Gravity casting automatic pouring system and method thereof for quickly searching pouring point

A gating system and gravity casting technology, applied in the control of molten metal pouring from ladles, casting equipment, manufacturing tools, etc., can solve the problems of long adjustment time and high skill requirements, and achieve improved adjustment time and convenient and intuitive operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

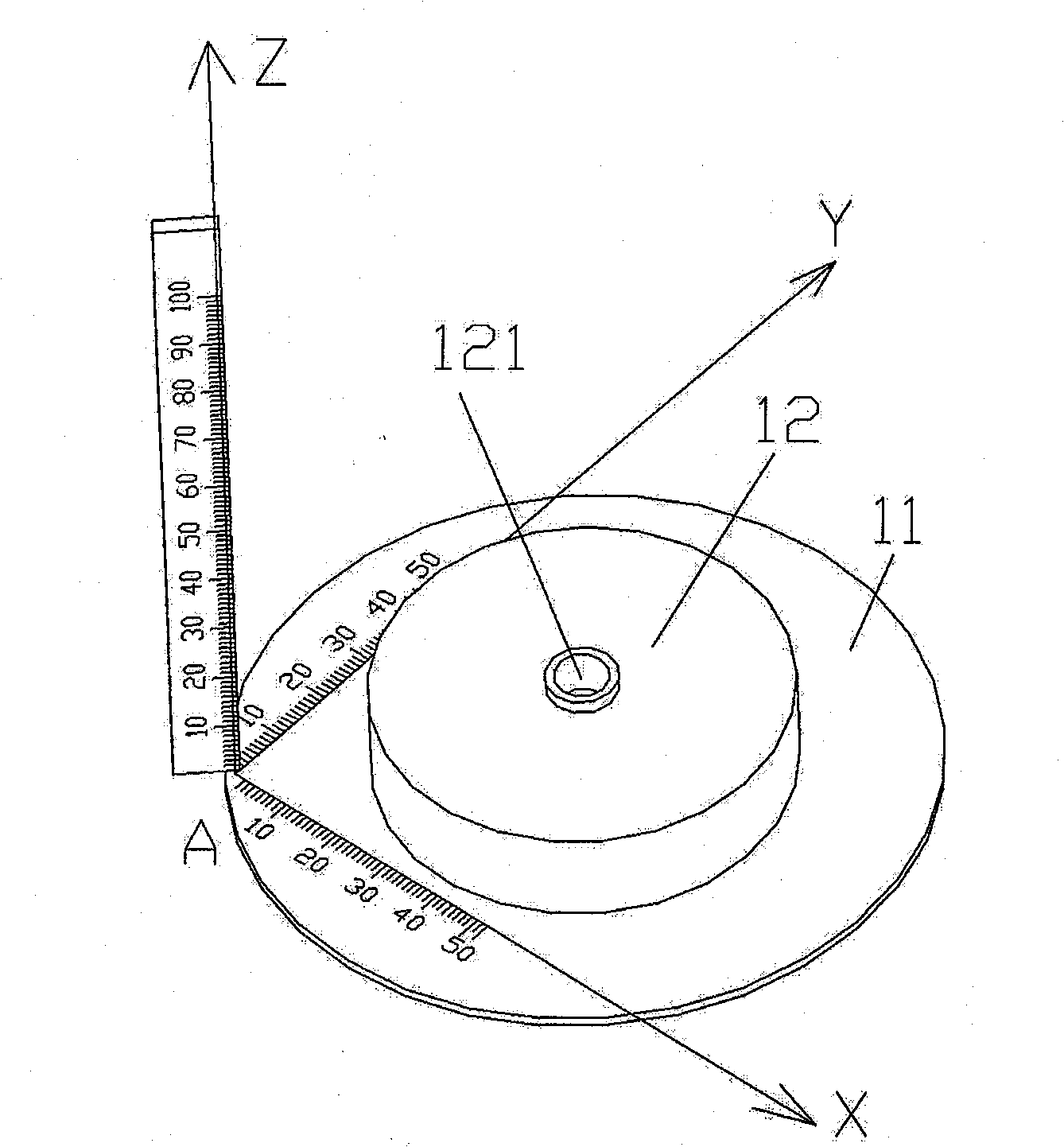

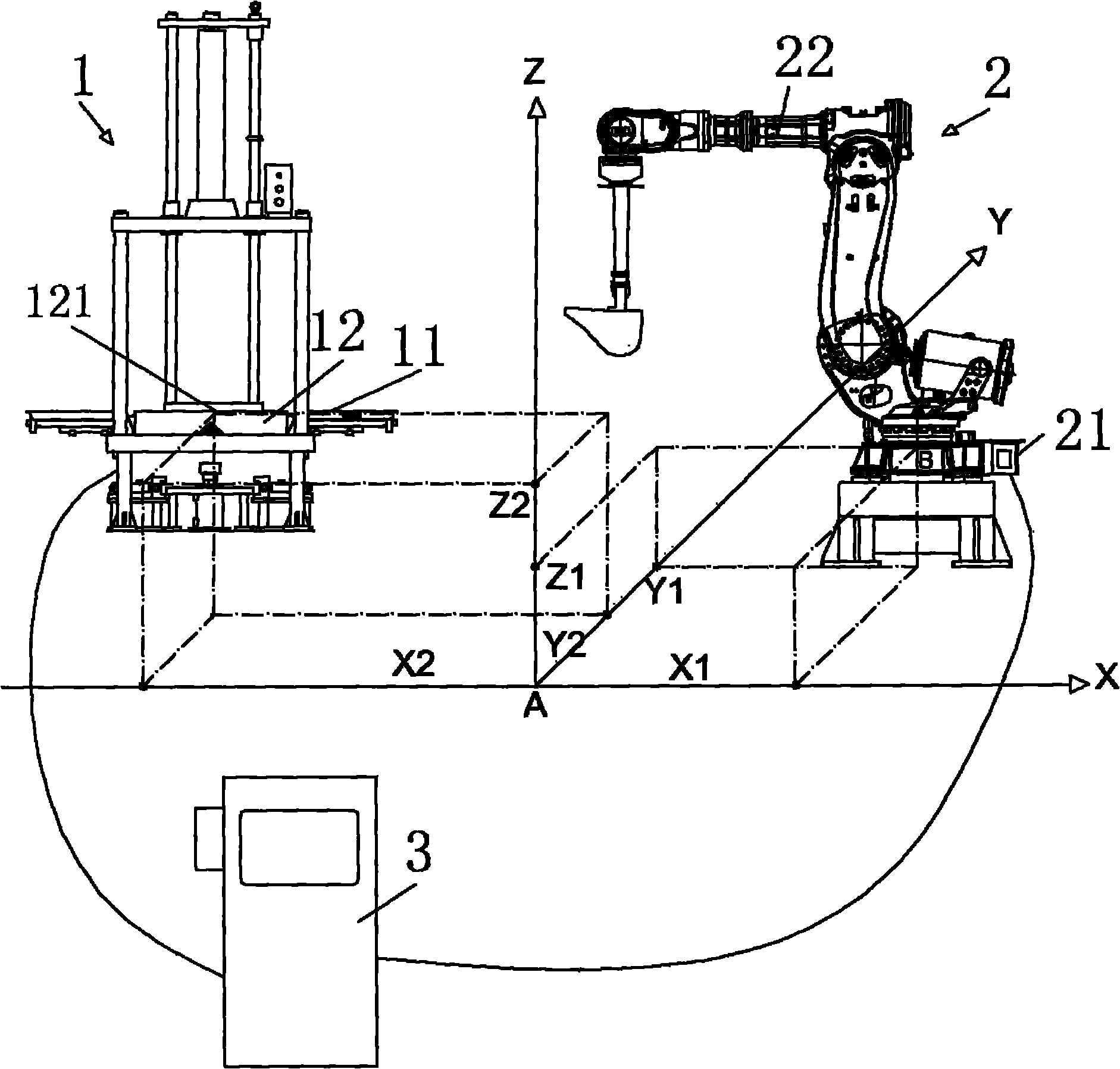

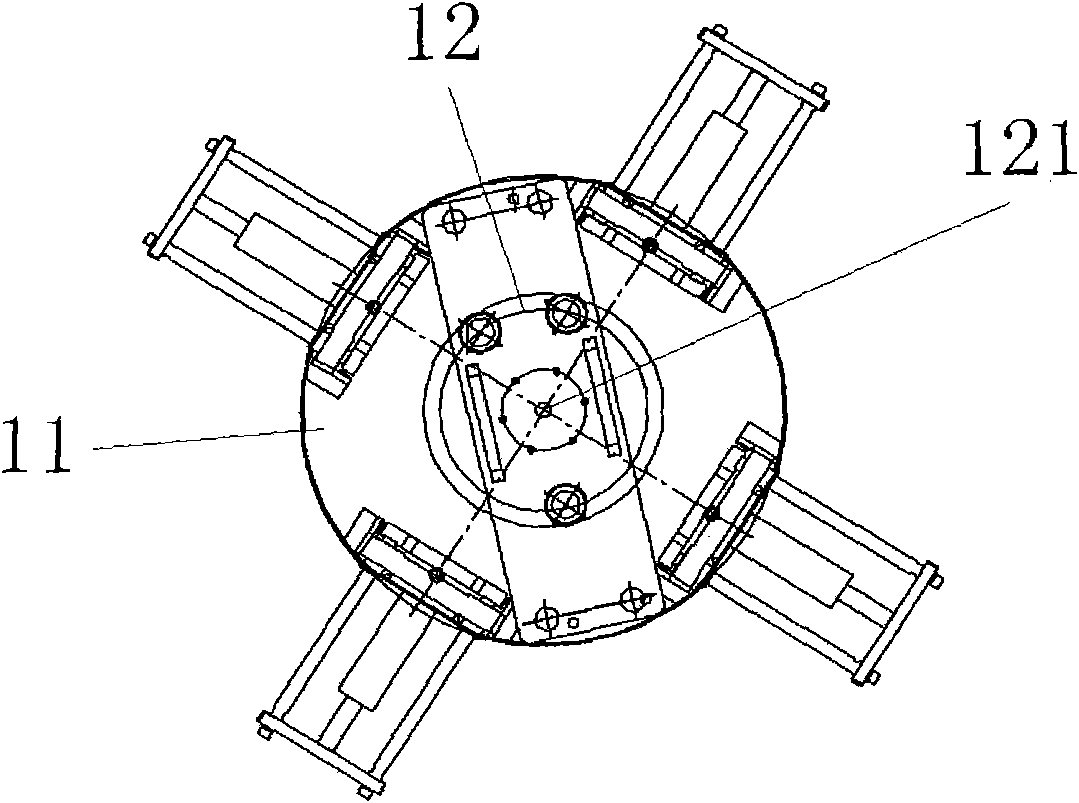

[0020] Example 1: see figure 1 , 2 As shown, the gravity casting automatic pouring system includes a gravity casting machine 1, a pouring robot 2 and a pouring system control host 3, a mold 12 to be poured is fixed on the mold clamp 11 of the gravity casting machine 1, the pouring robot 2 has a robot host 21, and the robot The numerical control system of the host 21 or the program in the pouring system host 3 sends out command signals to control the motor-driven pouring arm 22 to move in three dimensions, and the pouring robot 2 is fixed on the foundation, on the foundation in front of the gravity casting machine 1 or on the gravity casting machine 1 There is a three-dimensional coordinate origin A, and the three-dimensional coordinate values X1, Y1, Z1 between the three-dimensional coordinate origin A and the pouring robot’s own reference point B are input into the numerical control program in the robot host 21 or the program in the pouring system host 3, and the three-dim...

Embodiment 2

[0027] Example 2, see image 3 As shown, when the mold sprue center 121 is on the same straight line as the robot's own reference point in the three-dimensional coordinates centered on the three-dimensional coordinate origin A, the coordinate value X2 between the three-dimensional coordinate origin A and the mold sprue center 121, The coordinate value Z2 on the Z axis among Y2 and Z2 is 0.

[0028] Working principle: The pouring robot 2 itself has its own robot host 21 and the numerical control program in the robot host 21. At the same time, the pouring robot 2 can accept the instructions of the pouring system host 3 and execute the instructions of the host 3. In the prior art, the user adjusts the ladle mouth to the expected pouring point by operating the robot, such as moving the position of the pouring arm 22 of the robot, and inputting the value of the motor control command on the robot host. This speed is very slow, and adjustment It is very inconvenient. The input value...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com