Fuzzy control method for zinc smelting and roasting process based on trend event driving

An event-driven, fuzzy control technology, applied in adaptive control, general control systems, control/regulation systems, etc., to solve problems such as erroneous evaluation results, degradation of fuzzy controller performance, and inaccuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

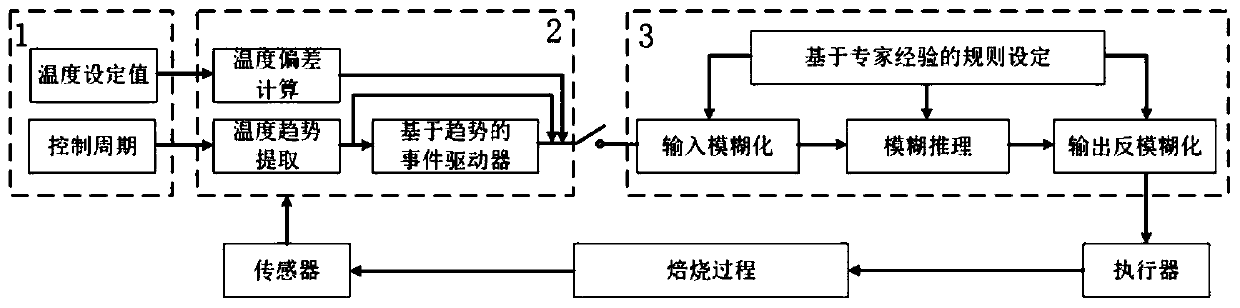

AI Technical Summary

Problems solved by technology

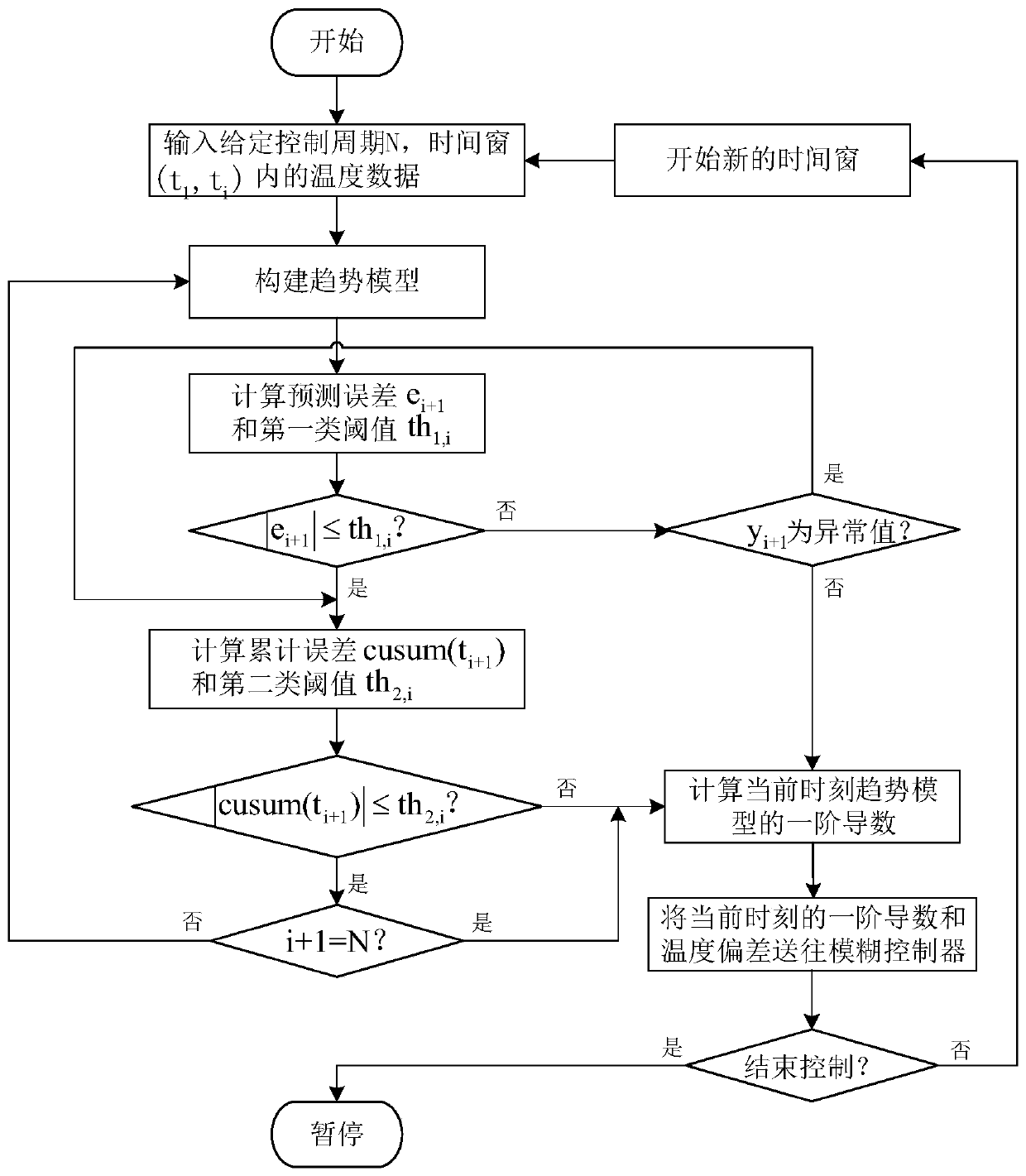

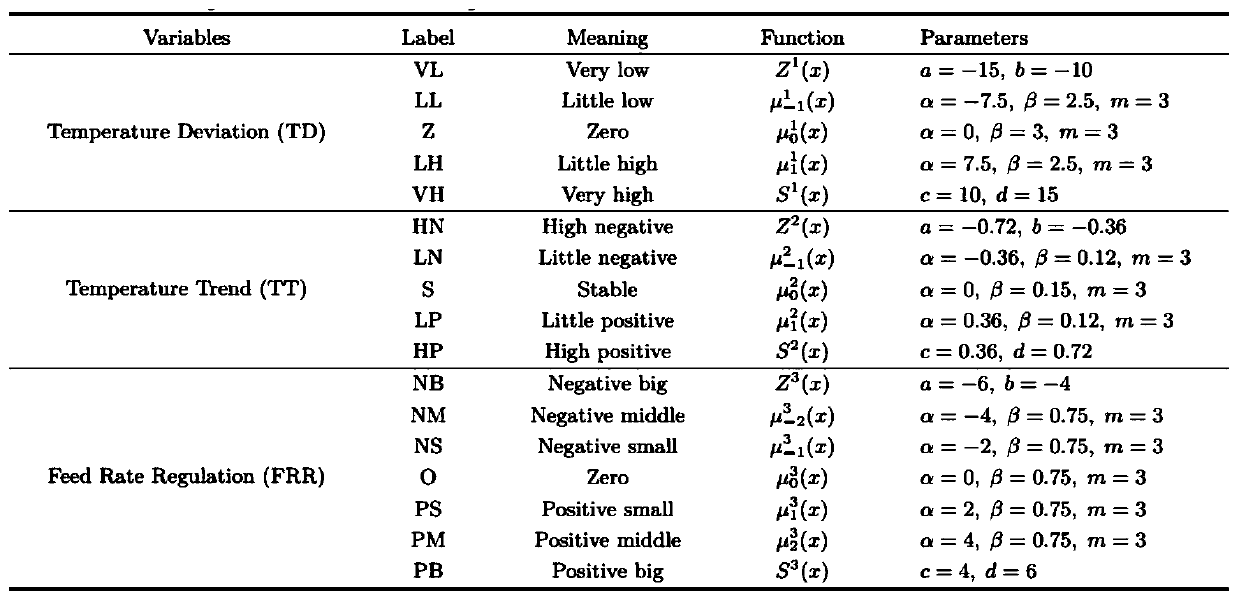

Method used

Image

Examples

Embodiment 1

[0133] In order to prove the effectiveness of this method, under the same initial conditions, the temperature setting value of the roasting process is set to 910°C, and the performance of the proposed fuzzy control method and conventional fuzzy control method is compared. The conventional fuzzy control method has the same membership function and fuzzy inference rules as the proposed method, but the difference is that the conventional method uses the rate of change of temperature deviation and has no corresponding event-driven strategy.

[0134] The control effect is compared to Figure 5 As shown, the overshoot of the fuzzy control method proposed by this method is 0.2706, and the adjustment time is 23 minutes, while the overshoot of the conventional fuzzy control method is 0.4829, and the adjustment time is 81 minutes. The fuzzy control method proposed by this method Compared with the conventional fuzzy control method, this method has a smaller overshoot and adjustment time. ...

Embodiment 2

[0136] In order to prove that the proposed method can effectively deal with the change of working conditions, when the set value is 910°C and both controllers reach a steady state, a step signal with an amplitude of 10°C is added to the system to simulate the working conditions change.

[0137] control effects such as Figure 7 As shown, the overshoot of the fuzzy control method proposed by this method is 1.0573, and the adjustment time is 57 minutes, while the overshoot of the conventional fuzzy control method is 1.0147, and the adjustment time is 207 minutes. The fuzzy control method proposed by this method Compared with the conventional fuzzy control method, it has a shorter adjustment time and no shock in the adjustment process. Since the proposed method has a smaller steady-state deviation, the overshoot of the system will be larger after the step signal is added. The specific comparison of the control performance after the working condition changes is as follows: Fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com