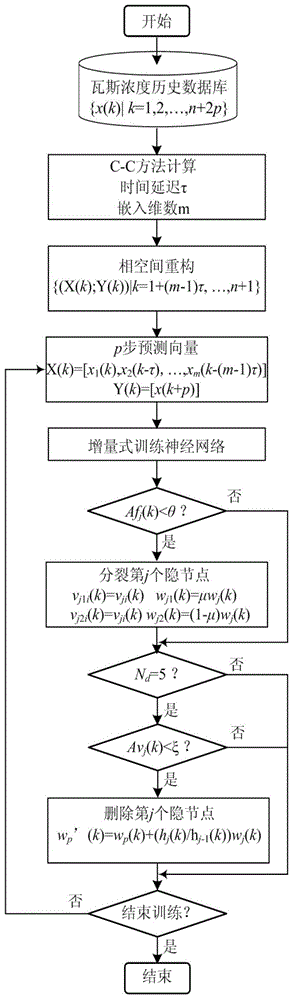

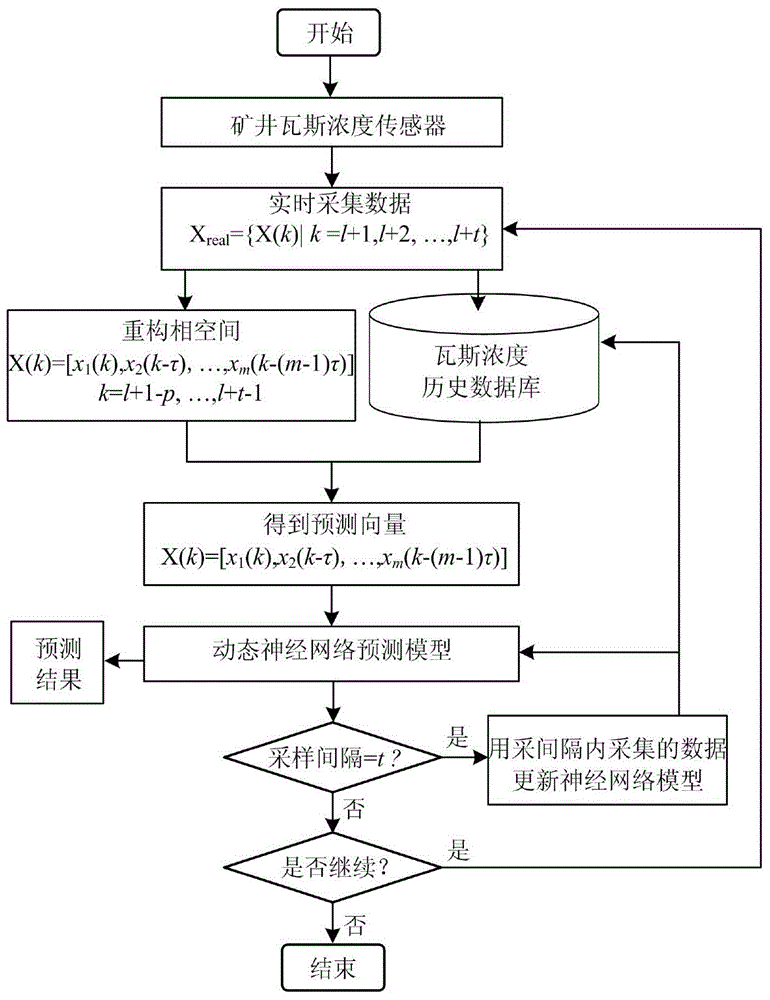

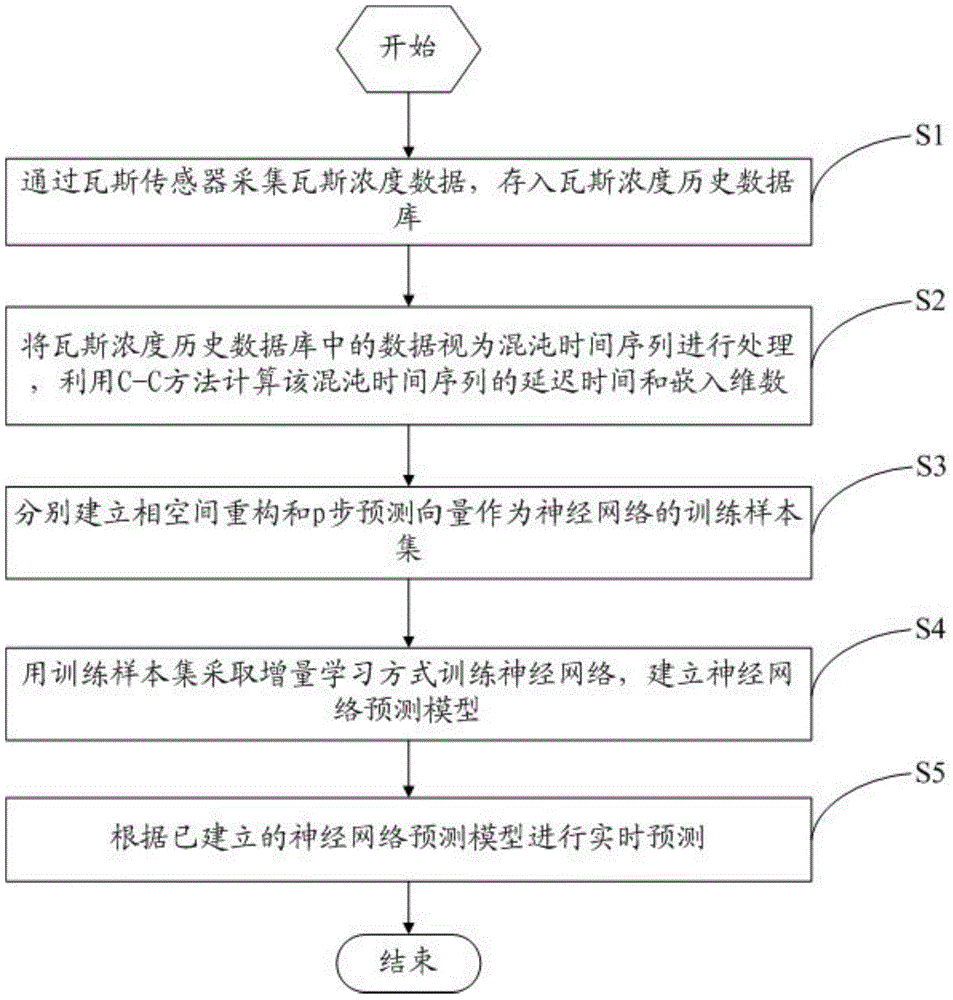

Gas concentration real-time prediction method based on dynamic neural network

InactiveCN104156422AImprove real-time performanceImprove stabilityMining devicesForecastingEngineeringArtificial intelligence

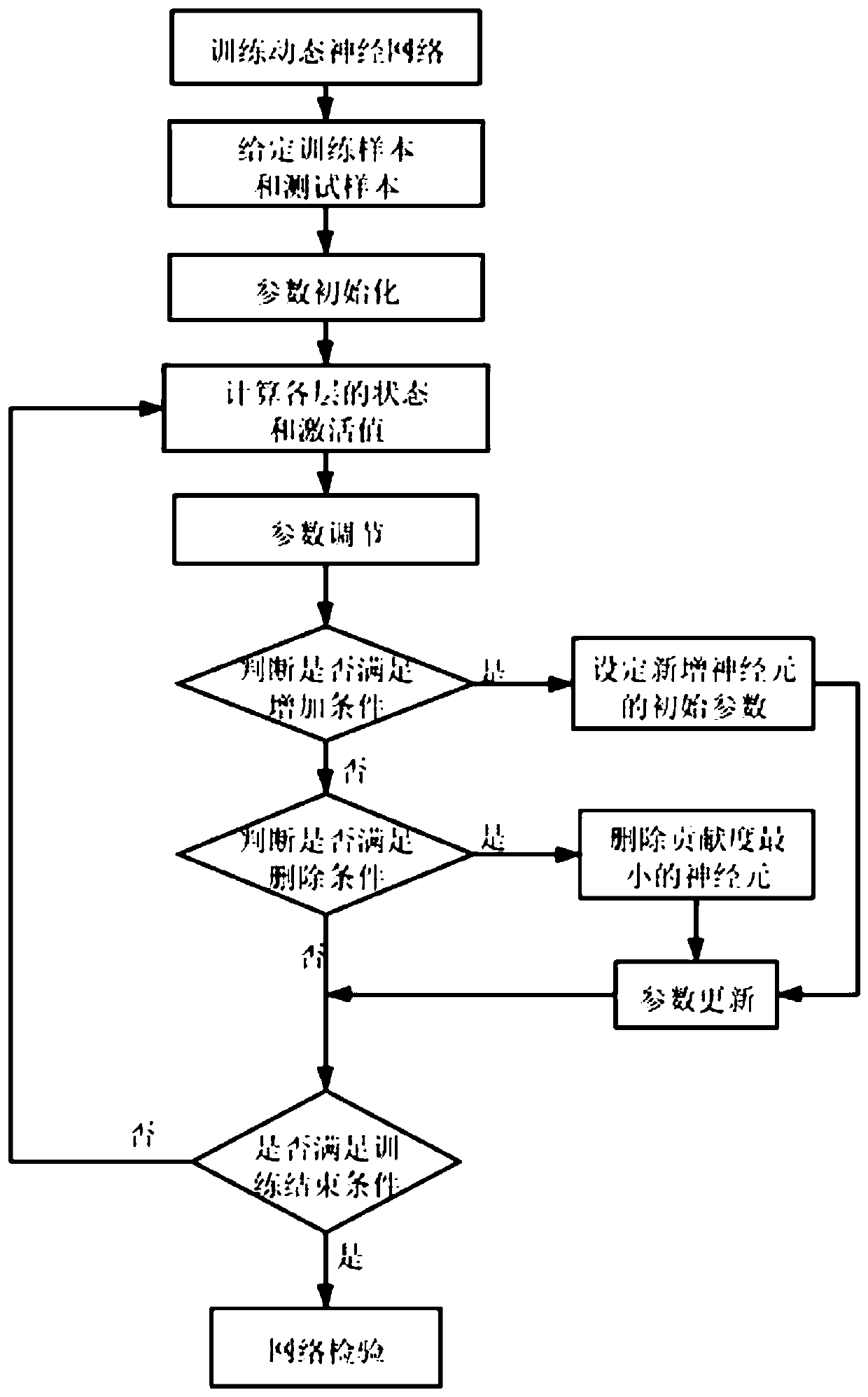

The invention provides a gas concentration real-time prediction method based on a dynamic neural network. Firstly, the neural network is trained by means of data in a mine gas concentration historical database, activeness of hidden nodes of the network and learning ability of each hidden node are dynamically judged in the network training process, splitting and deletion of the hidden nodes of the network are achieved, and a network preliminary prediction model is built; secondly, mine gas concentration information is continuously collected in real time and input into the prediction model of the neutral network to predict the change tendency of gas concentration in the future, and the network is trained timely through predicted real-time data according to the first-in first-out queue sequence to update a neutral network structure in real time, so that the neutral network structure can be adjusted according to real-time work conditions to improve gas concentration real-time prediction precision. According to the method, the neural network structure can be adjusted timely on line according to the real-time gas concentration data, so that gas concentration prediction precision is improved, and the technical requirements of a mine gas concentration information management system are met.

Owner:LIAONING TECHNICAL UNIVERSITY

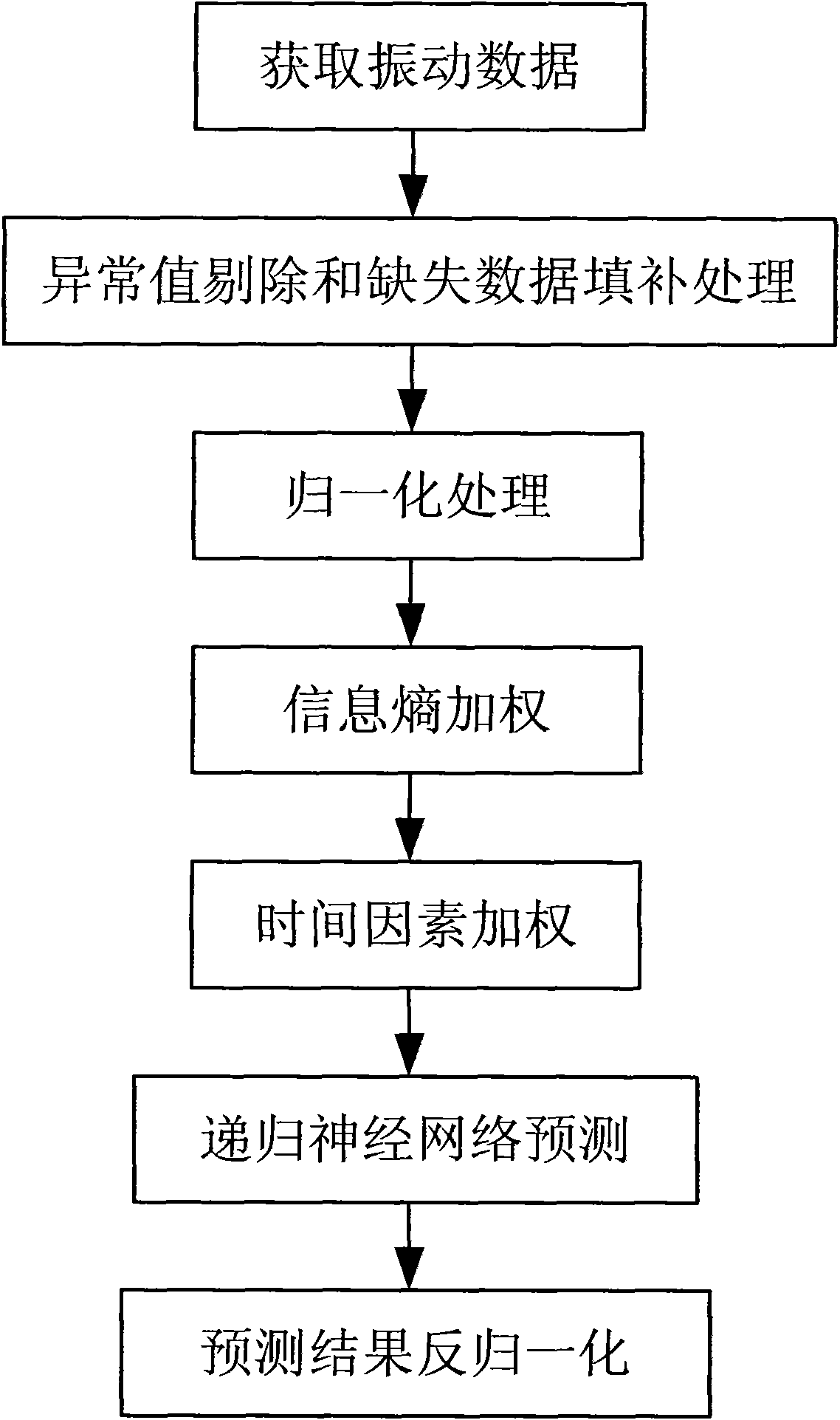

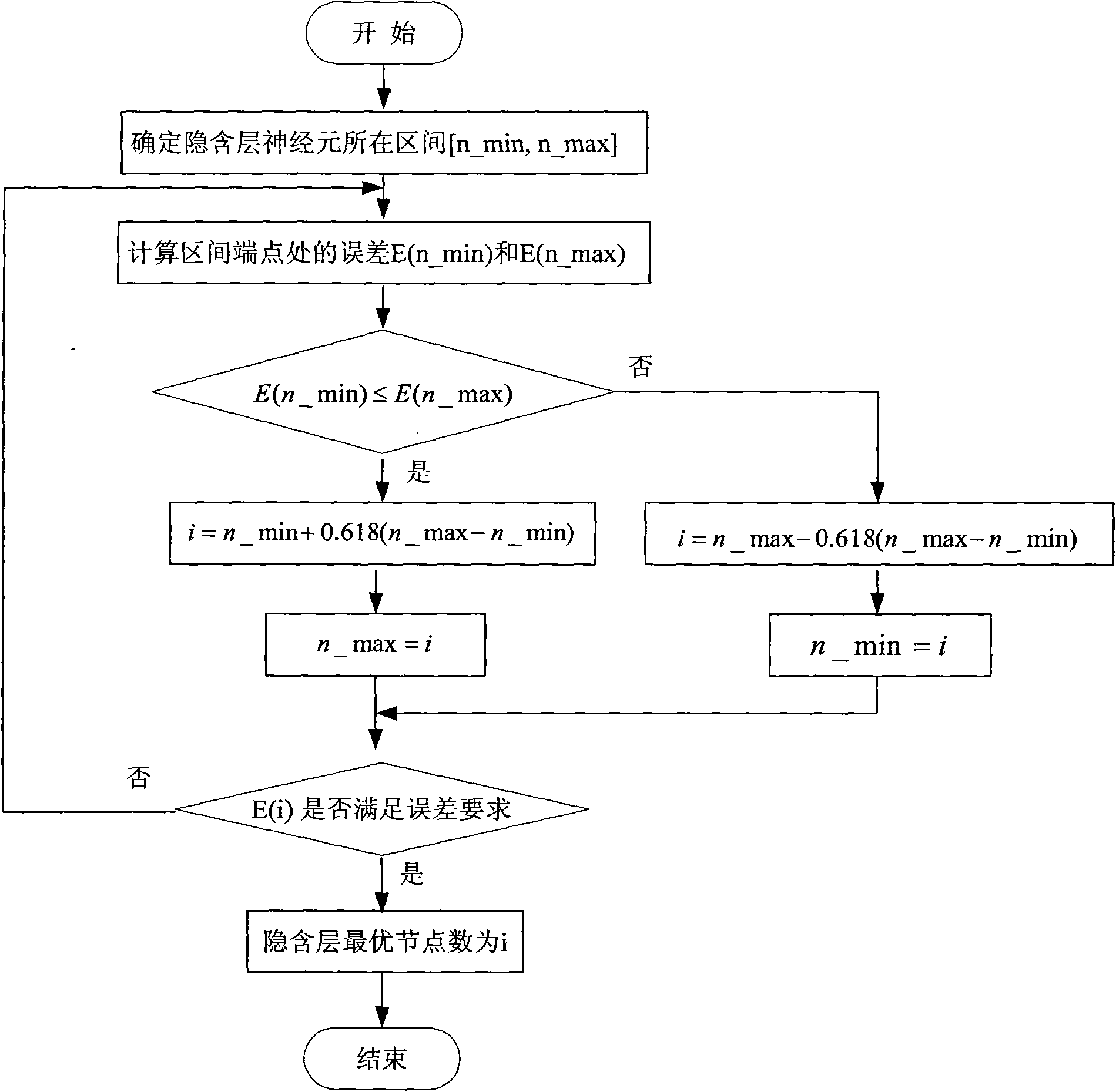

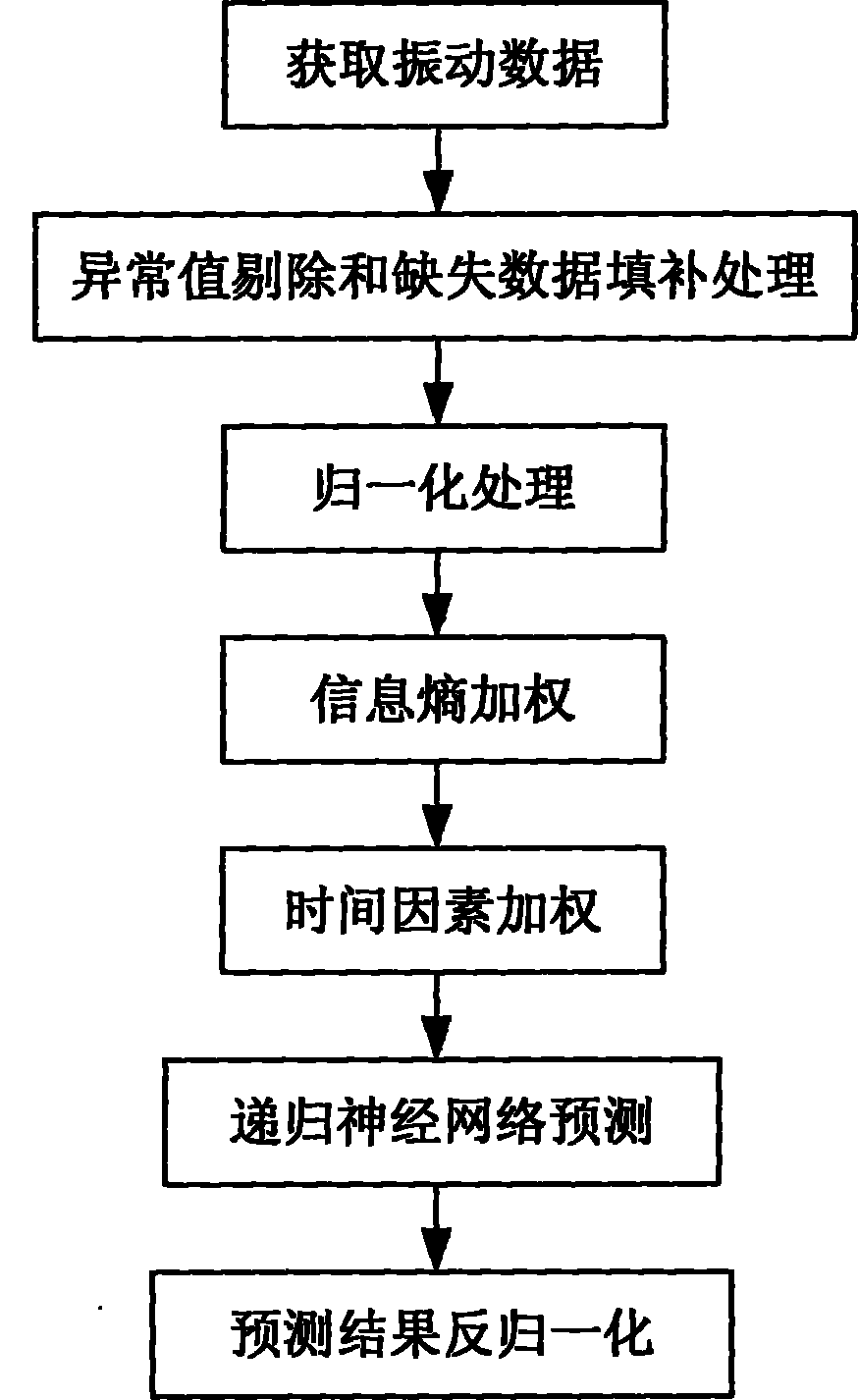

Electromechanical device neural network failure trend prediction method

InactiveCN101799367AEfficient use ofDynamic adaptiveSubsonic/sonic/ultrasonic wave measurementBiological neural network modelsHidden layerNerve network

The invention relates to an electromechanical device neural network failure trend prediction method, comprising the following steps: (1) obtain a section continuous vibration signal which is sensitive to the failure and is output by a measuring point sensor; (2) respectively carry out exceptional value elimination and missing data filling to the vibration data by a 3 sigma method and an interpolation method; (3) carry out a normalization process to a vibration data sequence; (4) calculate a vibration data sequence which is entropy-weighted according to the sequence which is carried out the normalization process; (5) carry out a time-weighted calculation to the vibration data sequence which is entropy-weighted by utilizing time weight due to the influence of time factor; (6) build a nonlinear dynamic recurrent neural network prediction model by utilizing the data sequence which is obtained by step (5) and determine a hidden layer optimal node number by utilizing a golden section method; (7) carry out normalization process to a trend prediction result and obtain a actual prediction result. A dynamic recurrent neural network model is adopted to carry out prediction in the invention, therefore, the failure prediction reliability is increased. The electromechanical device neural network failure trend prediction method can be widely applied to the failure prediction and analysis of all kinds of electromechanical devices.

Owner:BEIJING INFORMATION SCI & TECH UNIV

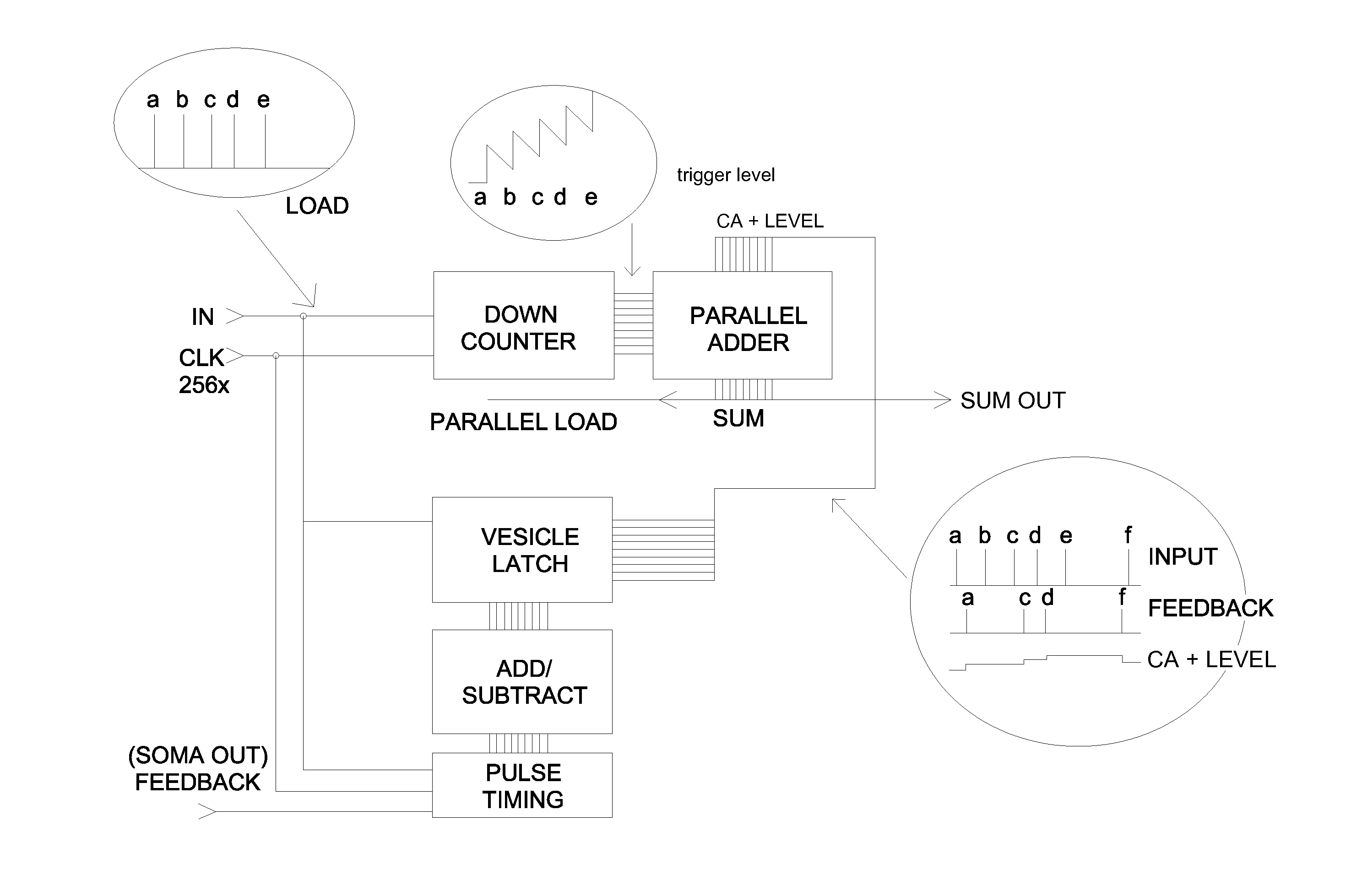

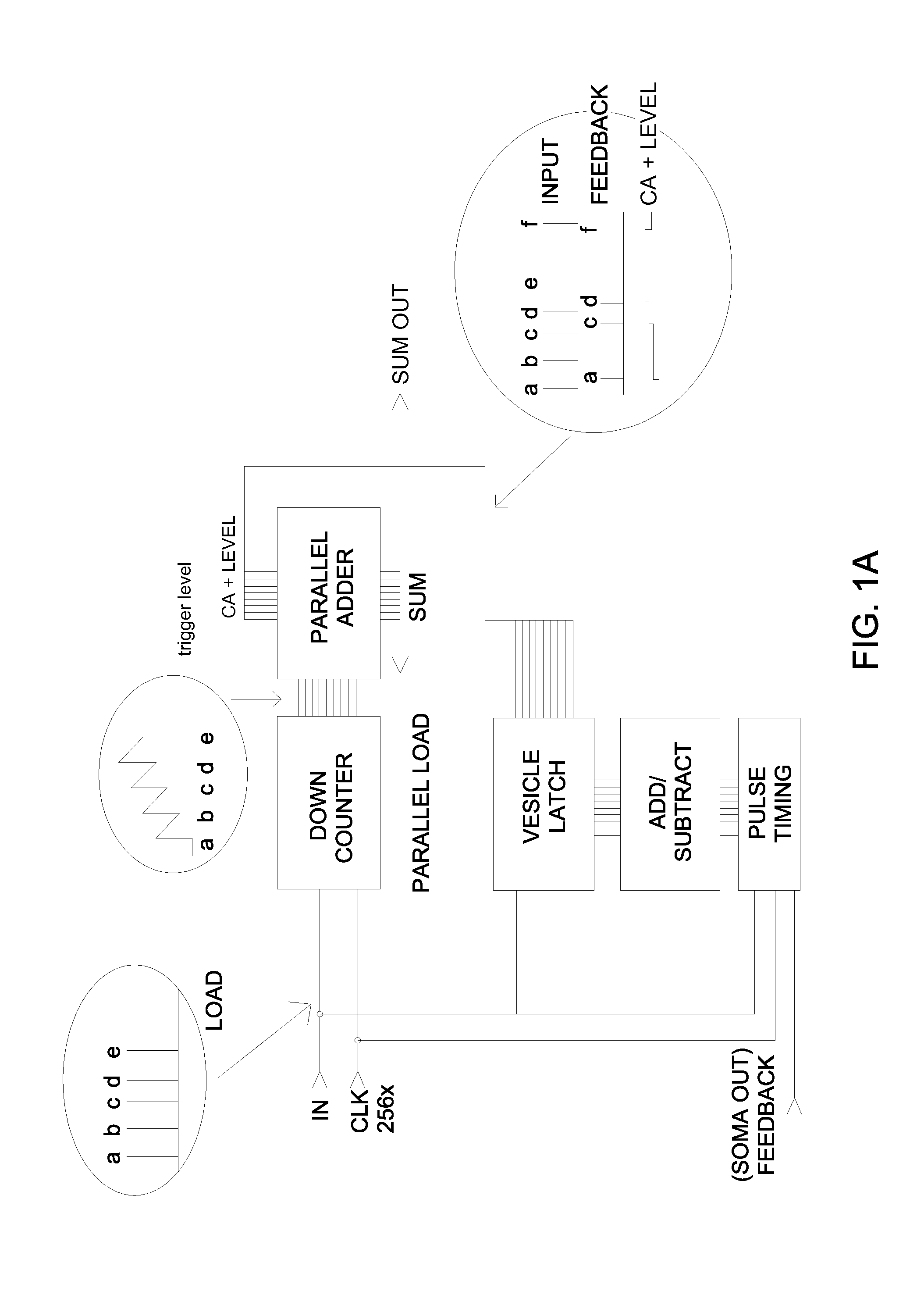

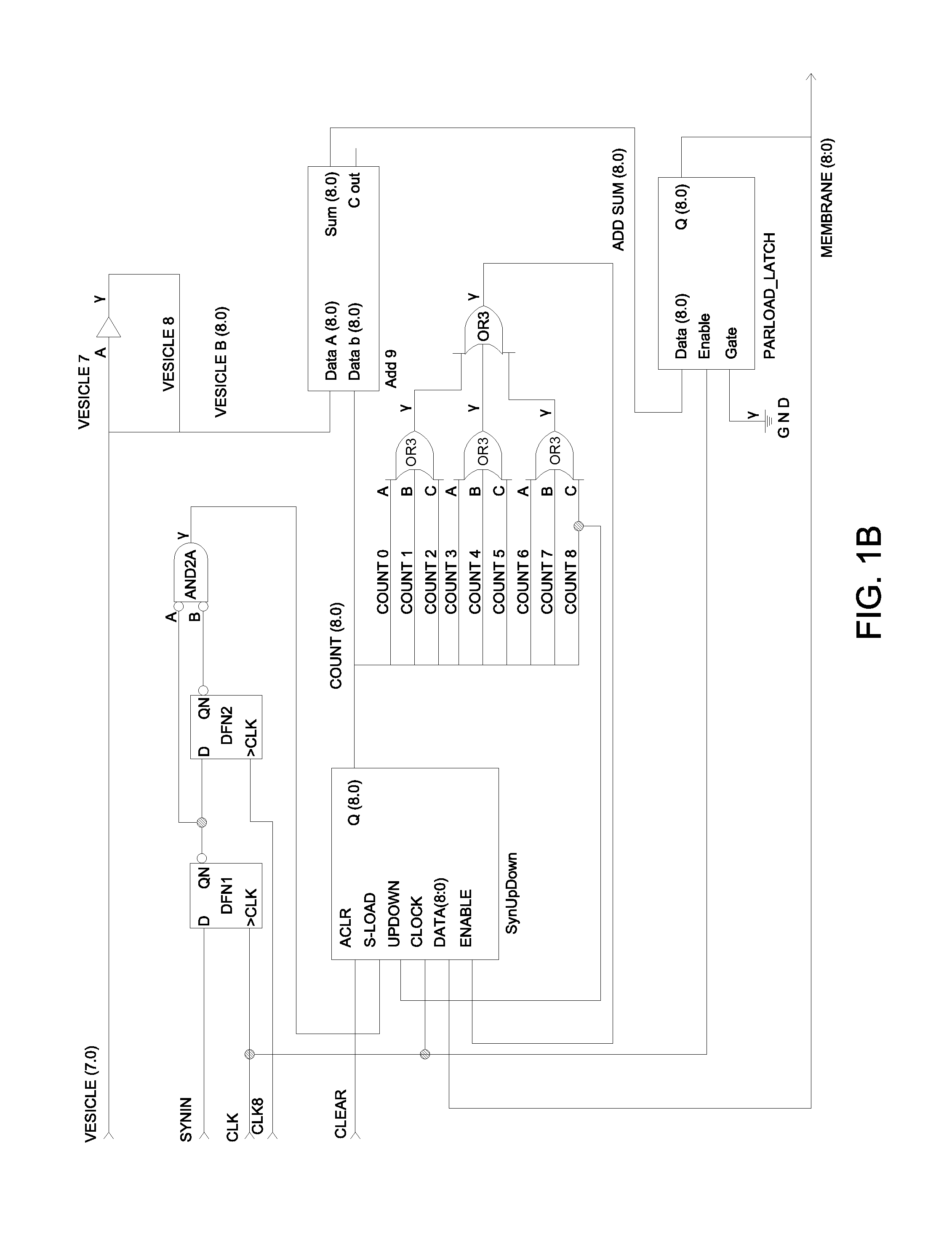

Spiking dynamical neural network for parallel prediction of multiple temporal events

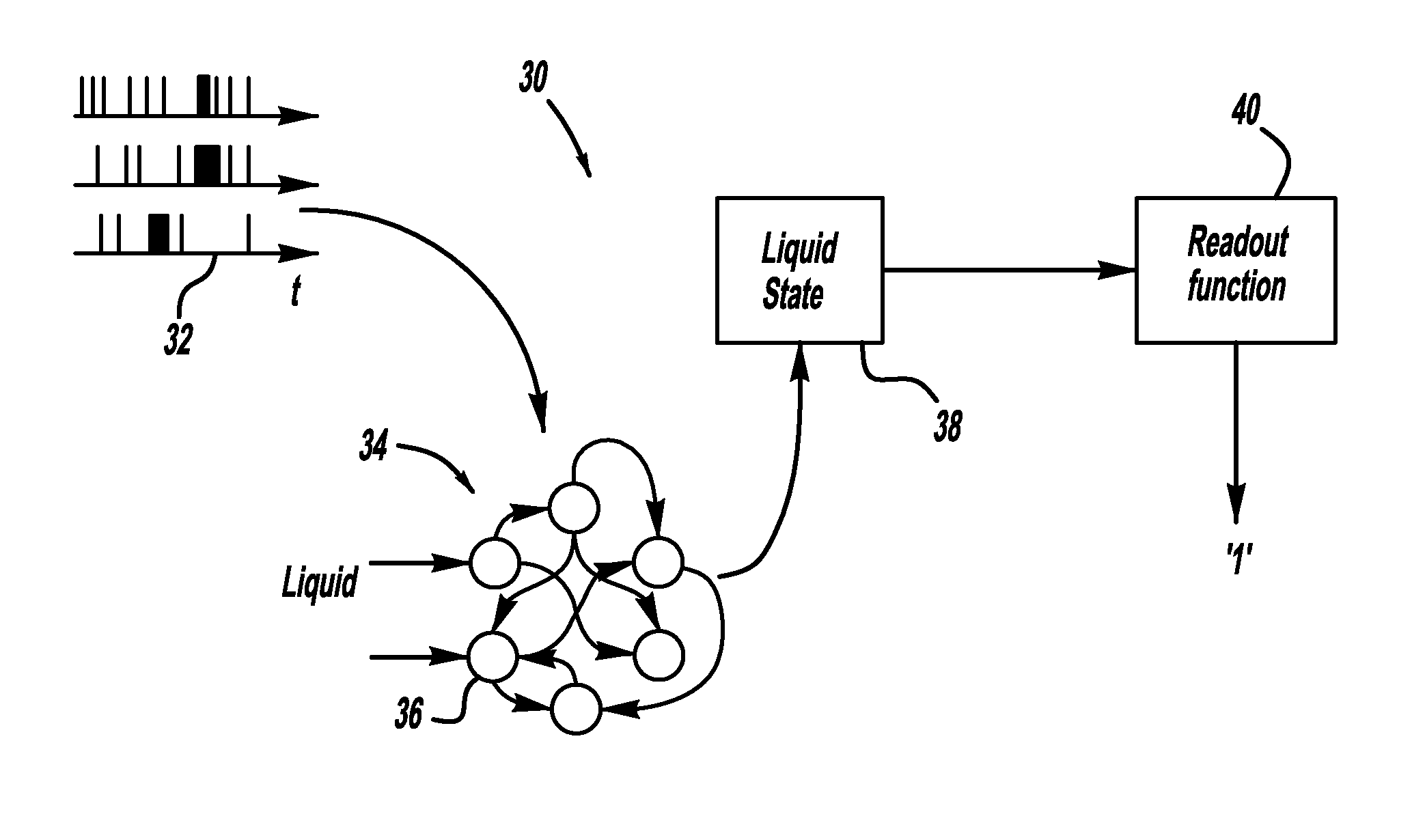

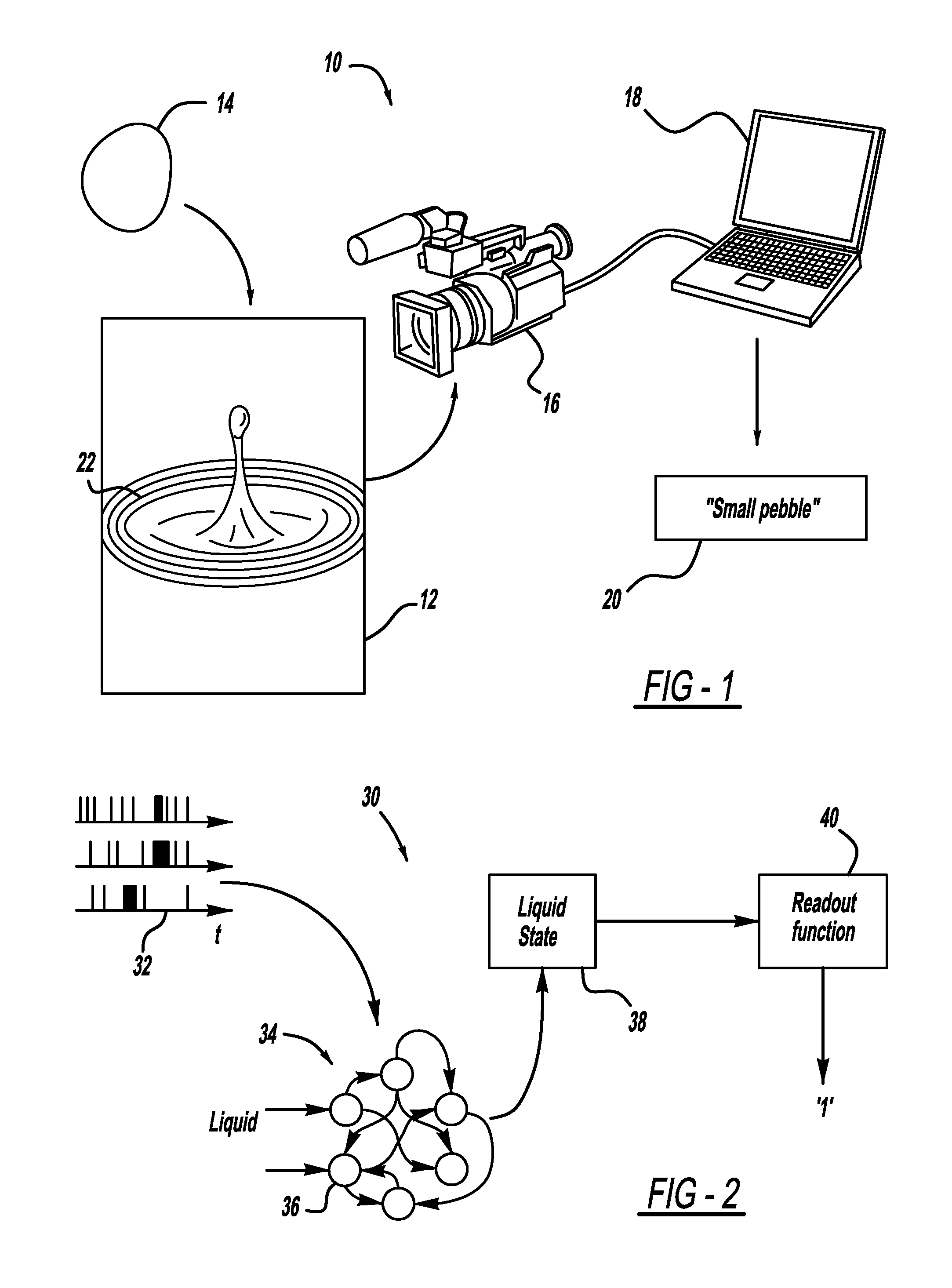

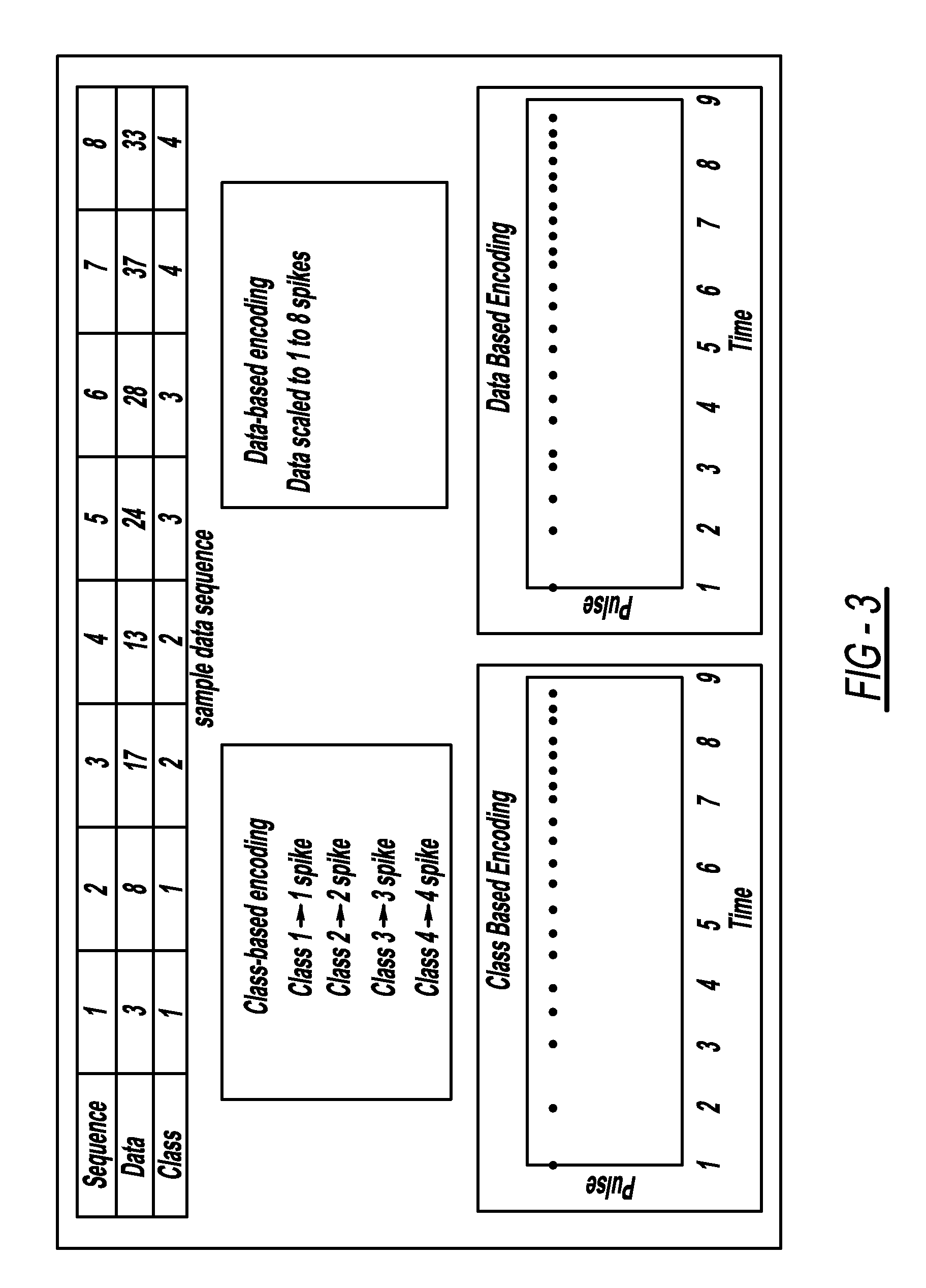

A system and method for determining events in a system or process, such as predicting fault events. The method includes providing data from the process, pre-processing data and converting the data to one or more temporal spike trains having spike amplitudes and a spike train length. The spike trains are provided to a dynamical neural network operating as a liquid state machine that includes a plurality of neurons that analyze the spike trains. The dynamical neural network is trained by known data to identify events in the spike train, where the dynamical neural network then analyzes new data to identify events. Signals from the dynamical neural network are then provided to a readout network that decodes the states and predicts the future events.

Owner:GM GLOBAL TECH OPERATIONS LLC

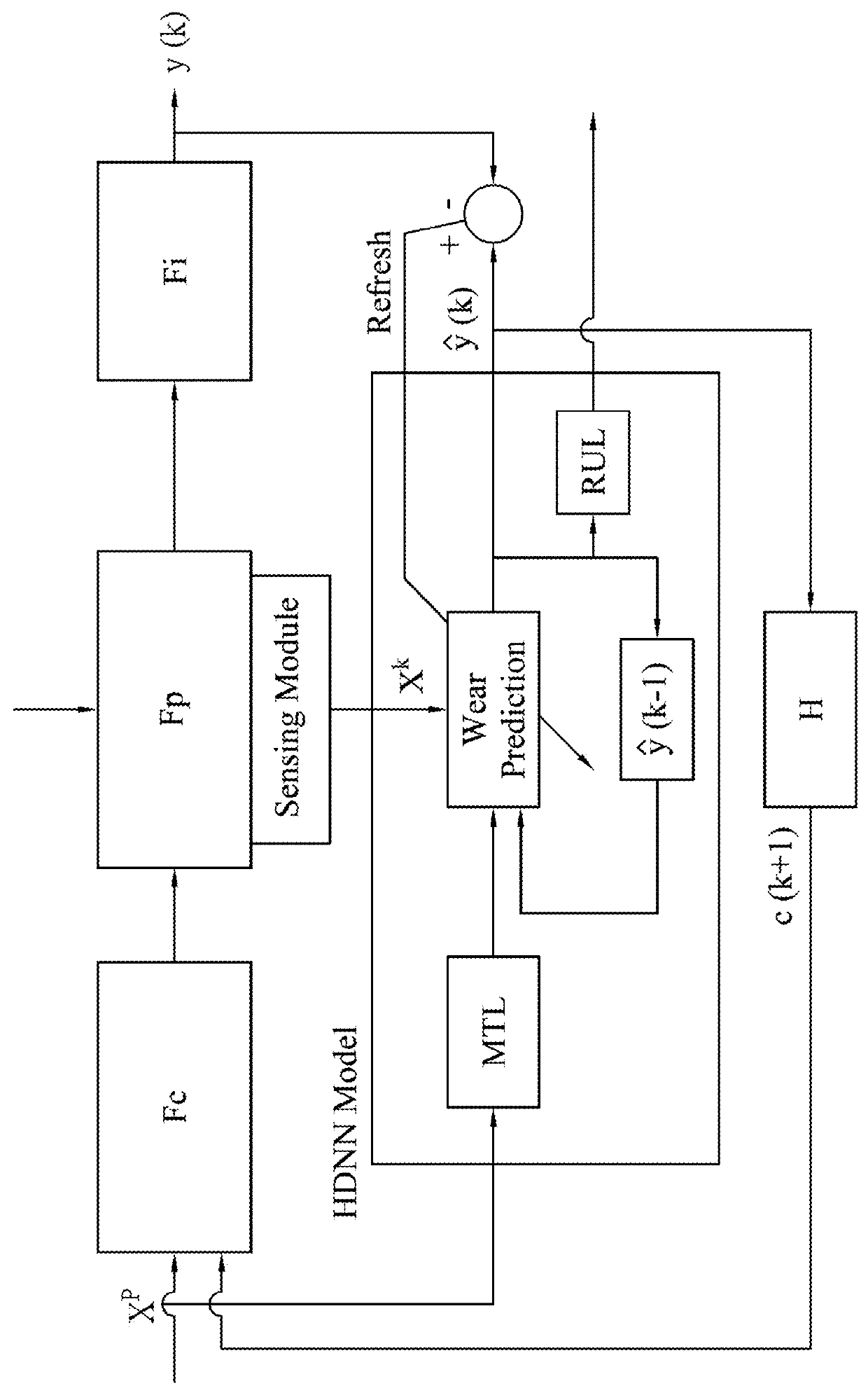

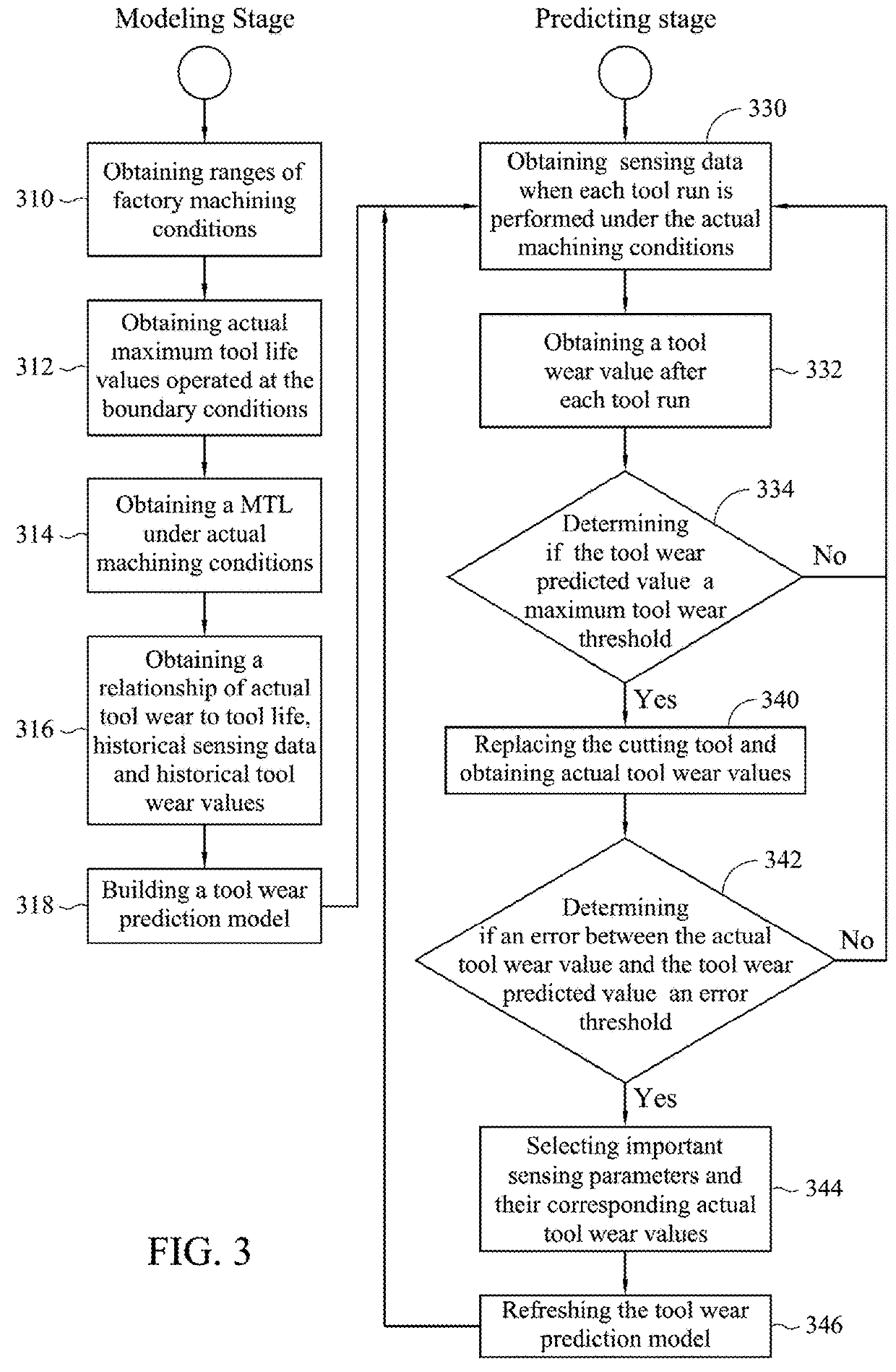

Tool wear monitoring and predicting method

A tool wear monitoring and predicting method is provided, and uses a hybrid dynamic neural network (HDNN) to build a tool wear prediction model. The tool wear prediction model adopts actual machining (cutting) conductions, sensing data detected at the current tool run of operation and the predicted tool wear value at the previous tool run of operation to predict a predicted tool wear value at the current tool run. A cyber physical agent (CPA) is adopted for simultaneously monitoring and predicting tool wear values of plural machines of the same machine type.

Owner:NAT CHENG KUNG UNIV

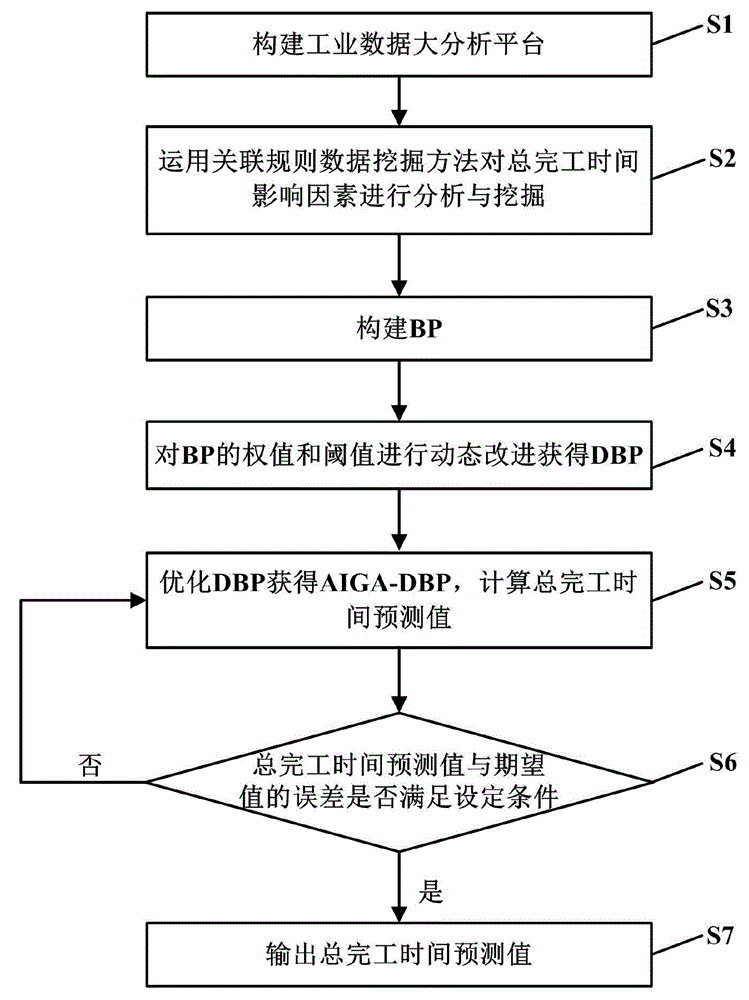

Industrial big data driven total completion time prediction method

InactiveCN104636479AEasy to produceIncrease productivityRelational databasesForecastingImmune genetic algorithmNetwork model

The invention discloses an industrial big data driven total completion time prediction method and relates to the field of engineering application. The method includes: establishing an industrial big data analysis platform; applying an association rule mining algorithm to analyze and mine total completion time influence factors; establishing a neural network model BP; dynamically improving a weight and a threshold of the neural network model BP to acquire a dynamical neural network model DBP; applying an AIGA (adaptive immune genetic algorithm) to optimize the dynamical neural network model DBP so as to acquire a prediction model AIGA-DBP, and computing a total completion time prediction value according to the prediction model AIGA-DBP; when an error of the total completion time prediction value and a total completion time expectation value meets preset conditions, outputting the total completion time prediction value. By the method, the total completion time can be predicated accurately, the work flow of enterprises is optimized, the production efficiency of the enterprises can be improved, and the method is adaptable to various changes of the enterprise due to time lapse.

Owner:XIDIAN UNIV +1

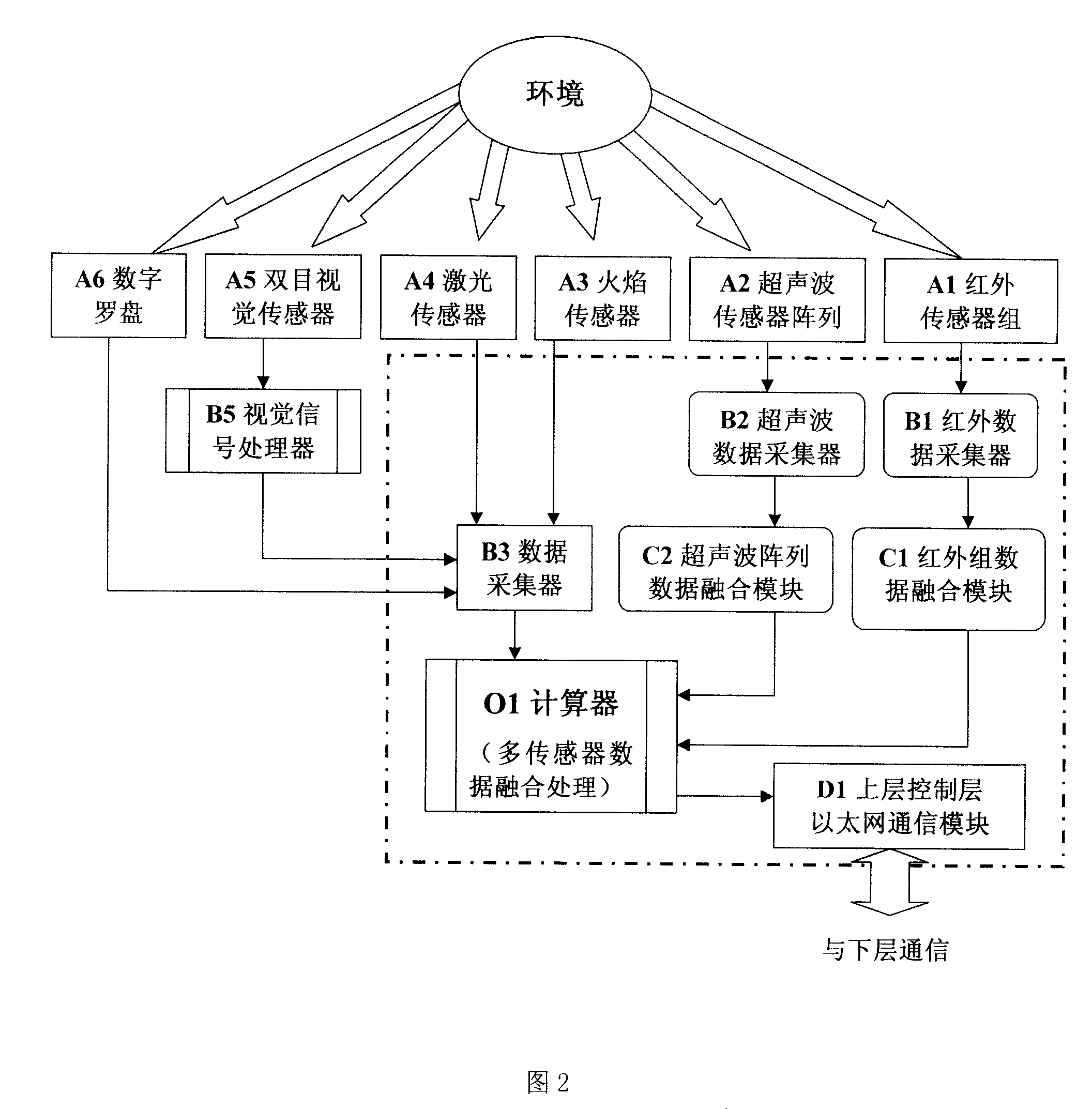

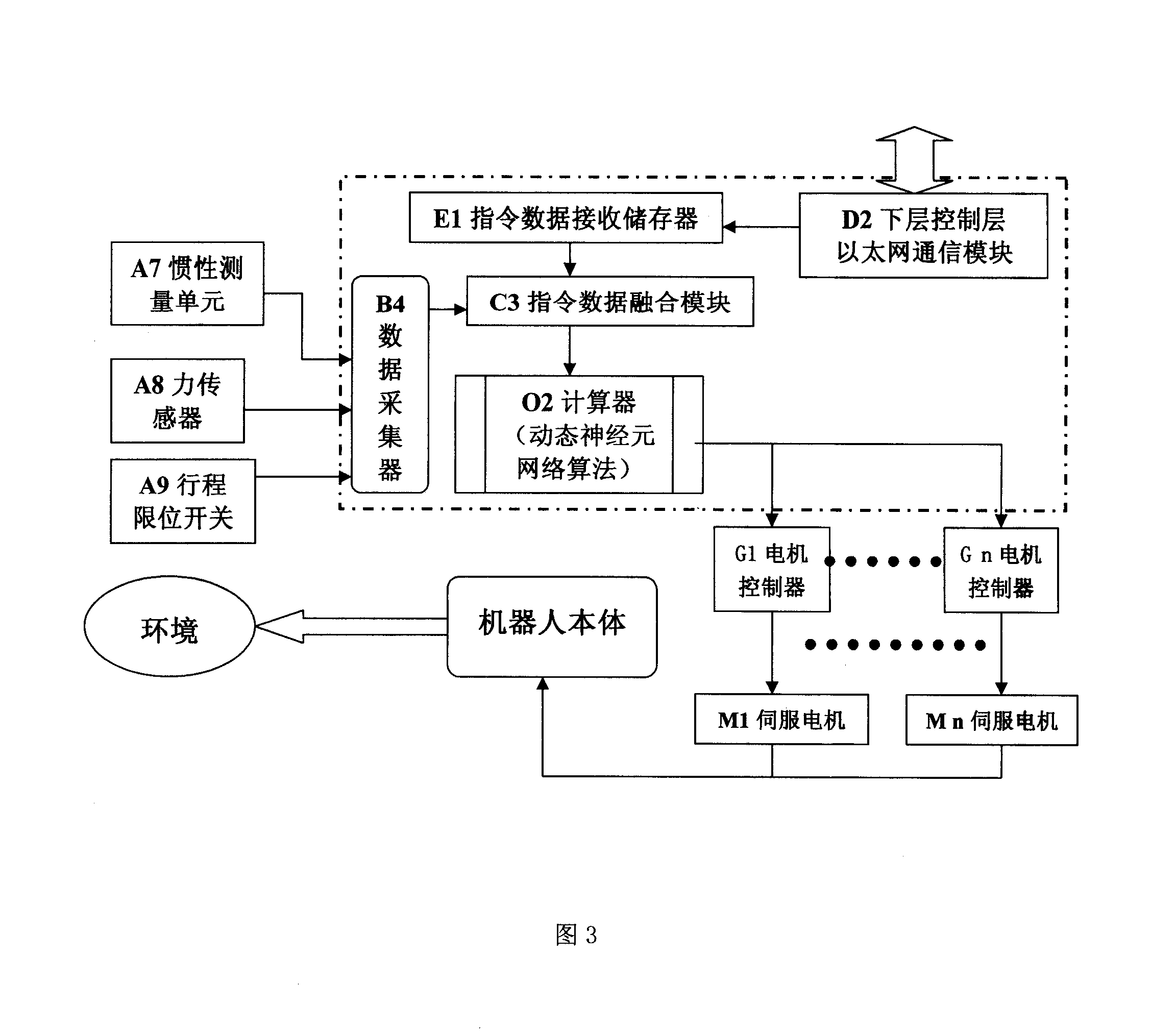

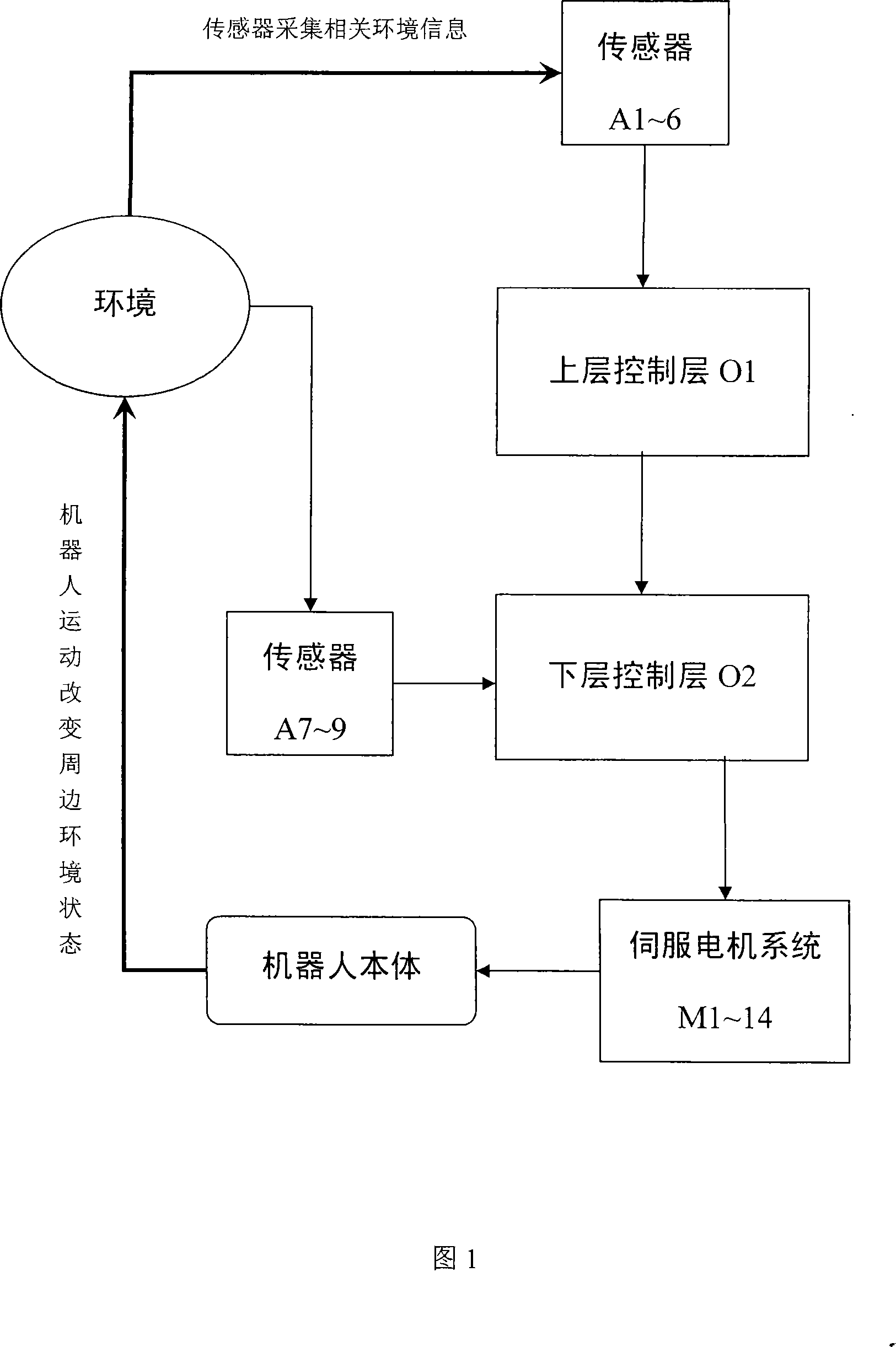

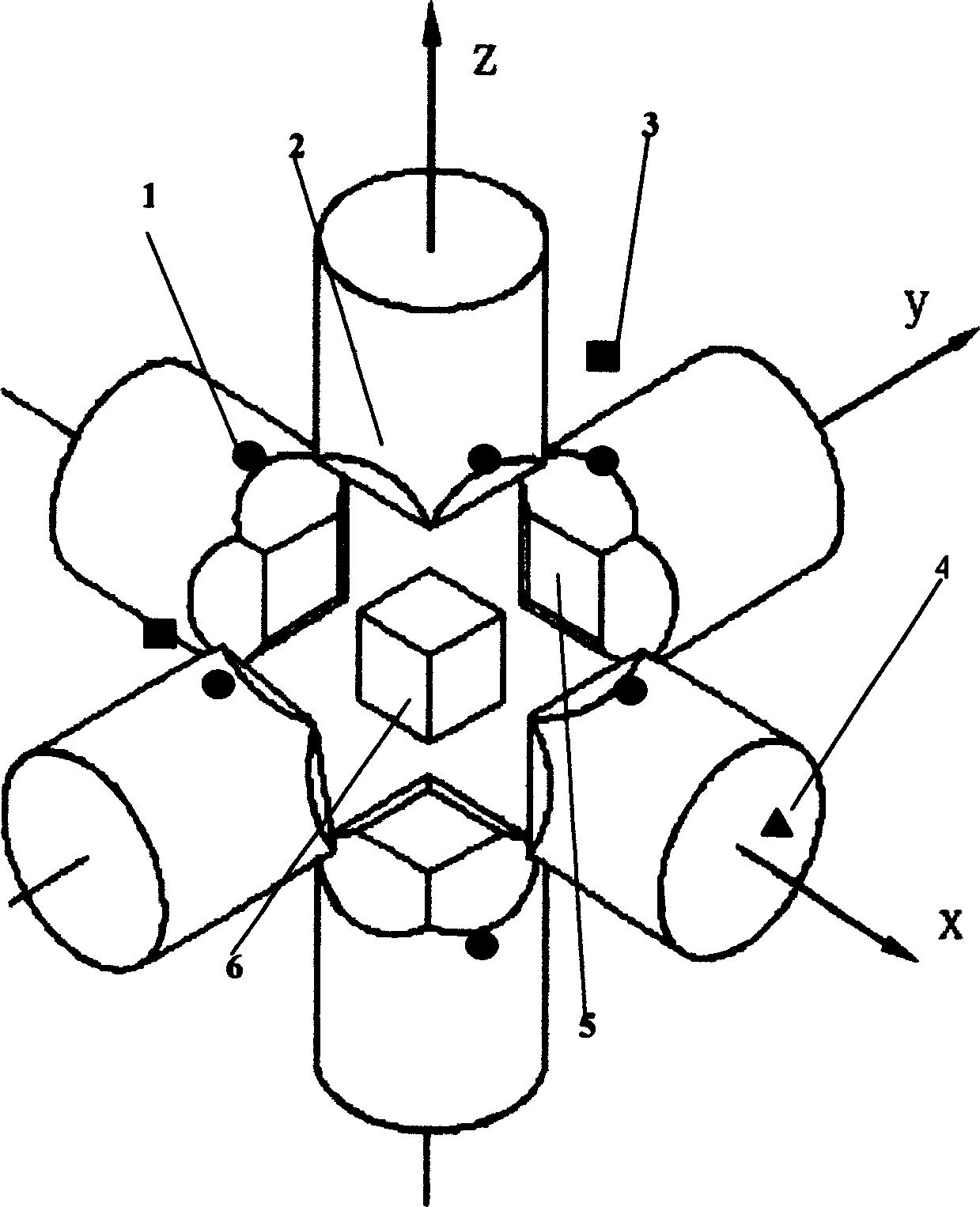

All fours type bionic robot control device

InactiveCN101251756AFlexible obstacle avoidanceConvenient obstacle avoidanceAttitude controlManipulatorControl layerDynamic neural network

The present invention discloses a four-foot type bionic robot control device, wherein an upper control layer and a lower control layer are established; sensors provide environment information for the robot control layers; an upper layer calculator and a lower layer calculator process acquired information and transmit a decision instruction to a servo motor; after the motor rotates to drive a robot body to move, the state of the robot is changed, and then the sensors survey new environment data. An upper layer control layer determines the orientation adjustment and conversion of the robot; a lower layer control layer utilizes a dynamic neural network algorithm to be integrated with the data of the sensors, and simultaneously transmits joint control signals to a motor controller so as to drive the servo motor. As the present invention establishes a four-foot type bionic robot control device capable of realizing self-perception, self-adaptation and self-regulation actions, the robot can have abundant information sources and intelligently regulate poses so as to adapt to complex environment.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

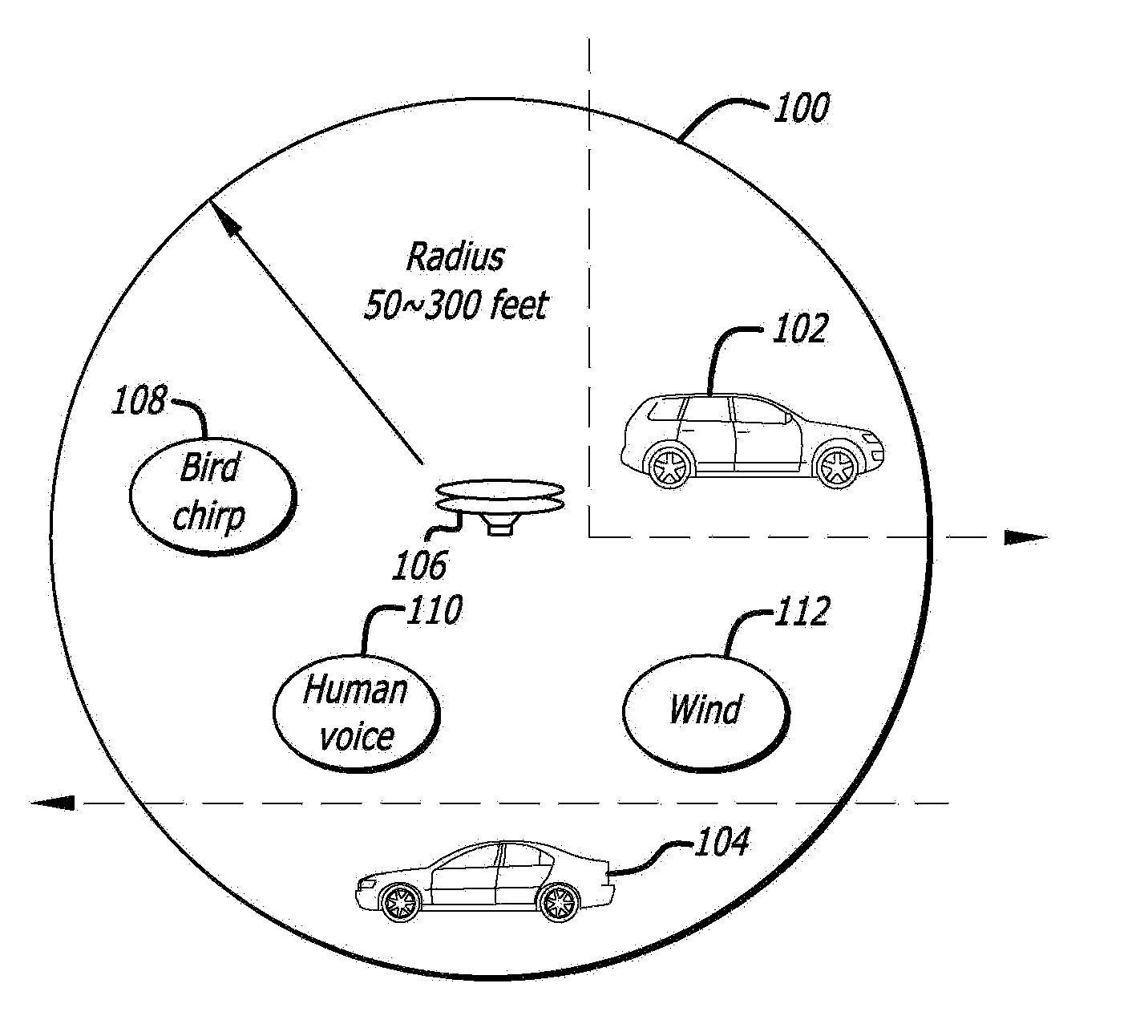

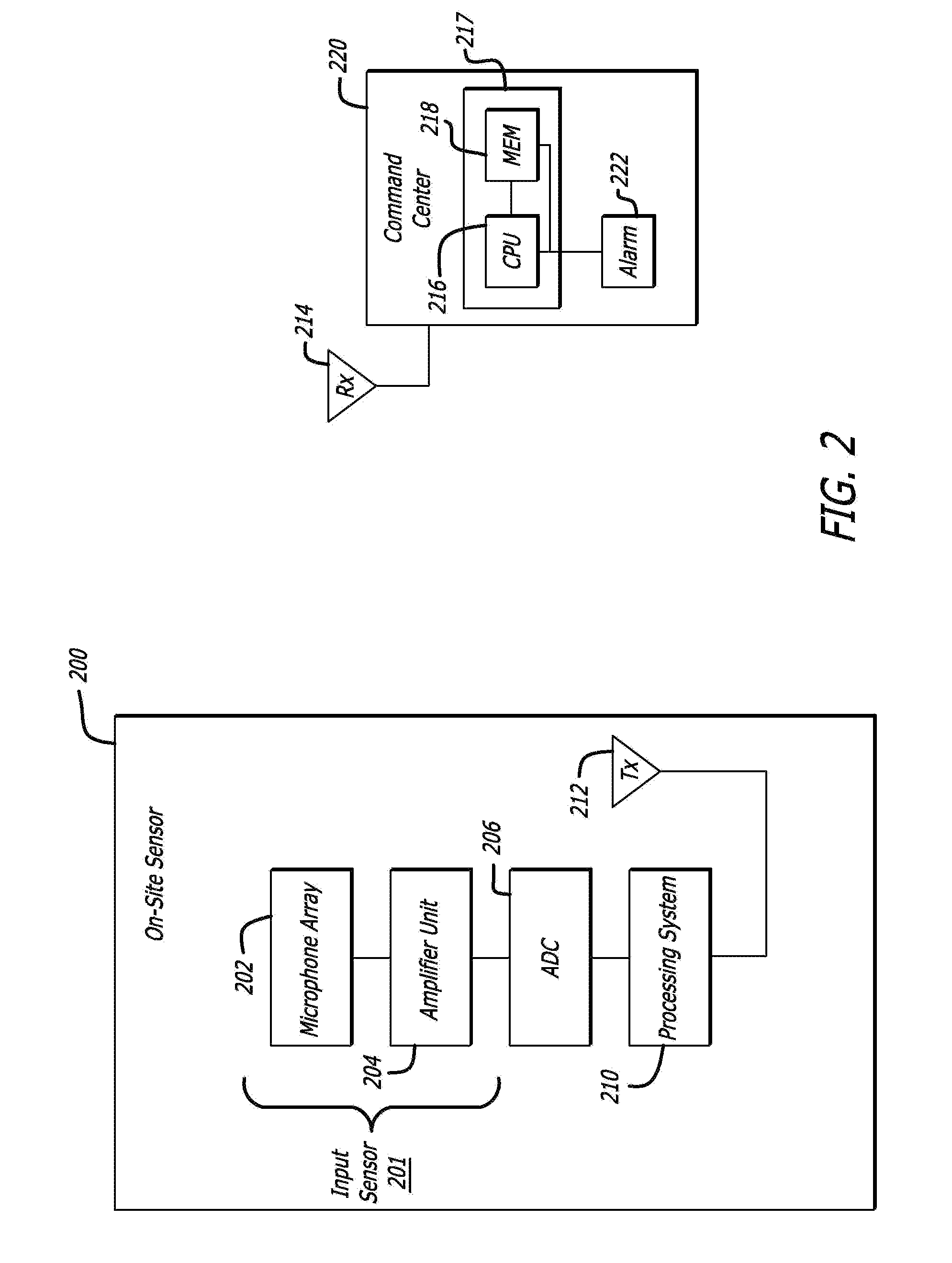

Acoustic signature recognition of running vehicles using spectro-temporal dynamic neural network

InactiveUS20110169664A1Vibration measurement in fluidDetection of traffic movementFeature vectorDynamic neural network

Owner:UNIV OF SOUTHERN CALIFORNIA

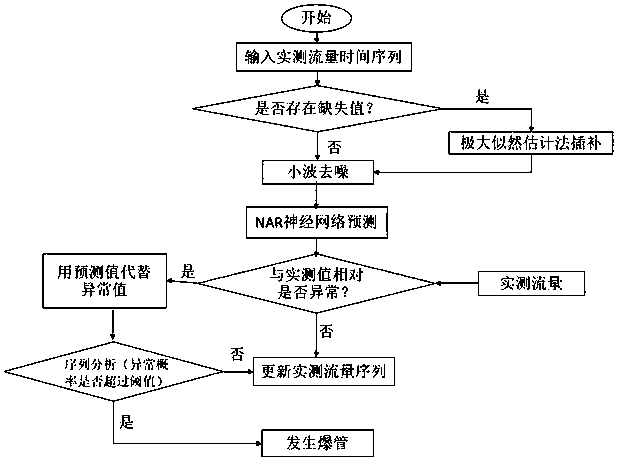

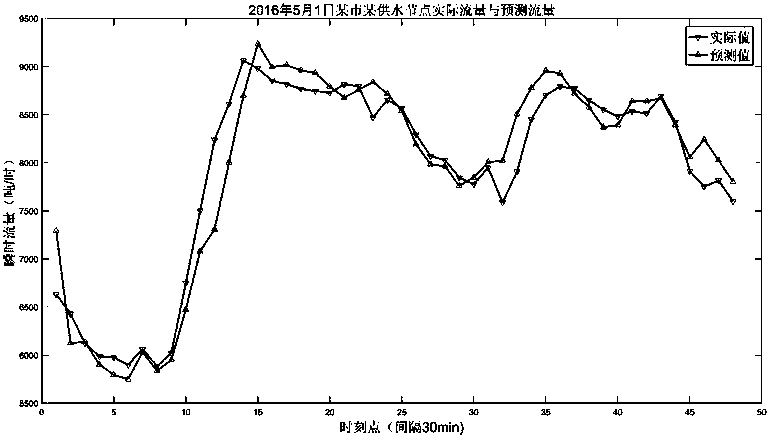

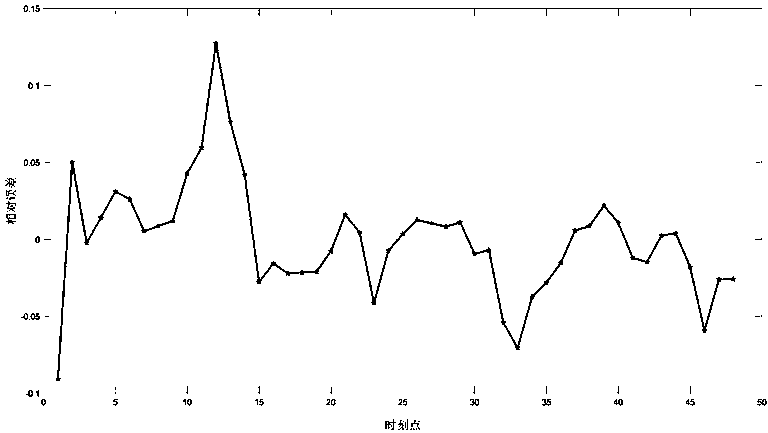

City water supply network burst detection method based on dynamic neural network prediction

ActiveCN108167653AImprove the detection rateHigh precisionPipeline systemsNODALPrediction algorithms

The invention discloses a city water supply network burst detection method based on dynamic neural network prediction. The method comprises the steps that 1, normal history flow data of the W durationof city water supply nodes is utilized to serve as the original time sequence; 2, the original time sequence is analyzed to obtain a pretreated time sequence; 3, wavelet analysis is carried out, wherein the wavelet analysis is utilized for carrying out denoising on the pretreated time sequence, and denoised flow data is obtained; 4, a model is set up, wherein the NAR dynamic neural network is utilized for training the denoised flow data, and the burst recognition model is set up; 5, a flow time window of the W duration slides backwards along with time, and the flow data is updated; 6, the flow time window of the W duration slides backwards continuously along with time, the step 5 is repeated, and until the accumulation probability of flow abnormality surpasses a set threshold value, it isjudged that the burst accident occur. According to the method, in combination with the wavelet analysis and the dynamic neural network prediction algorithm, burst accident detection of the city watersupply network based on dynamic neural network prediction is achieved.

Owner:ZHEJIANG UNIV

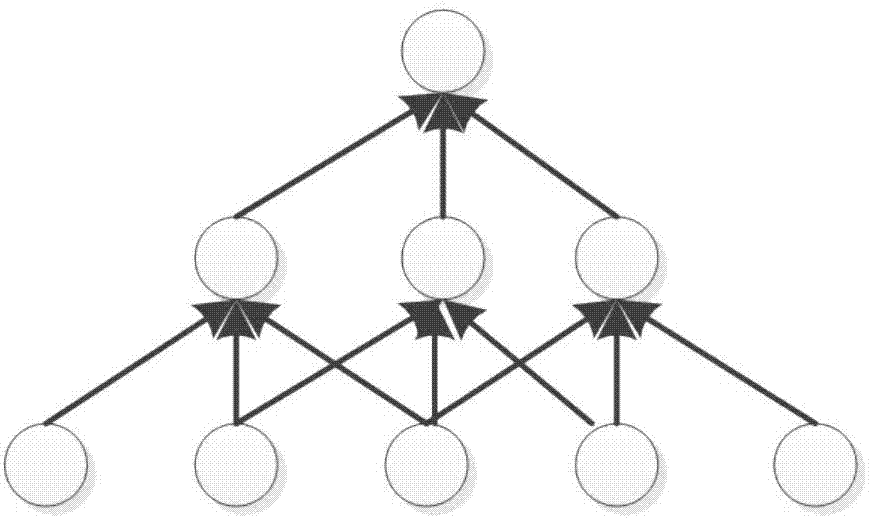

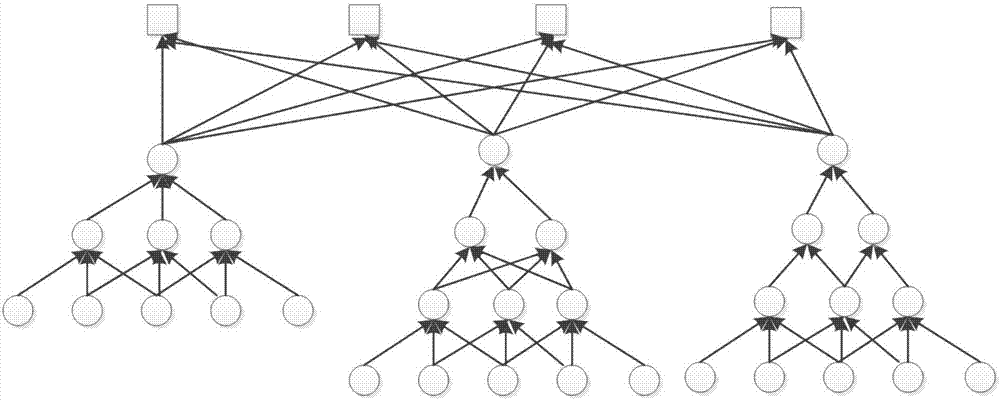

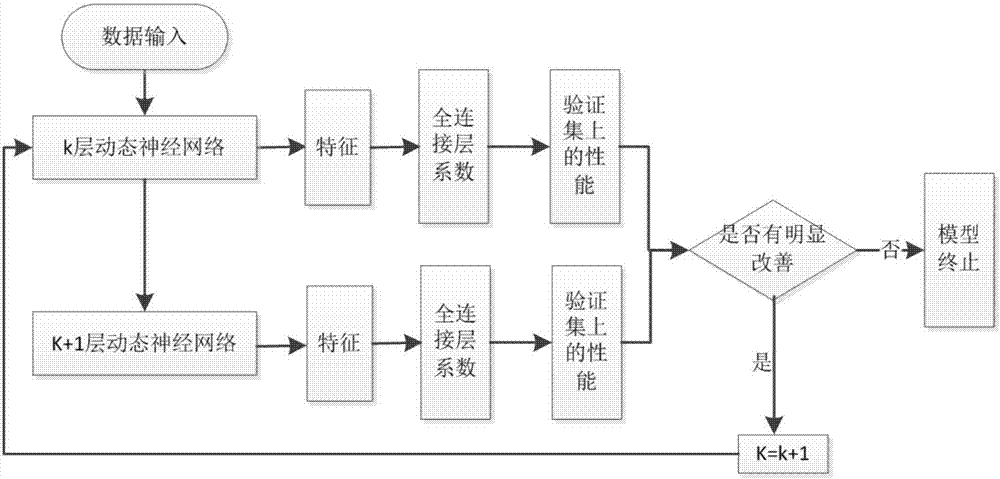

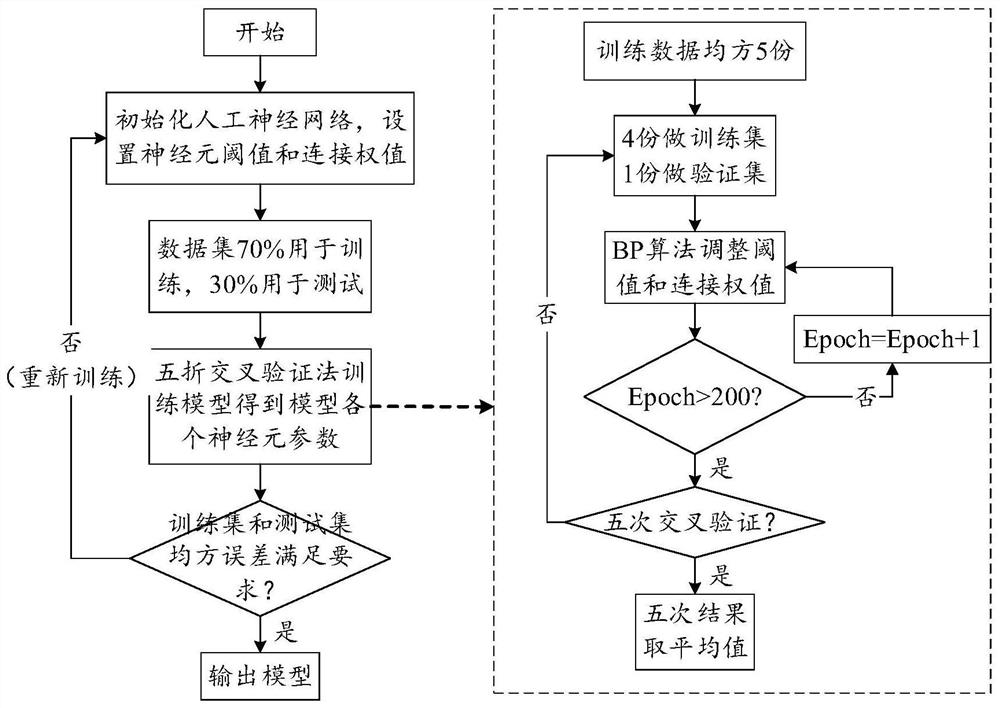

Dynamic neutral network model training method based on ensemble learning and dynamic neutral network model training device thereof

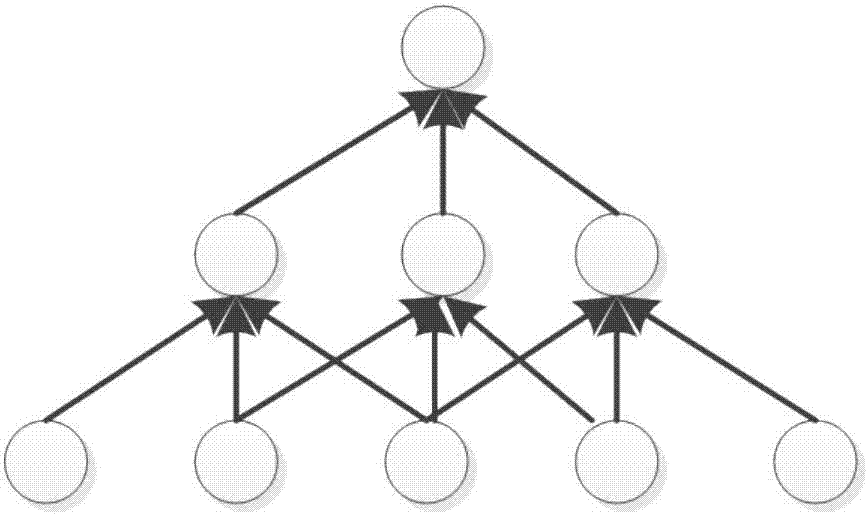

InactiveCN107480774AReduce design difficultyReduce depthNeural architecturesNeural learning methodsDynamic neural networkAlgorithm

The invention discloses a dynamic neutral network model training method based on ensemble learning and a dynamic neutral network model training device thereof. The method comprises the steps that as for each sub-model in an ensemble dynamic neutral network model, original data act as the input of a first layer of neurons, and the output characteristics of the layer can be obtained through processing of dynamic neurons; the number of layers of the neurons is increased, and the output characteristics of the previous layer act as the input of the next layer of neurons so as to obtain the characteristics of the corresponding layer, and the step is repeated until the number of layers reaches a certain preset value; a full connection layer is established between the output characteristics and the belonging class of the last layer, and the full connection weight between the output characteristics and the class is calculated; and the full connection layer is established between each sub-model and the belonging class, and the weight of each sub-model to the ensemble dynamic neutral network model is determined. A deep neural network is converted into multiple relatively shallow neural networks to be processed in parallel so that the training time can be saved and the training efficiency can be enhanced.

Owner:SHANDONG NORMAL UNIV

Variable cycle engine intelligent control method based on dynamic neural network

ActiveCN111042928ASimple structureEnhanced couplingGas turbine plantsEngine controlGrey correlation analysisDynamic neural network

The invention belongs to the technical field of aero-engine control and provides a variable cycle engine intelligent control method based on a dynamic neural network. A structure adjustment algorithmbased on a grey correlation analysis method is added into a neural network training algorithm, a neural network structure is adjusted, a dynamic neural network controller is constructed, and intelligent control of a variable-cycle engine is achieved. Dynamic neural network training is performed through a network structure adjustment algorithm based on the grey correlation analysis method designedin the invention, and a variable cycle engine dynamic intelligent controller based on the dynamic neural network is constructed. A coupling problem between nonlinear multivariables caused by increaseof control variables of the variable cycle engine and the problem that a traditional control method excessively depends on model precision are effectively solved. And meanwhile, the structure can be dynamically adjusted in a neural network training process so that the network structure is simpler, and an operation speed and the control precision are improved.

Owner:DALIAN UNIV OF TECH

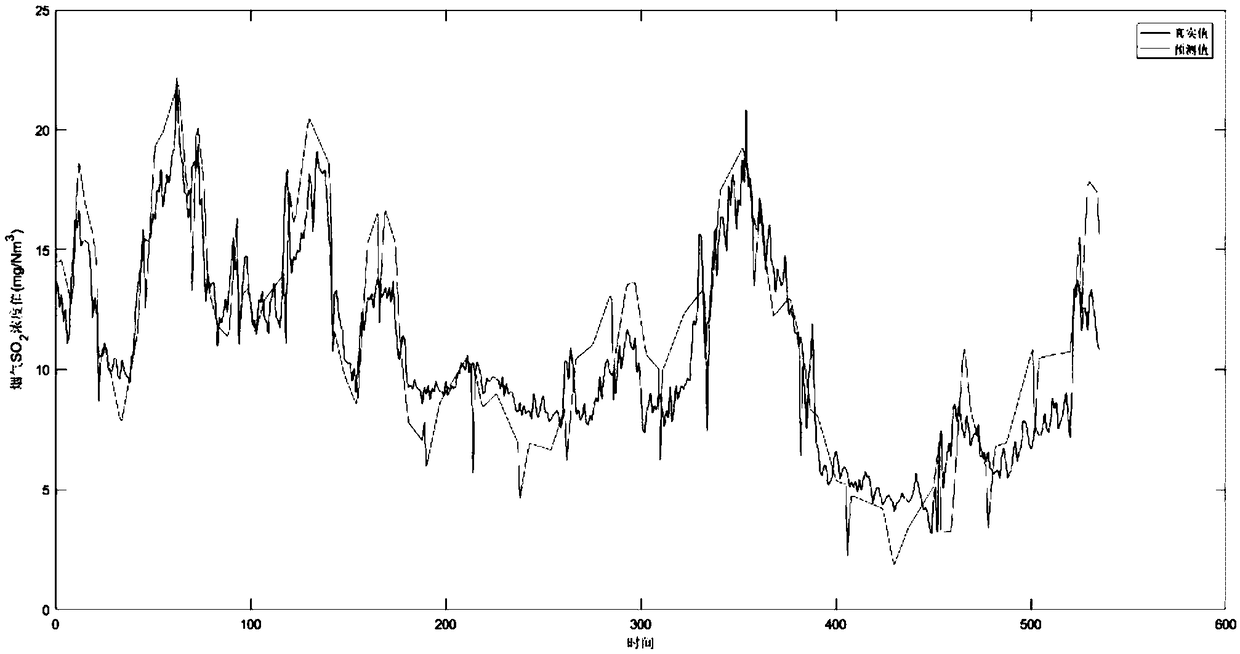

Soft Sensing Method of SO_2 Emission from Power Plant Based on Variable Compression BP Neural Network

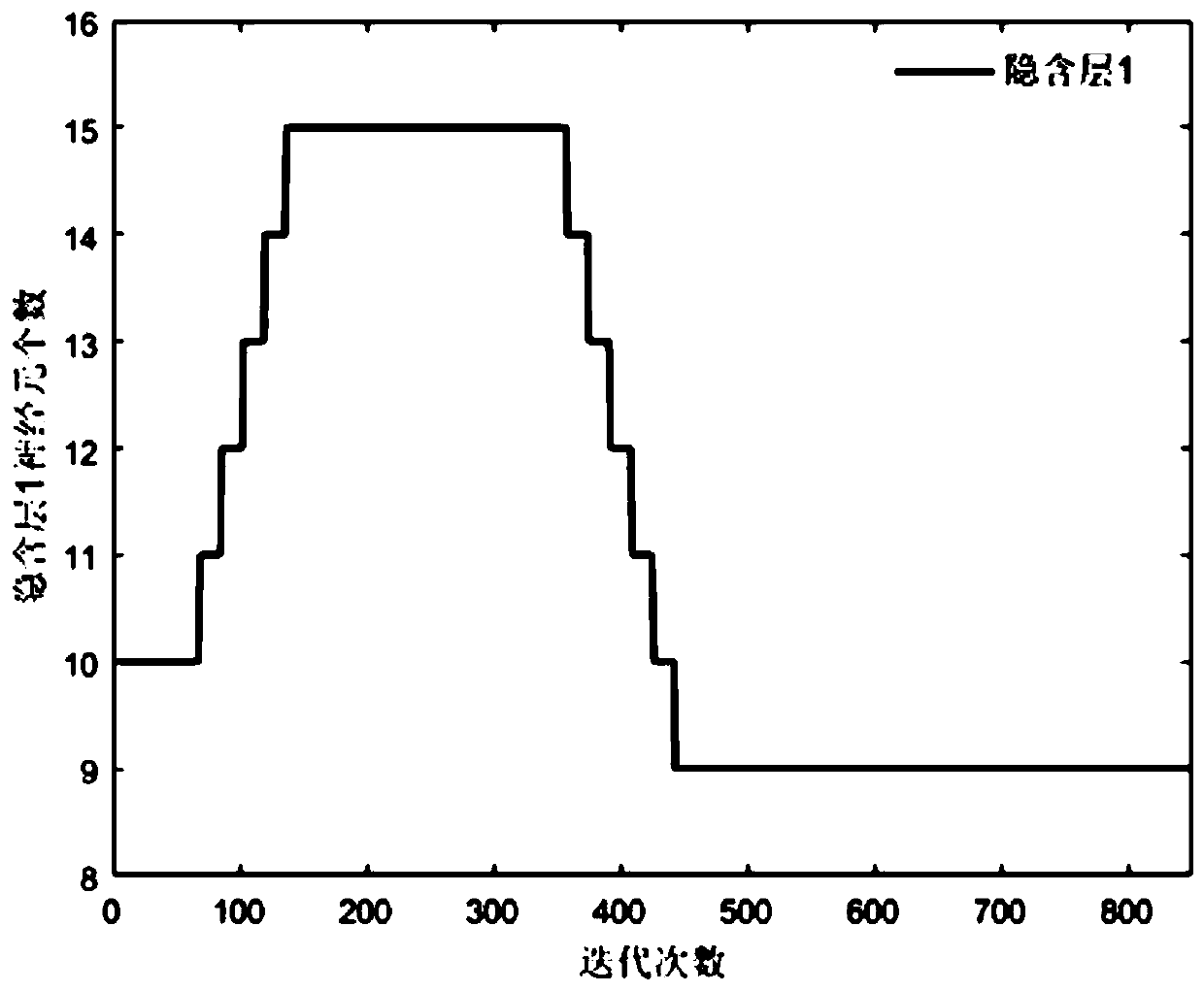

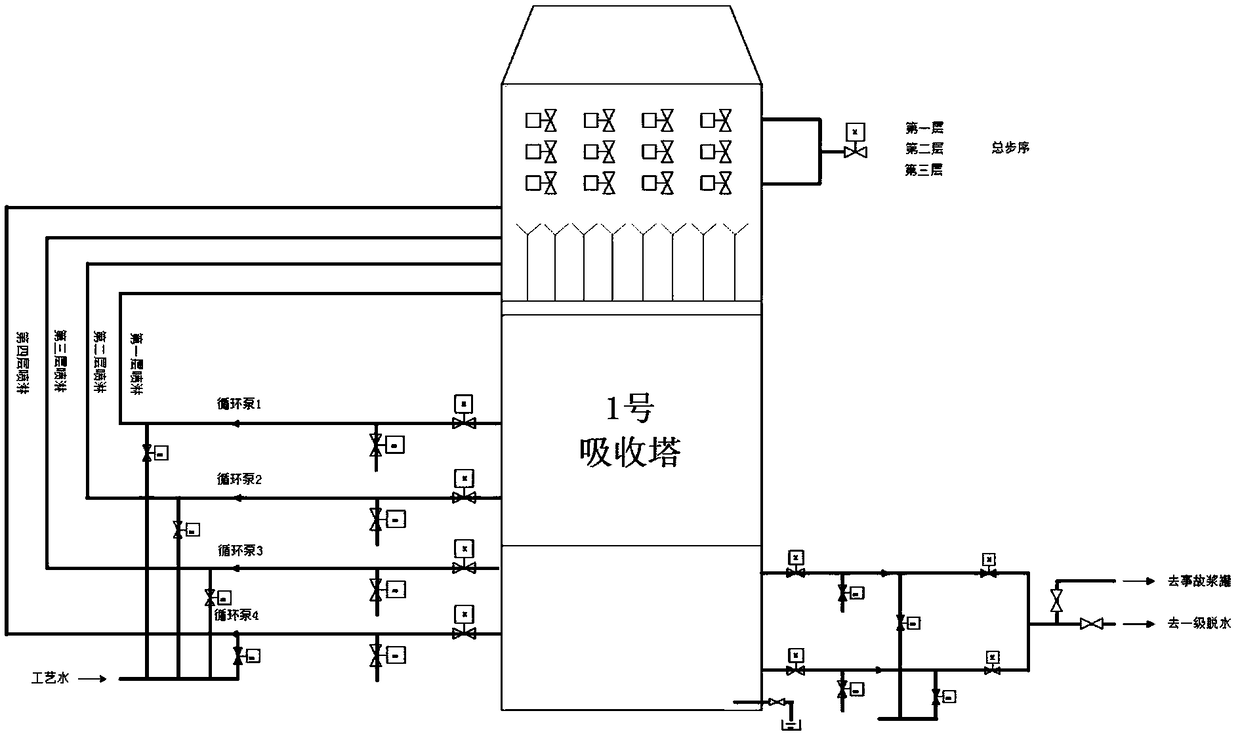

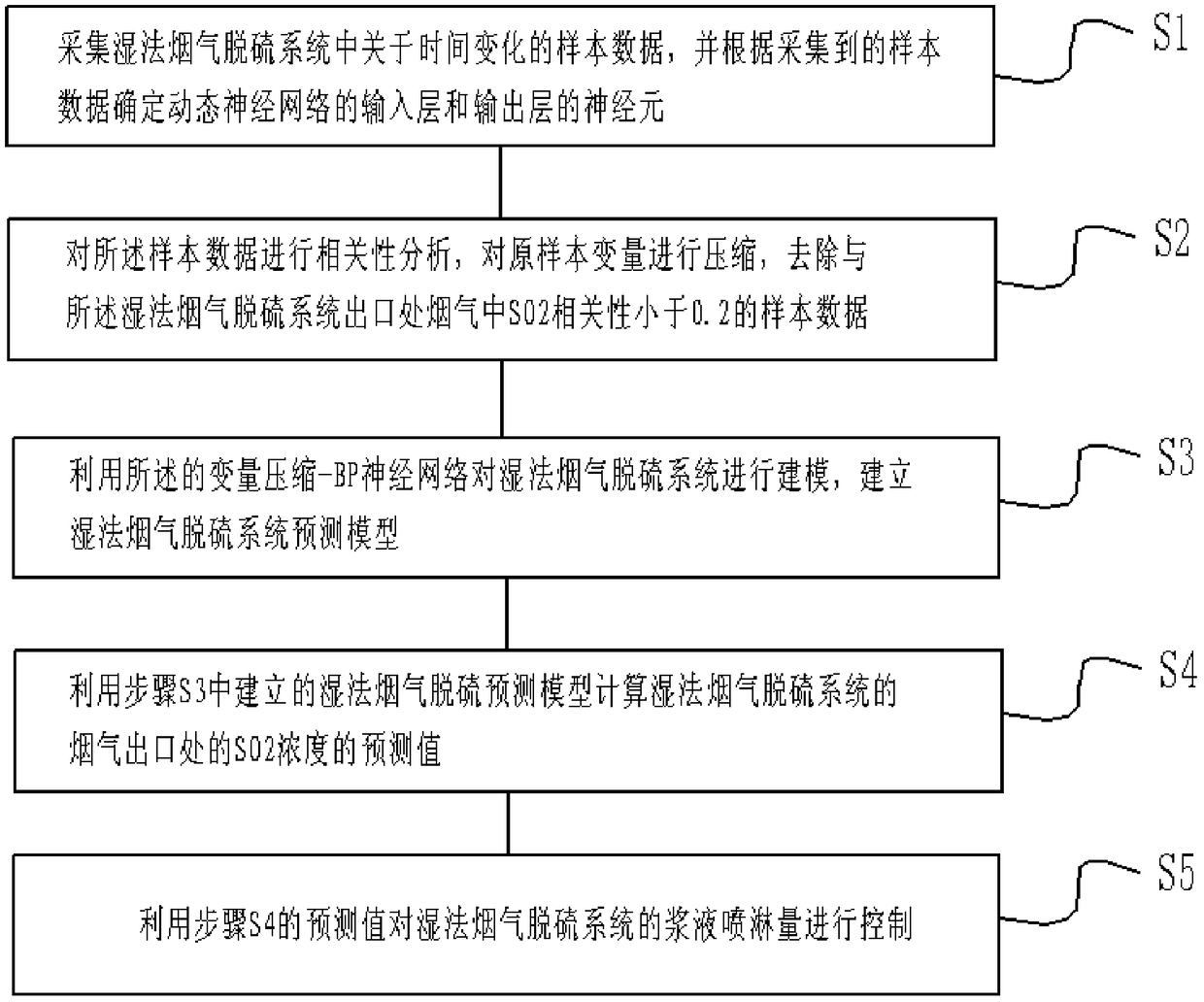

InactiveCN109508832ADenseIncrease disturbanceForecastingNeural architecturesDynamic neural networkFlue gas

The invention relates to a soft sensing method for SO2 emission of a power plant based on variable compression BP neural network, comprising the steps of S1, collecting sample data about time variation in a wet flue gas desulfurization system, and determining neurons of an input layer and an output layer of the dynamic neural network according to the collected sample data; 2, performing correlation analysis on that sample data, compressing the original sample variable to remove sample data whose correlation with SO2 in the flue gas at the outlet of the wet flue gas desulfurization system is less than 0.2; Step S3: Compressing by using the variable-BP neural network model wet flue gas desulfurization system, establish wet flue gas desulfurization system prediction model; Step S4, calculating the predicted value of SO2 concentration at the flue gas outlet of the wet flue gas desulfurization system by using the wet flue gas desulfurization prediction model established in the step S3; StepS5: controlling The slurry spraying amount of the wet flue gas desulfurization system by using the predicted value of step S4.

Owner:李东峰

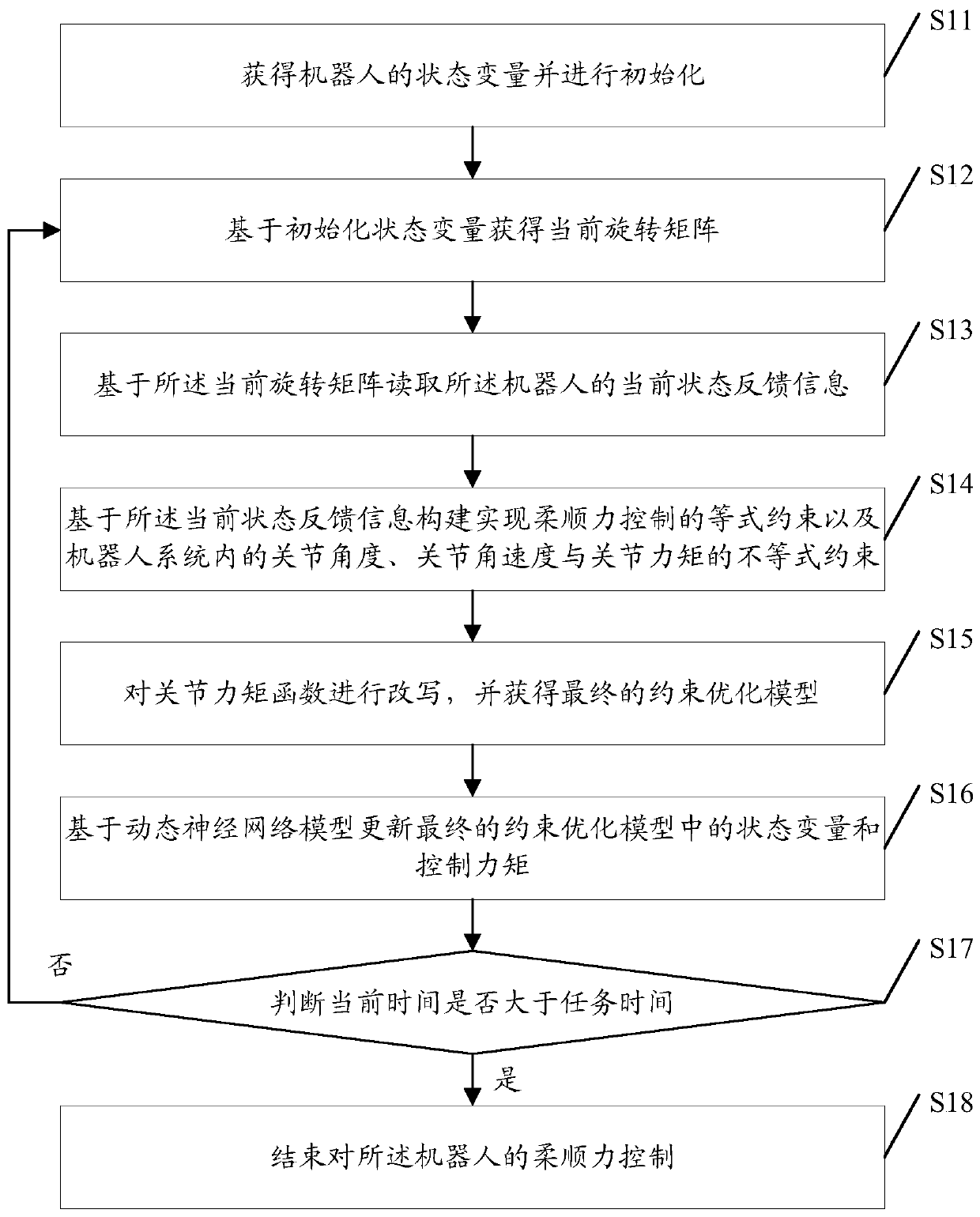

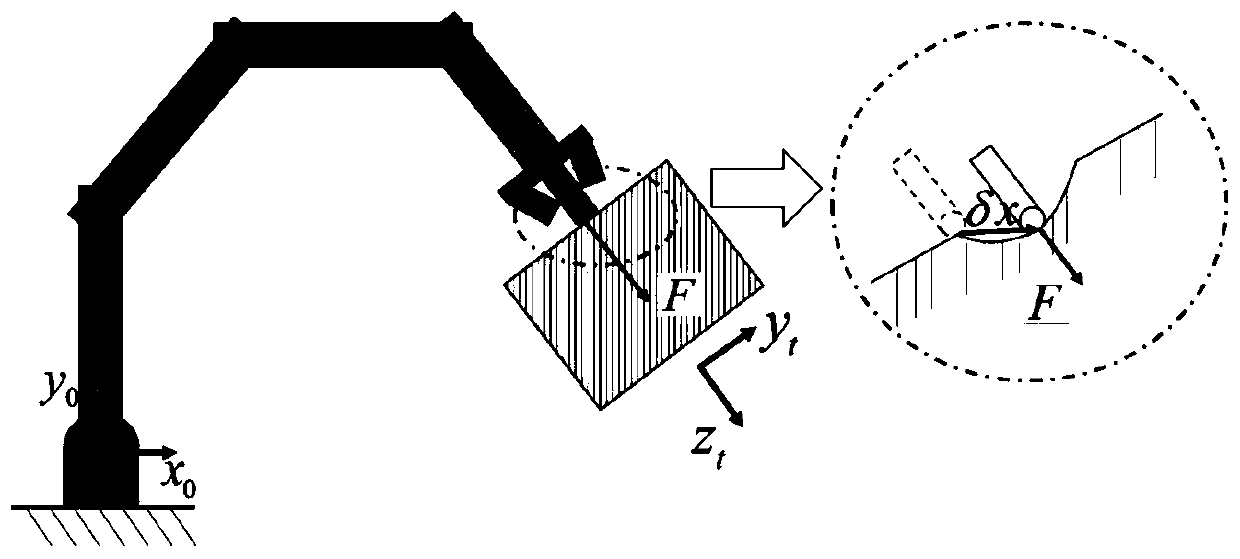

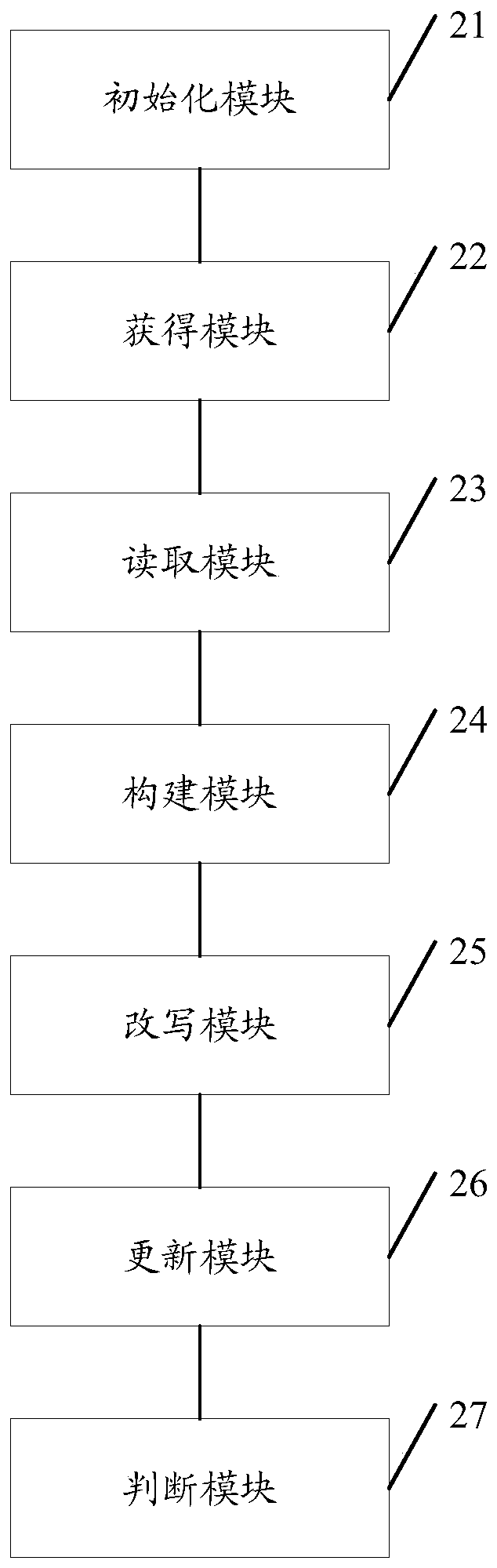

Cooperative robot compliance force control method and system

ActiveCN111037560ARealize online optimizationNot exceed physical constraintsProgramme-controlled manipulatorDynamic neural networkSimulation

The invention discloses a cooperative robot compliance force control method and system. The method comprises the steps that a state variable of a robot is obtained and initialized; a current rotationmatrix is obtained based on the initialized state variable; current state feedback information of the robot is read based on the current rotation matrix; equality constraints of compliance force control and inequality constraints of joint angle, joint angular velocity and joint moment in a robot system are established based on the current state feedback information; a joint torque function is rewritten, and a final constraint optimization model is obtained; the state variable and control torque in the final constraint optimization model are updated based on a dynamic neural network model; andwhether current time is longer than task time or not is judged, if yes, compliance force control is ended, and otherwise, the current rotation matrix is returned. In the method, high-precision force control in the contact force direction and motion control in the free movement direction can be realized at the same time.

Owner:INST OF INTELLIGENT MFG GUANGDONG ACAD OF SCI

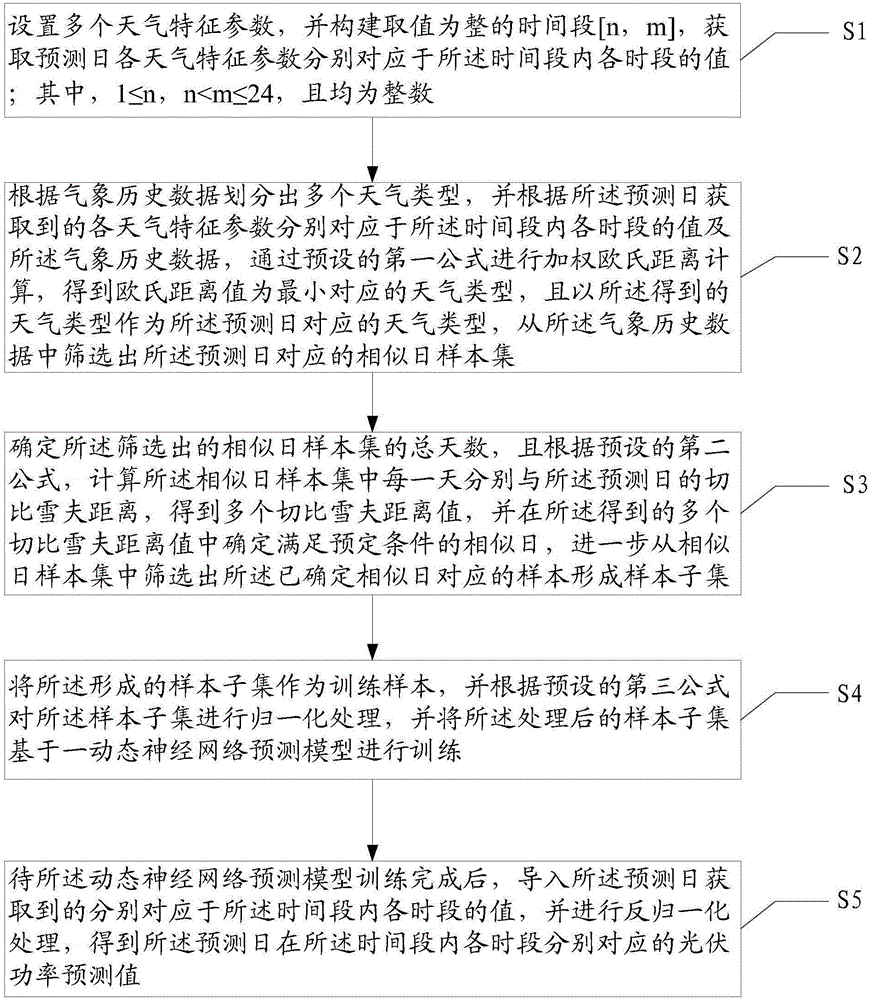

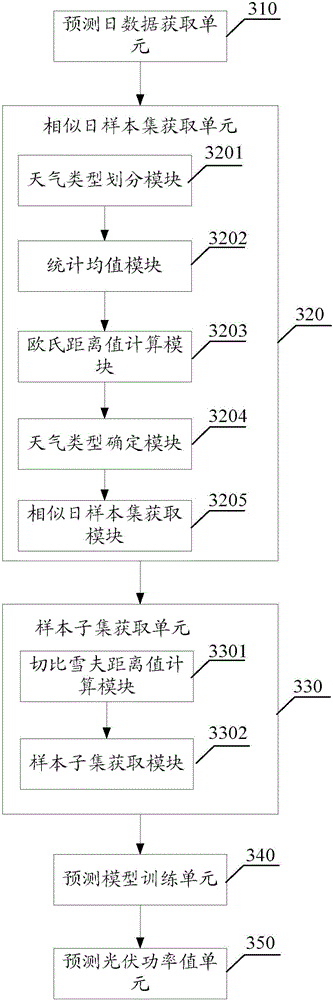

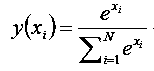

Method and system for predicting photovoltaic power based on dynamic neural network

The invention provides a method for predicting photovoltaic power based on a dynamic neural network. The method comprises the following steps of obtaining values which are respectively corresponding to weather characteristic parameters of a predicting daily in each time bucket in a set time bucket; dividing a weather type, identifying the weather type of the predicting daily based on the values obtained by the predicting daily through weighted Euclidean distance calculation, and constructing a similar day sample set of the predicting daily in history weather data according to the identified weather type; counting a number of days of the similar day sample set and solving a Chebyshev distance value thereof with the predicting daily for every day, and constructing a sample subset meeting a predetermined condition; carrying out normalization processing on the sample subset and training in a dynamic neural network prediction model; and after completing training, importing the values obtained by the predicting daily and carrying out renormalization processing to obtain photovoltaic power predicted values which are respectively corresponding the predicting daily in each time bucket of the set time bucket. By applying the embodiments of the invention, the predicting accuracy and the predicting speed can be simultaneously improved.

Owner:SHENZHEN POWER SUPPLY BUREAU +1

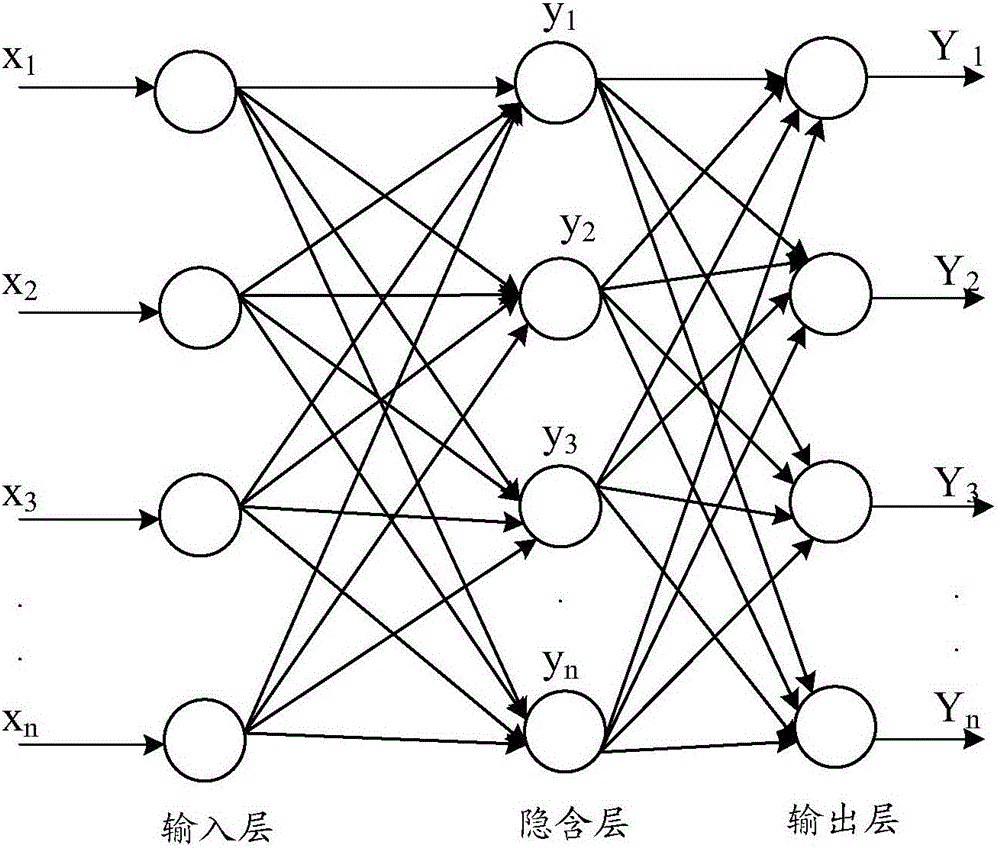

Dynamic neural network model training method and device

InactiveCN107169566AReduce design difficultyReduce training difficultyNeural learning methodsDynamic neural networkAlgorithm

The invention discloses a training method and device for a dynamic neural network model. The training method includes: inputting original one-dimensional data into the neurons of the first layer, and the corresponding output value is the feature of the layer, and then increasing the number of neuron layers, adding The features output by the upper layer are used as the input of the next layer of neurons to obtain the features of the corresponding layer, and this step is repeated until the number of layers reaches the preset value; a fully connected layer is established between the final output feature and the classified category, and reversed through BP The propagation algorithm determines the connection coefficients between the fully connected layers; among them, the neurons are modeled as dynamic neurons; the performance of the model is evaluated, and if the performance meets expectations, the training ends; otherwise, continue to add new neuron layers to the generated network model until the model performance meets expectations. The method of the invention can extract data features more efficiently, thereby improving training efficiency.

Owner:SHANDONG NORMAL UNIV

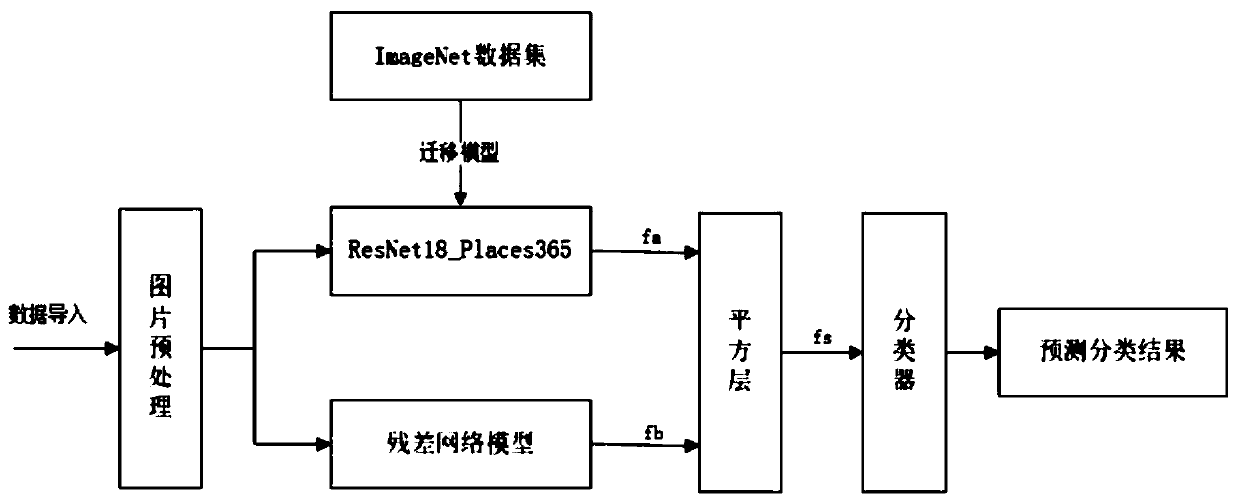

Scene classification method based on residual network training of transfer learning

InactiveCN109784237ASolve the problem of not being able to trainImprove accuracyCharacter and pattern recognitionNeural architecturesDynamic neural networkData set

The invention discloses a scene classification method based on residual network training of transfer learning. The method comprises: S1, collecting a data set; S2, importing the marked training data set; S3, taking the vector of the imported picture after preprocessing as the input of a ResNet 18 _ Place365 model; S4, loading a deep residual network model; S5, setting a square layer; S6, generating final prediction of square layer output through the fully connected softmax classifier, and outputting the category of the predicted picture; and S7, evaluating the scene classification method by taking the prediction accuracy of the algorithm on the test set picture as a final evaluation criterion. The beneficial effects of the invention are as follows: the invention provides a scene classification method based on residual network training of transfer learning. According to the method, the problem that training cannot be carried out when a neural network algorithm is deep in hierarchy is solved essentially, and the scene classification accuracy is improved limited by establishing a dynamic neural network algorithm and replacing a numpy module with PyTorch in a framework.

Owner:北京航天云路有限公司

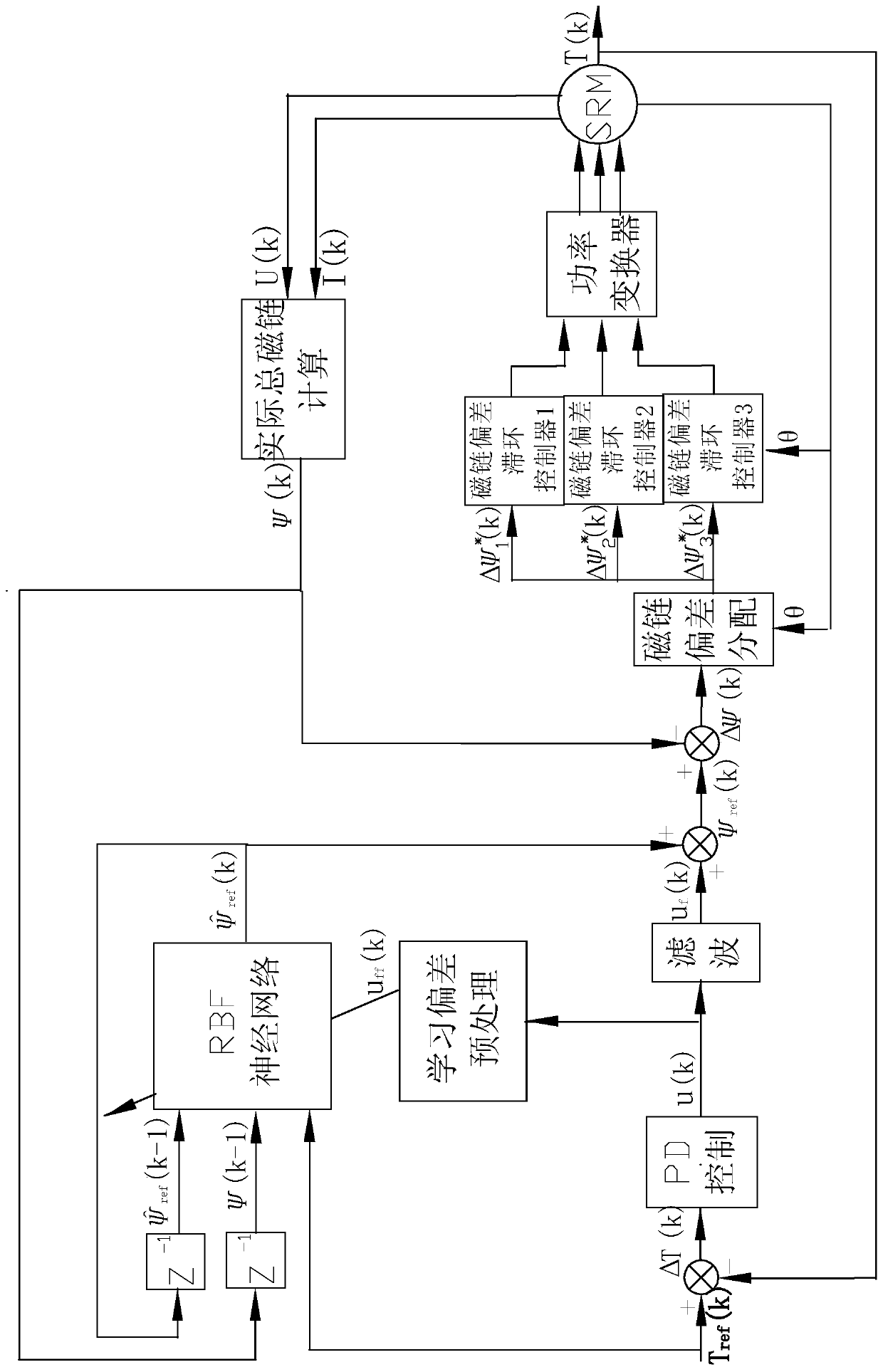

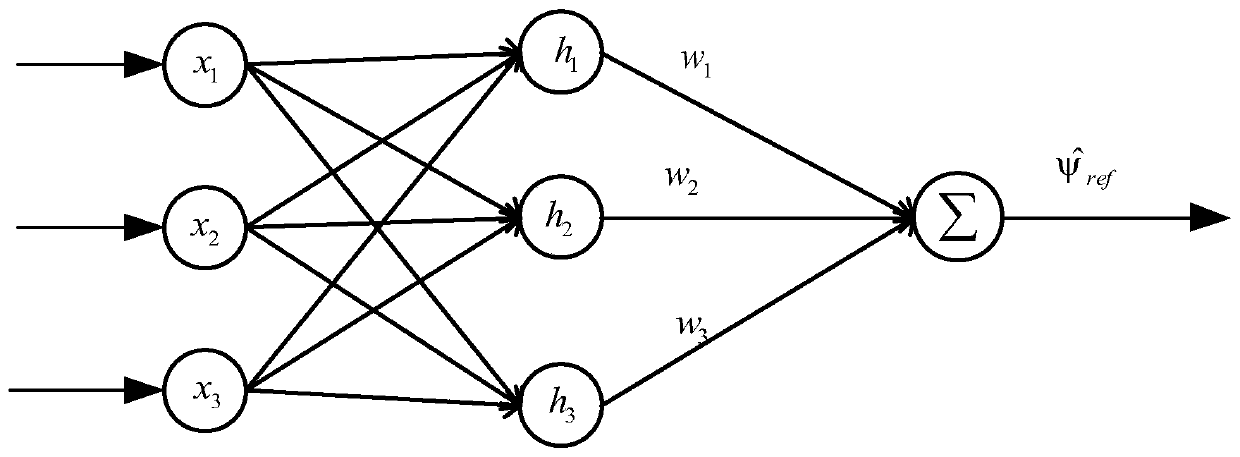

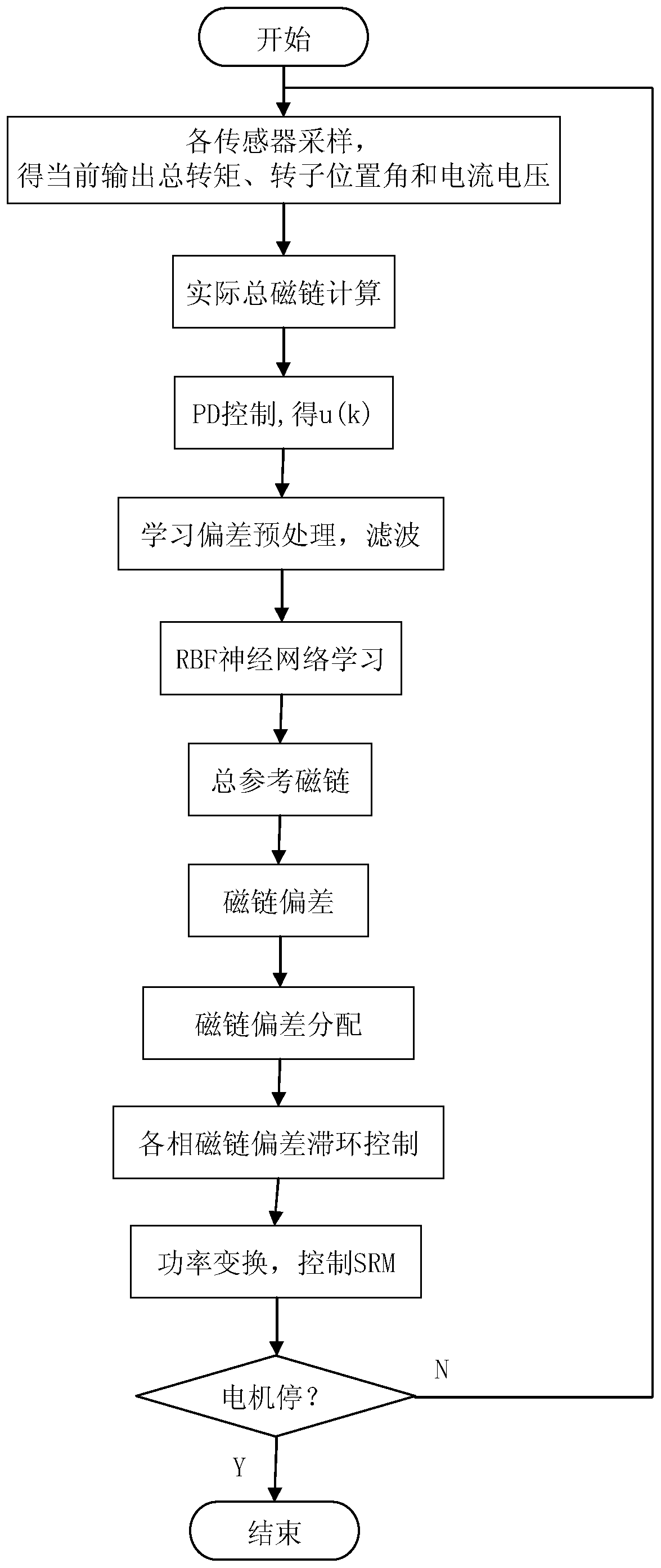

Dynamic neural network adaptive inverse SRM torque control method and system

ActiveCN109742999AImprove modeling accuracyInhibition effectField acceleration method controlDirect torque controlDynamic neural networkNeural network modeling

The invention provides a dynamic neural network adaptive inverse SRM torque control method and system. An actual total flux linkage at a previous moment of a system, a current reference torque and a previous-moment reference flux linkage output by an RBF neural network serve as input signals of the RBF neural network, the reference flux linkage is output, and a dynamic RBF neural network, namely,a torque-flux linkage model is formed; and a torque deviation is subjected to PD control to obtain a control quantity, the control quantity is pre-processed to serve as a learning deviation of RBF neural network adaptive inverse control, and the control quantity is subjected to filtering processing to serve as part of a total reference flux linkage, thereby compensating an output of the flux linkage model. The total reference flux linkage and the actual total flux linkage are subjected to subtraction to obtain a flux linkage deviation, and through flux linkage deviation distribution, the fluxlinkage deviation hysteresis control of each phase is accessed, so that the torque pulsation of an SRM is effectively inhibited. The rapid control requirement of the motor is met; a feedback error learning method accelerates the neural network modeling and improves the modeling precision; and the influence of the torque pulsation is reduced.

Owner:GUILIN UNIV OF ELECTRONIC TECH

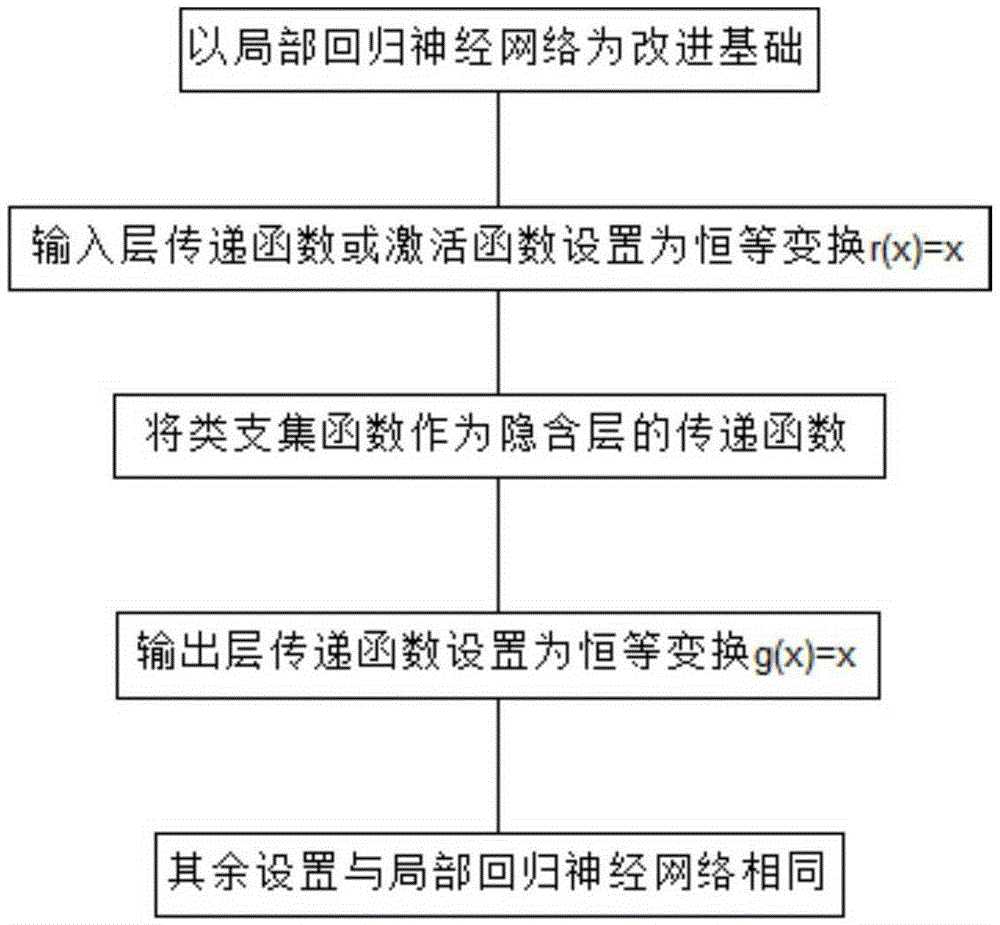

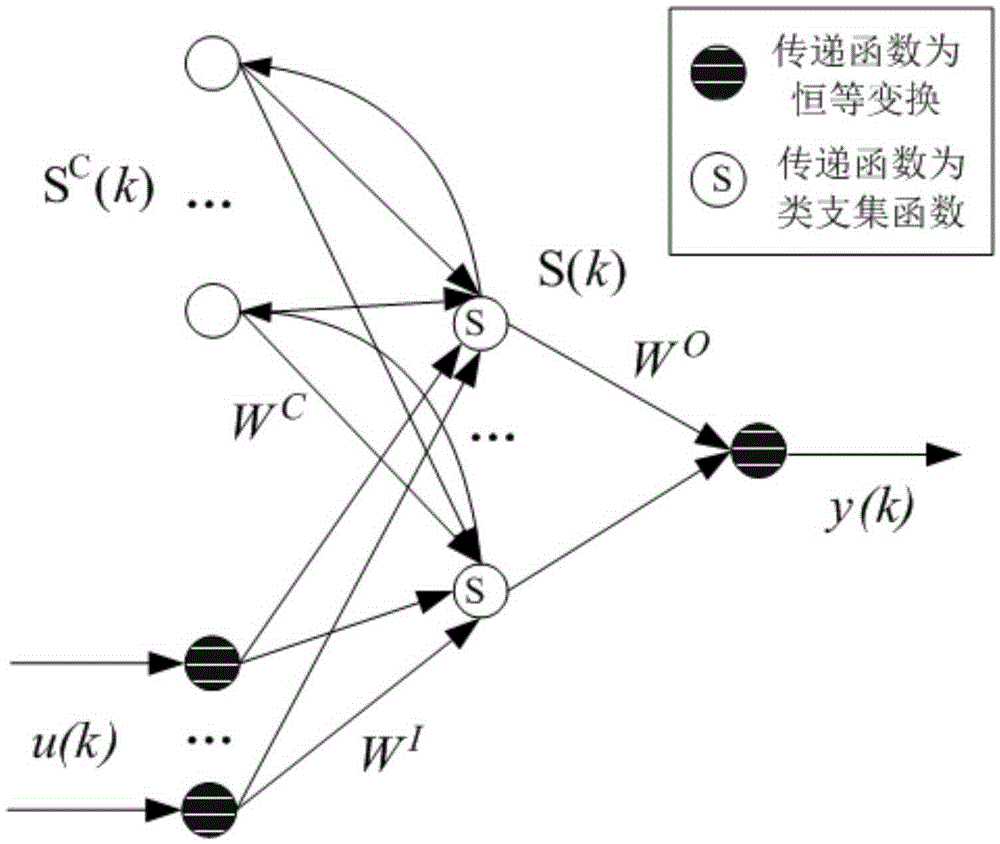

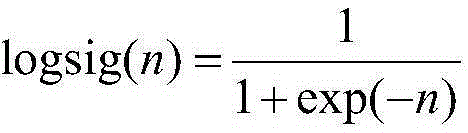

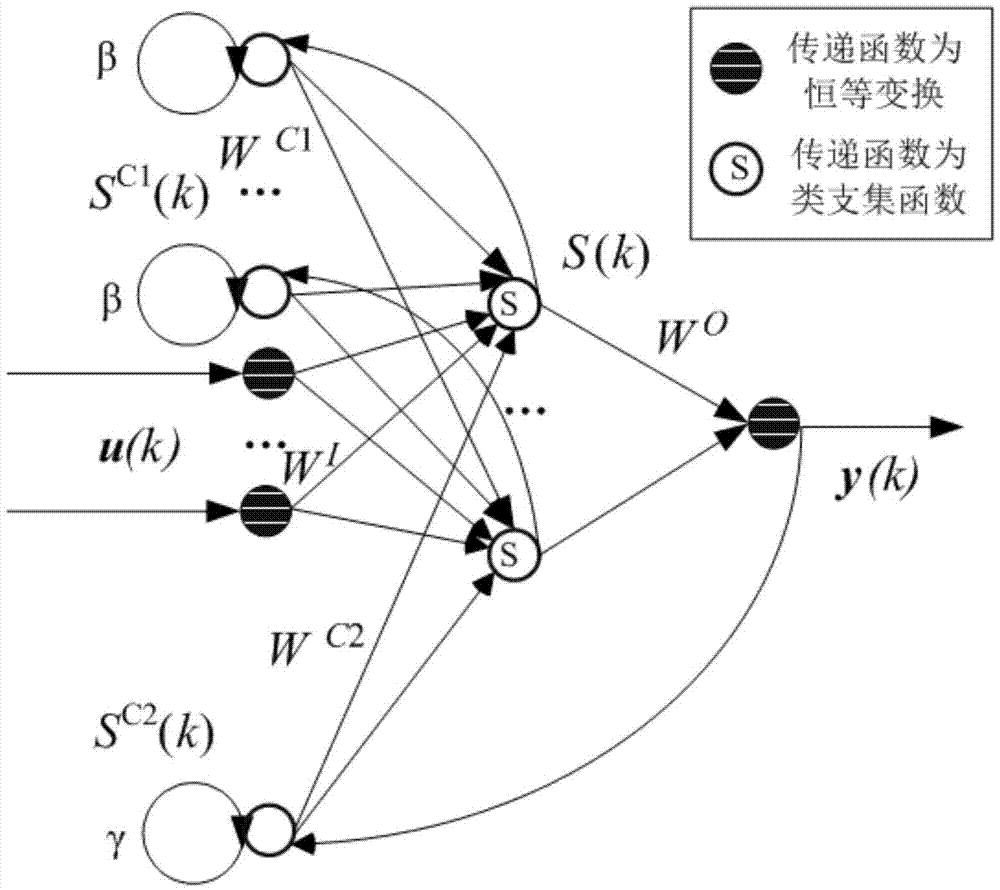

Method for constructing and training dynamic neural network of incomplete recursive support

InactiveCN105426962AIncrease reflectionStrong function approximation abilityNeural learning methodsActivation functionNerve network

The invention discloses a method for constructing and training a dynamic neural network of an incomplete recursive support. With a local recurrent neural network as the function, the construction method is used for setting a transfer function and an activation function of an input layer and an output layer of the local recurrent neural network, a similar support function is defined to serve as the transfer function of a network hidden layer, and a training method of the improved network is provided. The dynamic neural network with partial feedback is provided by the invention, due to the structural change, the dynamic neural network can better reflect dynamic system properties, and the function approximation ability is strong; and the method can be used for accurately determining the neural network structure according to training sample data, quickly completing the training and satisfying the required error precision.

Owner:CHANGAN UNIV

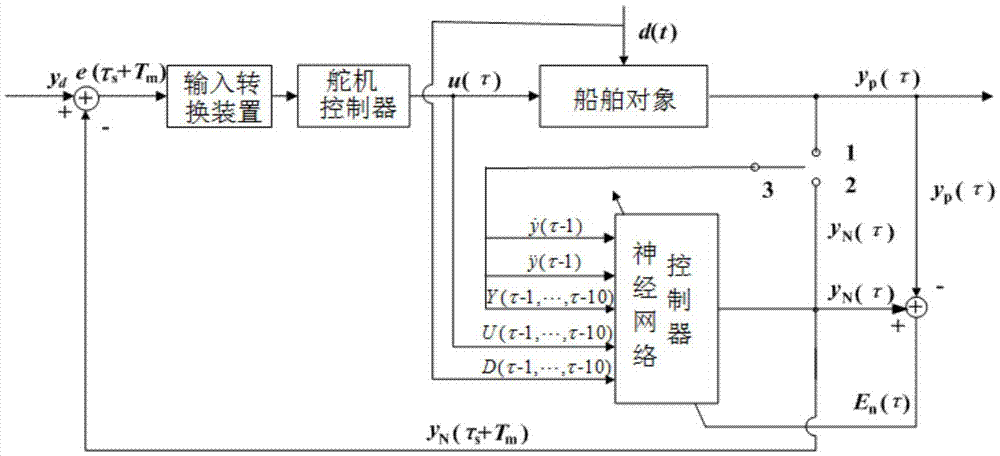

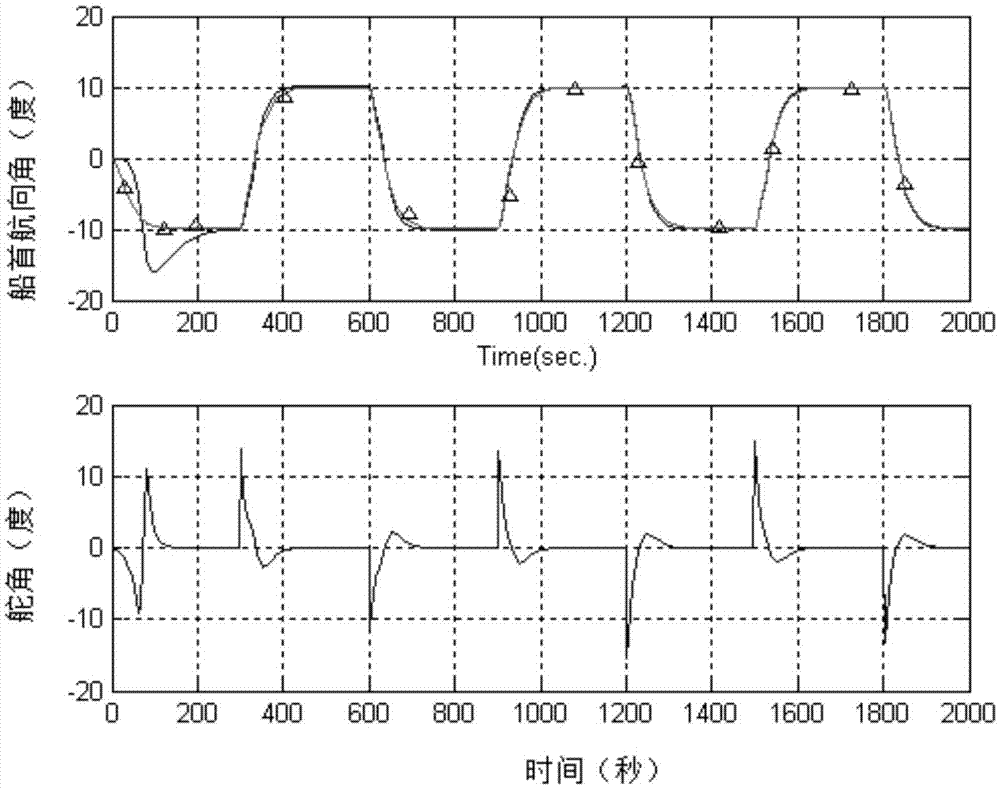

Ship course intelligence controller based on incomplete recursive branch-set dynamic neural network

InactiveCN105446136AThe course switching control process is fastThe course switching control process is smoothAdaptive controlNeural network controllerDynamic neural network

The invention discloses a ship course intelligence controller based on an incomplete recursive branch-set dynamic neural network. The controller comprises an input conversion device, a steering engine controller and a neural network controller which are successively connected. The incomplete recursive branch-set dynamic neural network is established in the neural network controller and a ship course prediction control strategy is given out. By using the controller of the invention, a problem that a traditional steering engine controller can not control a large lagged ship accurately is solved; and a ship course switching control process is rapid and smooth and a steering amount is small so that high-precision ship course control is realized.

Owner:CHANGAN UNIV

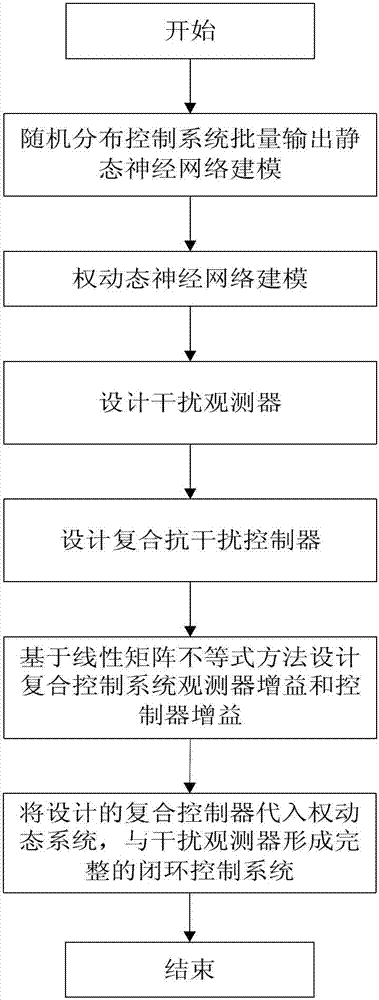

Dyanmic-static mixed nerve network modeling-based anti-interference control method for random system

ActiveCN102866629AHigh precisionRequirements to ensure modeling accuracyAdaptive controlDynamic neural networkNerve network

The invention discloses a dyanmic-static mixed nerve network modeling-based anti-interference control method for a random system, and relates to random distributed control system batch output static nerve network modeling, dynamic nerve network modeling of output weight and composite anti-interface control based on an observer. The method comprises the following steps of: firstly, building a static nerve network approaching model for batch output of a random distributed control system; forming a weight dynamic system to dynamic nerve network approach of s static nerve network model; then, designing the observer aiming at bounded interface in the system to evaluate and perform feedforward compensation; and finally, designing gain of the observer and gain of a controller on the composite control system based on a linear matrix non-equality method, so that the system is stable and meets certain anti-interference performance.

Owner:BEIHANG UNIV

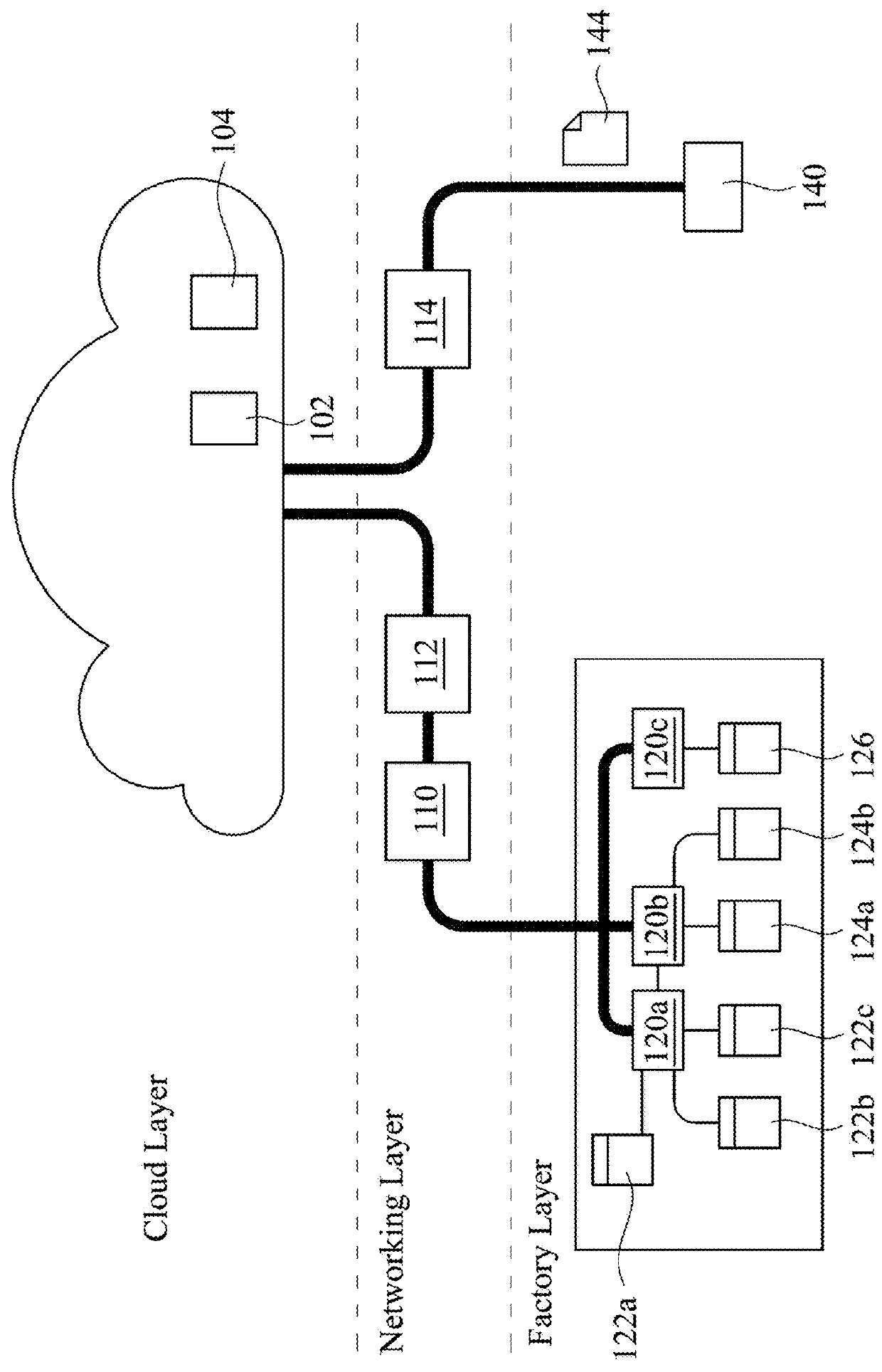

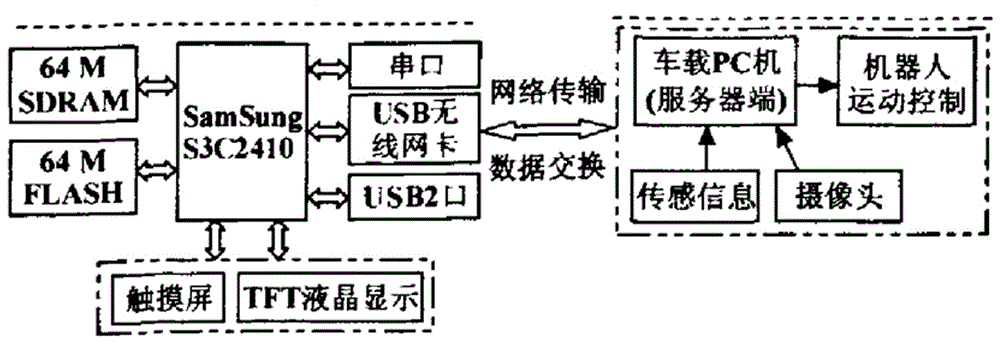

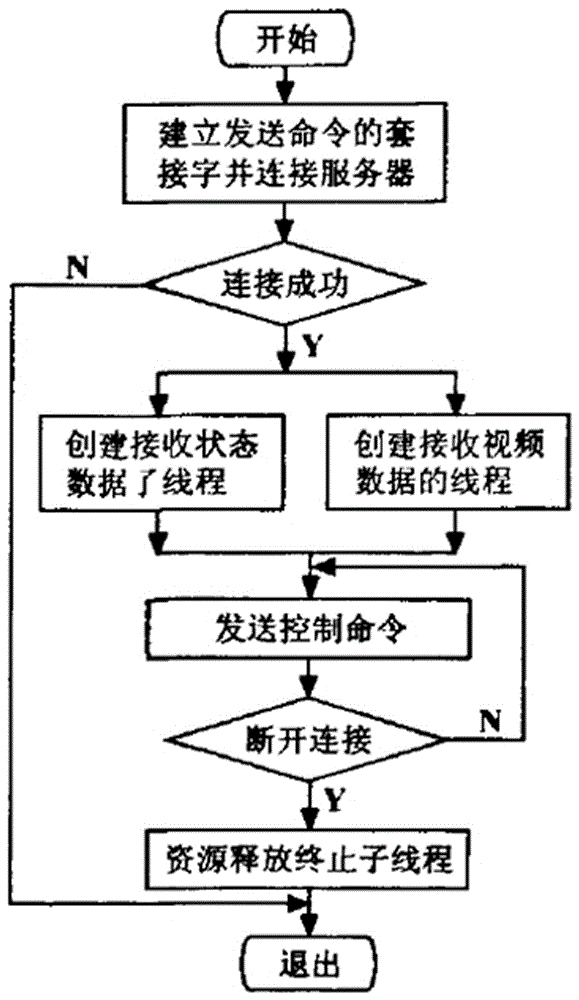

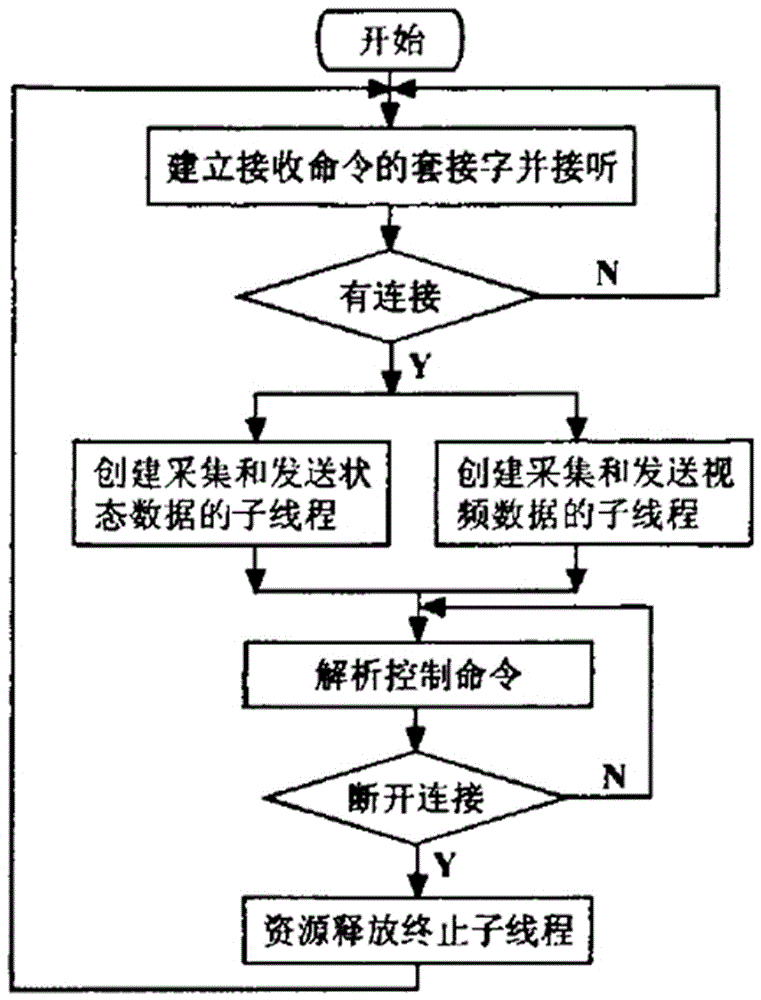

Mobile robot wireless remote control system based on embedded system

InactiveCN107526341AImprove bandwidth utilizationAvoid congestionTransmission systemsProgramme total factory controlEmbedded systemWireless network

The invention discloses a mobile robot wireless remote control system based on an embedded system, and the control system consists of three parts: an embedded remote control end (client), a wireless network transmission part, and a robot onsite control end (server). The control system employs an embedded linux system as a remote control end, and employs a wireless network as the remote communication mode. The control system employs the improved Elman dynamic neural network to predict the utilization rate of network bandwidth, adjusts the transmission rate of video data according to a prediction result, prevents the network congestion in advance, and improves the utilization rate of network bandwidth.

Owner:李征

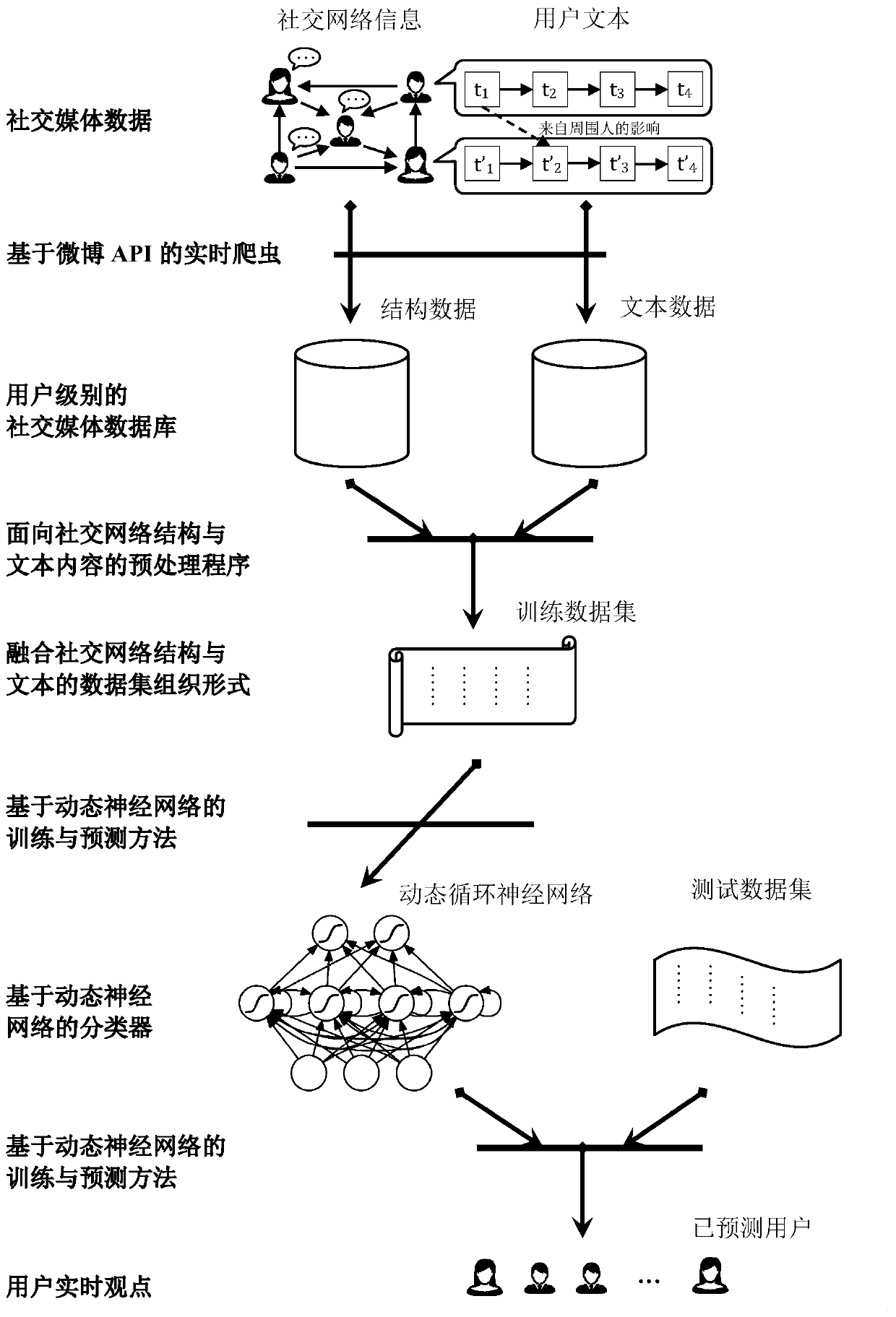

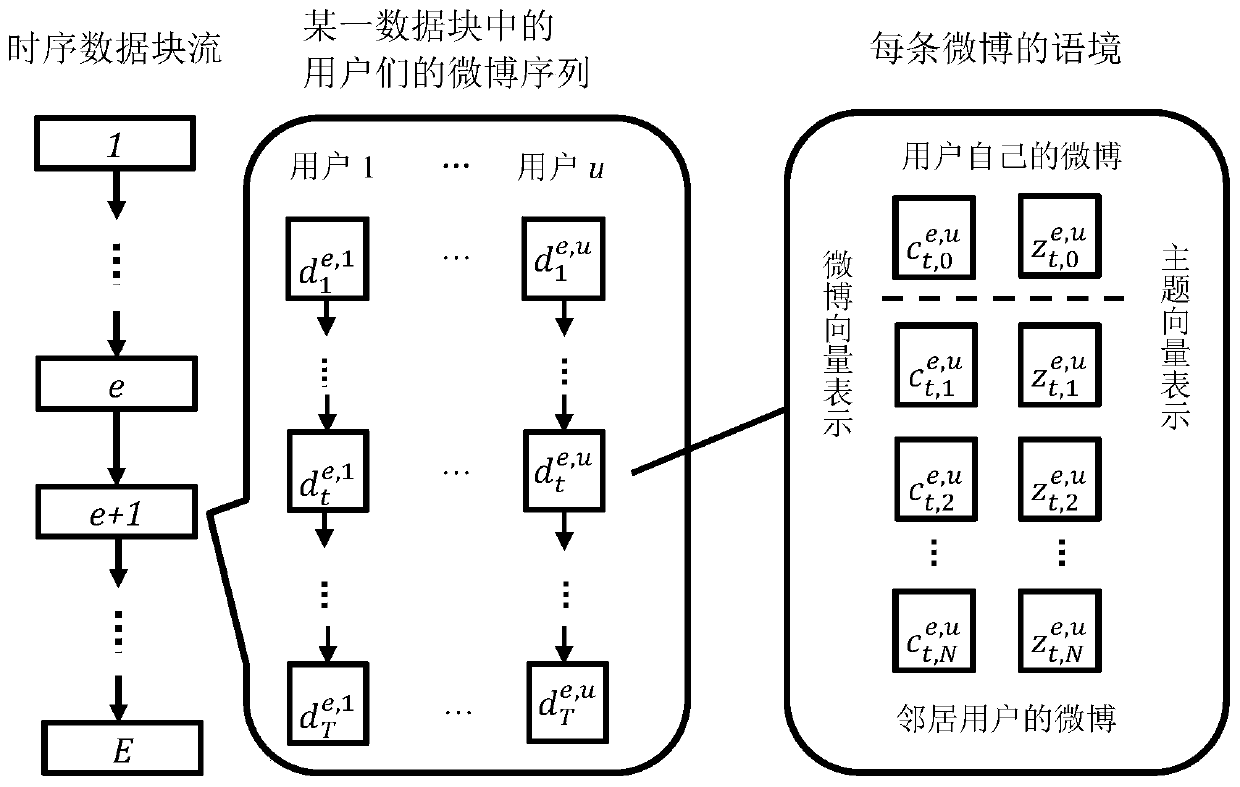

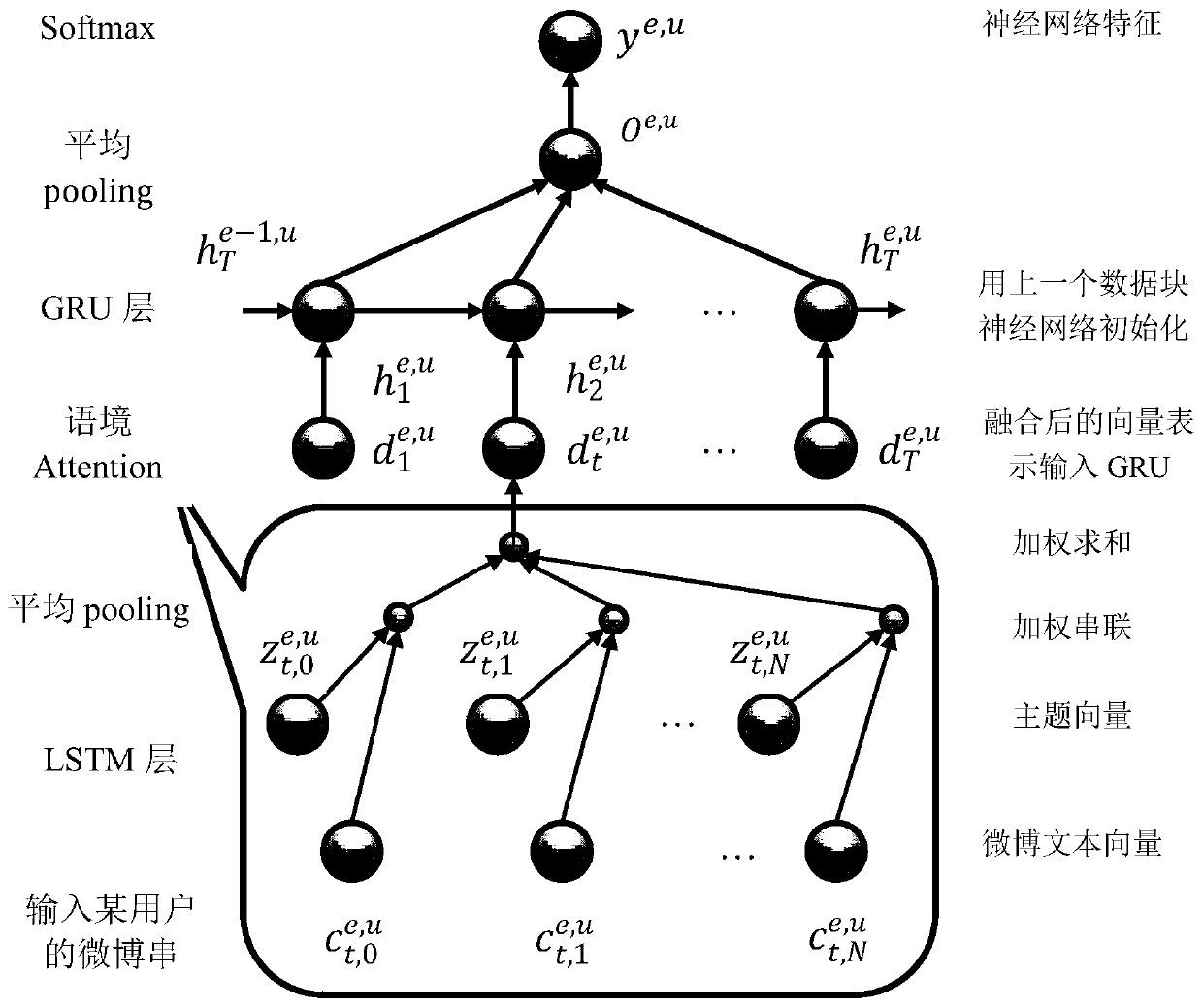

User real-time viewpoint detection method based on social media content and structure

InactiveCN110059190AImprove accuracyShort training timeData processing applicationsText database indexingViewpointsDynamic neural network

The invention discloses a user real-time viewpoint detection method based on social media content and structure. The method mainly comprises the following steps: crawling microblogs related to an event and social network information of a microblog author in real time based on a microblog API and a Hash label; based on the microblog text and the social network information of the user, generating training data by using a Hash label and a remote supervision technology; and based on the dynamic neural network model training, completing the dynamic viewpoint detection of the user level. According to the method, a lot of tagged corpora are not needed, the standpoint of a user about a certain topic in the next time period can be predicted, and higher accuracy is achieved due to simulation of theuser behavior by the recurrent neural network; the user viewpoints can be predicted by utilizing the social network information under the condition that the user corpora is lost; new microblog data can be obtained, iteration can be dynamically carried out on the trained dynamic neural network, and the problem that time is wasted when training is carried out from the beginning is solved.

Owner:SOUTHEAST UNIV

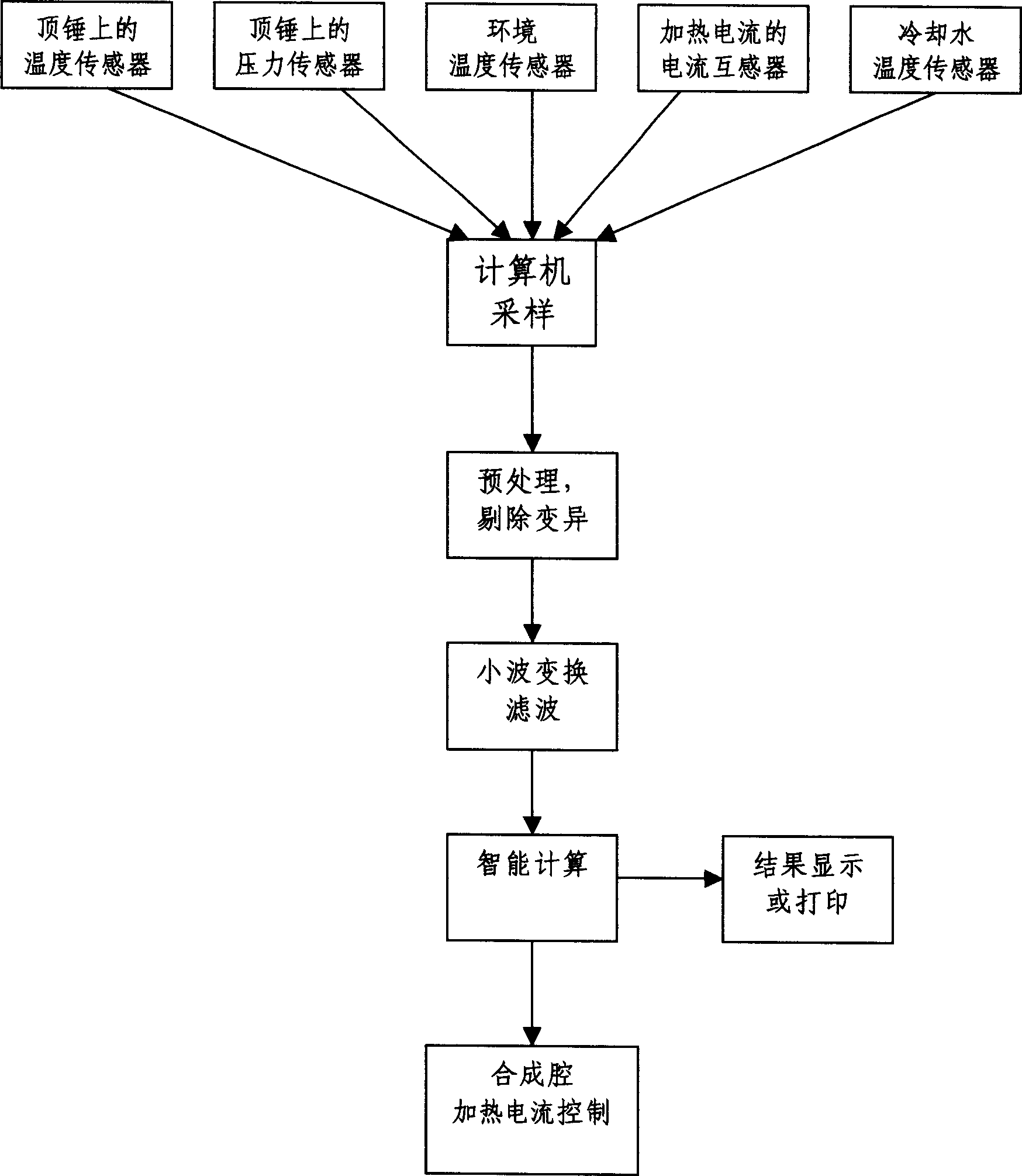

Method for measuring temp. in high-temp. high-pressure closed cavity

InactiveCN1598507AQuality improvementStrong scalabilityThermometers using electric/magnetic elementsUsing electrical meansNerve networkElement analysis

The invention is temperature measuring method in high pressure and high temperature sealed cavity, it assembles a temperature T1-Tn, pressure sensor on the external surface of the cavity and acquires the P, the near place is assembled with environmental temperature sensor and acquires the Th1-Thn and a cavity heating current sensor and acquires I. the computer carries on preprocess to the measured values, and eliminates the deformed signal. The processed signal value is carried on with wavelet transition, and sends then into primary element to be analyzed. The acquired data is transmitted to the dynamic nerve network to carry on self adaptable intelligent calculation, the temperature in the cavity is T=F (T1... Tn, Th1..., Thn, I, P). The invention uses multi-point measurement to measure multi variables, uses primary element analysis, nerve network and other technologies to realizes the dynamic measurement in the high temperature and high pressure cavity; the result will not be affected by the resistance in the cavity; then carries on wavelet transition filter, and online self adaptable correcting function, it guarantees the accuracy of the measurement; the result can be displayed or outputted. It can be applied to the temperature measurement and real-time control in the diamond synthesis cavity.

Owner:桂林电子工业学院

Method and a system for creating dynamic neural function libraries

ActiveUS20160019457A1Increased complexityReduce intensityDigital computer detailsNeural architecturesSynapseDynamic neural network

A method for creating a dynamic neural function library that relates to Artificial Intelligence systems and devices is provided. Within a dynamic neural network (artificial intelligent device), a plurality of control values are autonomously generated during a learning process and thus stored in synaptic registers of the artificial intelligent device that represent a training model of a task or a function learned by the artificial intelligent device. Control Values include, but are not limited to, values that indicate the neurotransmitter level that is present in the synapse, the neurotransmitter type, the connectome, the neuromodulator sensitivity, and other synaptic, dendric delay and axonal delay parameters. These values form collectively a training model. Training models are stored in the dynamic neural function library of the artificial intelligent device. The artificial intelligent device copies the function library to an electronic data processing device memory that is reusable to train another artificial intelligent device.

Owner:BRAINCHIP INC

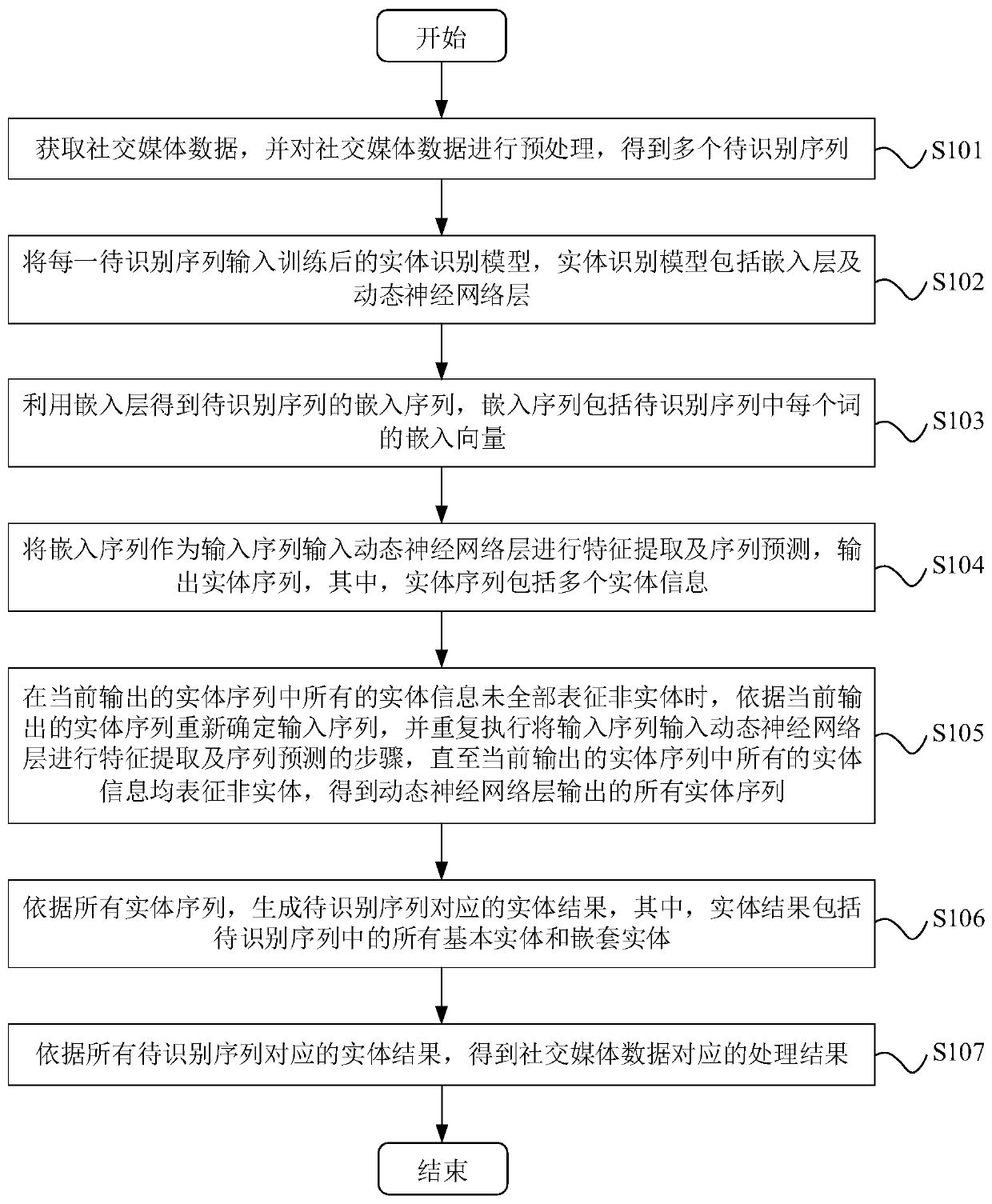

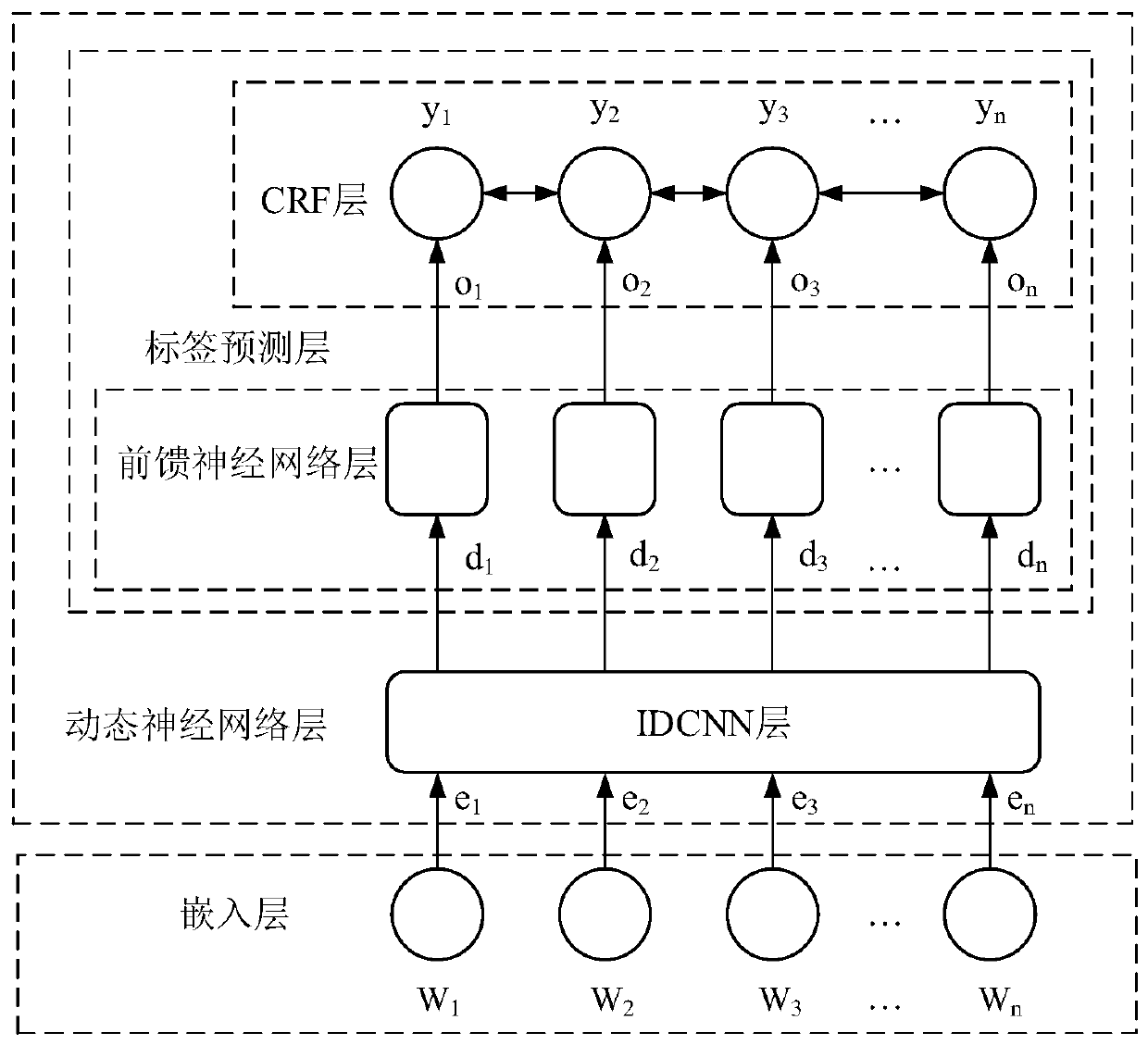

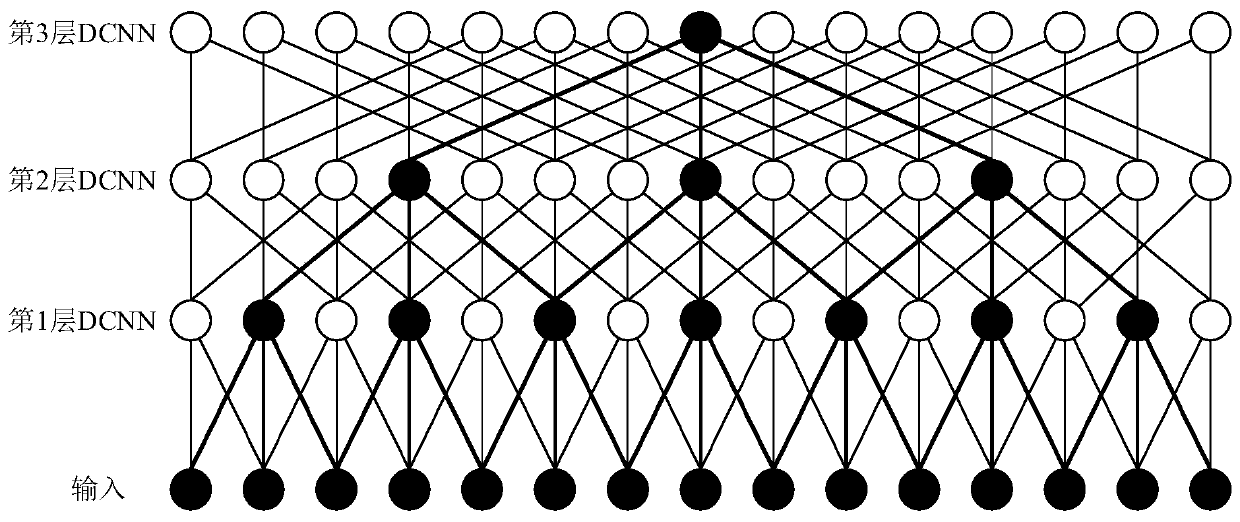

Social media data processing method, model training method and related devices

ActiveCN110472063AKnow quicklyData processing applicationsSpecial data processing applicationsSocial mediaDynamic neural network

The embodiment of the invention relates to the technical field of natural language processing, and provides a social media data processing method, a model training method and related devices. The method comprises the steps: preprocessing obtained social media data into a plurality of to-be-recognized sequences; inputting each sequence to be identified into the trained entity recognition model; themethod comprises the steps of obtaining an embedded sequence of a to-be-identified sequence by utilizing an embedded layer, then inputting the embedded sequence into a dynamic neural network layer for multiple rounds of feature extraction and sequence prediction to obtain all entity sequences output by the dynamic neural network layer, and obtaining all basic entities and nested entities in the to-be-identified sequence according to all the entity sequences; and finally, obtaining a processing result corresponding to the social media data according to the entity results corresponding to all the to-be-identified sequences. Compared with the prior art, all the basic entities and the nested entities in the social media data can be obtained, and then people are helped to quickly know the latest dynamic and hot events of the current society.

Owner:NEW H3C BIG DATA TECH CO LTD

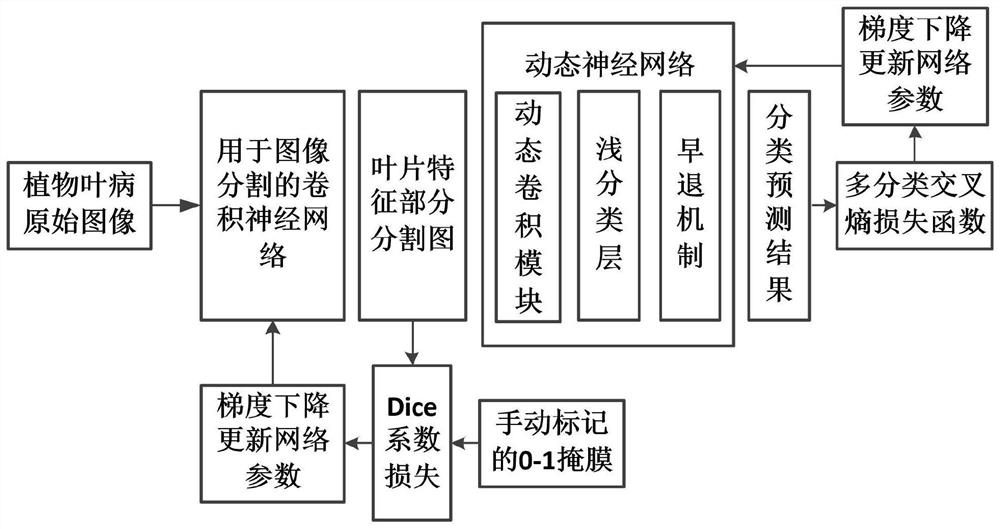

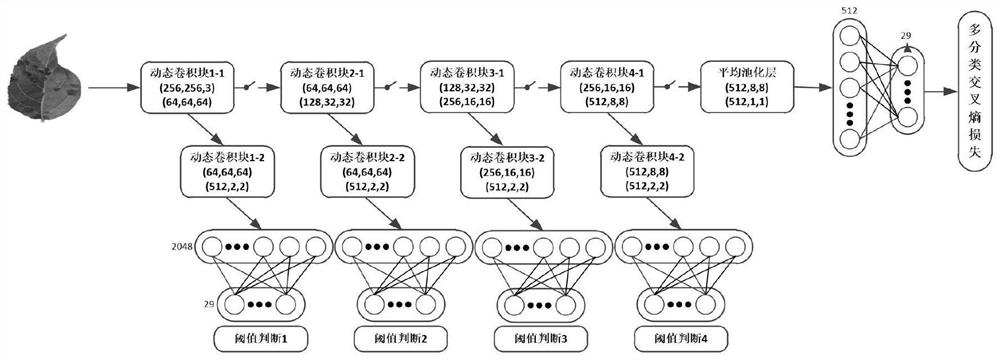

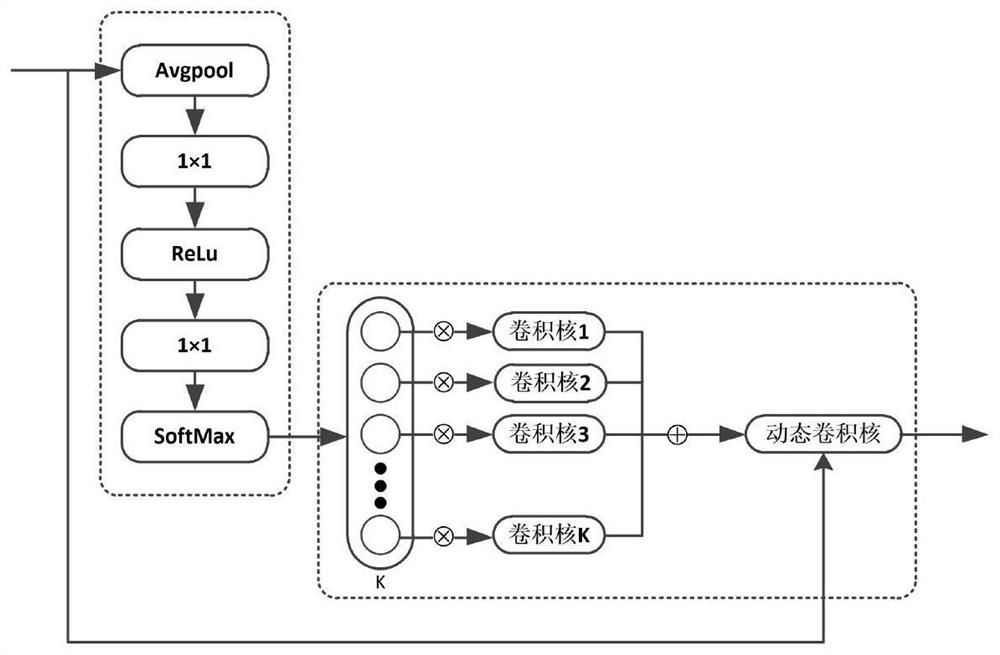

A multi-type crop leaf disease identification method based on a dynamic neural network

PendingCN114022872ARealize integrationMeet real-time requirementsCharacter and pattern recognitionNeural architecturesAutomatic segmentationDynamic neural network

The invention provides a multi-type crop leaf disease identification method based on a dynamic neural network, and the method comprises the steps of randomly selecting part of crop leaf disease image data for pixel-level marking, and training a convolutional neural network for image segmentation; then, automatically segmenting the crop leaf disease image by using the trained convolutional neural network, and extracting effective information in the image; and finally, designing a dynamic neural network which comprises three parts of a dynamic convolution module, a shallow classifier and an early-going mechanism, and realizing leaf disease identification based on a dynamic network structure. According to the scheme, the method can realize automatic segmentation and extraction of effective information of the crop leaf disease image and recognition of various types of crop leaf diseases, the adopted dynamic neural network can dynamically adjust the network structure according to the complexity of the crop leaf diseases, and the use of computing resources is reduced under the condition that the requirement for high recognition accuracy rate is met.

Owner:OCEAN UNIV OF CHINA

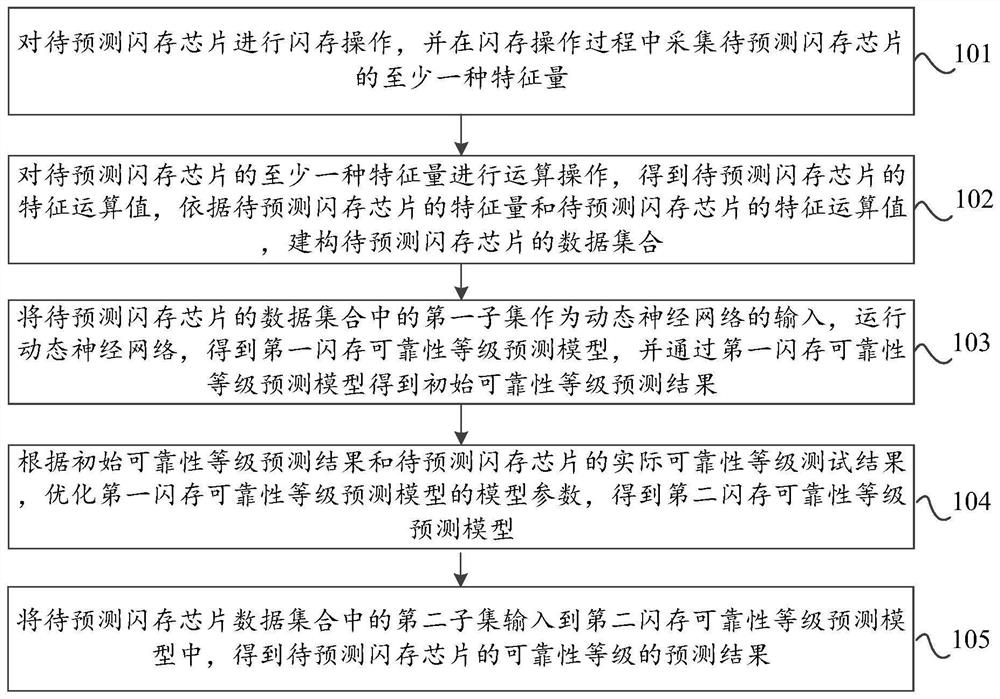

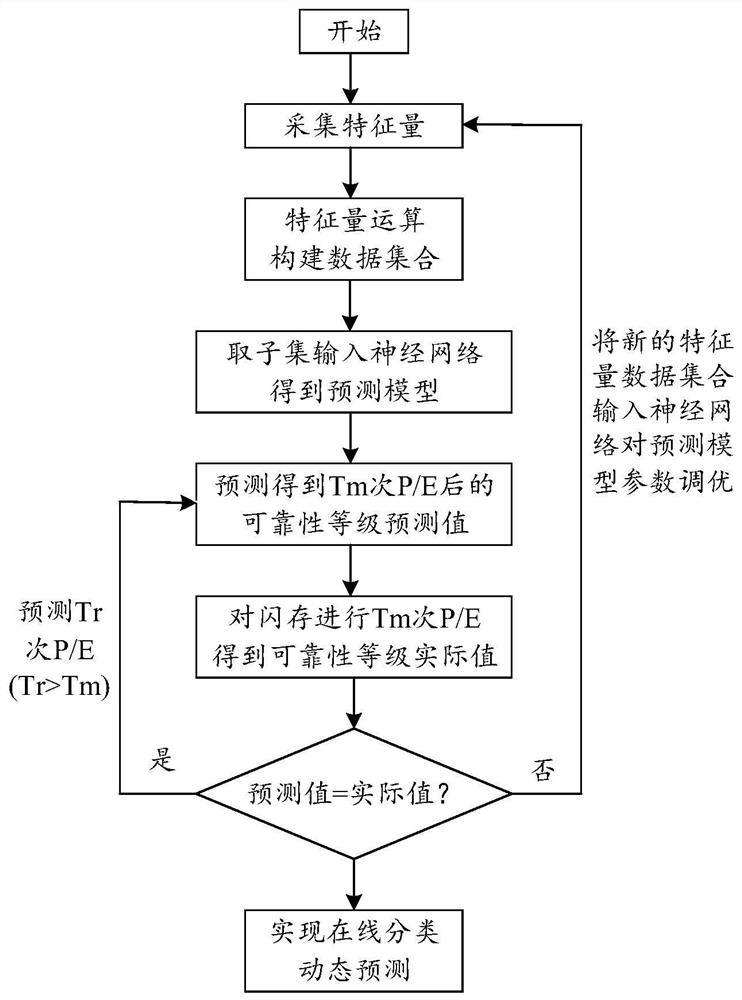

Flash memory reliability level online prediction method and device based on dynamic neural network

PendingCN112817524AImprove forecast accuracyAdjust the storage strategy in timeInput/output to record carriersStatic storageDynamic neural networkData set

The invention discloses a flash memory reliability level online prediction method and device based on a dynamic neural network, a storage medium and computer equipment. The method comprises the following steps: performing flash memory operation on a to-be-predicted flash memory chip, and collecting at least one characteristic quantity of the to-be-predicted flash memory chip in the flash memory operation process; computing at least one characteristic quantity of the to-be-predicted flash memory chip to obtain a characteristic operation value of the to-be-predicted flash memory chip, and constructing a data set of the to-be-predicted flash memory chip according to the characteristic quantity of the to-be-predicted flash memory chip and the characteristic operation value of the to-be-predicted flash memory chip; taking a first subset in the data set of the to-be-predicted flash memory chip as input of a dynamic neural network, running the dynamic neural network to obtain a first flash memory reliability level prediction model, and obtaining an initial reliability level prediction result through the first flash memory reliability level prediction model; according to the initial reliability grade prediction result and an actual reliability grade test result of the to-be-predicted flash memory chip, optimizing model parameters of the first flash memory reliability grade prediction model to obtain a second flash memory reliability grade prediction model; and inputting a second subset in the to-be-predicted flash memory chip data set into the second flash memory reliability level prediction model to obtain a prediction result of the reliability level of the to-be-predicted flash memory chip. According to the method, the prediction accuracy and flexibility of the reliability level of the flash memory chip can be improved.

Owner:FUTUREPATH TECH

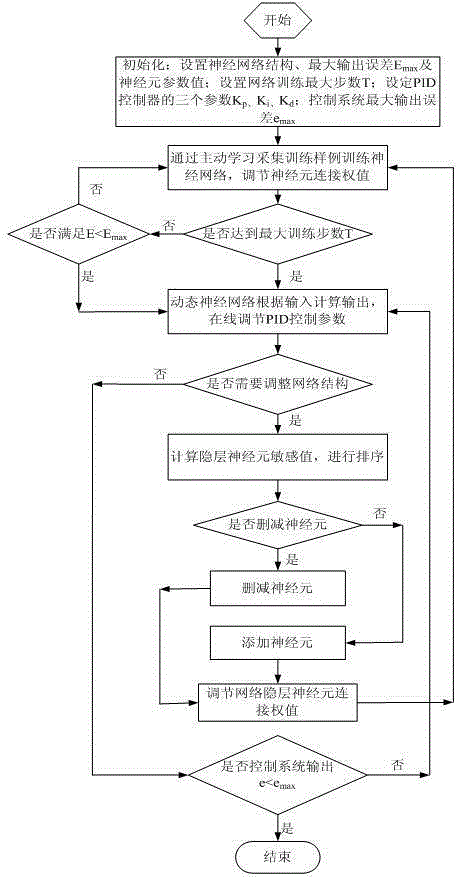

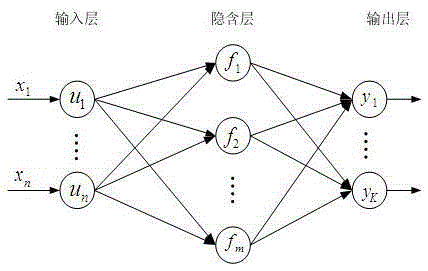

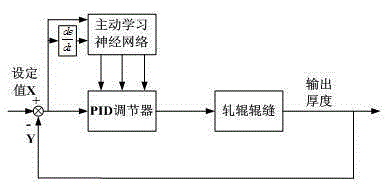

Board thickness intelligent control method based on active learning

InactiveCN105259754AImprove self-learning abilityImprove generalization abilityMaterial dimension controlAdaptive controlNerve networkDynamic neural network

The invention relates to a board thickness intelligent control method based on active learning, which belongs to the field of intelligent control technology. Self-learnable performance of a nerve network is used as a theoretical basis. A dynamic nerve network is combined with active learning; the parameter of a PID controller is adjusted in an online manner; and a development model based on active learning is constructed, thereby establishing an intelligent control system for thickness of band steel, so that the board thickness control system can perform self adjustment at proper time, and the control performance of the board thickness control system is improved through continuous training of the dynamic nerve network. The board thickness intelligent control method has functions of providing a mathematical model with high generalization capability and wide application range for online control parameter adjustment of the system; combining active learning with the dynamic nerve network, and improving self-learning capability of the network through active learning and acquiring network training samples, thereby improving adaptive capability of the system and realizing intelligent in a real meaning.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

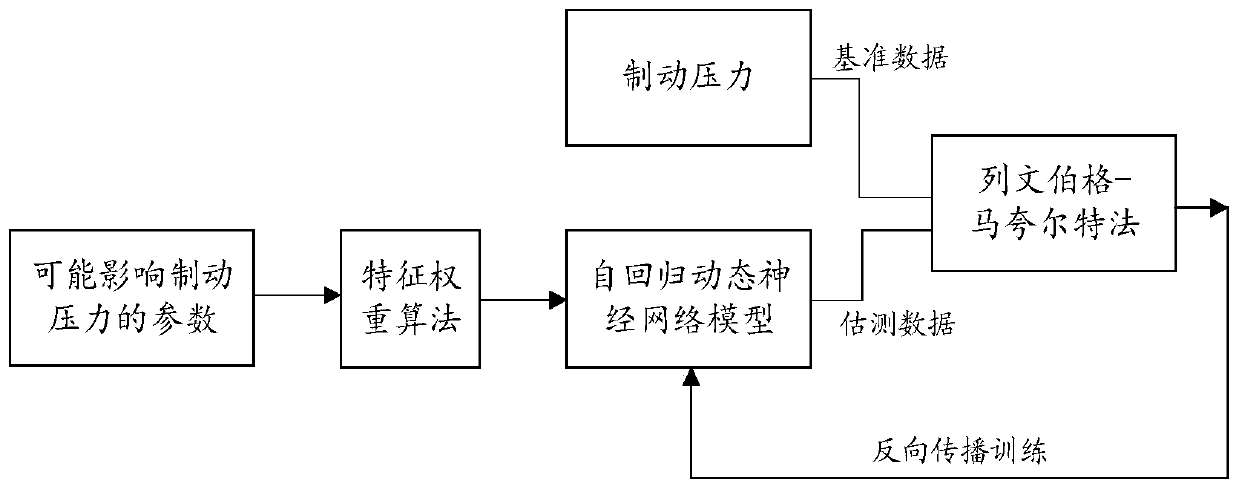

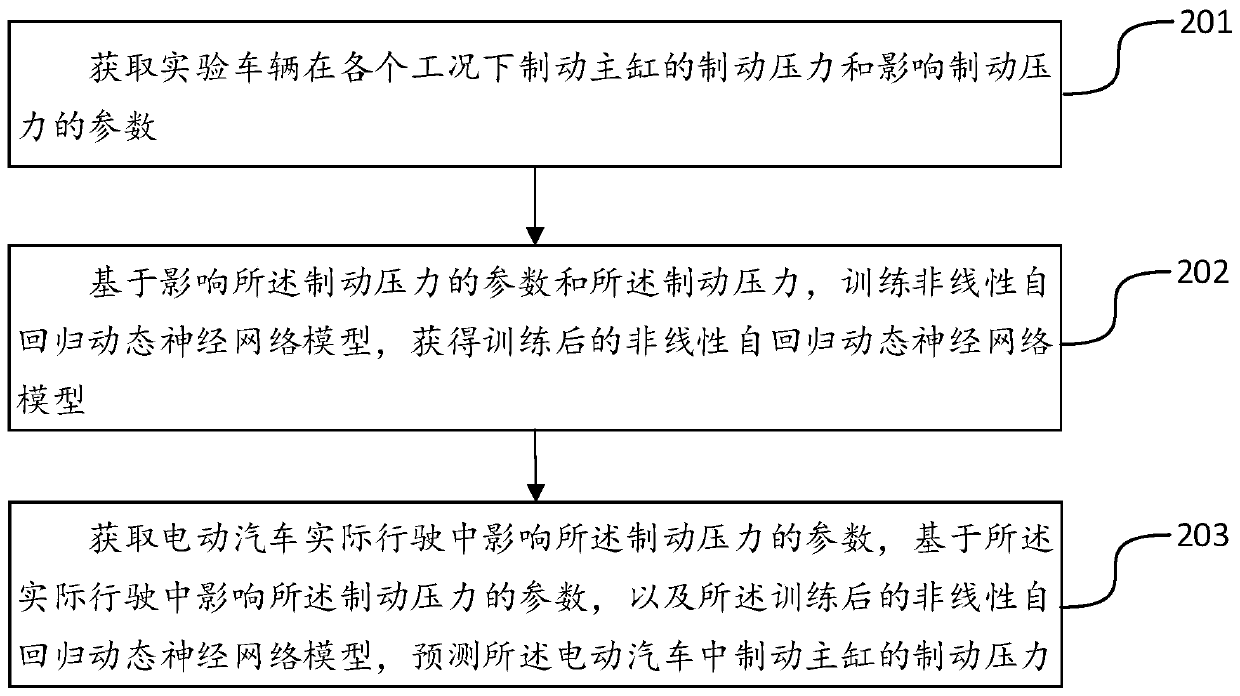

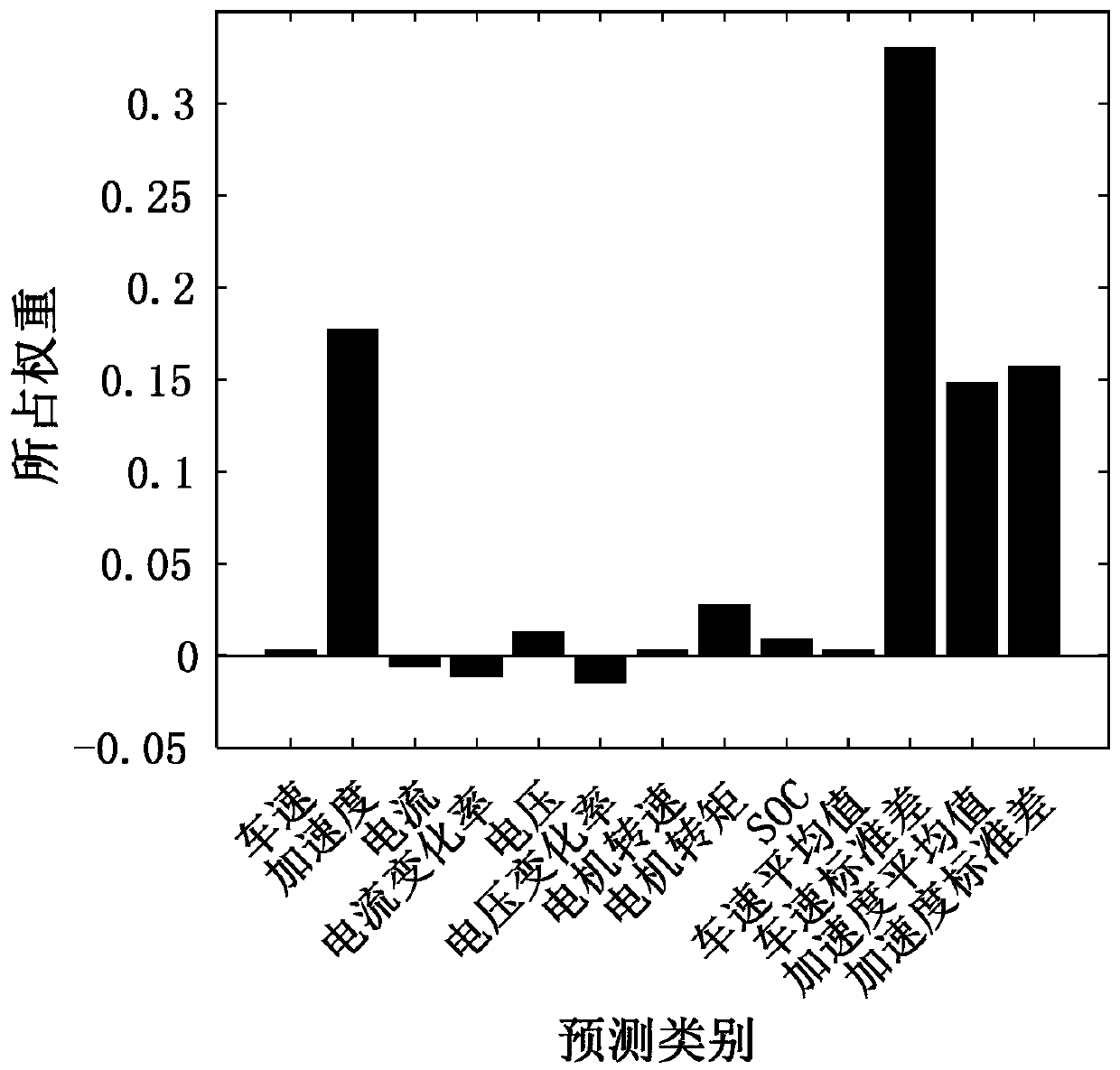

A method and apparatus for predicting brake pressure of electric vehicle

The invention discloses a method for predicting the brake pressure of an electric vehicle, and belongs to the technical field of electric vehicles. The method comprises the steps of acquiring the brake pressure of a brake master cylinder of an experimental vehicle under various working conditions and parameters influencing the brake pressure; based on the parameters influencing the brake pressureand the brake pressure, training a nonlinear autoregressive dynamic neural network model to obtain a trained nonlinear autoregressive dynamic neural network model; and acquiring parameters influencingthe brake pressure in actual driving of the electric vehicle, and predicting the brake pressure of a brake master cylinder in the electric vehicle based on the parameters influencing the brake pressure in the actual driving and the trained nonlinear autoregressive dynamic neural network model. The technical problem that a method for predicting the brake pressure of the electric vehicle is lackedin related technologies can be effectively solved.

Owner:CHERY AUTOMOBILE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com